Imagine boosting your factory’s efficiency with a perfectly designed stamping workshop. This article dives into the essentials of planning such a workshop for automobile parts, from equipment selection to layout optimization. By reading, you’ll discover how to enhance production capacity, ensure quality, and streamline operations. Dive in to transform your stamping workshop into a powerhouse of precision and productivity.

The stamping production conditions in the plant are facing several major problems due to the growing output of new models and rising quality standards in the stamping industry. These problems require urgent solutions.

(1) Overloading of Large Stamping Parts

The production of large stamping parts is expected to intensify in the next few years and could reach or even exceed 150% of the production capacity, according to the production program. The issue cannot be resolved as there is no capacity for mass production of large-scale stamping parts in the surrounding areas. To address this problem, large-scale stamping production lines must be added.

(2) Quality Assurance Ability

With the increasing quality requirements in the market for medium and heavy-duty commercial vehicles, the factory needs to improve its stamping quality assurance capabilities to meet quality standards, improve efficiency, and reduce costs. Improving quality assurance ability is a comprehensive improvement project that covers the entire stamping process, from raw material preparation to stamping production, warehousing, and logistics. The factory must change and improve its production conditions and management level.

(3) Insufficient Press Tonnage

The introduction of high-end commercial vehicle models has not only increased the production load of large-scale parts in the factory (by 20 streams), but also the demand for press tonnage. Currently, the largest press has a rated tonnage of 1600t, but the actual demand for the largest part exceeds 2200t. Based on a comprehensive analysis, it has been concluded that a larger tonnage press is required, with a maximum rated tonnage of 2400t, in line with the company’s product development plan and industry rules.

(4) Low Production Efficiency and High Labor Intensity

The stamping production lines in the factory are manual and have low efficiency, with a SPH of less than 240 times. The workers also face high labor intensity, handling a quality of over 10t in a single shift, with a maximum of 15t.

To address these problems and improve safety, environmental protection, inventory management, and technology, the following actions are required:

(1) Clean up, transform, and integrate the existing conditions to meet the needs of the phased construction of the “Stamping Center” project.

(2) Upgrade one 630t uncoiling blanking line.

(3) Add one new 2400t stamping automated production line.

(4) Complete the supporting facilities, including mold transformation, scrap line, lifting equipment, logistics equipment, and station appliances.

The stamping workshop production process primarily involves the creation of stamping blanks and parts, as well as auxiliary tasks such as mold trial and repair, stamping part repair, and waste transportation.

(1) Blank Production

Blanking refers to the process of transforming coils into the blanks required for stamping parts production. The production process involves:

To meet the production demands for blanks, the workshop must have a fully automatic uncoiling blanking production line or a fully automatic cutting production line. The former can perform both blanking and shearing, while the latter is only suitable for shearing.

Figure 1 illustrates an example of an uncoiling blanking line.

Figure 1 Uncoiling blanking line

Given the relatively high cost of an uncoiling blanking line, it is important to consider the cost-effectiveness of its configuration. Typically, one uncoiling blanking line can match the output of three fully automatic mechanical stamping production lines, and the choice of equipment should be based on the workshop’s product and output requirements.

(2) Stamping Production

The stamping production process for large-scale covering parts includes deep drawing, trimming, flanging, forming, punching, and shaping. The process is adjusted and combined based on the shape and structure of the stamping parts.

For example, the typical production process for a door frame is as follows:

For a top cover, the process is:

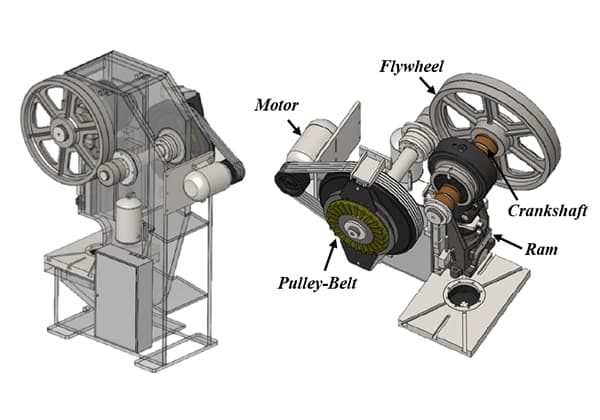

The arrangement of press connections for stamping production requires determining the number of presses based on the forming process of the stamping part and the shape of the stamping die. There are three, four, five, and six orders, with four orders being the most commonly used. However, it’s important to consider the complexity of mold design and the increased cost that may result from a complex die.

The parameters of the press equipment, such as nominal pressure, table size, and closing height, must be determined based on the product process. The choice of the number of press lines depends on the product, output, and press line productivity.

