Have you ever wondered how to accurately calculate the weight of steel or metal for your projects? In this blog post, we’ll explore the fascinating world of steel weight calculation formulas. As an experienced mechanical engineer, I’ll guide you through the essential concepts and provide practical examples to help you master this crucial skill. Whether you’re a professional or a DIY enthusiast, understanding how to determine the weight of various metals will empower you to tackle your projects with confidence and precision. Get ready to dive into the world of steel weight calculation and unlock valuable insights that will elevate your engineering prowess!

Calculating the weight of steel is a fundamental task in many engineering and construction projects. The basic formula to determine the weight of a steel object involves understanding the relationship between the volume of the steel and its density. The general formula is:

Weight= Volume x Density

The density of steel can vary depending on its composition. This variation impacts the weight calculations. Here are some common types of steel and their densities:

The following weight calculation formula can be used to calculate the steel/metal weight:

Weight (kg) = Sectional Area (mm2) × Length (m) × Density (ρ, g/cm3)× 1/1000

Above is the formula to calculate the steel weight in kg.

Understanding the density of different types of steel is essential for accurate weight calculations and various engineering applications. The density of steel varies depending on its composition, which directly impacts the weight and performance of steel objects in different contexts.

The standard density of steel is approximately 7850 kg/m³ or 7.85 g/cm³. This density is used for most general-purpose steels, including mild steel and carbon steel.

For the metal density, you can also refer to the following:

To assist you in calculating the weight of various metals and steels, including MS plate, GI sheet, structural steel, MS angle, mild steel, steel bar, square tube, angle, and aluminum, we have created a Steel Weight Calculator and Metal Weight Calculator to help you determine the weight of metals in different shapes.

The unit of measurement for calculating the theoretical weight of steel is kilograms (kg). The basic formula is:

W (Weight, kg) = F (Cross-sectional Area, mm²) × L (Length, m) × ρ (Density, g/cm³) × 1/1000

The density of steel is: 7.85g/cm³

Simply enter data indicated (Decimal Inches), move from left to right making computations by factors as shown.

PLATE SHAPES:

NOTE: Formulas Are Based on Nominal Weights at .2836 Lbs. Per Cubic Inch and Should Be Considered Approximations Only Rather Than Actual Scale Weight

