Have you ever wondered about the hidden complexities behind the humble square tube? In this captivating article, an experienced mechanical engineer takes you on a journey to uncover the secrets of these versatile steel structures. From their manufacturing process to the intricacies of weight calculations, get ready to gain a newfound appreciation for the unsung heroes of modern construction.

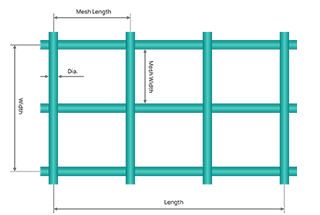

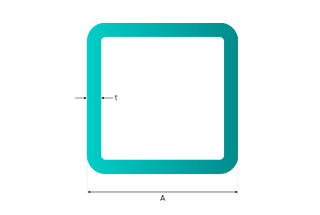

According to GB/T 3094-2012, the standard for cold-drawn special-shaped steel pipes, square steel tubes are typically manufactured in lengths ranging from 2000mm to 9000mm. These tubes can be supplied in either fixed lengths or double lengths to accommodate various industrial applications. In the market, square steel tubes are commonly sold based on either actual weight or theoretical weight, depending on the supplier and customer requirements.

When square tubes are delivered based on theoretical weight, the industry-standard density of 7.85g/cm³ is used for calculations. This density value represents the typical mass per unit volume of steel alloys used in structural applications, ensuring consistency in weight estimations across different manufacturers and suppliers.

To facilitate accurate weight calculations for square steel tubes, you can utilize the calculator provided below. This tool takes into account the tube’s dimensions, including length, outer side length, and wall thickness, to compute the theoretical weight based on the standard steel density. This calculator is particularly useful for engineers, fabricators, and procurement specialists in estimating material requirements, transportation costs, and structural load calculations.

It’s important to note that while this calculator provides a reliable estimate based on theoretical weight, actual weights may vary slightly due to manufacturing tolerances, surface finish, and specific alloy compositions. For critical applications requiring precise weight measurements, it’s advisable to consult with the supplier or perform physical measurements.

Related Tool: Steel Weight Calculator

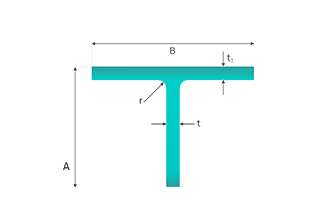

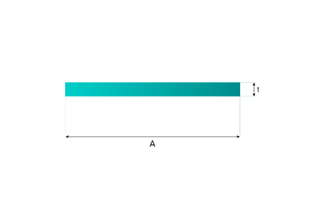

Square tube refers to both square and rectangular tubular steel products with either equal or unequal side lengths. These structural elements are manufactured through a sophisticated process that begins with strip steel. The production sequence involves uncoiling, precision leveling, edge preparation, forming, and high-frequency welding to create a round pipe. This cylindrical form is then subjected to a series of rolling operations, transforming it into the desired square or rectangular profile. Finally, the tube is cut to specified lengths to meet project requirements.

Square tubes are categorized into four main types based on their manufacturing processes, each offering distinct characteristics and applications:

Each type offers unique advantages in terms of mechanical properties, dimensional accuracy, and cost-effectiveness, catering to diverse industrial and construction needs.

The welded square pipe is divided into: