What makes intricate designs possible in 3D printing? The answer lies in support structures. This article explores the necessity, types, and design strategies of support structures that prevent part deformation and collapse. Whether you’re dealing with overhangs in metal printing or aiming for smoother finishes in SLA prints, understanding these supports can save you time, material, and effort. Dive in to learn how to optimize your designs and enhance your 3D printing success rate.

Support structures are an essential component to successfully manufacturing 3D printed parts.

Despite one of the key advantages of 3D printing being its ability to create freeform and complex geometrical shapes, much of the design freedom offered by 3D printing is difficult to realize without the use of support structures.

They are crucial for preventing part distortion and collapse among other uses, hence, understanding and designing support structures is a necessary skill for any additive manufacturing engineer.

This article discusses the requirements, pros and cons, removal, and how to minimize the use of support structures in various printing technologies.

Used in conjunction with virtually all 3D printing technologies, support structures play a crucial role in ensuring the printability of parts during the 3D printing process.

Supports help prevent deformation of the parts, secure them to the print bed, and assure their connection to the main body of the printed parts. Much like a scaffold, these supports are utilized during the printing process and then removed afterward.

Printing parts with complex design features, such as overhangs, holes, and bridges, poses significant challenges.

Take metal 3D printing as an example; when the print includes overhangs or bridging structures, deformation, even collapse, can occur during the process if support structures are not utilized.

These support structures help prevent the collapse of the formed parts during printing, considerably enhancing the success rate of printing. However, not all overhanging structures need additional support.

If the vertical angle of the overhang is less than 45 degrees, no support is necessary.

When the vertical angle of such a structure is less than 45 degrees, the 3D printer has minimal horizontal offset on successive layers, allowing each layer to provide support for the next level.

Therefore, 45 degrees is a critical angle, below which no support is necessary. Of course, this also depends on the performance of the printer and the properties of the materials used. If the printer’s performance is subpar, support may be needed even for angles less than 45 degrees.

Furthermore, technologies like metal 3D printing generally involve high-temperature processes, during which the support can also serve as a heat sink.

This is because the support structures added during the metal additive manufacturing process help carry heat away from the part, preventing the formation of residual stress due to high temperatures during printing and avoiding defects such as deformation, warping, and cracking.

Of course, it’s not only metal 3D printing that considers the addition of supports; almost all 3D printing technologies need to contemplate the inclusion of support structures to some extent.

The following table illustrates the differences in support usage among various 3D printing methods:

| Technical Principles | Materials | Is support required? |

| Selective Laser Melting (SLM) Direct Metal Laser Sintering (DMLS) Direct Energy Deposition (DED) Electron Beam Melting (EBM) | Metal Materials | Yes |

| Stereolithography (SLA) | Photopolymer | Yes |

| Selective Laser Sintering (SLS) | Powdered Materials | No |

| Material Jetting | Powdered Materials | Yes |

| Fused Deposition Modeling (FDM) | Thermoplastic Plastic | Yes |

| Adhesive Spray | Powdered Materials | No |

Support structures are indispensable in metal 3D printing. Despite components formed by powder bed fusion technology being surrounded by loose powder, which provides some support, these technologies always require support to ensure they are secured to the base and to mitigate the effects of residual stress.

