What if the color of your stainless steel weld could tell you everything about its quality? In this article, you’ll discover how different weld colors—from silver-white to dark blue—indicate specific welding conditions and outcomes. By understanding these visual cues, you’ll learn how to achieve optimal weld quality and avoid common pitfalls. Dive in to master the art of interpreting stainless steel weld colors and ensure your projects meet the highest standards.

Compared to ordinary carbon steel, the welding process for stainless steel and the technical requirements for welders should be stricter, and the appearance of the weld should be of the utmost importance.”

Here’s the revised version:

In comparison to ordinary carbon steel, welding stainless steel requires stricter processes and demands higher technical skills from welders. Moreover, the appearance of the weld is crucial and must be of the highest quality.

As for my personal views and opinions, based on my welding experiments using manual, automatic, and argon arc welding methods, I’ve found that welds can be classified into:

1. Silver white

2. Golden yellow

3. Five colors (golden yellow+blue);

4. Blue;

5. Dark blue;

6. Gray black (with luster);

7. Dead black ash.

The quality of weld color is inseparable from the welding process parameters and the technical level of welders.

The main problems are:

1. Cleanliness of groove before welding;

2. Purity and flow of shielding gas;

3. Size of welding current;

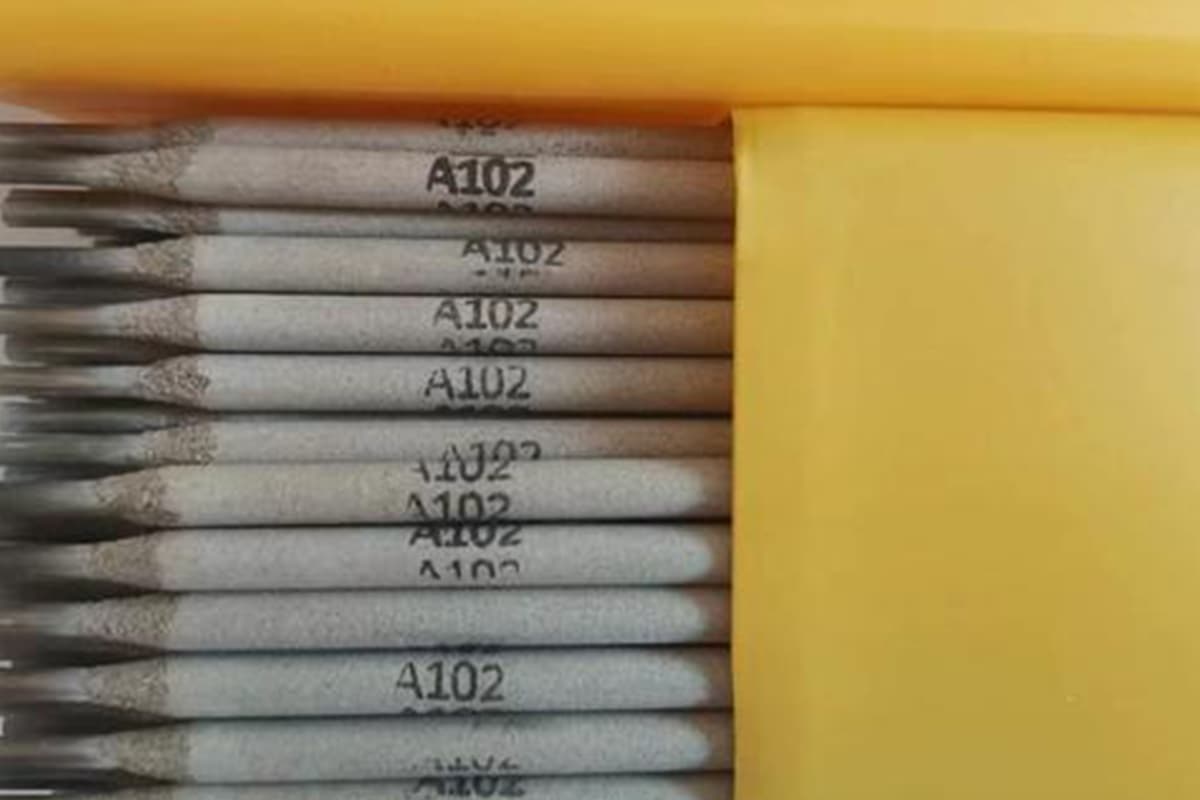

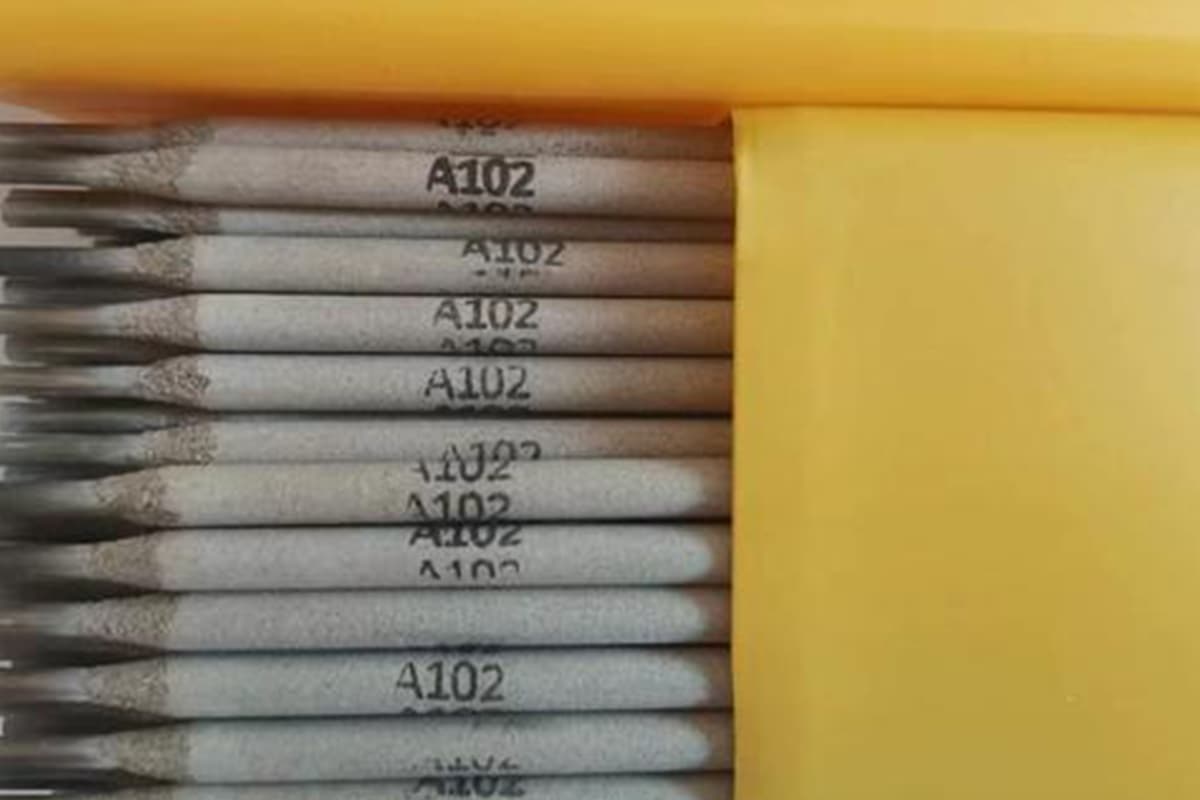

4. Quality of welding materials;

5. Number and layers of welds;

6. Welding speed;

7. Control of interlayer temperature;

8. Control of heat input.

When the welding process conditions are met, the weld should appear silver-white, and the physical and chemical values of the weld should also be the best.

For automatic submerged arc welding equipment, the welding parameters and heat input must be strictly controlled.

In fact, the different thickness of each weldment requires reasonable matching of welding current, voltage, welding speed, and wire feeding speed.

