Ever wondered why steel sometimes cracks during bending? In this article, we explore the fascinating world of steel bending technology, uncovering the reasons behind common defects like corner and central cracking. Discover how proper techniques and material quality can make all the difference in preventing these issues. Get ready to learn practical insights that can enhance your understanding and application of steel processing!

Bending processing technology is a type of steel processing technology that is widely used in various fields such as automobile manufacturing, engineering machinery, bridges, ships, and construction.

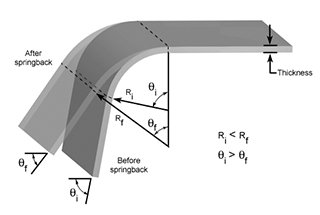

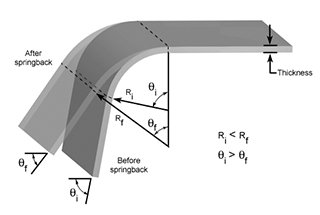

Under the pressure of the upper or lower die on the bending machine, the metal sheet undergoes elastic deformation first and then plastic deformation.

In the beginning stage of plastic bending, as the upper or lower die bends the sheet metal, the sheet metal gradually fits tightly against the inner surface of the V-groove of the upper or lower die, while the curvature radius also gradually decreases.

As the pressure continues until the end of the stroke, the upper and lower dies come into full contact with the sheet metal, forming the V-shaped bend, which is commonly processed using bending machines and rolling equipment.

Bending cracking is a major defect in the use of steel processing. According to the location of the cracking, it can be divided into corner cracking and central cracking.

The factors that cause cracking include improper processing technology and material quality defects, which have a negative impact on steel production enterprises.

Researchers analyzed, summarized, and studied typical quality cases and referred to relevant materials to analyze various factors that cause bending cracking and propose improvement measures.