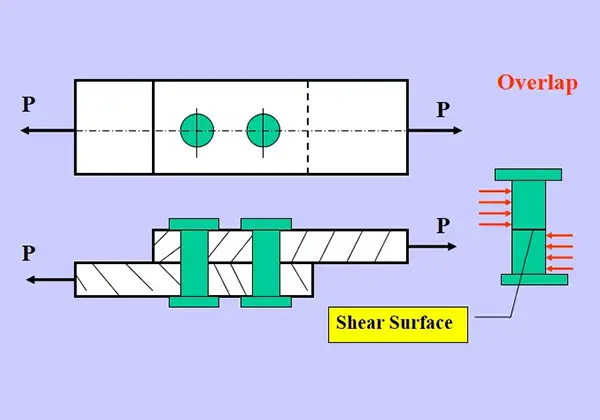

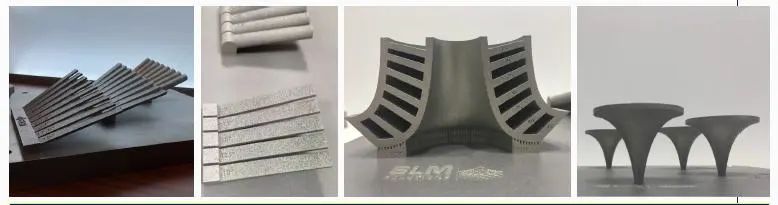

Without support structures, overhanging or tilted components, as well as the internal stress of the metal, could damage the printed object itself, leading to print failure. Generally, support structures in powder bed-based printing technology are mainly divided into two types:

Linear support: This type of support consists of vertical columns connected to the entire overhanging structure. However, this type of support is more difficult to remove.

Tree-like support: This type of support resembles the shape of tree branches. It is used to support the overhanging parts of the component. It is only connected to the overhanging positions.

Its advantage is that it is easier to dismantle and will not cause any damage to the component itself.

However, it should be noted that tree-like support structures are only suitable for non-planar overhangs. For planar overhangs, they cannot provide sufficient support.

Support can be added in the contact area between the bottom of the printed part and the print bed, where the residual stress is most concentrated.

This helps to draw heat away from the part, thereby minimizing thermal deformation that could lead to cracking, warping, sagging, delamination, and shrinkage.

Direct Energy Deposition is a process that manufactures parts by directly melting the material and building it up layer by layer.

Unlike parts formed by powder bed fusion which are supported by the surrounding powder bed, parts printed using DED exist independently within three-dimensional space.

Hence, they also require supportive structures to ensure the stability of the part, the printability of complex features, and heat dissipation.

When designing supports for parts produced using powder bed fusion technology, it’s crucial to ensure they can be easily detached from the main body, otherwise, they cannot be removed during post-processing.

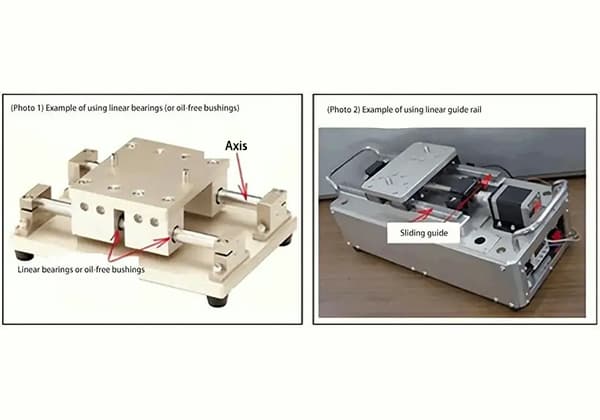

Supports for metal parts are typically printed as a grid structure.

In this way, they act as heat sinks, transferring heat away from the part, allowing it to cool in a more controlled manner and preventing distortion, while saving on material costs and build time.

Adding more supports usually results in more precise parts, but it also increases costs and post-processing time. Interestingly, the Dutch company MX3D has created a metal 3D printing tool that combines a multi-axis robotic arm with a welding machine, enabling the printing of metal parts without the need for any supports.

Removing supports from metal parts is usually more challenging than polymer-based processes and typically requires cutting tools.

Additionally, if the appearance of the finished part is important, post-processing (like polishing) of the metal part is necessary to achieve a smooth surface finish.

During model disassembly, most supports are easy to remove if the method is correct. First, you can gently pry open the brackets with your fingers where it’s possible to manipulate by hand.

For special positions, we may choose to use tools to dismantle the supports, including needle-nose pliers, scrapers, and carving knives.

Stereolithography works by using a light source to solidify liquid resin. This technology requires support structures to firmly attach parts to the print bed and prevent warping.