Weights of Various Metals in Pounds Per *Cubic Foot

| Aluminum | 168.48 | Copper | 559.87 |

| Antimony | 419.99 | Gold | 1206.83 |

| Beryllium | 113.7 | Gun Metal (Aver.) | 544 |

| Bismuth | 611 | Iridium | 1396 |

| Brass (Approx.) | 535.68 | Iron | 491.09 |

| Bronze, Alum. | 481 | Iron, Cast Grey | 442 |

| Bronze (Approx.) | 541 | Iron,Wrought | 480 |

| Cadmium | 540.86 | Iron, Slag | 172 |

| Chromium | 428 | Lead | 707.96 |

| Cobalt | 552.96 | Magnesium | 108.51 |

| Manganese | 463.1 | Silver | 654.91 |

| Mercury | 849 | Stainless Steel (18-8) | 494.21 |

| Molybdenum | 637.63 | Steel, Cast/Rolled | 490 |

| Monel Metal | 556 | Tin | 455.67 |

| Nickel | 555.72 | Titanium | 283.39 |

| Osmium | 1402 | Tungsten | 1204.41 |

| Palladium | 712 | Vanadium | 374.97 |

| Platinum | 1339.2 | Zinc | 445.3 |

| Rhodium | 755 | *1728 CU. IN. PER CU. FT. | |

| Ruthenium | 765 | ||

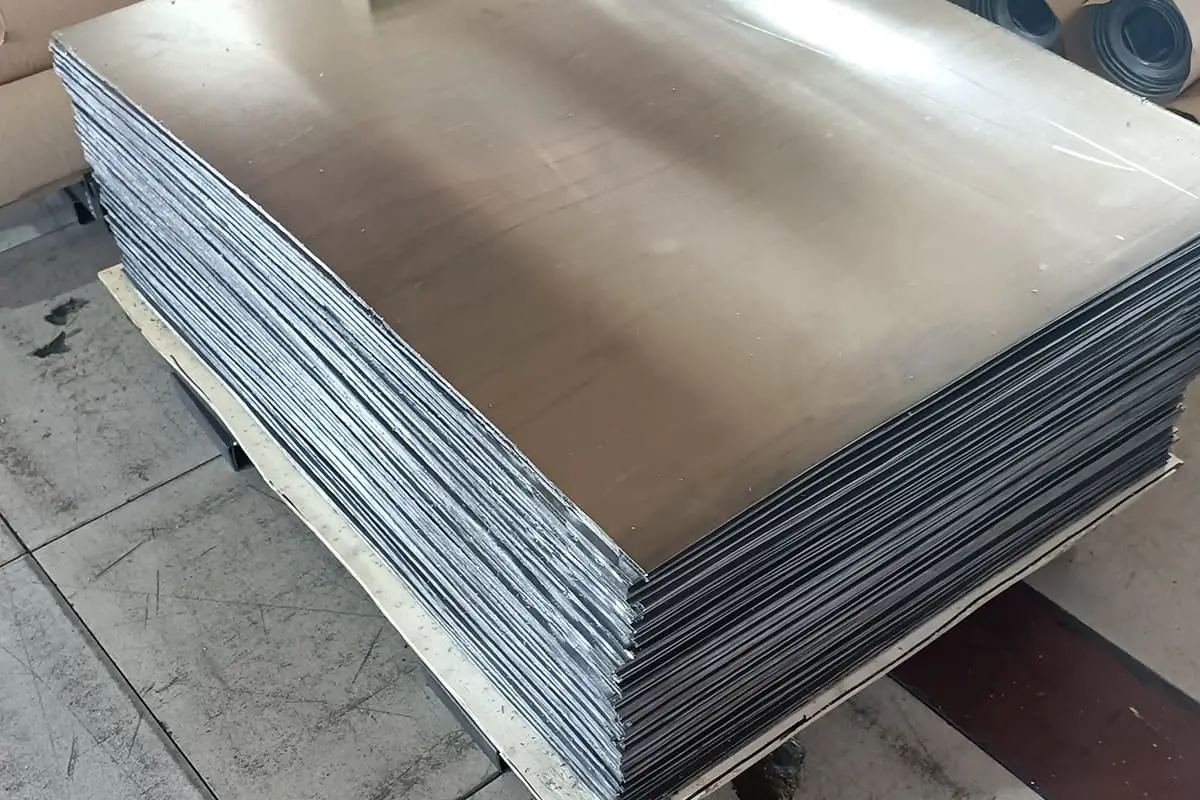

1. Steel Plate weight calculation formula

• Formula: length(m)×width(m)×thickness(mm)×7.85

• E.g: 6m (length)×1.51m(width)×9.75mm (thickness)

• Calculation: 6×1.51×9.75×7.85=693.43kg

2. Steel Pipe weight calculation formula

• Formula: (OD-wall thickness)×wall thickness(mm)×length(m)×0.02466

• E.g: 114mm(OD)×4mm(wall thickness)×6m(length)

• Calculation: (114-4)×4×6×0.02466=65.102kg

3. Steel Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00617

• E.g: Φ20mm (dia.)×6m(length)

• Calculation: 20×20×6×0.00617=14.808kg

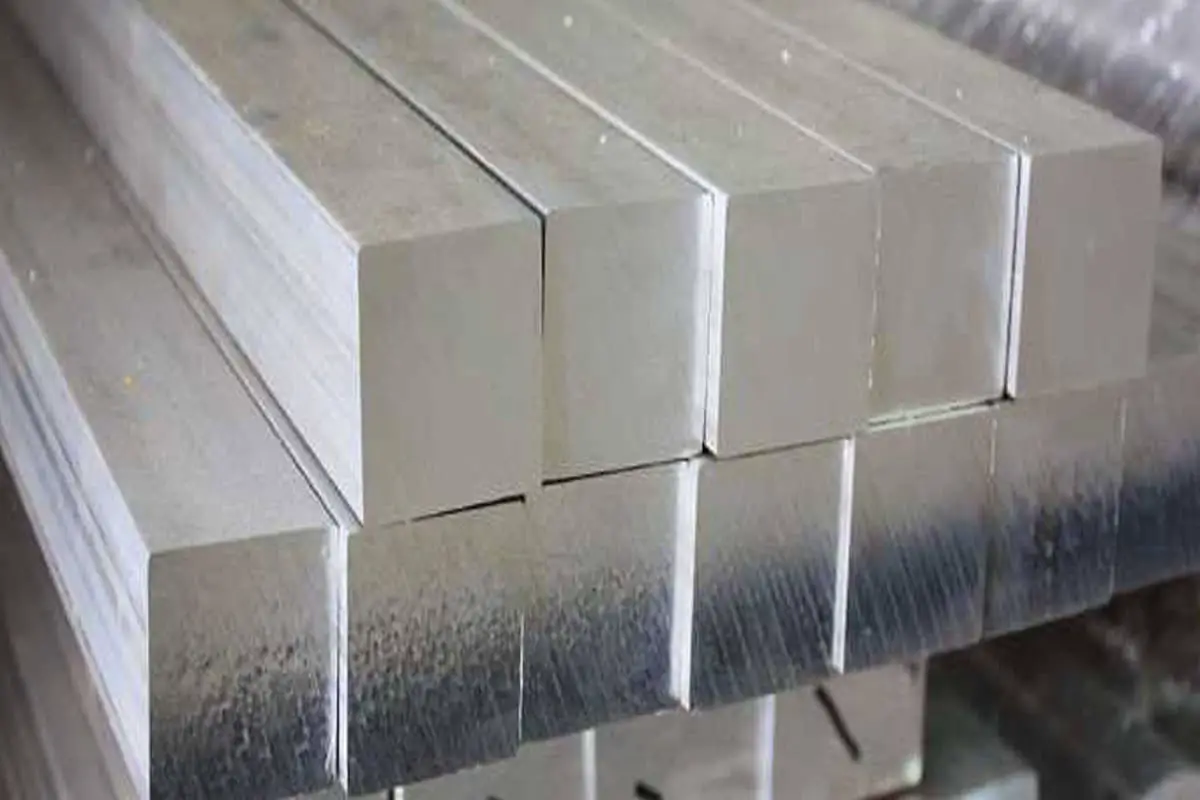

4. Square Steel weight calculation formula

• Formula: side width(mm)×side width(mm)×length(m)×0.00785

• E.g: 50mm(side width)×6m(length)

• Calculation: 50×50×6×0.00785=117.75(kg)