1.1.1 Macroscopic Morphology

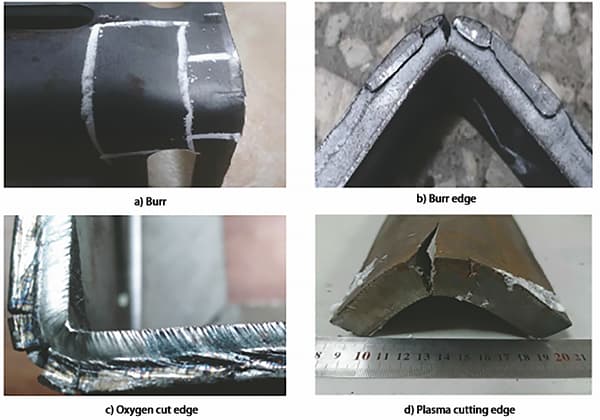

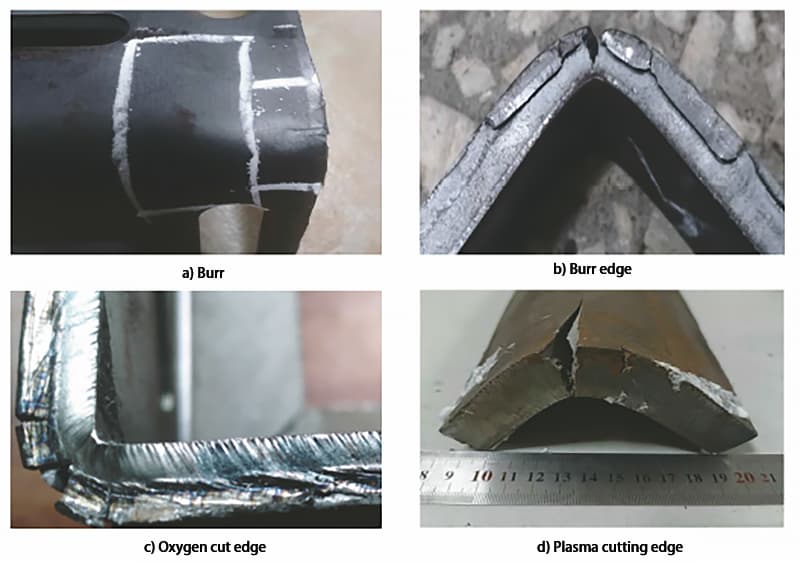

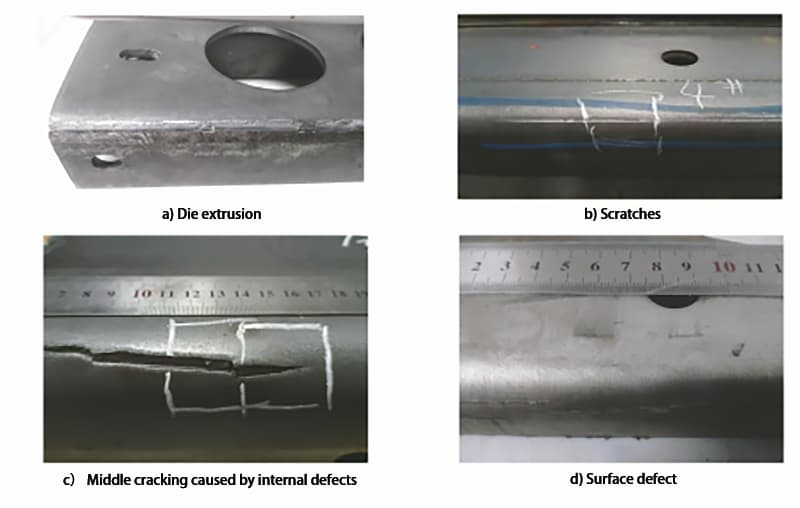

Corner cracking is the most common type of defect in bending cracking, and there are usually burrs, rough edges, oxygen cutting edges, or plasma cutting edges at the corner cracking position. If the edge of the workpiece is not sandblasted or incompletely treated during bending processing, corner cracking will occur, and the cracks at the corner cracking are usually short and located in the work-hardened area of the corner.

Typical defects of Q235B steel and Q355B steel were selected for analysis, and the macroscopic morphology of corner cracking is shown in Figure 1.

1.1.2 Chemical Composition Analysis

Four typical corner crack samples of Q235B steel and Q355B steel were selected for chemical composition analysis, and the results met the requirements.

1.1.3 Mechanical Property Testing

The mechanical properties of the above four typical corner crack samples of Q235B steel and Q355B steel were tested, and the results are shown in Table 1 (D is the bending diameter, a is the sample thickness), and the results met the requirements.

Table 1: Mechanical performance test results of Q235B and Q355B steel samples with corner cracking

| Steel grade | Yield strength /MPa | Tensile strength /MPa | Elongation after fracture % | Bending test results |

| Q235B | 310 | 450 | 32 | D=1.5a, 180 ° intact |

| Q235B | 315 | 466 | 30.5 | D=1.5a, 180 ° intact |

| Q235B | 304 | 436 | 33 | D=1.5a, 180 ° intact |

| Q355B | 431 | 557 | 21.5 | D=1.5a, 180 ° intact |

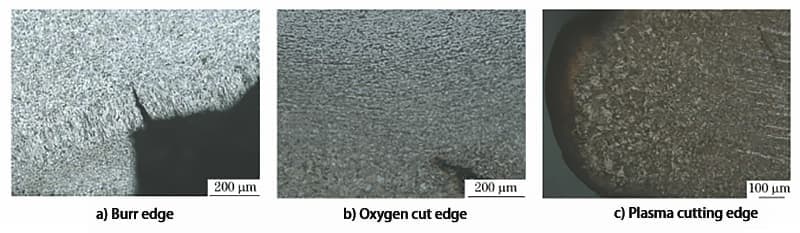

1.1.4 Metallographic Examination

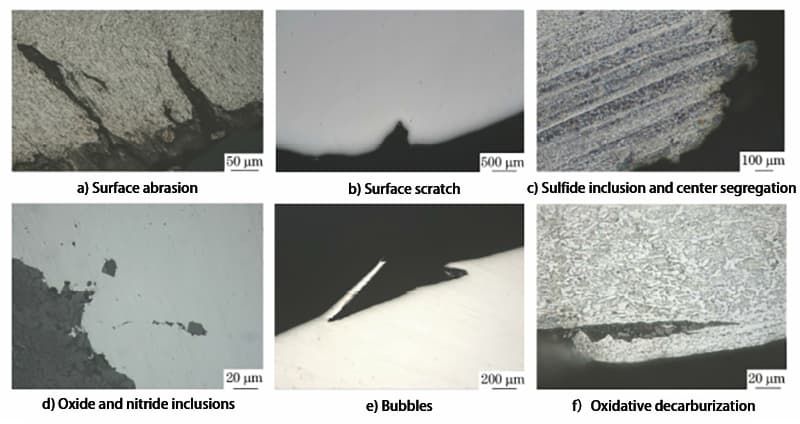

Metallographic examination was carried out on the cracking positions of the above four typical corner crack samples of Q235B steel and Q355B steel, and the results are shown in Figure 2. As can be seen from Figure 2, there is grain cold deformation in the tissue at the cracking position, and there is a thermal influence structure at the oxygen cutting and plasma cutting cracking position.