The supports used in SLA are very thin and lightly touch the parts to save materials. This means they can be easily manually removed, either by hand or using pliers. However, since removing supports will leave traces on the final part, it is necessary to sand it to ensure a smooth surface finish.

SLA is often used for applications requiring aesthetics or smooth surface finishes, such as visual prototypes, molds, and hearing aids.

If this is the case, it’s crucial to design the parts to ensure that the front-facing area of the print does not make contact with the support structures. This is where part orientation design comes into play.

Part orientation is a crucial consideration in the design phase because repositioning parts can help reduce the amount of support required. For example, tubular parts, if placed horizontally, will occupy more space and thus require more support.

In contrast, positioning the same part vertically ensures that it connects to the build plate with minimal support.

Fused Deposition Modeling (FDM) technology creates parts by extruding heated filament layer by layer, each of which bonds with the previous one after cooling and solidifying.

In the FDM process, each layer slightly protrudes so it can extend beyond the width of its previous layer. This means features can be created at angles up to 45 degrees without support.

However, when an FDM part’s overhang exceeds 45 degrees or the part includes features such as bridges and protruding surfaces larger than 5 millimeters, support is required. The support in FDM can take the form of a lattice structure or a tree-like structure.

One technique for removing supports from FDM prints is through a chemical dissolution solution.

Typically, industrial FDM 3D printers (with two print heads) use soluble support materials such as Polyvinyl Alcohol (PVA) and High Impact Polystyrene (HIPS). These materials can be deposited onto the model using a separate extruder.

While PVA dissolves in water, it can be affected by temperature changes, leading to print head blockages. HIPS, on the other hand, dissolves in limonene instead of water and is not easily affected by temperature changes.

Using soluble supports eliminates the need for manual operations and the requirement for further sanding and polishing to remove traces left by the supports. On the other hand, this process can be time-consuming (taking several hours) and costly.

When using a Material Jetting 3D printer, support is always needed for overhanging structures, regardless of the angle.

However, these supports are typically made of different materials that are either water-soluble or can be easily removed afterwards with pressurized water or by immersion in an ultrasonic bath.

Selective Laser Sintering and Binder Jetting are both powder-based technologies that usually do not require any support structures.

This is because in these two technologies, the printed parts are encapsulated in loose powder that serves as the support structure.

Although necessary, support structures add to the overall printing time and material costs of the production process.

Material Expenses:

The generation of supports necessitates additional material during the printing process, thereby increasing time and material costs. Equally important is the fact that supports are not reusable and are typically discarded, leading to material wastage.

Limited Geometric Freedom:

When manually removing supports, the utilization of hands or tools must be considered during the design of supports. However, this may limit your ability to design certain geometric shapes that require supports but are inaccessible by hand or tool.

Added Time:

Designing a part to accommodate support structures, and then creating the supports themselves, requires extra time. Despite the availability of software that automatically generates supports, creating support structures for industrial applications still requires manual modifications and a certain level of design expertise.

Additional Post-processing:

Once the part is completed, supports must be removed, sometimes by hand, thus increasing the time required for post-processing.

Risk of Damage: During the post-processing stage, supports must be removed, and the part’s surface needs to be polished.

Any mishandling during the disassembly of supports can cause defects on the part’s surface, affecting its dimensional accuracy and aesthetic appearance.

Moreover, when supports are incorrectly placed, such as on fine features, it may lead to structural fractures. They may break off along with the support structures, leading to a complete failure of the print.

Therefore, employing support structures has certain drawbacks and should only be added when necessary.

Furthermore, we can also eschew the use of chamfered supports. Chamfering transforms the overhang locations into safe overhangs with angles less than 45 degrees, bypassing the need for supports and ensuring efficient material utilization.

