Why do springs fail, and what can we learn from their fractures? In our latest article, we dive into the causes and analysis of spring fractures, exploring microscopic examinations and testing methods. Discover how fatigue, material defects, and manufacturing processes contribute to these failures. By understanding these factors, you’ll gain insights into improving spring durability and performance. Read on to uncover the intricate details behind spring fractures and enhance your engineering solutions.

Recently, a group of springs from a company broke during testing. The manufacturing process of the springs involves cooling heat treatment, grinding, curved forming, pre-shot peening, gas nitriding, shot peening, and hot setting.

An analysis was conducted to determine the reason for the cracking of the broken spring.

Test content: macro morphology analysis;

Testing equipment:

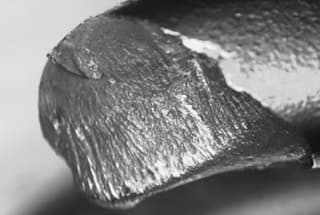

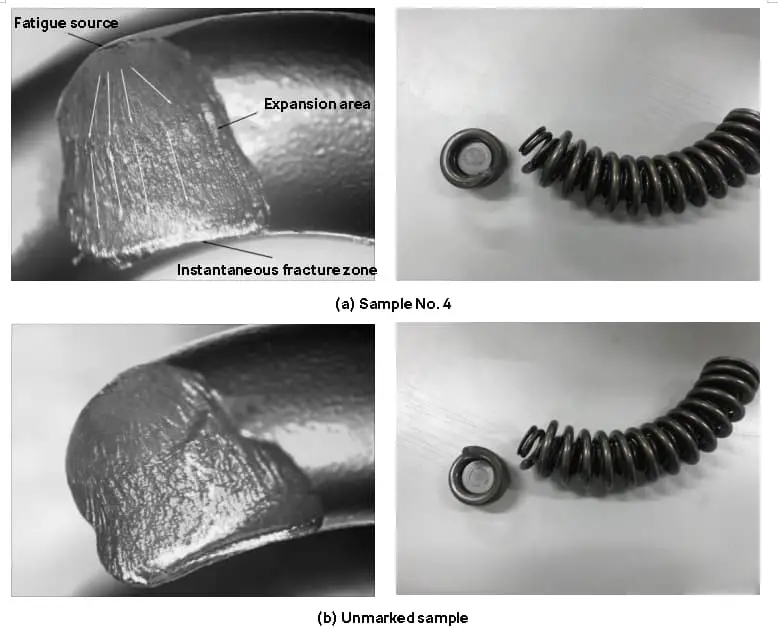

After conducting tests on three marked samples following the spring, they were identified as No. 4 sample, No. 3 sample, and No. 3 sample, as recorded. Fig. 1 shows that all three samples have experienced fatigue fracture.

Based on the flatness of the fracture surface and the area of the instantaneous fracture zone, it can be concluded that No. 4 sample experienced the initial fracture, followed by No. 3 sample, and finally No. 3 sample again.

The light yellow color of the spring is a result of nitriding treatment. Nitriding treatment is a chemical heat treatment process that involves allowing nitrogen atoms to penetrate the surface layer of the workpiece in a particular medium at a specific temperature. Parts that undergo nitriding treatment exhibit excellent wear resistance, fatigue resistance, corrosion resistance, and high-temperature resistance.

The fracture of the spring is located at the fatigue source and appears bright white. Due to wear and tear of the nitride layer, the surface’s fatigue strength is reduced, leading to fatigue cracking.

Fig. 1 macro photo of fracture of broken spring

Please refer to Fig. 2 for the metallographic micrograph displaying the cross-section of the broken spring.

As depicted in Fig. 2, there is a thin white nitrided layer on the surface of the spring, which appears to be corrugated and uneven in thickness.

Fig. 2 metallographic micrograph of fracture spring cross section

See Fig. 3 for the metallographic micrograph of the longitudinal section of the broken spring.

From Fig. 3, it can be seen that there is a white nitrided layer on the surface of the spring and there is an obvious strip structure.

Fig. 3 metallographic micrograph of longitudinal section of fracture spring

See Fig. 4 for the metallographic micrograph of the cross-section of the spring through fatigue test.

From Fig. 4, it can be seen that there are white pulse like structures on the surface of the spring through fatigue test.

Fig. 4 metallographic micrograph of spring cross section through fatigue test

The vein structure is a type of nitride network that is formed through high temperatures, nitrogen potential, or extended nitriding time.

As the nitriding layer on spring parts is extremely thin, any adverse effects of a prolonged process can be minimized.

The likely cause of such effects could be excessively high nitriding temperatures or nitrogen potentials.

The presence of a vein structure may diminish the fatigue strength of the nitriding layer.

The surface microhardness test results of the spring show that the surface microhardness of the spring is about 560hv and the core microhardness is about 510HV.

Figure 5 shows the SEM micrograph of the spring fracture.

Based on the micrograph, it is evident that the fracture is a result of fatigue, and it initiated from the external surface of the spring.

The fatigue expansion zone is relatively small, constituting only around 20% of the fracture.

Beyond the fatigue expansion zone, a region of fast expansion follows.

This area displays an unstable herringbone pattern and local bands of fast expanding fatigue.

Scratch marks and pits are noticeable at the origin of the spring fracture, indicating them to be the primary cause of the fracture.

Additionally, there are spherical particles present in the fracture source region.

Fig. 5 SEM micrograph of fracture spring

To examine the origin of fracture particles, we conducted an analysis of the micro area composition using EDS energy spectrum.

The findings of the analysis reveal that the primary elements in the particles are Mo and Cr, which may indicate the presence of lubricants in the lubricating oil.

Table 1 EDS energy spectrum analysis results of particulate matter (%)

| element | % by weight |

| CK | 3.83 |

| OK | 4.07 |

| CrK | 8.77 |

| FeK | 56.28 |

| NiK | 3.85 |

| MoL | 23.20 |

| total | 100 |

Fig. 6 EDS energy spectrum analysis results of particulate matter

Table 2 2EDS energy spectrum analysis results of particulate matter (%)

| element | % by weight |

| CK | 2.28 |

| OK | 16.35 |

| CrK | 3.83 |

| Mn K | 0.46 |

| FeK | 38.49 |

| NiK | 38.59 |

| total | 100.00 |

Fig. 7 2EDS energy spectrum analysis results of particulate matter

The fracture mode of the spring is fatigue fracture.

The fatigue source of the broken spring appears to be wear, as indicated by the bright white appearance and the worn nitride layer. This wear has reduced the fatigue strength of the surface, resulting in fatigue cracking.

The presence of a pulse-like structure on the surface will also contribute to a reduction in the material’s fatigue strength.