Is stainless steel truly stronger than aluminum alloy, or is it just a matter of perspective? This article dives into the differences between these two versatile materials, exploring their strengths, weaknesses, and the unique properties that make each ideal for various applications. Whether you’re curious about corrosion resistance, weight, or cost-effectiveness, you’ll gain valuable insights to help you make informed decisions for your projects. Read on to discover which material is the perfect fit for your needs.

All metals react with oxygen in the atmosphere and form an oxide film on their surface. Iron oxide, formed on ordinary carbon steel, continues to oxidize and eventually causes holes through corrosion. The carbon steel can be protected through electroplating with paint or oxidation-resistant metals such as zinc, nickel, and chromium, but this protection is only temporary and can be easily damaged.

Stainless steel is resistant to weak corrosive media such as air, steam, and water, as well as chemical corrosive media such as acid, alkali, and salt. The term “stainless steel” is often used to refer to steel that is resistant to weak corrosion, while “acid-resistant steel” is used to describe steel that is resistant to chemical corrosion.

The distinction between the two is due to differences in chemical composition. Not all stainless steel is resistant to chemical corrosion, while acid-resistant steel is generally corrosion-resistant. The corrosion resistance of stainless steel depends on the alloying elements it contains, with chromium being the key element for achieving corrosion resistance.

When the chromium content in the steel reaches about 1.2%, chromium reacts with oxygen in the corrosive environment to form a thin oxide film on the steel’s surface, preventing further corrosion. Other commonly used alloying elements include nickel, molybdenum, titanium, niobium, copper, and nitrogen, to meet the various needs and requirements of stainless steel in terms of microstructure and properties.

Ferritic Stainless Steel

Ferritic stainless steel contains between 12% and 30% chromium. Its corrosion resistance, toughness, and weldability all improve as the chromium content increases, and it has better resistance to chloride stress corrosion than other types of stainless steel.

Austenitic Stainless Steel

Austenitic stainless steel has a chromium content of over 18%, along with 8% nickel and small amounts of molybdenum, titanium, nitrogen, and other elements. It has excellent comprehensive performance and can resist corrosion from various media.

Austenitic-Ferritic Duplex Stainless Steel

Austenitic-ferritic duplex stainless steel combines the benefits of both austenitic and ferritic stainless steel and has superior ductility.

Martensitic Stainless Steel

Martensitic stainless steel has high strength but poor plasticity and weldability.

Precipitation-hardened stainless steel boasts good formability and weldability, making it a popular choice for ultra-high strength applications in the nuclear, aviation, and aerospace industries.

Based on its composition, precipitation-hardened stainless steel can be classified into four categories: Cr-system (SUS400), Cr-Ni system (SUS300), Cr-Mn-Ni (SUS200), and precipitation-hardening system (SUS600).

200 series: Chromium-nickel-manganese austenitic stainless steel.

300 series: Chromium-nickel austenitic stainless steel.

301: Known for its good ductility, this type of stainless steel is often used for molding products and can be hardened by machine speed. It has excellent weldability and boasts better wear resistance and fatigue strength compared to 304 stainless steel.

302: Has the same corrosion resistance as 304, but with a higher carbon content, which results in improved strength.

303: Contains a small amount of sulfur and phosphorus, making it easier to cut.

304: Also known as 18/8 stainless steel and 0Cr18Ni9 in the GB brand.

309: Offers better temperature resistance than 304.

316: The second most widely used stainless steel after 304, it is primarily used in the food industry and for surgical equipment. The addition of molybdenum gives it a special corrosion-resistant structure and improved chloride corrosion resistance, making it a popular choice for “marine steel” applications.

SS316 is commonly used in nuclear fuel recovery units and is usually specified in the 18/10 grade.

321 series – Similar to 304, except that the addition of titanium reduces the risk of weld corrosion.

400 series – Ferritic and martensitic stainless steel.

408 – Good heat resistance but weak corrosion resistance. Composition: 11% chromium and 8% nickel.

409 – The cheapest model (British and American) used mainly as automobile exhaust pipes. Ferritic stainless steel (chromium steel).

410 – Martensitic (high strength chromium steel) with good wear resistance but poor corrosion resistance.

416 – Sulfur addition improves the material’s processability.

420 – Martensitic “cutting tool grade” steel similar to early stainless steels like Brinell high chromium steel. Also used for surgical tools that can be made very bright.

430 – Ferritic stainless steel used for decoration, such as automotive accessories. Good formability, but poor temperature resistance and corrosion resistance.

440 – High strength cutting tool steel with slightly higher carbon content. Can obtain higher yield strength with appropriate heat treatment and hardness can reach 58 HRC. One of the hardest stainless steels. Commonly used in razor blades. Three common models: 440A, 440B, 440C, and 440F (easy to process).

500 series – Heat-resistant chromium alloy steel.

600 series – Martensitic precipitation-hardening stainless steel.

630 – The most commonly used precipitation-hardening stainless steel model, also known as 17-4. Composition: 17% chromium and 4% nickel.

Characteristics and uses of stainless steel:

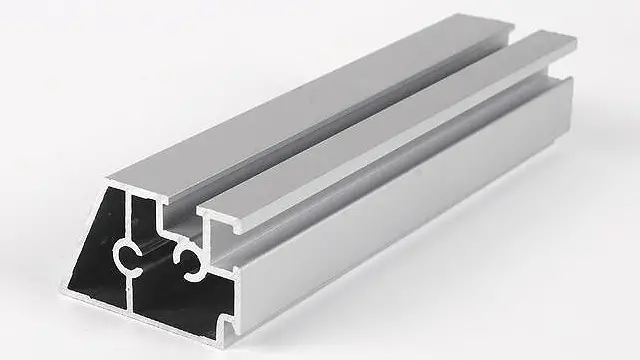

The general term for aluminum-based alloys refers to a group of materials composed mainly of aluminum and other elements such as copper, silicon, magnesium, zinc, and manganese. Secondary alloy elements, including nickel, iron, titanium, chromium, and lithium, are also present in smaller quantities.

Aluminum alloys are known for their low density and high strength, which is comparable to or even greater than that of high-quality steel. Additionally, aluminum alloys possess good plasticity and can be easily molded into various shapes. These alloys also have excellent electrical and thermal conductivity, as well as superior resistance to corrosion.

Due to its versatility and durability, aluminum alloy is widely used in various industries, second only in popularity to steel. The use of aluminum alloy can be divided into two categories: cast aluminum alloy and deformed aluminum alloy. Cast aluminum alloys are used as is, while deformed aluminum alloys can withstand pressure processing, resulting in higher mechanical properties.

Wrought aluminum alloys are further divided into two subcategories: non-heat treatable strengthened aluminum alloys and heat treatable strengthened aluminum alloys. Non-heat treatable alloys, such as high-purity aluminum, industrial high-purity aluminum, industrial pure aluminum, and antirust aluminum, can only be strengthened through cold working deformation and not by heat treatment. Heat treatable strengthened aluminum alloys, on the other hand, can be improved through heat treatment methods like quenching and aging, and are divided into hard aluminum, forged aluminum, superhard aluminum, and special aluminum alloy.

Cast aluminum alloys can be classified based on their chemical composition, including aluminum silicon alloy, aluminum copper alloy, aluminum magnesium alloy, aluminum zinc alloy, and aluminum rare earth alloy. Within the aluminum silicon alloy category, there are two subtypes: simple aluminum silicon alloy and special aluminum silicon alloy. The former has low mechanical properties but good casting properties, while the latter can be strengthened by heat treatment and has both high mechanical properties and good casting properties.

As an example of its widespread use, the “Xiangyun” torch used in the 2008 Beijing Olympic Games was made of aluminum alloy.