Have you ever considered how critical precise measurements are in steel production? In the world of steel, dimensions such as length, width, diameter, and thickness aren’t just numbers—they ensure the right fit and function in countless applications. This article unpacks the essentials of steel dimensions, including fixed, multiple, and short lengths, setting you up with the knowledge to navigate material specifications confidently. Dive in to learn how these measurements impact everything from construction to manufacturing.

The dimensional characteristics of steel are fundamental to its specification and application across various industries. These critical measurements encompass length, width, height, diameter, radius, inner diameter, outer diameter, and wall thickness. Each dimension plays a crucial role in determining the steel’s suitability for specific manufacturing processes and end-use applications.

In the global steel industry, the International System of Units (SI) is widely adopted, with meters (m), centimeters (cm), and millimeters (mm) serving as the standard units of measurement. These metric units provide precision and consistency in steel fabrication and quality control processes. For instance, high-precision manufacturing may require tolerances expressed in micrometers (μm) for critical components.

While not officially recognized as statutory units, imperial measurements, particularly inches (“), remain prevalent in certain markets, notably North America. This dual system necessitates careful attention to unit conversion in international trade and collaborative engineering projects to prevent costly errors. Many manufacturers now provide specifications in both metric and imperial units to accommodate global market demands.

It’s worth noting that the choice of measurement unit can significantly impact the efficiency of material utilization and manufacturing processes. For example, optimizing steel sheet dimensions based on standard metric sizes can reduce waste in cutting operations, thereby improving material yield and cost-effectiveness in production.

1. Range Dimensions of Steel

Setting range dimensions for steel is an effective measure to save materials. Range dimensions mean that the length or product of length and width is not less than a certain size, or that the size is within a certain range for delivery. The production unit can supply according to these dimensional requirements.

2. Indefinite Length (Usual Length)

The term “indefinite length” refers to product dimensions (length or width) that are within the standard range but not fixed. The indefinite length is also known as the usual length.

For metal materials delivered according to indefinite length, delivery is acceptable as long as it falls within the defined length range. For example, for ordinary round steel not exceeding 25mm, the usual length is defined as between 4 and 10m. Any round steel within this range can be delivered.

3. Fixed Length

Fixed length refers to cutting into specific sizes as per the order requirements. When delivering at a fixed length, the supplied metal material must have the length specified in the customer’s purchase contract.

For example, if the contract stipulates a fixed length delivery of 5m, then all delivered materials must be 5m long. Anything shorter or longer than 5m is deemed unacceptable. However, in reality, not all deliveries can be exactly 5m long, so a positive deviation is permitted, but a negative one is not.

4. Multiple Length

Multiple length refers to cutting into integer multiples of a specific size as per the order requirements. When delivering at a multiple length, the length of the supplied metal material must be an integer multiple (plus the saw cut) of the length (called single length) specified in the customer’s purchase contract.

For example, if the customer’s contract requires a single length of 2m, then when cut into double length, the length will be 4m; when cut into triple length, it will be 6m, each with one or two saw cut amounts added. The saw cut amount is stipulated in the standard. When delivering at a multiple length, only a positive deviation is allowed; a negative value is not acceptable.

5. Short Length

Short length refers to a length that is less than the lower limit of the standard indefinite length but not less than the allowable shortest length.

For example, in the standard for water and gas transmission steel pipes, it is allowed to have 10% (calculated by root number) short length steel pipes of 2-4m length in each batch. Here, 4m is the lower limit of the indefinite length, and the shortest permissible length is 2m.

6. Narrow Width

Widths that are smaller than the standard specified lower limit, but not less than the permitted narrowest width, are referred to as narrow widths. When delivering according to narrow widths, one must pay attention to the standard regulations concerning the proportion of narrow widths and the narrowest width.