5. Flat Steel weight calculation formula

• Formula: side width(mm)×thickness(mm)×length(m)×0.00785

• E.g: 50mm(side width)×5.0mm(thickness)×6m(length)

• Calculation: 50×5×6×0.00785=11.775(kg)

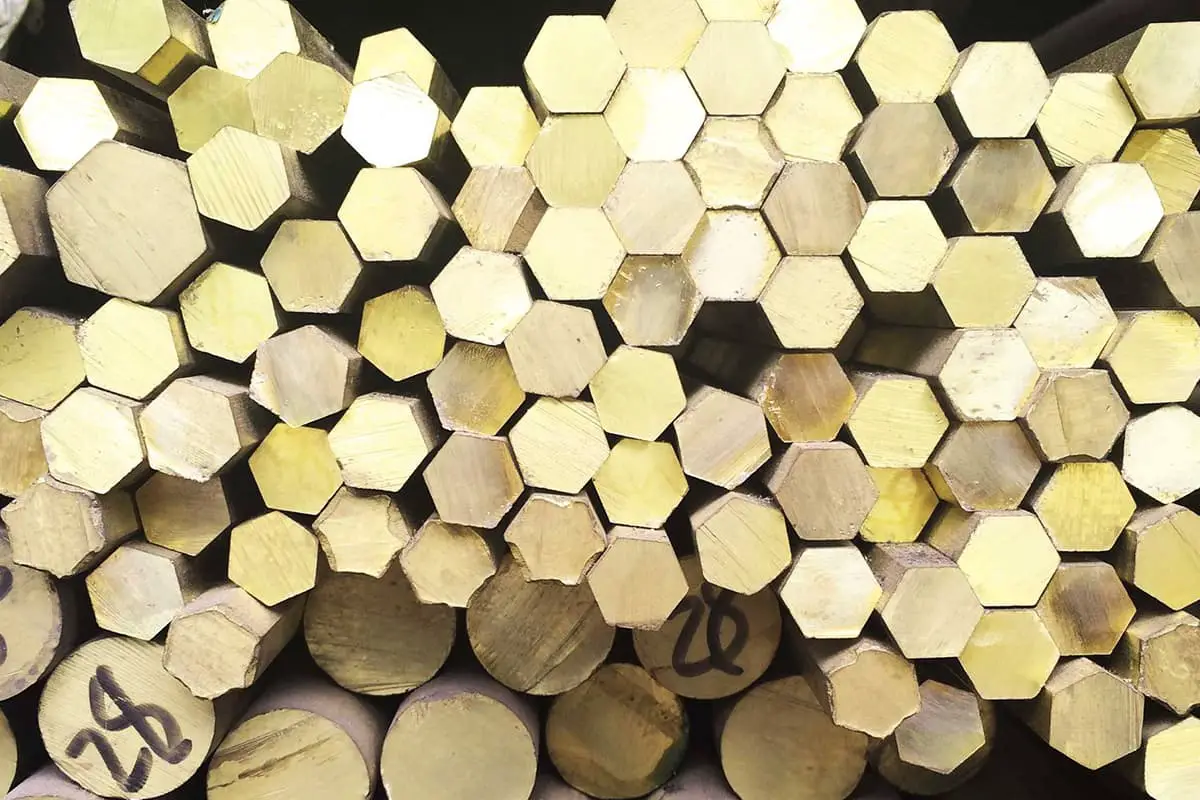

6. Hexagonal Steel weight calculation formula

• Formula: side-to-side dia.×side-to-side dia.× length(m)×0.0068

• E.g: 50mm(dia.)×6m (length)

• Calculation: 50×50×6×0.0068=102(kg)

7. Rebar weight calculation formula

• Formula: dia.mm×dia.mm×length(m)×0.00617

• E.g: Φ20mm(dia.)×12m(length)