Reducing the number of required supports is often a sound strategy. It aids in saving material costs and production time. Here are four critical tips on how to maximize their reduction, saving both print time and materials:

Experimenting with part orientation is one of the best ways to decrease the number of needed supports. The right orientation significantly impacts printing time, cost, and the surface roughness of the part.

Depending on the direction of the part (vertical, horizontal, or angled), fewer or more supports may be necessary.

Consider a part printed in the shape of the letter ‘T’. Positioned in its regular direction, both arms of the letter would collapse without support structures. However, if the part’s orientation is inverted – arranged in an upside-down ‘T’ position – no support is needed.

This example illustrates that a part can be built in various ways. Each face of the part can have a different surface connected to the print bed, implying varying needs for support. These needs are largely dependent on the part’s orientation.

Another example: when designing parts with hollow tubular features, a horizontal orientation takes up more space, while a vertical or angled orientation saves space and reduces the number of supports needed.

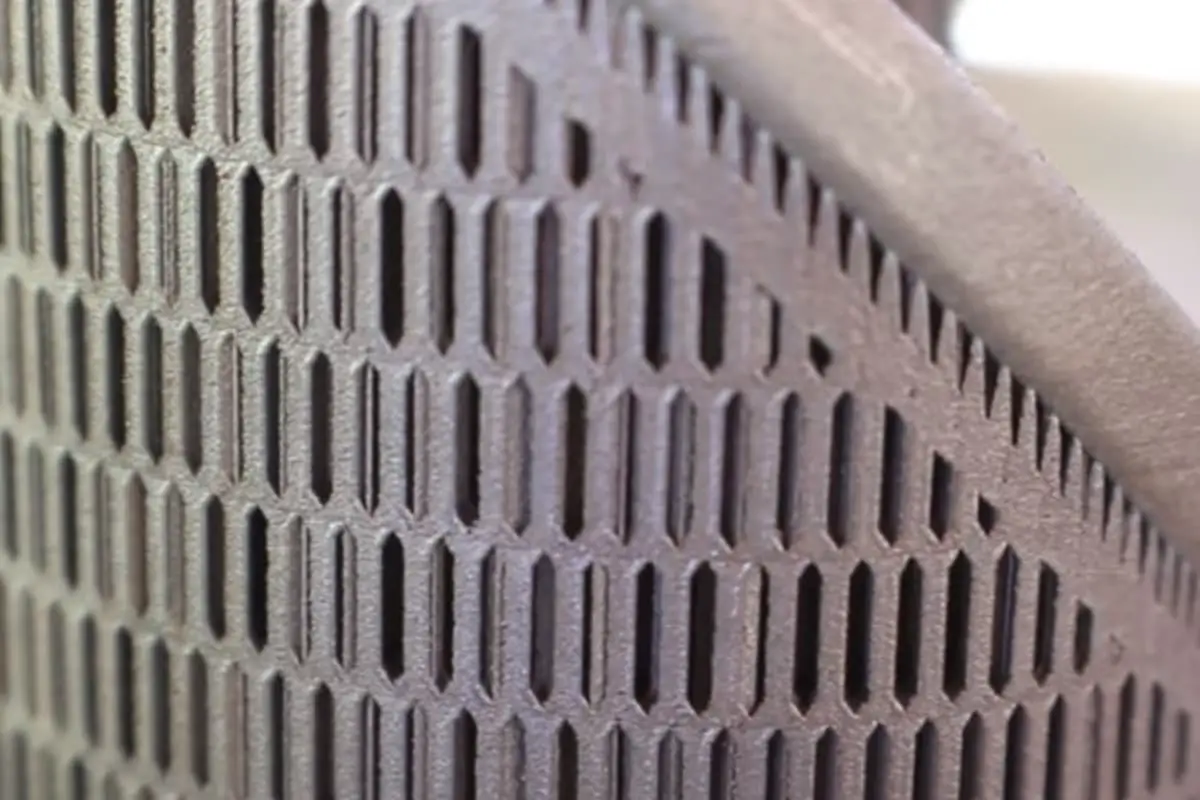

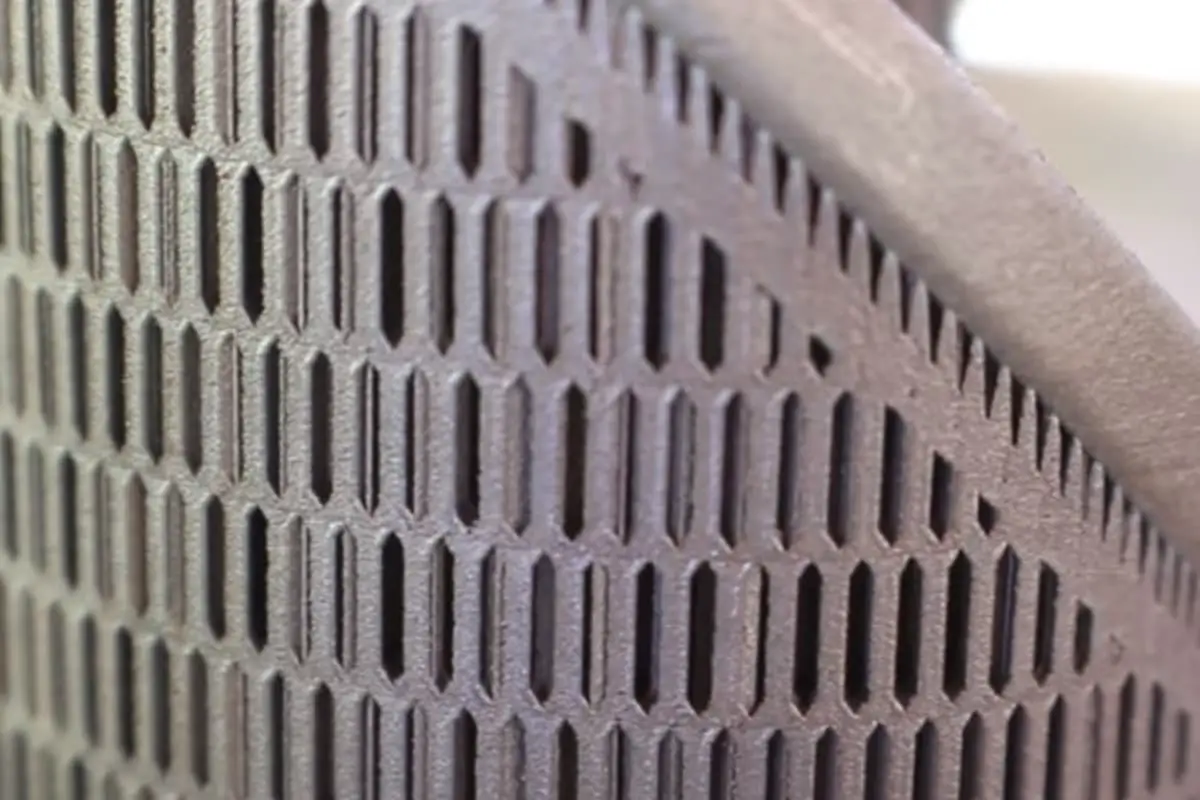

When supports are unavoidable, they should be optimized to use as little material as possible and accelerate the printing process. For instance, one could utilize topology optimization design and lattice structure support to reduce the volume of supports, thereby saving material.

For many 3D printing processes, conventional support generation techniques are limited to producing strictly vertical structures. These are not space-efficient, especially when there are many areas above the print bed that need support.

Contrarily, creating tree-like support structures might be a viable choice. These supports resemble a branching tree and can reduce material use by approximately 75% compared to straight vertical structures.

Autodesk Meshmixer is one of the software tools available for creating such structures for FDM, SLA, and DMLS processes.

Fillets and chamfers can serve as alternative solutions for creating support structures on overhung surfaces that exceed 45 degrees.