The formula is:

the number of press lines = ∑ (number of mold sets × production program) ÷ press line productivity (ASPM) ÷ equipment annual time base.

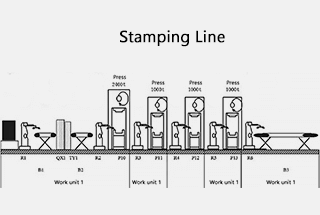

Figure 2 shows a fully automatic stamping production line with 1 x 2400t and 3 x 1000t presses.

Figure 2 1×2400t+3×1000t automatic stamping production line

(3) Auxiliary Area

A simple machine repair setup is typically located in the stamping workshop for convenient, daily repairs of the dies.

If the production line has a high load rate, it may be necessary to establish a trial press in the mold repair area. The specifications of the trial press should match those of the largest equipment in the production line.

Stamping production generates punching waste, so it is advisable to set up a waste conveyor line to collect and dispose of the waste, based on the press line.

For online loading and unloading of stamping parts, a trim area should be established to remove burrs and address surface defects of the stamping parts.

The workshop layout is designed based on the production process for stamped parts.

The stamping workshop typically consists of areas for coil storage, uncoiling and blanking production, blank stacking, mold stacking, mold maintenance, stamping production, temporary storage for stamped parts, and maintenance for stamped parts, among others.

Furthermore, the workshop includes a room for waste materials, a storage area for forklifts, an office area, and a living area.

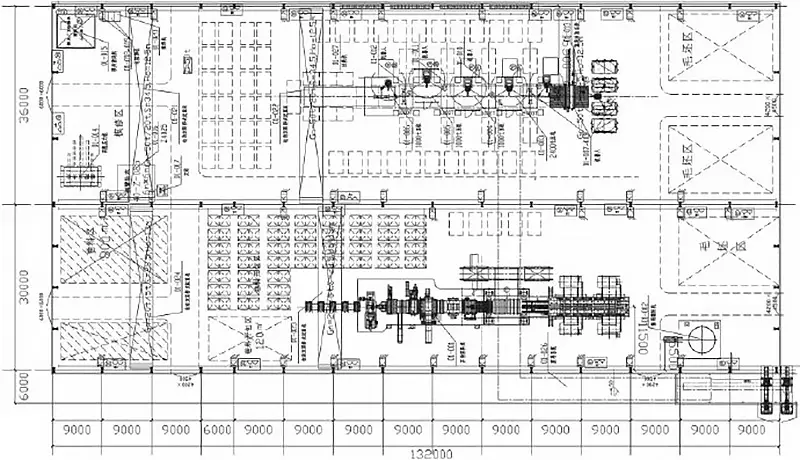

Figure 3 illustrates the layout of the press shop.

Figure 3 Schematic diagram of the layout of the press shop

The logistics flow in the stamping workshop is well-defined, mainly including the following routes:

(1) The logistics route for stamping production is displayed in Figure 4.

Figure 4 The logistics route of stamping production

(2) Molds, the logistics route for molds is illustrated in Figure 5.

Figure 5 Logistics route of stamping die

Once the production program, technology, and equipment of the stamping workshop have been established, the necessary requirements for civil engineering must be identified to fulfill the production needs.

(1) Workshop Size

The size of the workshop is mainly determined by the type of die change on the press. There are three main upper die forms on the press: front upper die, side upper die, and left and right upper die. The front upper die has the smallest area, and a workshop with a span of 15 meters is sufficient. The side upper die has a slightly larger area and requires a workshop span of 24 meters. The left and right upper molds have the largest area and are mostly used in fully automatic production lines for improved efficiency, which requires a workshop span of 30 or 36 meters. The stamping parts warehouse requires a span of at least 24 meters for ease of forklift transportation.

The length of the automatic stamping production area is generally about 60 meters, based on the layout of the press in the span. The length of the die stacking area needs to be determined based on the number of dies. If there is only one stamping line, the workshop length is typically about 120 meters. If there are many dies, the workshop may need to be extended accordingly. The corresponding unwinding blanking span also requires a length of 120 meters.

To accommodate large presses for transportation and to minimize costs for mold transportation and equipment maintenance, the column spacing in the stamping workshop is set at 9 to 12 meters.

The height of the press shop is determined by the height of the press. For large covering parts, the maximum press is usually 2400 tons, with a height of 11 to 11.5 meters above the ground. The height of the crane rail top in the workshop, considering safety distances, is 13 to 14 meters, and the roof truss of the stamping workshop is set at a lower chord height of approximately 17 meters based on the selected crane height. The choice of press and crane has a significant impact on the workshop height. The height of the uncoiling blanking span is determined by the press on the uncoiling blanking line, with a rail top height of 12 meters. The height of the stamping parts warehouse is based on the height and number of layers of the stamped parts stack, and for forklift transportation only, it is generally 7 meters.