• Calculation: 20×20×12×0.00617=29.616kg

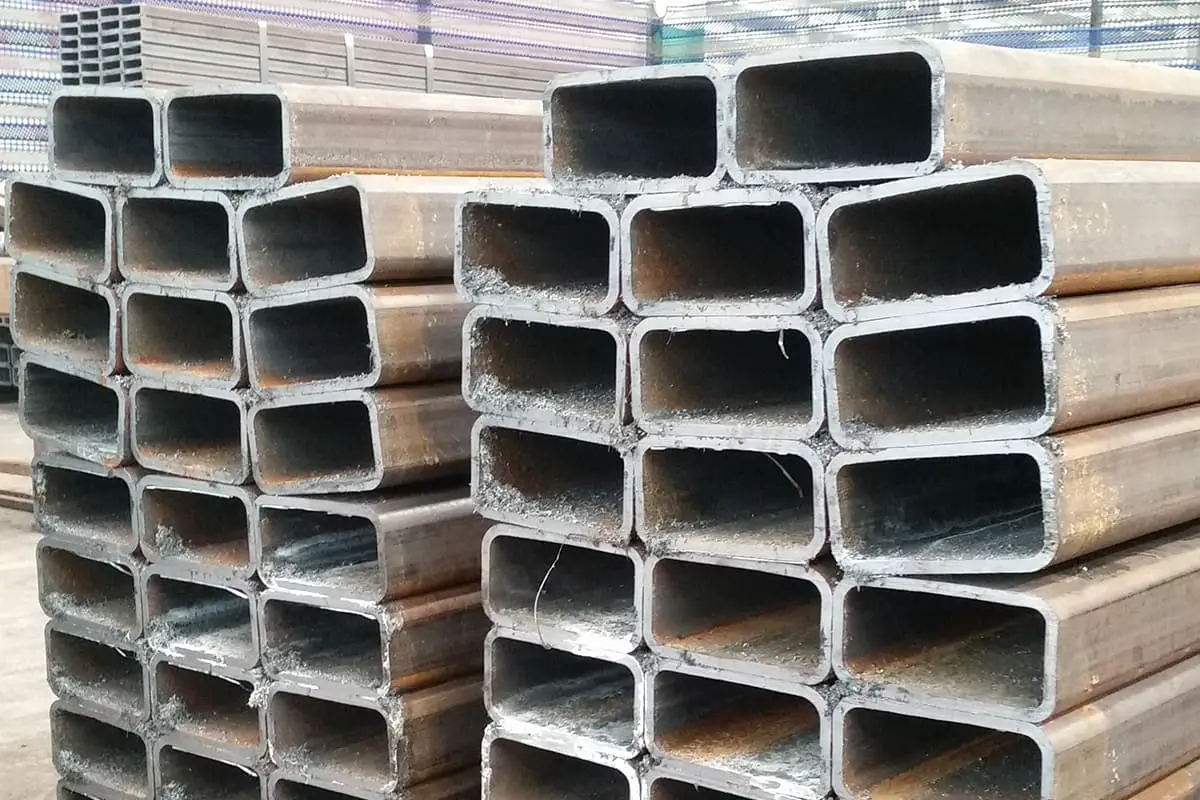

8. Flat Steel Tube weight calculation formula

• Formula: (side length+side width)×2×thickness×length(m)×0.00785

• E.g: 100mm×50mm×5mm(thickness)×6m (length)

• Calculation: (100+50)×2×5×6×0.00785=70.65kg

9. Rectangular Steel Tube weight calculation formula

• Formula: side width(mm)×4×thickness×length(m)×0.00785

• E.g: 50mm×5mm (thickness)×6m(length)

• Calculation: 50×4×5×6×0.00785=47.1kg

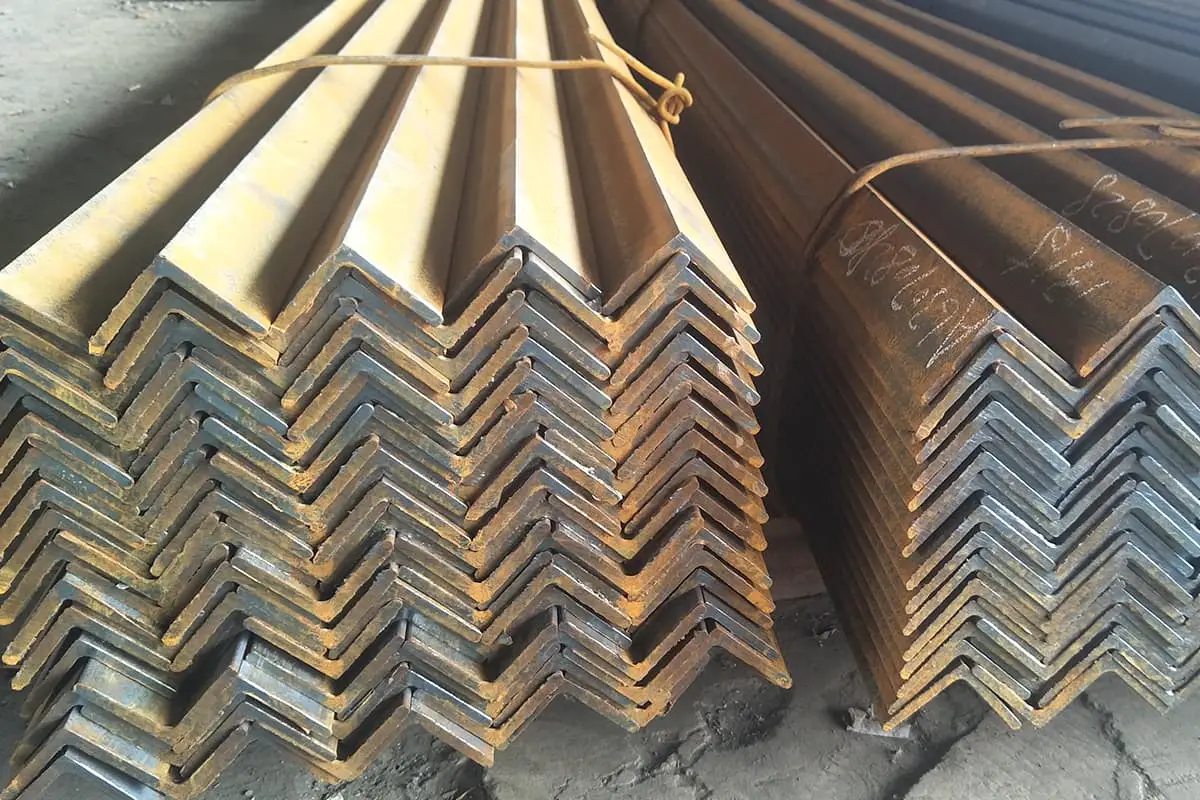

10. Equal-leg Angle Steel weight calculation formula

• Formula: (side width×2-thickness)×thickness×length(m)×0.00785

• E.g: 50mm×50mm×5(thickness)×6m(length)

