Have you ever considered the impact of surface roughness on your products? In this blog post, we’ll explore the critical role surface roughness plays in manufacturing and how it affects product quality, performance, and durability. Our expert mechanical engineers will share valuable insights and practical tips to help you optimize your manufacturing processes and deliver superior products to your customers. Get ready to discover the secrets of achieving the perfect surface finish!

In technical communication, the term “surface finish” is commonly used. However, it should be noted that “surface finish” is based on human perception, while “surface roughness” is based on the actual surface microgeometry.

To align with international standards (ISO), the use of “surface finish” is no longer acceptable in national standards. The preferred and more accurate term is “surface roughness.”

Surface roughness refers to the unevenness of a machined surface, characterized by small peaks and valleys with close spacing. The distance between these peaks and valleys, known as wave distance, is typically less than 1mm, which falls under the category of microgeometry errors.

It is specifically defined by the level of high and low micro peaks and valleys (Z) and the spacing (s) between them.

Generally according to S:

In national standards, three indicators are commonly used to assess surface roughness (unit is μm).

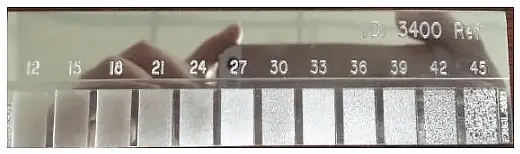

The Ra index is widely used in actual production. The maximum microscopic height deviation of a contour, Ry, is commonly referred to as Rmax in Japan and other countries, while the VDI index is commonly used in Europe and America. The following table compares VDI3400, Ra, and Rmax.

The VDI3400 surface has a corresponding relationship with the widely used Ra standard. Many people find it necessary to consult reference data to determine the corresponding value. The following table is comprehensive and it is recommended to keep it for reference.

Comparison table of VDI3400 standard and Ra

| VDI | Ra | VDI | Ra |

|---|---|---|---|

| 3400 | μm | 3400 | μm |

| 0 | 01 | 23 | 1.4 |

| 1 | 0.112 | 24 | 1.6 |

| 2 | 0.126 | 25 | 1.8 |

| 3 | 0.14 | 26 | 2 |

| 4 | 0.16 | 27 | 2.2 |

| 5 | 0.18 | 28 | 2.5 |

| 6 | 0.2 | 29 | 2.8 |

| 7 | 0.22 | 30 | 3.2 |

| 8 | 0.25 | 31 | 3.5 |

| 9 | 0.28 | 32 | 4 |

| 10 | 0.32 | 33 | 5 |

| 11 | 0.35 | 34 | 5 |

| 12 | 0.4 | 35 | 5.6 |

| 13 | 0.45 | 36 | 6.3 |

| 14 | 0.5 | 37 | 7 |

| 15 | 0.56 | 38 | 8 |

| 16 | 0.63 | 39 | 9 |

| 17 | 0.7 | 40 | 10 |

| 18 | 0.8 | 41 | 11.2 |

| 19 | 0.9 | 42 | 12.6 |

| 20 | 1 | 43 | 14 |

| 21 | 1.12 | 44 | 16 |

| 22 | 1.26 | 45 | 18 |

Comparison table of RA and Rmax

| Ra (μm) | Rmax (μm) |

|---|---|

| 0.1 | 0.4 |

| 0.2 | 0.8 |

| 0.4 | 1.5 |

| 0.56 | 2.4 |

| 0.8 | 3.3 |

| 1.12 | 4.7 |

| 1.6 | 6.5 |

| 2.2 | 10.5 |

| 3.2 | 12.5 |

| 4.5 | 17.5 |

| 6.3 | 24 |

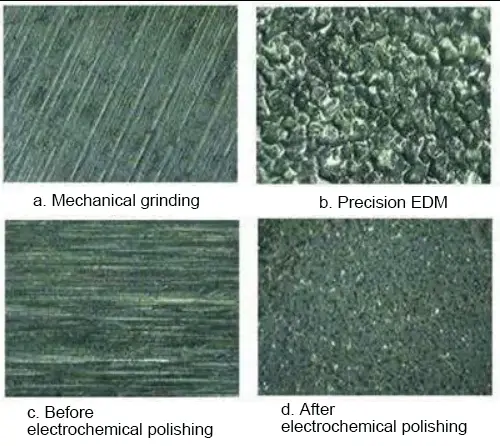

Surface roughness is typically formed by various factors, including the processing method used.