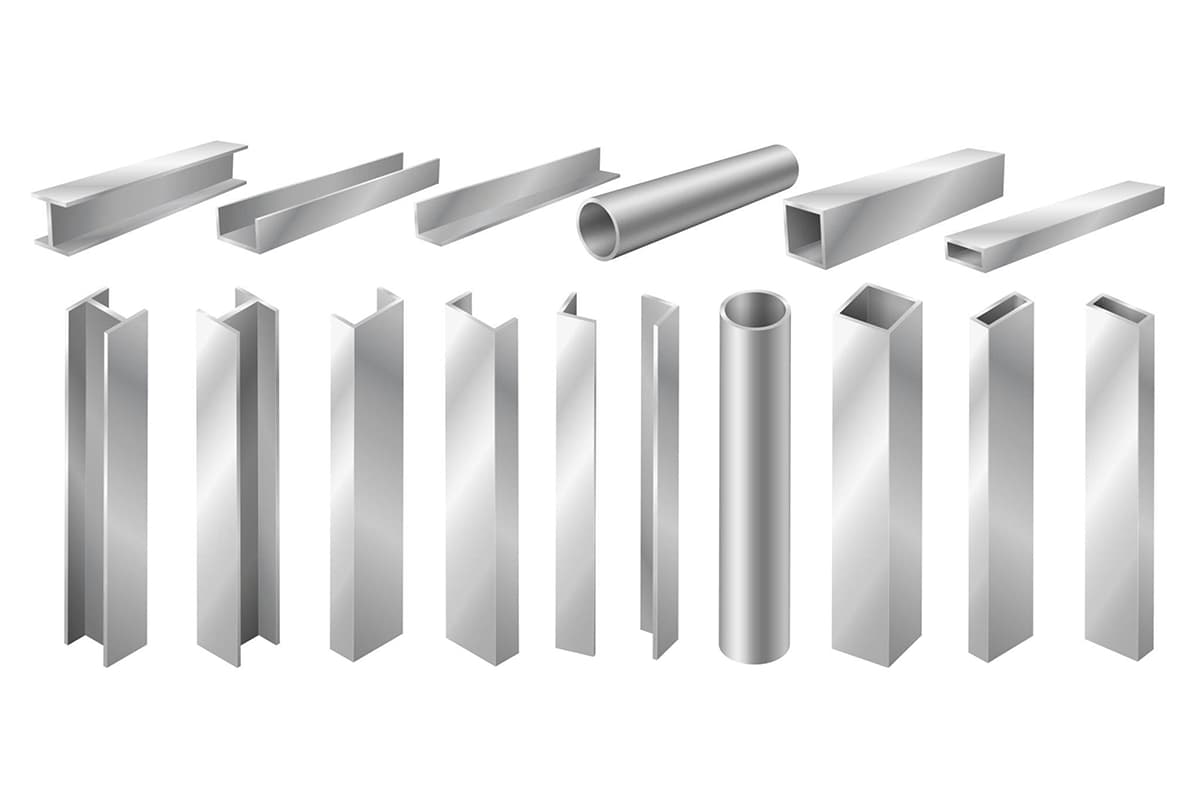

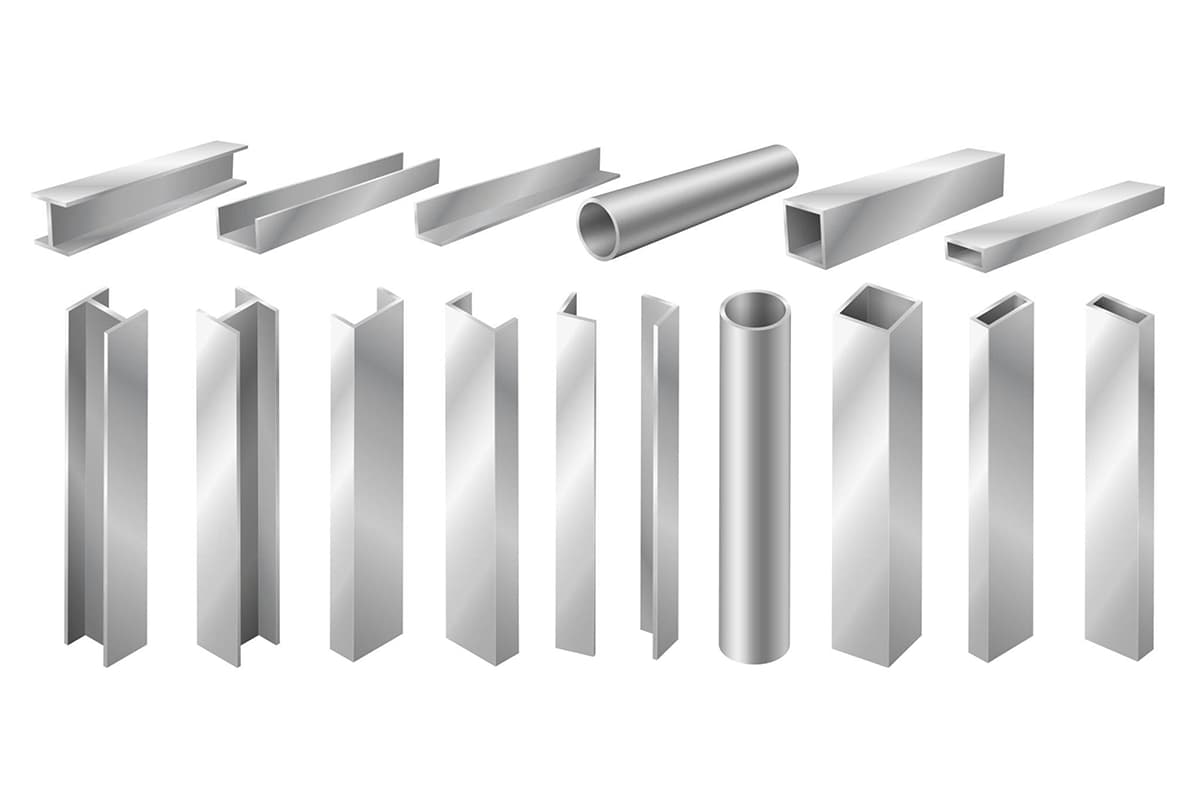

1. Structural Steel Length Dimensions

a) Standard lengths for rail tracks are 12.5m and 25m, optimized for efficient transportation and installation in railway construction.

b) Round steel, wire rod, and steel wire dimensions are specified by diameter (d) in millimeters (mm). This standardization ensures precise material selection for various applications, from reinforcement to electrical conductors.

c) Square steel dimensions are denoted by side length (a) in millimeters (mm), providing a uniform reference for structural and architectural applications.

d) Hexagonal and octagonal steel dimensions are characterized by the distance across corners (s) in millimeters (mm). This measurement is crucial for applications requiring specific torque or grip characteristics.

e) Flat steel dimensions are defined by width (b) and thickness (d) in millimeters (mm), offering versatility in structural, automotive, and manufacturing sectors.

f) I-beam and channel steel dimensions are specified by the height of the web (h), flange width (b), and web thickness (d) in millimeters (mm). These parameters are critical for load-bearing calculations and structural integrity in construction.

g) Equal angle steel dimensions are denoted by the equal side width (b) and side thickness (d) in millimeters (mm). For unequal angle steel, dimensions are specified by side widths B, b, and side thickness (d) in millimeters (mm). This distinction allows for precise selection in various structural applications.

h) H-beam dimensions are characterized by the height of the web (h), width of the flange (b), thickness of the web (t1), and thickness of the flange (t2) in millimeters (mm). These comprehensive measurements enable engineers to select the optimal profile for specific load-bearing requirements in construction and industrial applications.