• Calculation: (50×2-5)×5×6×0.00785=22.37kg

11. Unequal-leg Angle Steel weight calculation formula

• Formula: (side width+side width-thickness)×thickness×length(m)×0.0076

• E.g: 100mm×80mm×8(thickness)×6m(length)

• Calculation: (100+80-8)×8×6×0.0076=62.746kg

12. Brass Pipe weight calculation formula

• Formula: (OD-wall thickness)×thickness(mm)×length(m)×0.0267

13. Copper Pipe weight calculation formula

• Formula: (OD-wall thickness)×thickness(mm)×length(m)×0.02796

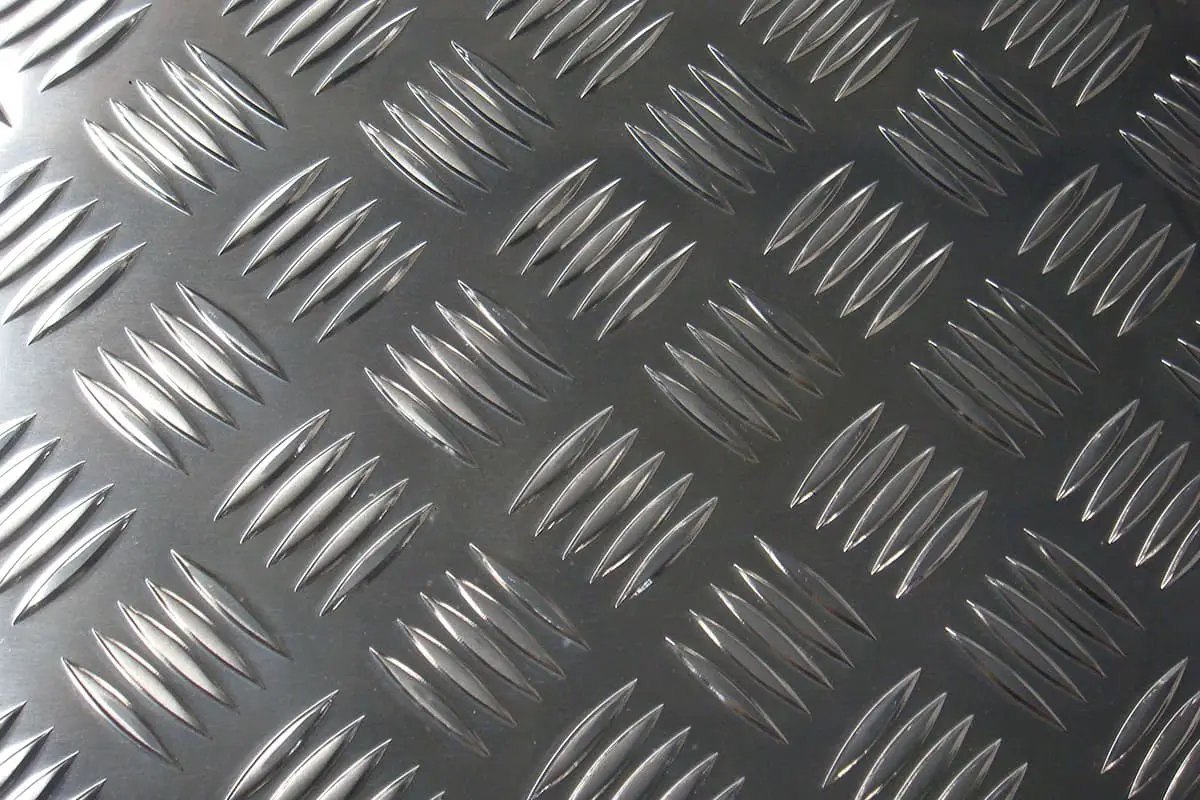

14. Aluminum Checkered Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness (mm)×0.00296

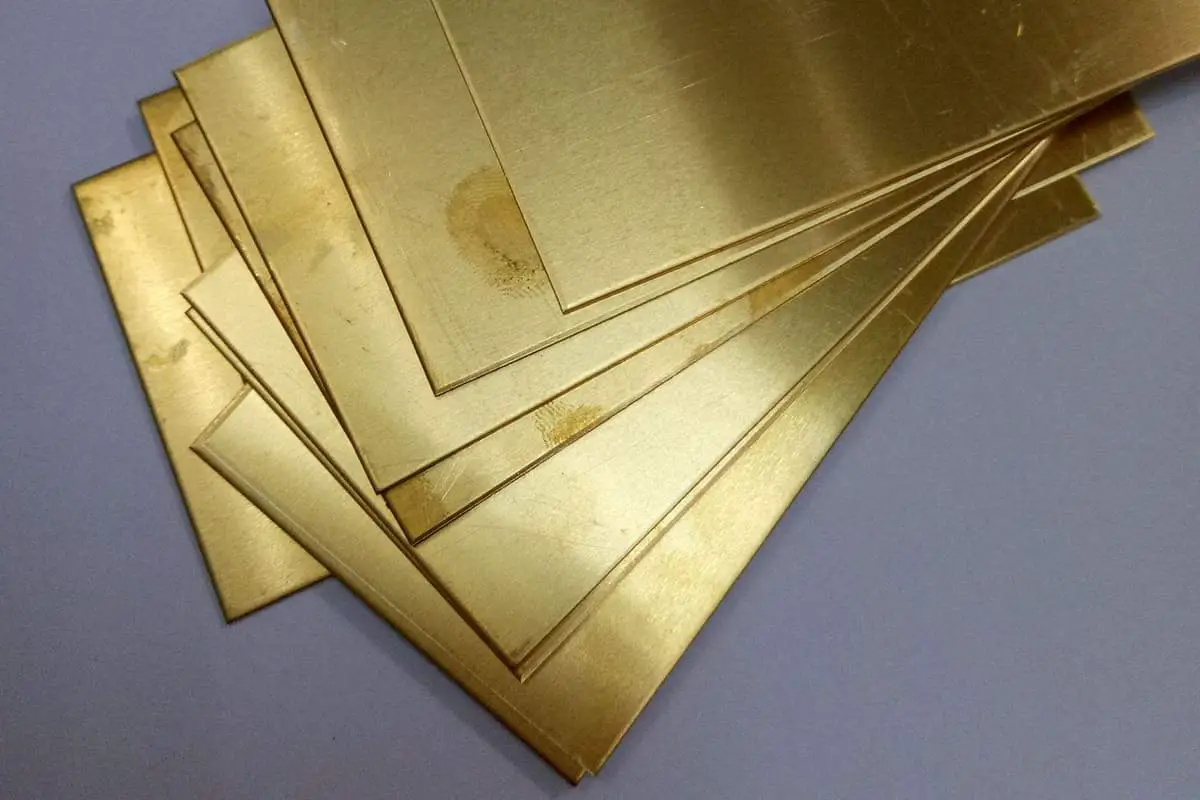

15. Brass Pipe weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0085

16. Copper Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0089

17. Zinc Plate weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.0072

18. Lead Sheet weight calculation formula

• Formula: length(m)×width(mm)×thickness(mm)×0.01137

19. Octagonal Steel weight calculation formula

• Formula: length(m)×across width(mm)×across width(mm)×0.0065

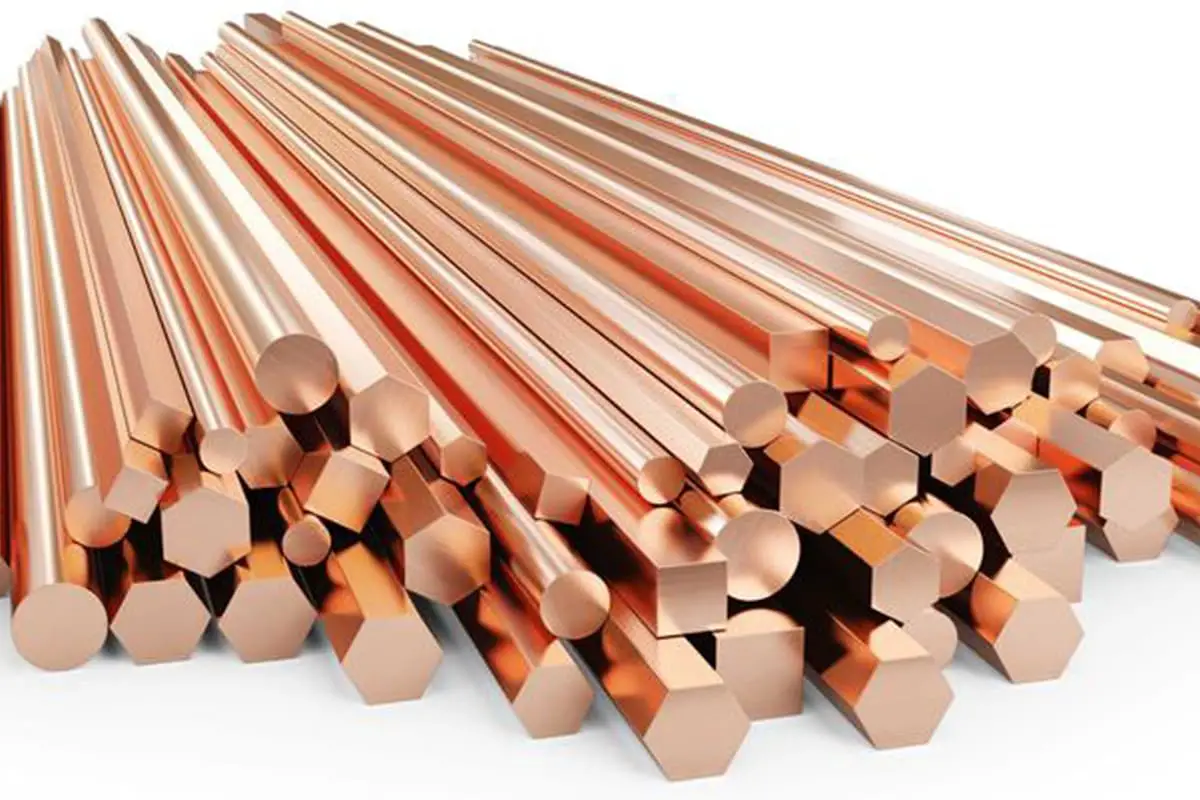

20. Copper Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00698

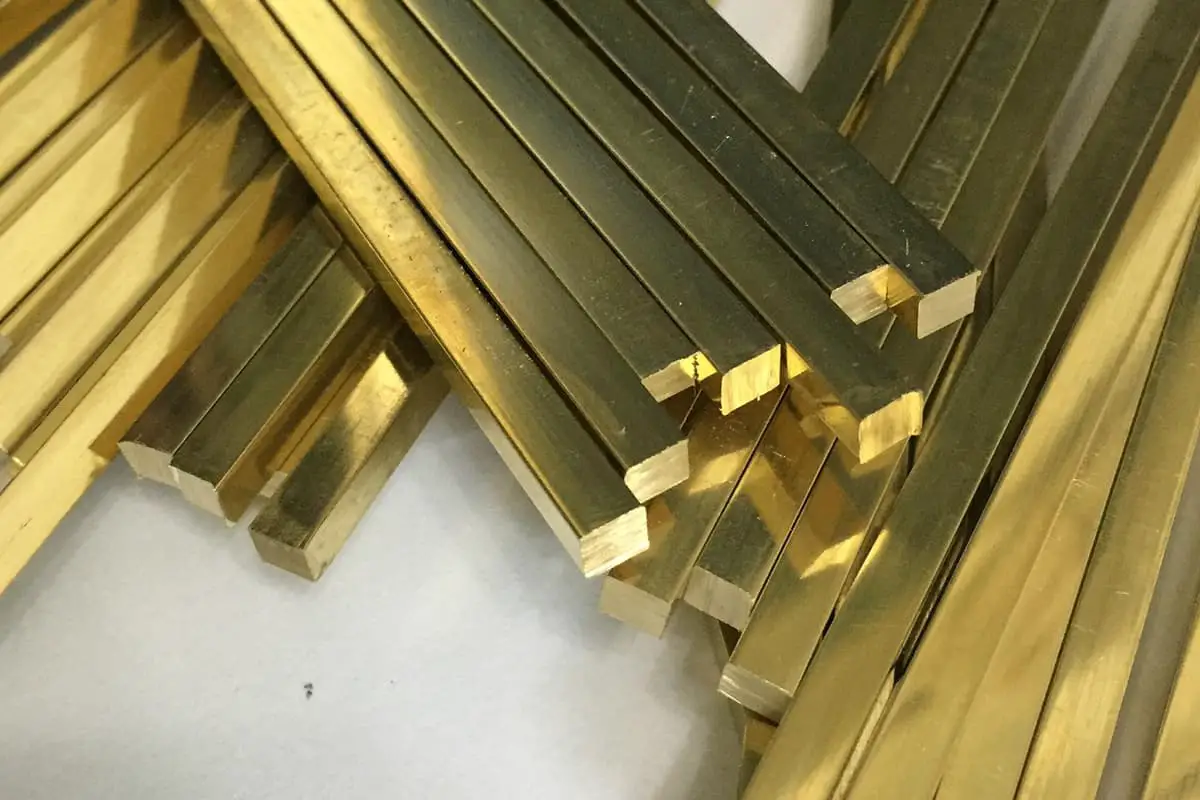

21. Brass Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.00668

22. Aluminum Rod weight calculation formula

• Formula: dia.(mm)×dia.(mm)×length(m)×0.0022

23. Square Copper Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0089

24. Square Brass Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0085

25. Square Aluminum Rod weight calculation formula

• Formula: width(mm)×width(mm)×length(m)×0.0028

26. Hexagonal Copper Rod weight calculation formula

• Formula: across width(mm)×across width(mm)×length(m)×0.0077

27. Hexagonal Brass Rod weight calculation formula

• Formula: width(mm)×across width(mm)×length(m)×0.00736

28. Hexagonal Aluminum Rod weight calculation formula

• Formula: across width(mm)×across width(mm)×length(m)×0.00242

29. Aluminum Plate weight calculation formula

• Formula: thickness(mm)×width(mm)×length(m)×0.00171

30. Aluminum Pipe weight calculation formula

• Formula: thickness(mm)×(O.D(mm)-thickness(mm))×length(m)×0.00879

Accurate weight calculation of metal materials is crucial for various industrial applications, yet several factors can introduce errors. Understanding these sources is essential for precise engineering and cost estimation. The following are key points to consider:

Density Variations: The accuracy of material density is paramount in weight calculations. Density can vary due to alloy composition, manufacturing processes, and even within the same batch of materials. For instance, the density of steel can range from 7.75 to 8.05 g/cm³ depending on its carbon content and alloying elements. Using a generic density value instead of the specific grade’s density can lead to significant errors, especially in large-scale projects.

Dimensional Tolerances: Manufacturing processes inherently produce components with dimensional variations within specified tolerances. These deviations from nominal dimensions directly impact weight calculations. For example:

Thermal Expansion Effects: Temperature fluctuations can significantly affect material dimensions and, consequently, weight measurements. The linear thermal expansion coefficient (α) varies among metals:

Theoretical vs. Actual Weight Discrepancies: Even under ideal conditions, theoretical weight calculations may deviate from actual weights due to factors such as:

Material Processing Effects: Various manufacturing processes can alter the material’s weight distribution:

These factors, often overlooked in theoretical calculations, can contribute to weight discrepancies, especially in fabricated assemblies.

By accounting for these potential sources of error, engineers and manufacturers can improve the accuracy of their weight calculations, leading to more precise material planning, cost estimation, and structural design in metal fabrication projects.

Accurately calculating the weight of steel is essential for ensuring structural integrity, cost estimation, and efficient resource management in engineering and construction projects.