For instance, factors contributing to surface roughness include friction between the tool and the surface of the part during machining, plastic deformation of the surface layer metal during chip separation, high-frequency vibrations in the processing system, and discharge pits in electrical machining.

The depth, density, shape, and texture of the marks left on the processed surface can vary due to differences in processing methods and workpiece materials.

The Impact on Wear Resistance:

The rougher the surface, the smaller the effective contact area between mating surfaces, the higher the pressure, and the higher the frictional resistance, resulting in faster wear.

The Impact on Gap Fit Stability:

For gap fit, a rougher surface leads to increased wear and a gradual increase in the gap during operation. In the case of interference fit, the actual effective interference is reduced due to the flattening of microscopic convex peaks during assembly, leading to a decrease in connection strength.

The Impact on Fatigue Strength:

The rough surface of a part has large troughs that are susceptible to stress concentration, similar to sharp-edged notches and cracks, affecting the part’s fatigue strength.

The Impact on Corrosion Resistance:

Rough part surfaces can easily allow corrosive gases or liquids to penetrate the microscopic valleys on the surface and reach the metal inner layer, causing surface corrosion.

The Impact on Sealability:

Rough surfaces do not fit tightly against each other, allowing gases or liquids to leak through the gaps between contact surfaces.

The Impact on Contact Stiffness:

Contact stiffness refers to a part’s bonding surfaces’ ability to resist deformation under external forces. The stiffness of a machine is largely dependent on the contact stiffness between its parts.

The Impact on Measurement Accuracy:

Parts are measured by their surface and the roughness of the measuring tool’s surface will directly affect measurement accuracy, especially in precision measurement.

Additionally, surface roughness has a variable effect on a part’s coating, thermal and contact resistance, reflectance and radiation properties, resistance to liquid and gas flow, and current flow through the surface of a conductor.

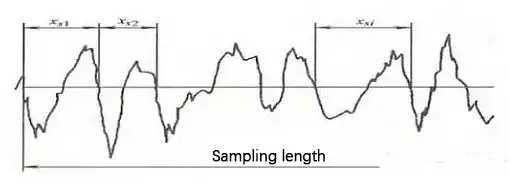

The sampling length is the length of a designated reference line used to evaluate surface roughness.

To accurately reflect the surface roughness characteristics of a part, the sampling length should be selected based on the formation and texture of the actual surface. The sampling length should be measured in accordance with the general profile of the actual surface.

The purpose of specifying and selecting the sample length is to minimize the impact of surface ripple and shape errors on surface roughness measurement results.

The unit length and sampling length for each surface roughness parameter are determined by a specified reference line for evaluation.

According to ISO1997 standards, the common reference lengths are 0.08mm, 0.25mm, 0.8mm, 2.5mm, and 8mm.

Sampling length Ln and evaluation length L of RA, RZ and Ry

| Ra(μm) | Rz.Ry(μm) | L(mm) | Ln=5L(mm) |

|---|---|---|---|

| ≥ 0.008-0.02 | ≥ 0.025-0.10 | 0.08 | 0.4 |

| >0.02-0.1 | >0.10-0.50 | 0.25 | 1.25 |

| >01-2.0 | >0.50-10.0 | 0.8 | 4 |

| >2.0-10.0 | >10.0-50.0 | 2.5 | 12.5 |

| >10.0-80.0 | >50.0-320 | 8 | 40 |

The evaluation length is a required length used to assess the contour and may include one or multiple sampling lengths.

Since the surface roughness of a part’s surface is not always uniform, it may not be possible to accurately reflect a specific surface roughness feature with just one sampling length. Hence, multiple sampling lengths on the surface are necessary to evaluate the surface roughness.

Typically, the evaluation length consists of five sampling lengths.

The baseline is the centerline of the profile used to evaluate surface roughness parameters. There are two types of baselines:

While the least-squares centerline is an ideal baseline in theory, it is challenging to obtain in practical applications. As a result, the arithmetic mean centerline of the contour is commonly used instead and can be measured using a straight line with an approximate position.

Contour Arithmetic Mean Deviation (Ra):

Ra is the arithmetic mean of the absolute value of the contour deviation within the specified sampling length (lr).

In actual measurements, a higher number of measurement points results in a more accurate Ra value.