A chamfer is an angled or beveled corner or edge, while a fillet is a rounded corner or edge. Essentially, these features change angles greater than 45 degrees into 45-degree angles or less, and can be added to the interior or exterior of a part.

For highly complex 3D models, it often makes sense to print parts individually and then assemble them together. This not only reduces the number of supports but also accelerates the printing process while saving material.

However, bear in mind that if 3D printed parts are to be assembled, they must be printed in the same orientation to ensure a proper fit with each other.

For a long time, support structures have been seen as an unavoidable “drawback” in 3D printing. However, recent advances in hardware and software are slowly challenging this notion.

Take, for instance, Desktop Metal, a metal 3D printer manufacturer, who recently developed a solution known as “Separable Supports” for their studio and production systems, securing a patent in the process.

These supports for 3D printed metal parts can be removed by hand. Desktop Metal’s Separable Supports operate using a layer of ceramic powder as an interface between the part surface and the support structure.

After the sintering process, the ceramic layer gets dissolved, allowing for effortless removal of the supports from the part.

PostProcess Technologies is another company aiming to simplify and accelerate the support removal step for 3D printed parts. The company offers a range of automated, hands-free support removal solutions for parts additively manufactured through FDM, SLA, PolyJet, and CLIP technologies.

However, one company has gone even farther in the support realm. Velo3D, the company behind the powder bed fusion Sapphire system, offers a technology called Intelligent Fusion for its system, which enables the printing of complex metal parts, with a focus on achieving near-supportless printing.

Compared to other powder bed metal systems, the use of Velo3D’s proprietary simulation software and closed-loop monitoring can reduce the supports needed for part production by up to five times.

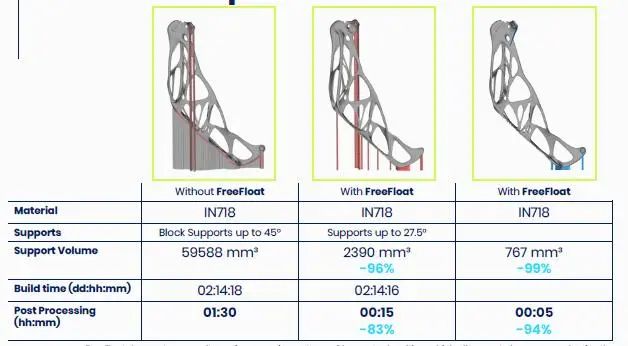

In 2021, SLM Solutions released the “FreeFloat Supportless Technology,” which significantly reduces or eliminates the need for support structures in part printing through the unified integration of multiple technologies.