Accurate steel weight calculation is crucial in various engineering and construction contexts. It ensures structural stability, helps in budgeting, and facilitates efficient material handling. For example, in bridge construction, precise weight calculations are vital to avoid overloading the structure, which could lead to catastrophic failures.

Steel density varies depending on its composition. Carbon steel typically has a density of about 7850 kg/m³ or 7.85 g/cm³, while stainless steel can have a slightly different density due to its alloying elements like chromium and nickel. Knowing the exact type of steel and its density is essential for accurate weight calculations.

Precise measurements of the steel component’s dimensions are critical. Use accurate instruments such as calipers or micrometers, and double-check measurements to ensure accuracy. For example, when measuring a steel beam, ensure you measure its length, width, and height precisely to avoid errors in the final weight calculation.

Maintain a consistent unit system throughout your calculations. If you start with metric units (meters, centimeters), ensure all measurements and constants are in the same unit system. Similarly, if using imperial units (inches, feet), maintain consistency to avoid conversion errors.

Different shapes of steel components require specific formulas for volume calculation:

For example, to calculate the weight of a steel plate measuring 2 meters in length, 1 meter in width, and 0.01 meters in thickness:

Alternatively:

where ( D ) is in millimeters and ( L ) is in meters.

For example, to calculate the weight of a cylindrical steel rod with a diameter of 50 mm and length of 2 meters:

For complex shapes, break them down into simpler geometric figures and sum their volumes.

Online metal weight calculators can be a handy tool for quick estimations. These calculators allow you to input the dimensions and material type, providing an estimated weight. They support various shapes and alloys, simplifying the process.

Actual weights can vary due to fabrication and composition tolerances. Use calculated weights as estimates rather than exact values. For critical applications, consult with material suppliers or manufacturers for precise weights.

Ensure that all measuring instruments, such as calipers, micrometers, and tape measures, are regularly calibrated to maintain accuracy. Inaccurate instruments can lead to significant errors in weight calculations.

Always verify your calculations by cross-checking with multiple methods or formulas. For complex shapes, consider breaking down the shape into simpler geometric figures and summing their volumes.

By following these tips and using the appropriate formulas, you can accurately calculate the weight of steel components, ensuring efficient project planning and resource management.

Below are answers to some frequently asked questions:

To calculate the weight of steel, you use a general formula that involves determining the volume of the steel object and then multiplying it by the density of steel. The general formula is:

First, calculate the volume of the steel object. The method to find the volume depends on the shape of the object:

For a rectangular plate, sheet, or bar:

For a round bar:

For a square tube:

For a round tube:

Once you have the volume, multiply it by the density of steel to get the weight. The standard density of steel is approximately 7850 kg/m³ or 490 lb/ft³.

For example, to find the weight of a rectangular steel plate with dimensions 6 inches by 8 inches by 0.25 inches, and assuming the density of steel is 0.2836 lb/in³:

This formula is useful for various shapes and types of steel, allowing for accurate weight calculations in engineering and construction projects.

To calculate the volume of a steel plate, you use the formula:

Volume = Length × Width × Thickness

First, ensure all measurements are in the same unit, typically meters. For example, if the dimensions are given in millimeters, convert them to meters:

Then, apply the formula: Volume = 6 meters × 4 meters × 0.032 meters = 0.768 cubic meters

This formula helps you determine the volume of the steel plate, which is essential for further calculations, such as determining the weight of the plate by multiplying the volume by the steel’s density.

The density of carbon steel is approximately 7.85 grams per cubic centimeter (g/cm³) or 7.85 tons per cubic meter (t/m³). In imperial units, this translates to about 0.284 pounds per cubic inch (lb/in³) or 490 pounds per cubic foot (lb/ft³). Understanding the density of carbon steel is essential for calculating its weight accurately. By using the formula Weight = Density × Volume, one can determine the weight of a carbon steel object by first calculating its volume based on its shape, such as a flat sheet or a cylindrical rod.

To calculate the weight of a cylindrical steel rod, you can follow these steps:

Convert the diameter to meters if it is given in millimeters. This is done by dividing the diameter in millimeters by 1000.

Calculate the volume of the cylinder using the formula:

where ( d ) is the diameter in meters and ( l ) is the length in meters.

Multiply the volume by the density of steel. The typical density of steel is around 7850 kg/m³.

Here’s an example calculation for a steel rod with a diameter of 20 mm and a length of 2 meters:

Convert the diameter to meters: d=20mm=0.02 m

Calculate the volume:

Multiply by the density of steel:

For a quicker calculation using the diameter in millimeters and length in meters, the simplified formula is:

Using this formula for a diameter of 20 mm and a length of 2 meters:

This method ensures you accurately calculate the weight of a cylindrical steel rod.

To calculate the weight of a steel sheet, you can use the following example with the given dimensions:

Let’s say we have a steel sheet with the following dimensions:

Here are the steps for the calculation:

Alternatively, if you prefer to work in millimeters, you can use the formula:

Weight = (Length / 1000) × (Width / 1000) × Thickness × Density

Using the same dimensions in millimeters:

Weight = (2000 / 1000) × (1000 / 1000) × 10 mm × 7.85 g/cm³ = 2 × 1 × 10 mm × 7.85 g/cm³ = 157 kg (after converting units appropriately)

By following these steps, you can accurately calculate the weight of a steel sheet.