1.2.1 Macroscopic Morphology

Central cracking often manifests as non-continuous cracking in the middle of the workpiece, and the cracks are usually long, with some instances of short cracks. The macroscopic morphology of central cracking is shown in Figure 3.

1.2.2 Chemical Composition Analysis

Six typical central crack samples of Q235B steel, Q355B steel, and 610L steel were selected for chemical composition analysis, and the results met the requirements.

1.2.3 Mechanical Property Testing

The mechanical properties of the above six typical central crack samples of Q235B steel, Q355B steel, and 610L steel were tested, and the results are shown in Table 2, and the results met the requirements.

1.2.4 Metallographic Examination

Metallographic examination was carried out on the above six typical central crack samples of Q235B steel, Q355B steel, and 610L steel, and the results are shown in Figure 4.

As can be seen from Figure 4, there is grain cold deformation at the grinding tool extrusion position, and scratch openings can be seen at the root of longer and straighter cracks. The samples also contain clustered sulfide inclusions, center segregation, high-temperature oxidation particles, decarburization due to oxidation, and bubble features.

2.1.1 The influence of bending diameter

When bending steel, the outer layer of the bent area undergoes tension while the inner layer undergoes compression. When the material thickness is constant, the smaller the bending radius, the more severe the tensile and compressive stresses on the material. If the tensile stress at the outer corner exceeds the material’s ultimate strength, cracking or fracture will occur, mainly at the middle of the workpiece and sometimes at the corners.

2.1.2 The influence of bending tools

If the V-grooves of the bending tools are rough, the workpiece will be subjected to uneven forces when passing through the bending machine, causing surface wear or local pressure, leading to surface defects, followed by extrusion cracking. The cracks usually appear straight and long, with visible cold deformation of the grains at the crack roots.

2.1.3 The influence of logistics

During steel transportation and loading and unloading, surface scratches may occur, which destroy the continuity of the substrate surface. Cracking is prone to occur at the scratched area during bending. These cracks are usually longer and straight, with visible scratch openings at the root of the crack.

2.2.1 The influence of harmful elements, inclusions, and gases in steel

During the smelting process, high sulfur and phosphorus content in steel leads to high sulfide inclusion content or, even if the overall content does not exceed the standard, these elements aggregate locally and cause serious central segregation at the inclusions. This leads to a decrease in the steel’s plasticity and toughness, making it susceptible to bending and cracking.

In addition, microcracks on the surface of the ingot are oxidized at high temperatures during rolling, and the high oxygen and nitrogen content in the steel, especially the nitrogen element, easily forms TiN with titanium. The TiN particles precipitated along the grain boundaries during continuous casting can cause original cracks in the billet, which can lead to cracking during bending.

2.2.2 The influence of steel surface quality

Microcracks and air holes on the surface of the steel are prone to cracking at the crack site under stress after bending. Multiple small cracks can be visible at the bend arc with the naked eye.

2.2.3 The influence of mechanical properties and anisotropy of steel

The better the plasticity of the material, the more stable the plastic deformation, and the larger the elongation at break, the better the bending performance. Even if the bending diameter is small, it is not easy to crack.

In addition, the longitudinal and transverse properties of steel are different, and the longitudinal banded structure is more severe than the transverse. This means that the longitudinal plasticity index of the steel is higher, so when bending along a direction perpendicular to the rolling direction, the bending performance of the steel is better and less prone to cracking compared to bending along the transverse direction.

(1) Solutions to the cracking problem caused by burrs, sharp edges, and oxygen cutting in corner areas: manually sand and round the burrs and sharp edges, or use a deburring machine to automatically remove them and eliminate the hardened processing area to reduce the cracking rate.

Change the bending process to continuous roll forming, then cut after forming to avoid the hardened processing caused by cutting. Remediate minor defects through subsequent welding processes.

(2) To address the issue of small bending radii, the R angle should be enlarged within the allowable range of the design to avoid too small of a bending radius.

(3) Avoid surface scratches during the logistics process of transporting and unloading steel materials.

(4) In the steelmaking process, improve the purity of the steel, reduce the content and aggregation of inclusions in the steel. The argon blowing process should be fully utilized to ensure that larger sulfides in the steel are completely floated and separated.

The appropriate flow field should be maintained during the steel flow process to ensure the proper and stable flow field in the crystallizer, which can further remove inclusions in the steel while preventing contamination from slag entrapment.