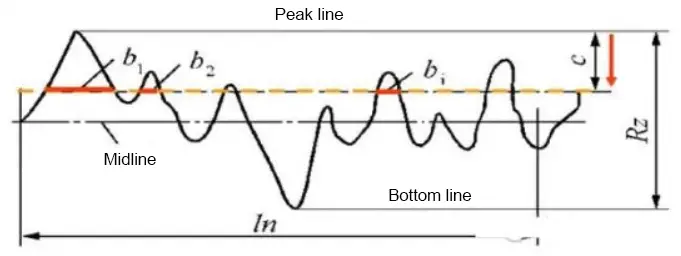

Contour Maximum Height (Rz):

Rz is the distance between the top and bottom lines of the contour.

In common range of magnitude parameters, Ra is preferred.

Prior to 2006, the national standard included an evaluation parameter known as “the height of ten points of micro-unevenness,” which was expressed as Rz and the maximum height of the profile was expressed as Ry.

However, after 2006, the national standard abolished the “ten-point height of microcosmic unflatness” and instead expressed the maximum height of the profile as Rz.

Rsm:

Rsm is the average width of the contour unit, representing the average of the microscopic unevenness spacing over the sampled length.

The microscopic unevenness distance refers to the length between a profile peak and the adjacent profile valley on the midline.

Even with the same Ra value, the Rsm value may not be the same, resulting in a different reflected texture.

Surfaces that prioritize texture usually consider both Ra and Rmr metrics.

The Rmr shape feature parameter is expressed as the contour support length ratio, which is the ratio of the contour support length to the sampling length.

The profile support length is calculated as the sum of the length of each section of the profile obtained by drawing a straight line parallel to the centerline and at a distance of “c” from the top line of the profile within the sampling length.

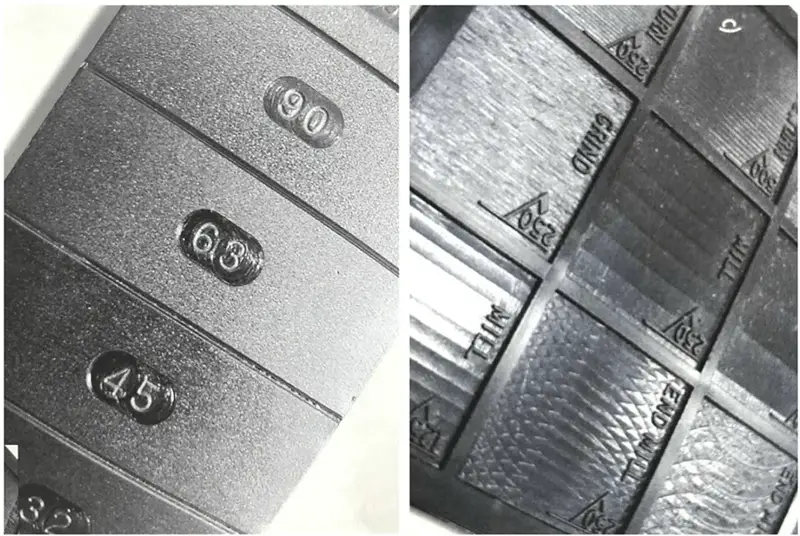

It is used for on-site measurement in workshops and is often employed for measuring medium to rough surfaces.

The method involves comparing the measured surface to a roughness model marked with a specific value to determine the roughness value of the measured surface.

Roughness comparators, which are nickel-based electroformed specimens, are ideal for metalworking and serve as an effective aid. The operator simply scrapes their fingernail across each surface in a group to find the closest match to the part being compared.

While some people use these model groups as reference tables, it’s important to note that they are not official material standards.

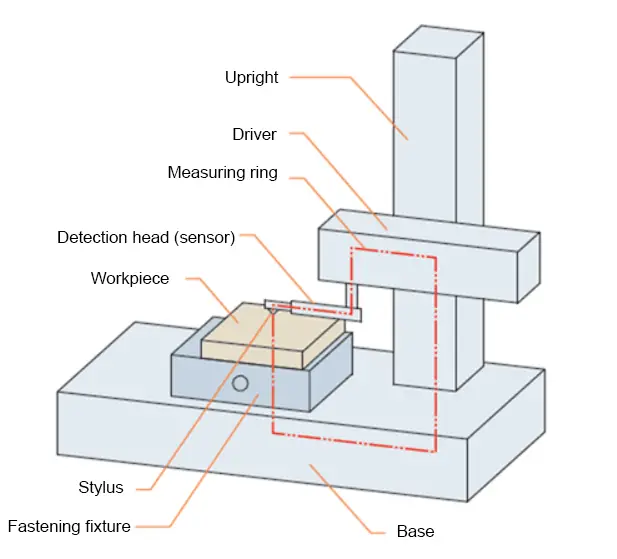

There are various roughness measuring machines available, each with different functions, evaluation methods, and costs. Before choosing a model, it’s recommended to consult with a professional manufacturer to select the most suitable option for your needs.