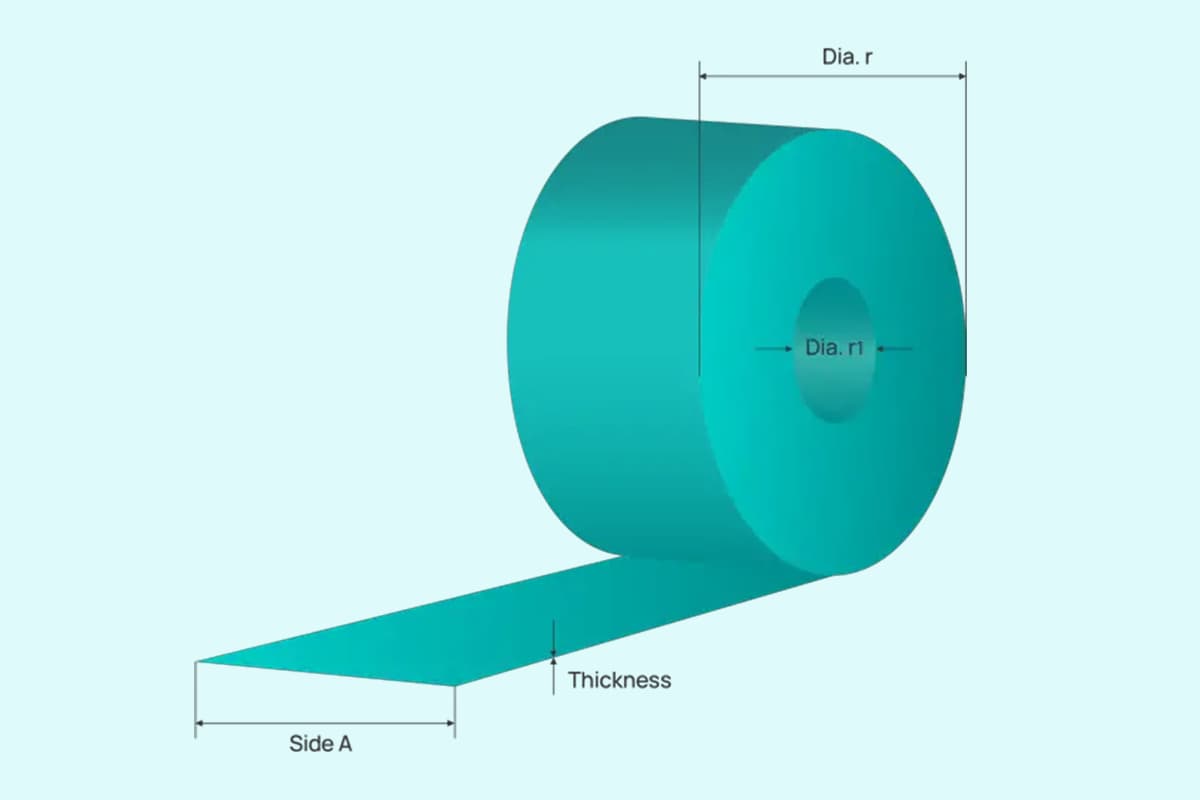

2. Dimensions of Steel Plates and Strips

⑴ The thickness ‘d’ of steel plates is typically specified in millimeters (mm). For strips, both the width ‘b’ and thickness ‘d’ are expressed in millimeters (mm). This standardized measurement system ensures precision in manufacturing and facilitates clear communication across the industry.

⑵ Steel plates are manufactured in a range of standardized dimensions to meet diverse industrial requirements. For example, hot-rolled steel plates are available in various combinations of thickness and size:

These standardized dimensions optimize material utilization, reduce waste in downstream processes, and streamline inventory management. However, custom sizes can often be ordered to meet specific project requirements, subject to manufacturing capabilities and minimum order quantities.

3. Dimensions of Steel Pipes

(1) Steel pipe dimensions are typically specified using three key parameters: outside diameter (OD) denoted as ‘D’, inside diameter (ID), and wall thickness ‘S’. These measurements are generally expressed in millimeters (mm) in accordance with international standards such as ISO and ASTM.

(2) Each steel pipe type is manufactured to precise dimensional specifications, offering a range of options to suit various industrial applications. For example: