Imagine a production line that not only boosts efficiency but also slashes costs and enhances safety. The automated steel door frame production line achieves just that by integrating advanced robotics and precise sheet metal forming processes. In this article, discover how this technology transforms labor-intensive tasks into streamlined operations, ensuring consistent quality and compliance with stringent security standards. Learn how automation can revolutionize manufacturing, offering tangible benefits for both productivity and worker safety.

Manual loading and unloading tasks are labor-intensive, pose risks for workplace injuries, and offer lower efficiency.

Moreover, they do not guarantee consistent product quality, failing to meet the high-volume, high-quality production demands of businesses.

Our company has implemented an automated production line for the sheet metal forming of door frames, integrating multiple machines operated by industrial robots. By pairing these robots with sheet metal equipment, we can automate processes such as material feeding, positioning, coordination with the sheet metal machines, handling, and finished product unloading.

This greatly reduces labor and material costs and enhances production efficiency.

The door frame is an essential component of anti-theft security doors. The precision in forming the door frame directly impacts the security level and performance specifications of the door.

According to the national standard GB17565-2022 “Technical Conditions for Anti-Theft Security Doors”, door frames must adhere to the following specifications:

1. Based on the security grades of B, C, and D, the steel plate thickness for door frames should be 2.00mm, 1.80mm, and 1.50mm, respectively. The steel used must meet the tolerances specified in Table 1.

| Allowable deviation of rolling method | Tolerance thickness/mm | 1.50 | |

| 2.00 | 1.80 | ||

| Allowable deviation of cold rolled steel sheet | -0.15 | -0.14 | -0.12 |

| Allowable deviation of hot-rolled steel sheet | -0.17 | -0.17 | -0.15 |

2. The diagonal dimensions of both the door frame and door leaf, as well as the tolerances for the frame’s groove and the door leaf’s exterior dimensions, should comply with the requirements in Table 2.

| Size/mm | <1000 | 1000~2000 | 2000~3500 | >3500 |

| Tolerance range/mm | ≤2.0 | ≤3.0 | 4≤ | ≤5.0 |

3. The overlap width between the door leaf and frame must be no less than 8mm. The door frame and door leaf, or other parts, may have an anti-intrusion device installed. The device and its connecting strength should withstand a 30kg sandbag impact test three times. Post-testing, no breakage or detachment should occur.

The national standard GB17565-2022 has set higher requirements for the material and precision of door frames. Traditional rolling processes do not meet these precision demands.

To address this, our company has developed a fully automated production line using a die pressing process for metal forming. This not only meets national standards but also increases product yield, boosts production efficiency, and reduces both labor and material costs.

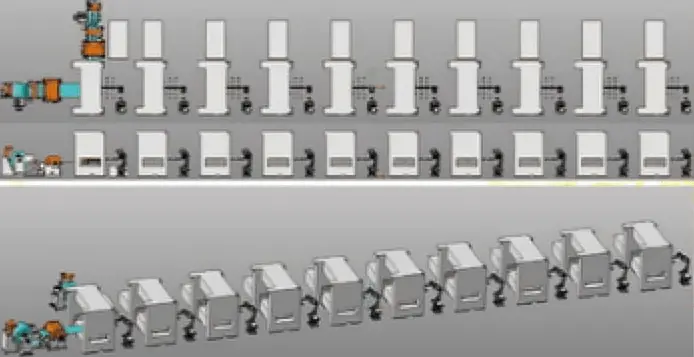

1. The sheet metal forming automated production line for door frames consists of ten six-axis robots, seven press brakes, two punching and trimming machines, two three-in-one feeders, one conveyor, one shearing machine, and one safety enclosure, spanning a total length of 65 meters. (Refer to Figure 1)

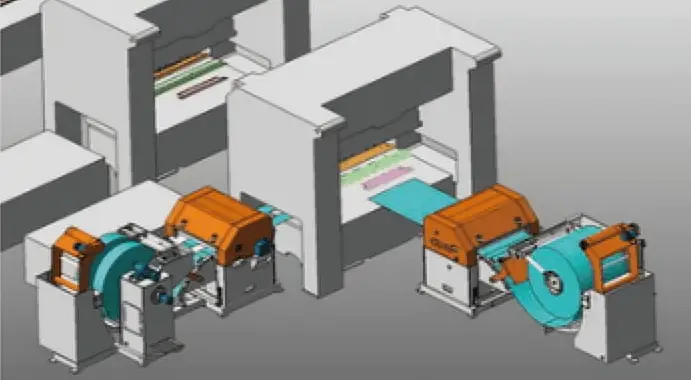

2. Material feeding is done using roll feeding. Two products on one side share a feeder, while a product on the opposite side uses a separate feeder. (Refer to Figure 2)

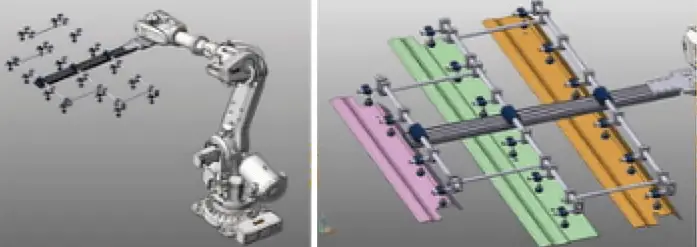

3. The pick-up method employs a modular suction cup end effector, versatile enough to handle a variety of products and easily adjustable. (Refer to Figure 3)

4. Basic features of the robot units include:

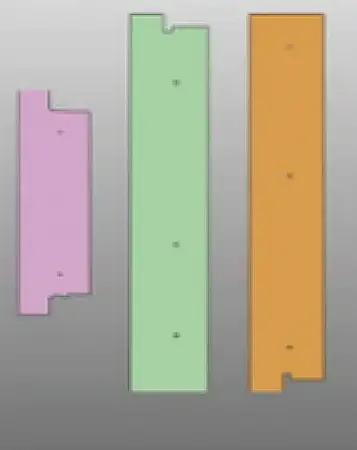

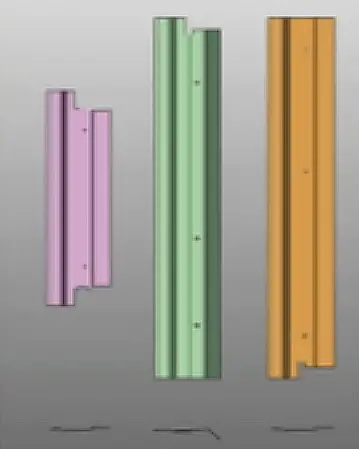

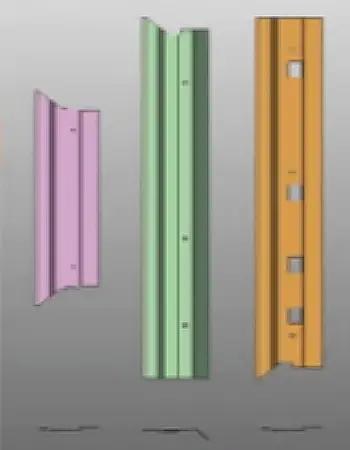

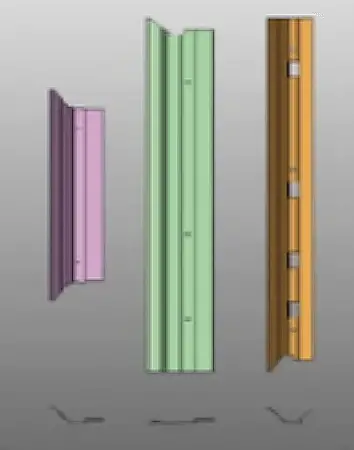

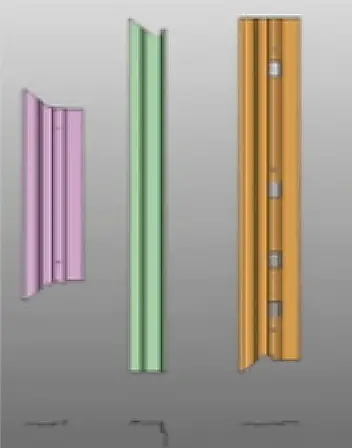

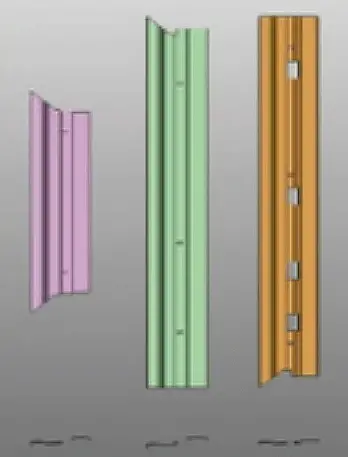

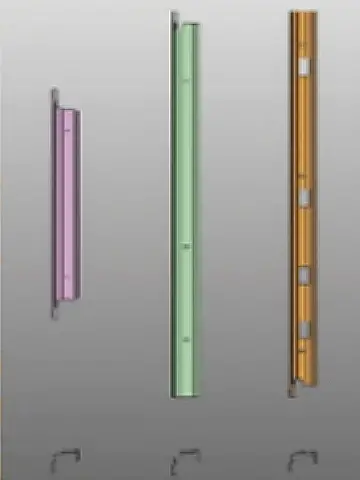

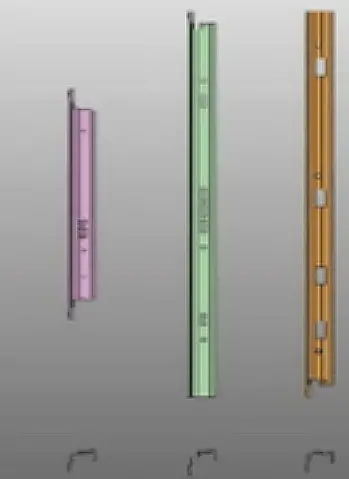

Based on the door frame product structure, our company analyzed the fabrication processes of its three components, comprising ten operations in total.

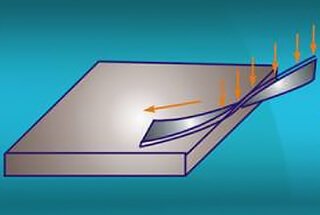

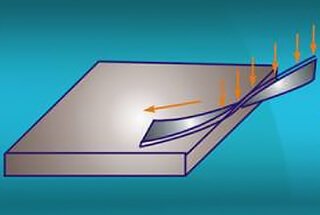

Step 1: A three-in-one feeder sends the metal sheet into the shearing machine. Once it reaches the set length, a signal is sent, and the shearer cuts the metal sheet. The machine then waits for the robot to retrieve the cut material, as shown in Figure 4.

Step 2: Six-axis robot 1 transports the cut sheet to the mold of Press Brake A to start bending. Meanwhile, the robot returns to fetch another sheet, as illustrated in Figure 5.

Step 3: Six-axis robot 2 transfers the component from Press Brake A to Press Brake B. Upon receiving the signal, the machine begins the bending process. The robot then retrieves another piece, detailed in Figure 6.

Step 4: After Press Brake B completes the bending, six-axis robot 3 places the part inside Punching and Edging Machine C to begin the punching and edging process. The robot subsequently fetches another part, as depicted in Figure 7.

Step 5: Once the punching and edging are completed, six-axis robot 4 moves the part from Machine C to Press Brake D. The bending process commences upon signal, with the robot returning for another part. See Figure 8 for reference.

Step 6: After bending in Press Brake D, six-axis robot 5 transfers the component to Press Brake E. The bending resumes after a signal prompt. Concurrently, the robot retrieves another piece, as highlighted in Figure 9.

Step 7: Following the bending process in Press Brake E, six-axis robot 6 moves the component to Press Brake F, where bending ensues after signaling. The robot then fetches the next piece, shown in Figure 10.