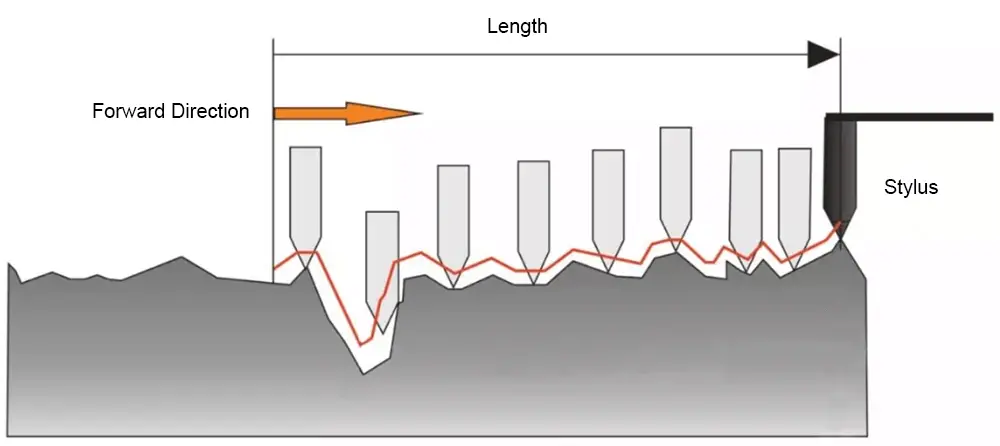

Surface roughness measurement involves using a diamond stylus with a tip curvature radius of approximately 2μm to move along the measured surface.

The upward and downward displacement of the diamond stylus is converted into an electrical signal by an electrical length sensor. After amplification, filtering, and calculation, the surface roughness value is displayed on an instrument and the measured profile curve can also be recorded by a recorder.

Instruments that only display surface roughness values are called surface roughness gauges, while those that record surface profile curves are referred to as surface roughness profilers.

Both types of tools have electronic calculation circuits or computers that automatically calculate the contour arithmetic mean deviation (Ra), ten-point height of microscopic unevenness (Rz), maximum contour height (Ry), and other evaluation parameters.

These tools have high measurement efficiency and are suitable for measuring surface roughness with Ra values ranging from 0.025 to 6.3 μm.

In the old national standard GB/T3505-1983, it is stipulated that the evaluation parameters of surface roughness should be selected from three aspects: the arithmetic mean deviation of the contour (Ra), the ten-point height of micro-unevenness (Rz), and the maximum height of the contour (Ry).

Ra is known as the arithmetic mean deviation of the contour or the mean value of the centerline. It is the arithmetic average of the heights of the points on the contour within the measurement length.

Rz is known as the ten-point height of micro-unevenness. It is the sum of the average values of the five highest contour peaks and the five deepest contour valleys within the sampling length l.

Ra is the primary evaluation parameter, while Rz is generally only used to represent shorter surfaces. In actual processing, Ra is more commonly used to express roughness than Rz.

The arithmetic mean deviation Ra refers to the arithmetic average of the absolute values of the vertical coordinate Z within a sampling length, denoted as Ra. Rz is the sum of the average values of the five highest contour peaks and the five deepest contour valleys within the sampling length.

Since Rz has fewer measurement points, it does not reflect the characteristics of the height of the micro-geometric shape as fully as the Ra parameter. It does not have the precision of Ra, but it is easier to measure than Ra.