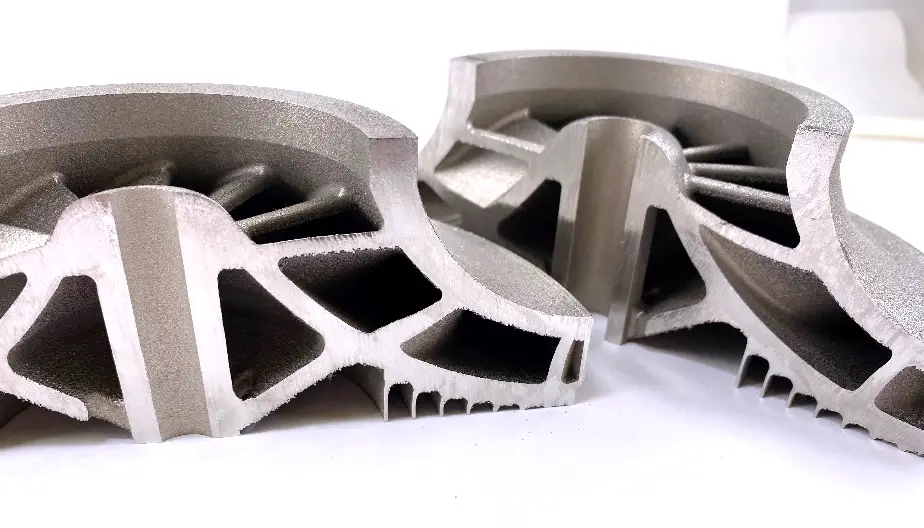

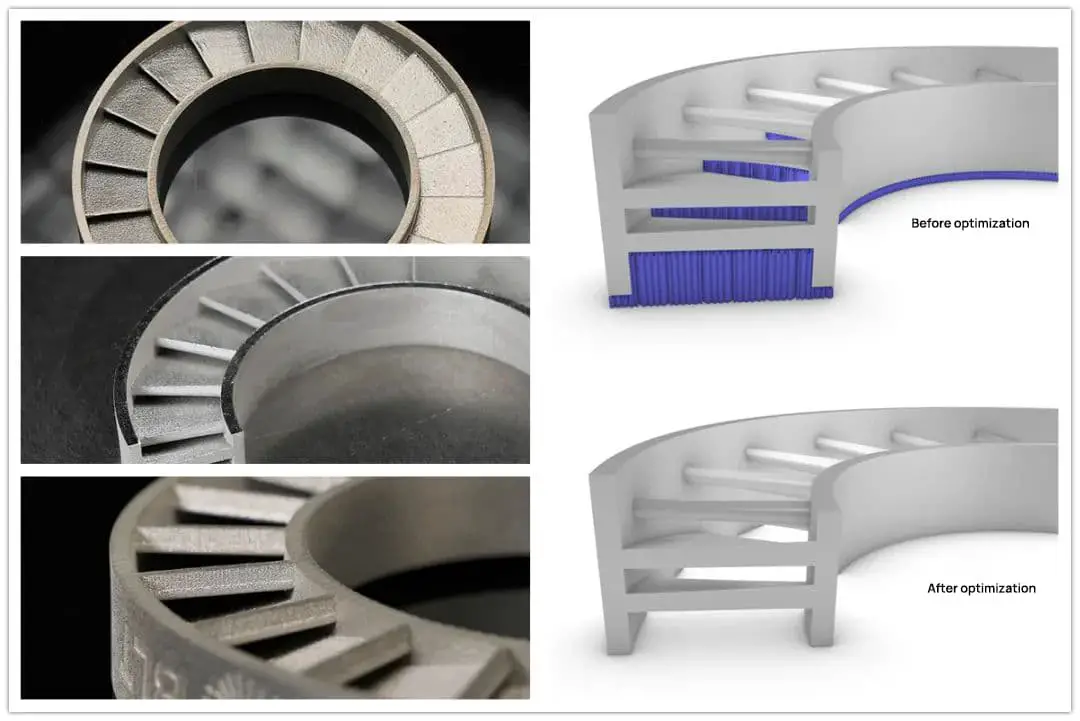

In 2022, experts from EOS developed a variety of process optimization techniques for producing unsupported 3D printed parts such as stator rings, casings, turbine pumps, oil tanks, heat exchangers, valves, and impellers, with the enclosed impeller being a particularly typical example.

Through the optimization of design software and parameter sets, EOS has enabled users to print cantilevers and bridges at much lower angles, sometimes even at zero degrees, requiring significantly fewer supports, or even none at all.

Undoubtedly, domestic manufacturers have made remarkable strides in unsupported printing. Not long ago, it is reported that the leading 3D printing company, Polite, had broken through with a solution for unsupported printing: structures with an overhang of less than 30° require no support.

Polite has conquered the challenge of unsupported SLM metal 3D printing technology.

Generally speaking, optimizing support design and removal is a key challenge in making the 3D printing workflow faster and simpler.

As can be seen from the above examples, the additive manufacturing industry is continually developing solutions to overcome this challenge.

However, beyond technology, practitioners need a higher level of skills and knowledge to push out better solutions.

Hopefully, this article has expanded your knowledge on how to use support structures more effectively in 3D printing, thus helping to turn them from foes into allies.