(2) Architectural Forms

The press shop building typically comes in three forms: concrete structure, steel structure, or steel-concrete structure, depending on the specific requirements of the project.

In the past, concrete was the primary material used for constructing stamping workshops. However, now, due to the cost-effectiveness of steel structure and its simple and efficient production and installation process, as well as a shorter construction period, steel structure has become the preferred material for most stamping workshops.

The workshop floor must be clean and durable. Both epoxy resin flooring and high-strength wear-resistant flooring are suitable options, while the steel sand flooring is recommended for more demanding environments.

(3) Load Requirements

The load of the press is dependent on the weight of the press itself, the weight of the die change cart, and the weight of the die. It is important to consider the dynamic load when calculating the load of the press, as mechanical presses generate a significant impact load during operation.

In the stamping workshop, cranes with a capacity of 32t and 50t are usually used. The deadweight, wheel pressure, wheelbase, and other parameters should be determined based on the specifications of the crane product.

Most of the stamping workshop area, excluding the press line area, is used for mold stacking. Typically, the number of stacking layers is two, resulting in a floor load of approximately 100kPa. The coil or sheet stacking area should be determined based on the stacking method. If a specialized rack is used for stacking and exceeds the second floor, the floor load must be considered at 150kPa.

The press shop has pipes for water, electricity, gas, air, and firefighting on the pillars, and their loads must be considered in the calculation. In addition, an electrical cabinet platform is usually required near the press line to accommodate the press and the power distribution cabinet of the automation device, and the load of the column must also be taken into account.

(4) Press Foundation

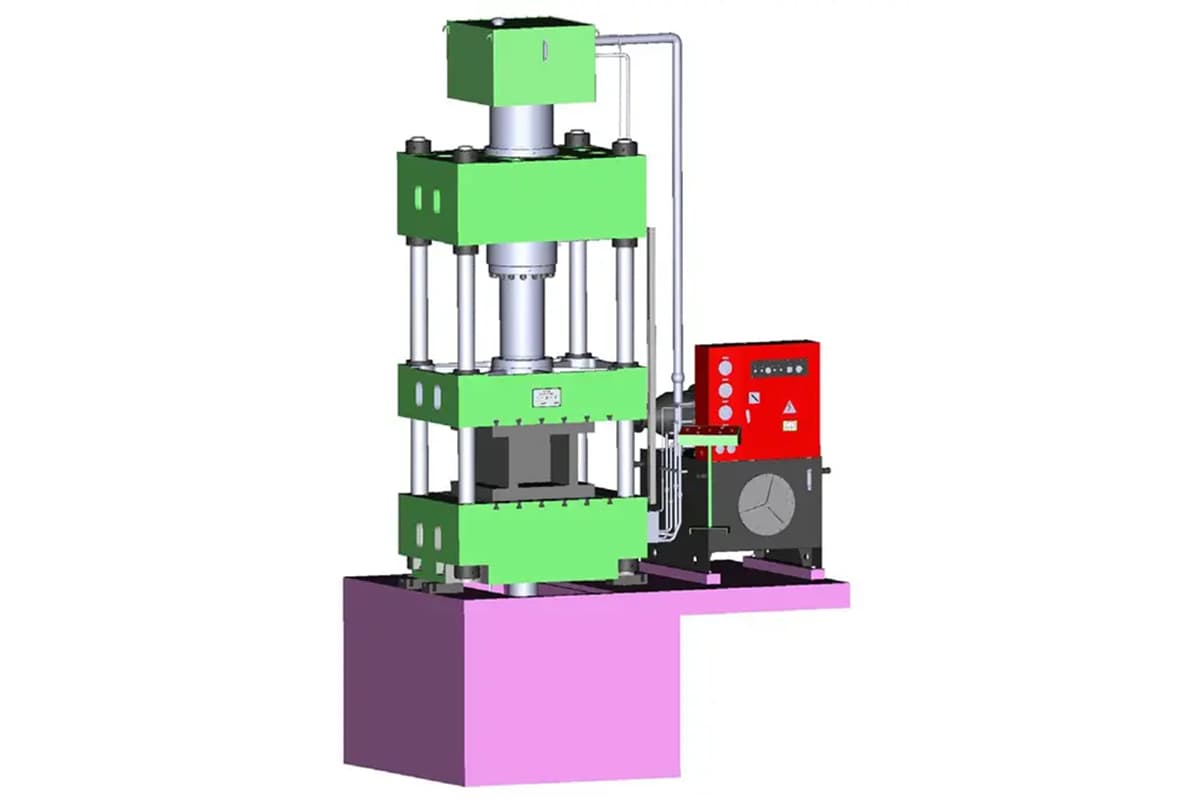

The foundation of the automated press line in the press shop is a critical aspect of civil engineering and has three types: independent foundation, through foundation, and basement foundation.

An independent foundation refers to each press on the press line having its own separate foundation, not connected to each other. This method is the least expensive but requires each press equipment to be individually unloaded and transported within the workshop, which significantly impacts production and logistics in mass production. Therefore, this form is not commonly used.

The through foundation involves laying out the foundation for each press and installing a waste conveying line within the foundation to collect stamping waste and transport it to the waste room. This form separates waste logistics from production logistics, making press maintenance more convenient, and is currently more widely used.

The basement foundation involves constructing a basement within the range of the press or placing the press line on the second floor. This form creates a large space for the press foundation, which can also accommodate public power, power distribution facilities, and some maintenance areas, effectively increasing the workshop’s usable area. However, this form is not frequently used due to its high cost.

The foundation of the through-type press varies based on the equipment, with product data differing among different suppliers. Typically, a 4-station press line pit has a net width of 9.5m, a depth of 7m, and a length of approximately 35m. A pit for the main line of the waste conveying line must also be established, connected to the press pit and arranged vertically. Its depth is the same or shallower than the press pit, with a width of approximately 4m.

The public support facilities at the press workshop are generally basic.

Water, electricity, and gas are essential for the equipment, while the decision to include facilities such as air conditioning, heating, and dehumidification depends on the specific project requirements.

(1) Electricity:

Electricity is the primary energy source used in stamping plants, primarily in the automatic stamping line and uncoiling blanking line. As such, the workshop transformers are positioned as close to the equipment as possible.

(2) Compressed air:

The main areas for compressed air in the stamping workshop include stamping equipment, mold repair, and stamping part repair. The compressed air must meet the following quality standards: air source pressure of 6 bar, oil content of 25 mg/m3, particle diameter of 40 μm, and particle content of 10 mg/m3.

(3) Circulating cooling water:

Circulating cooling water is mainly used for press equipment. The inlet water temperature should be 32°C, while the outlet water temperature should be 37°C. Soft or pure water is necessary to prevent scaling damage to the equipment.

(4) Other considerations:

The stamping workshop falls under Category E production and has no specific fire protection or smoke exhaust requirements.

The primary environmental impact of the press shop is noise generated by press production and vibration and noise from waste conveyor lines. To mitigate these impacts, the doors and walls of the press shop should use soundproof materials, and the windows should feature double-paned vacuum glass. Additionally, vibration isolation pads must be installed under the press to reduce noise and vibration effects on the surrounding environment. Additionally, when planning the layout, consideration must be given to minimizing the proximity of residential, school, hospital, and other civilian facilities to the stamping workshop.

Compared to manual lines, the number of workers per shift is significantly lower in automatic lines. This shift in staffing requires a change from manual stamping workers with high physical labor demands to highly skilled automation operators. As seen in Table 1, the physical labor intensity of workers is reduced.

| Production mode

Type of work | Automatic line staff structure | manual line staff structure | Note |

|---|---|---|---|

| Monitor | 1 | 1 | single line

single shift |

| Acting monitor | 1 | ||

| Stamper | 18 | ||

| Underpaid staff | 1 | ||

| Site management | 1 | ||

| Stamping operator | 1 | ||

| Automation preparation | 1 | ||

| Engineering quality | 1 | ||

| Crane operator | 2 | 1 | |

| Check | 2 | 1 | |

| Packing | 3 | 3 | |

| Repair | 3 | 1 | |

| Hand in | 3 | 3 | |

| Warehousing | 2 | 3 | |

| Total | 22 | 31 |

Compared to the manual line, the main factor behind the significant disparity in staffing is the focus on both production stability and quality stability. The automated line boasts a production capacity that is over three times greater than that of the manual line.

As a result, there is a need for a larger number of individuals to handle equipment and die maintenance to ensure stable production. Additionally, a significant increase in the number of online inspectors is required to detect quality issues early and maintain quality stability. It’s important to note that the newly added staff members will need to be trained to acquire the necessary skills and qualities.

The press shop has a heavy workload and demands high standards for civil engineering and infrastructure. This article provides a comprehensive overview of various aspects involved in the design of a stamping workshop from an engineering design perspective. The aim is to serve as a reference guide for process technicians responsible for designing this type of workshop.