China-U.S. Surface Roughness Comparison Table

| Old Chinese Standard (Smoothness) | New Chinese Standard (Roughness) Ra | U.S. Standard (Microns) Ra | U.S. Standard (Microinches) Ra |

| ▽4 | 6.3 | 8 | 320 |

| 6.3 | 250 | ||

| ▽5 | 3.2 | 5 | 200 |

| 4 | 160 | ||

| 3.2 | 125 | ||

| ▽6 | 1.6 | 2.5 | 100 |

| 2 | 80 | ||

| 1.6 | 63 | ||

| ▽7 | 0.8 | 1.25 | 50 |

| 1 | 40 | ||

| 0.8 | 32 | ||

| ▽8 | 0.4 | 0.63 | 25 |

| 0.5 | 20 | ||

| 0.4 | 16 |

Domestic Surface Finish and Surface Roughness Ra, Rz Conversion Table (Unit: μm)

| Surface Finish | ▽1 | ▽2 | ▽3 | ▽4 | ▽5 | ▽6 | ▽7 | |

| Surface Roughness | Ra | 50 | 25 | 12.5 | 6.3 | 3.2 | 1.60 | 0.80 |

| Rz | 200 | 100 | 50 | 25 | 12.5 | 6.3 | 6.3 | |

| Surface Finish | ▽8 | ▽9 | ▽10 | ▽11 | ▽12 | ▽13 | ▽14 | |

| Surface Roughness | Ra | 0.40 | 0.20 | 0.100 | 0.050 | 0.025 | 0.012 | – |

| Rz | 3.2 | 1.60 | 0.80 | 0.40 | 0.20 | 0.100 | 0.050 | |

International Standard Processing Method for Surface Roughness

| Standard Grade Code | Surface Roughness | Processing Tool (Method) | Processing Material and Hardness Requirements | Luminosity Description | |||

| Coarse Grinding Sand Grain Size | Fine Grinding Sand Grain Size | Diamond Paste Polishing | |||||

| SPI(A1) | Ra0.005 | S136 | 54HRC | Very high gloss, mirror effect | |||

| 8407 | 52HRC | ||||||

| SPI(A2) | Ra0.01 | DF-2 | 58HRC | Lower gloss, no sandpaper texture | |||

| XW-10 | 60HRC | ||||||

| SPI(A3) | Ra0.02 | S136 | 300HB | Even lower gloss, but no sandpaper texture | |||

| 718SUPREME | 300HB | ||||||

| SPI(B1) | Ra0.05 | No brightness, slight 3000# sandpaper texture | |||||

| SPI(B2) | Ra0.1 | No brightness, slight 2000# sandpaper texture | |||||

| SPI(B3) | Ra0.2 | No brightness, slight 1000# sandpaper texture, direction of processing traces indistinguishable | |||||

| Ra0.4 | Precision Processing: Precision Turning\Precision Planning\Precision Milling\Grinding\Reaming\Scraping | Slight discernible direction of processing traces | |||||

| Ra0.8 | Precision Processing: Precision Turning\Precision Planning\Precision Milling\Grinding\Reaming\Scraping | Discernible direction of processing traces | |||||

| Ra1.6 | |||||||

| Ra3.2 | |||||||

| Ra6.3 | |||||||

| Ra12.5 | |||||||

| Ra25 | |||||||

| Ra50 | |||||||

Reference Table for the Relationship between Surface Roughness and Gloss (Unit: μm)

| Surface Roughness | GB1031-1983 | Surface Gloss | GB1031-1968 | Surface Condition |

| Ra | Ra | Grade | ||

| 0.012 | 0.01 | ▽14 | Matte Mirror Surface | |

| 0.025 | 0.02 | ▽13 | Mirror-Like Glossy Surface | |

| 0.05 | 0.04 | ▽12 | Bright Glossy Surface | |

| 0.1 | 0.08 | ▽11 | Dark Glossy Surface | |

| 0.2 | 0.16 | ▽10 | Unidentifiable Machining Trace Direction | |

| 0.4 | 0.32 | ▽9 | Slightly Identifiable Machining Trace Direction | |

| 0.8 | 0.63 | ▽8 | Identifiable Machining Trace Direction | |

| 1.6 | 1.25 | ▽7 | Unrecognizable Machining Marks | |

| 3.2 | 2.5 | ▽6 | Slightly Visible Machining Marks | |

| 6.3 | 5 | ▽5 | Visible Machining Marks | |

| 12.5 | 10 | ▽4 | Slightly Visible Tool Marks | |

| 25 | 20 | ▽3 | Visible Tool Marks | |

| 50 | 40 | ▽2 | Clearly Visible Tool Marks | |

| 100 | 80 | ▽1 | ||