Reasonably control the casting temperature, pulling rate, and cooling rate during continuous casting. Proper use of the lightweight pressing technology and electromagnetic stirring technology can improve the internal quality of the billet, reduce center segregation, and prevent the formation of centerline cracks.

(5) In the rolling process, strengthen the control of heating, rolling temperature, and post-rolling cooling processes, avoid the formation of abnormal structures such as bainite, martensite, coarse grains, and mixed crystals, and reduce strength within the allowable range of product standards while improving plasticity and toughness.

Below are answers to some frequently asked questions:

Cracks during metal bending are primarily caused by several interrelated factors. One key factor is the material properties and direction, such as the rolling direction of the metal. Bending parallel to this direction can increase the likelihood of cracks due to the alignment of the grain structure. Additionally, metals like aluminum experience work hardening, which increases brittleness and susceptibility to cracking under further deformation.

The bending process and geometry also play a crucial role. A tight bend radius can lead to excessive tensile stress on the outer fibers of the metal, potentially exceeding the material’s tensile strength and causing cracks. Narrow bends can further exacerbate this issue by creating a crushed state. The surface quality, including surface roughness and burr direction, affects the material’s elongation limit, with smoother surfaces reducing the likelihood of cracks.

External factors such as temperature significantly impact the bending process. Bending at lower temperatures can increase brittleness, particularly in high-strength alloys or work-hardened materials. Preheating the metal can enhance ductility and reduce cracking risk. The quality and alignment of tooling are also crucial; improper tooling or misalignment can lead to stress concentrations and increased cracking risk.

Choosing the right alloy with higher ductility or specific design for bending, like certain aluminum alloys, can mitigate cracking. Increasing the bend radius, preheating the material, and avoiding excessive deformation are effective preventive measures. Understanding these factors and implementing appropriate strategies can significantly minimize the risk of cracking during metal bending.

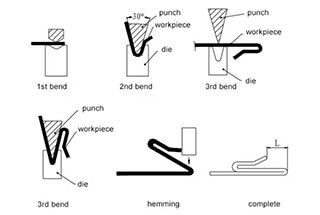

To prevent cracks when bending metal, several key factors and techniques should be considered and implemented. First, selecting the appropriate material and ensuring it has suitable hardness is crucial; softer metals are generally more malleable and less prone to cracking. Bending metal at right angles to the rolling direction also minimizes the risk of cracks. Calculating and adhering to the minimum bending radius based on the material and its thickness is essential; for instance, steel typically requires a radius of one to three times the sheet thickness.

Slowing down the bending speed can help reduce stress on the material, and ensuring the burr direction is set inside the bend can also mitigate cracking. Using preformed dies that fit the desired inner radius can produce precise bends without cracks. For certain alloys, particularly aluminum, heating the material before bending (hot bending) can make it softer and more ductile, reducing the likelihood of cracks. Techniques like the soot method can help control temperature during this process.

Edge preparation is another important factor. Minimizing the heat-affected zone (HAZ) during cutting processes like laser or plasma cutting can prevent the edges from becoming too brittle. Performing test bends on sample pieces before working on the actual metal sheet is a good practice to ensure the bending parameters are correct. Lastly, improving surface roughness can increase the material’s elongation limit, making it less likely to crack during bending. By following these guidelines, you can achieve more reliable and precise results in your metalworking projects.

Material properties significantly influence the occurrence of bending cracks in metals. The composition of the alloy is crucial, as different series (e.g., 1000, 2000, 7000) exhibit varying levels of ductility and strength. Alloys that are heat-treated for increased strength often have reduced ductility, making them more susceptible to cracking during bending. Ductility, or the ability of a material to undergo plastic deformation before fracturing, is vital; materials with low ductility are more prone to cracking.

Grain structure also plays a role, with coarse or irregular grains providing weak points for crack initiation. Work hardening, which occurs when metal is bent, increases hardness but decreases ductility, contributing to brittleness and a higher likelihood of cracking. The bending radius is another critical factor; tight bends can create excessive tensile stress on the outer fibers, leading to cracks if the stress surpasses the material’s tensile strength. Temperature impacts bending behavior as well, with materials becoming more brittle and prone to cracking at lower temperatures. Heating the metal prior to bending can improve ductility and reduce cracking risks.

Additionally, shear deformation in the material’s thickness direction can create shear zones that lead to bending wrinkles and cracks. Material anisotropy, where properties vary in different directions, also affects bendability. The presence of inclusions and the microstructure of the material can further influence the likelihood of bending cracks. By carefully considering these material properties and controlling the bending process, engineers can minimize the risk of bending cracks and ensure the structural integrity of the final product.