Step 8: Post bending in Press Brake F, six-axis robot 7 places the component back in Press Brake C for further bending. The robot then collects another piece, illustrated in Figure 11.

Step 9: After Press Brake G’s bending operation, six-axis robot 8 shifts the component from Press Brake C to Press Brake H. Bending continues after a signal, with the robot fetching the subsequent part, detailed in Figure 12.

Step 10: Once Press Brake H completes bending, six-axis robot 9 moves the component from the sheet metal bender to Punching and Edging Machine I to initiate punching, as seen in Figure 13. After punching, six-axis robot 10 transports the component to the assembly line, marking the completion of a production cycle.

This automated line utilizes a centralized CPU control structure. The entire control system employs a strict hierarchical control. Without permission from the main operating station, equipment cannot operate independently.

Various intelligent sensors and readers communicate through buses with corresponding PLCs or remote I/O units. This includes onsite operation stations, field equipment detection units (proximity switches, photoelectric switches, etc.), other field input devices, and field actuators (like inverters, electromagnetic gaps, etc.).

Interlocking signals between the automation line PLC and the press machine PLC connect through buses or I/Os, while the line PLC exchanges data with the robot control system via a bus.

This automated production line operates in two modes: “Manual” and “Automatic.” Each operating station features an “Automatic/Manual” mode switch.

1. Automatic Mode:

A standard production mode with continuous sequential operations. In this mode, the sheet metal forming equipment operates in a single stroke manner, halting at the slider’s top dead center awaiting commands.

During the sheet metal equipment’s operational cycle, robots collect slider position data and complete the loading and unloading actions.

2. Manual Mode:

A maintenance and debugging mode that carries out all equipment actions following predetermined production trajectories.

Our company’s developed door frame sheet metal forming automated production line produces 7-8 pieces per minute, achieving component precision standards.

Compared to traditional production methods, efficiency increases by 30%, workpiece qualification rates rise by 25%, labor costs drop by 90%, and material costs reduce by 15%.