Welding is like acting. The lead actor and supporting role must achieve 100% tacit understanding to achieve the highest effect.

For instance, workpieces with the same material but different wall thicknesses require different welding parameters.

If the parameters are too large, intergranular corrosion may occur, resulting in chromium depletion. In severe cases, cracks may occur, and the color may be unsightly.

Based on experience, silvery-white and yellow welds are acceptable, with silvery-white being the best.

Multicolored welds may produce intergranular corrosion and poor chromium, resulting in chromium carbide, which causes stainless steel to lose its corrosion resistance and stain resistance.

There is no specific color name to indicate the welding quality beyond blue and dark blue.

In practical welding, process parameters cannot be applied strictly as they vary with different factors such as ambient temperature, thickness and size of the weldment, and welding speed.

For welding large weldments with thicker walls, a higher current is required.

Related reading: Wire Feeding Speed and Welding Current

Multi-layer and multi-pass welding should be used, if necessary, and the interpass temperature must be controlled to ensure welding quality.

Without proper precautions, the weld’s appearance may be excellent, but the interior may not meet welding quality standards.

When employing multi-layer and multi-pass welding, lower weld bead welding can be performed after the previous weld bead has cooled, producing better results.

During automatic welding, welding speed and wire feeding speed must be matched with the corresponding current and voltage to achieve the best welding effect for a given weldment.

To maintain optimal weld quality, welding speed, current, voltage, and heat input should be adjusted as needed when the welding speed, current, or wire feeder speed change. The welding speed should be chosen based on the metal’s melting point and welding quality to ensure the best outcome.

When argon arc welding is adopted, the following points shall be noted: