Have you ever wondered how we can extend the life of industrial machinery while enhancing their performance? Surfacing welding offers a fascinating solution by depositing wear-resistant materials onto surfaces, restoring worn parts, and improving resistance to corrosion and heat. In this article, you’ll discover various techniques of surfacing welding, their applications in different industries, and how they contribute to cost savings and material efficiency. Learn how surfacing welding not only repairs but also fortifies machinery, making it indispensable in modern manufacturing and maintenance.

Surfacing welds are primarily used to restore worn surfaces, enhance corrosion resistance, and improve the mechanical properties of a material. They provide an additional layer on existing structures, extending their lifespan and durability. This process is often used in industries like manufacturing and construction for maintenance and repair tasks.

Surfacing welding, also known as hardfacing or weld overlay, is an advanced metallurgical process that deposits a layer of specialized metal onto the surface or edge of a workpiece. This technique is designed to impart superior wear resistance, corrosion resistance, or heat resistance to the base material, significantly enhancing its performance and longevity.

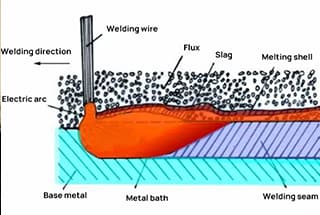

The process involves carefully selecting and applying a filler material with specific properties to meet the desired characteristics of the final product. Common methods for surfacing welding include:

Surfacing welding offers numerous benefits:

The selection of appropriate surfacing techniques and materials depends on various factors, including:

Related reading: The Ultimate Guide to Welding

Automated surfacing is commonly used for cement equipment such as vertical mills, roller mills, screw conveyors, fans, and rotary kilns.

For iron and steel equipment, automated surfacing can be used for converters, rolls, blast furnaces, continuous casting machines, and conveyor wheels.

When it comes to power equipment, automated surfacing is often employed for coal mills, grinding rollers, boiler tubes, turbines, drain pipes, and gears.

To illustrate the surfacing welding process, let me share some examples with you. Let’s dive right in.

Case:

Rolls are a critical spare part in the rolling mill, and they consume a significant amount of steel during the rolling process.

With an annual steel output of over 600 million tons in China, the value of rolls consumed exceeds 17 billion yuan.

Therefore, using surfacing methods to repair old rolls and extend their service life has become an important measure for steel rolling enterprises in China to reduce production costs and improve economic benefits.

When an original roll reaches the end of its useful life, it can be repaired through surfacing welding.

Surfacing-welded rolls have the advantages of low cost, long service life, and excellent performance. They are widely embraced by steel rolling enterprises and align with China’s fundamental policies of energy conservation, clean production, and circular economy.

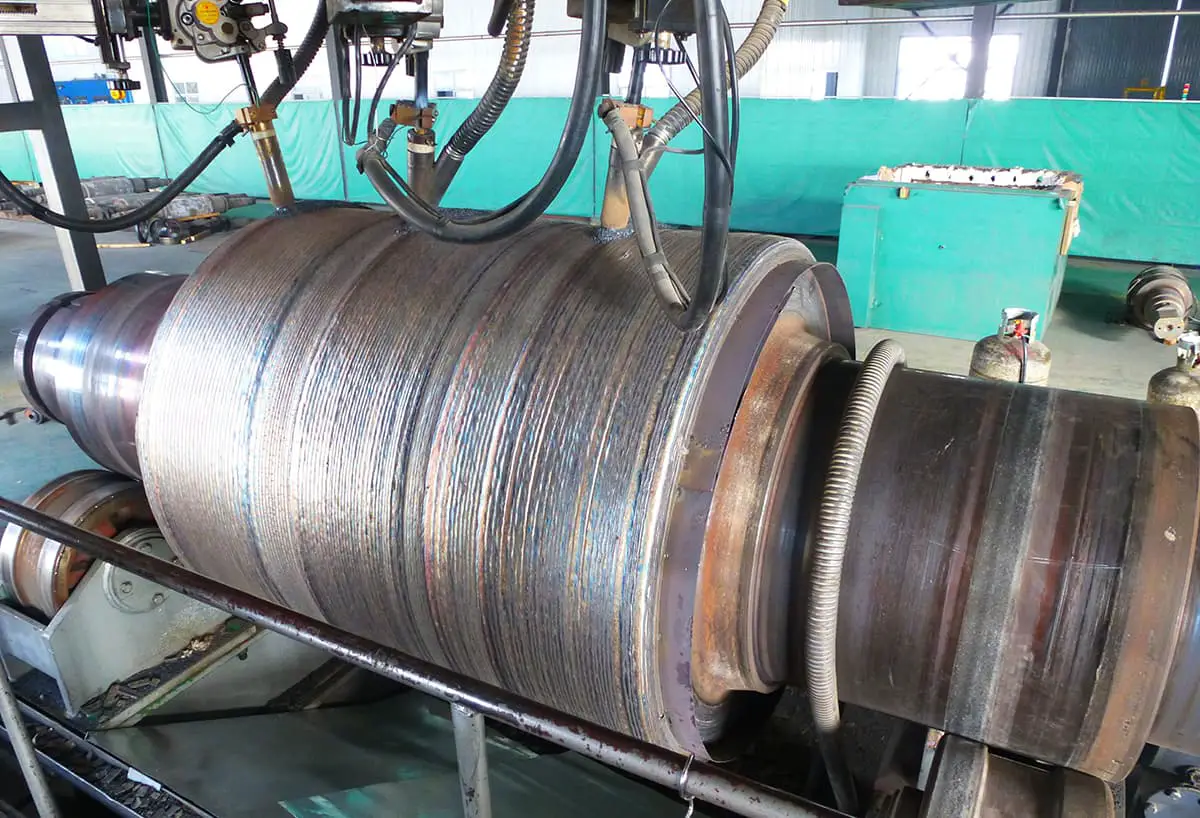

The image below depicts an old roll that has been repaired through surfacing welding.

Old roll repaired by surfacing weld

As science and technology continue to advance, mechanical equipment for various products is evolving towards larger, more efficient, and higher parameter designs. As a result, the demand for reliable and high-performance products is increasing.

Material surface surfacing, as a branch of welding technology, is an effective means of improving product and equipment performance and extending service life.

In addition to metals and alloys, ceramics, plastics, inorganic nonmetals, and composites can also be used as surfacing alloy materials.

As a result, surfacing technology can imbue parts with various special properties such as wear resistance, heat resistance, corrosion resistance, high temperature resistance, lubrication, insulation, and more.

Currently, surfacing technology is widely used in mechanical manufacturing, metallurgy, electric power, mining, construction, petrochemical, and other industrial sectors.

Automatic submerged arc strip surfacing weld

Surfacing welding is a process in which materials with specific properties are deposited onto the surface of a workpiece using welding methods.

Related reading: 10 Different Types of Welding You Should Know

The purpose of surfacing welding differs from that of general welding methods.

Rather than connecting workpieces, surfacing welding modifies the surface of the workpiece to obtain a cladding layer with specific properties such as wear resistance, heat resistance, corrosion resistance, or to recover insufficient size due to wear or processing errors.

These two applications in surface engineering are referred to as repair and strengthening.

The following image depicts the surface of a component after surfacing.

Surface of parts after surfacing weld

The advantages of surfacing welding over other surface treatment methods are:

Electroslag strip automatic surfacing weld

Classification of Surfacing Welds

Surfacing welding technology is a type of fusion welding that can use all methods that belong to fusion welding.

The following table illustrates the classification of common surfacing welding methods.

Currently, the two most widely used methods are electrode arc surfacing and oxyacetylene flame surfacing.

Table 9-1 Classification of Common Surfacing weld Methods

| Surfacing weld method | Dilution ratio (%) | Deposition speed/(kg/h) | Minimum overlay thickness | Deposition efficiency (%) | |

| Oxyethylene flame surfacing | Electrode wire feeding | 1~10 | 0.5-1.8 | 0.8 | 100 |

| Automatic wire feeding | 1~10 | 0.5-6.8 | 0.8 | 100 | |

| Powder surfacing | 1~10 | 0.5-18 | 0.2 | 85-95 | |

| Electrode arc surfacing | 10-20 | 0.5-5.4 | 3.2 | 65 | |

| Tungsten electrode chlorine arc surfacing | 10-20 | 0.5-4.5 | 2.4 | 98-100 | |

| Electrode arc surfacingTungsten electrode chlorine arc surfacing | 10-40 | 0.9~5.4 | 3.2 | 90-95 | |

| 15-40 | 2.3-11.3 | 3.2 | 80-85 | ||

| Arc management surfacing | Monofilament | 4.5-11.3 | 3.2 | 95 | 95 |

| Multifilament | 11.3-27.2 | 4.8 | 95 | 95 | |

| Series arc | 11.3-15.9 | 4.8 | 4.8 | 95 | |

| Monopole | 12-36 | 3.0 | 3.0 | 95 | |

| Multiband electrode | 22-68 | 4.0 | 4.0 | 95 | |

| Plasma arc surfacing | Automatic powder feeding | 0.5-6.8 | 0.25 | 0.25 | 85-95 |

| Welding rod powder feeding | 1.5-3.6 | 2.4 | 2.4 | 98-100 | |

| Automatic wire feeding | 0.5-3.6 | 2.4 | 2.4 | 98-100 | |

| Double hot filament | 13-27 | 2.4 | 2.4 | 98-100 | |

| ESW | 10~14 | 15~75 | 15 | 95-100 | |

Surfacing weld technology, as a branch of the welding field, has a broad application scope that spans across various industries. It is extensively used in manufacturing, including mining machinery, transportation machinery, metallurgy machinery, power machinery, agricultural machinery, automobiles, petroleum equipment, chemical equipment, construction, and the manufacturing and maintenance of tool molds and metal structures.

Surfacing welding is ideal for repairing metal parts and products with subpar appearances, and it can also be used to manufacture bimetal parts. Additionally, it is an effective way to extend the service life of parts, reduce costs, and enhance product design. This is particularly beneficial for the rational use of materials, especially precious metals.

The application of surfacing weld technology is mainly demonstrated in the following aspects, based on the application and working conditions of the workpiece:

(1) Restoring workpiece size using surfacing weld:

It is a prevalent problem for factories and mining enterprises that the workpiece size is insufficient due to wear or processing errors. In such cases, surfacing welding is a common process method used for repairing these workpieces.

The repaired workpieces can not only function normally but can also often exceed the service life of the original workpieces. This is because the use of new processes and materials in surfacing repair can significantly improve the performance of the original parts.

Examples of such repairs include surface surfacing repair of cold roll, hot roll, and profiled roll, as well as surfacing repair of worn parts of agricultural machinery such as tractors, agricultural vehicles, transplanters, and harvesters.

According to statistics, the amount of surfacing alloy used to repair old workpieces accounts for 72.2% of the total amount of surfacing alloy used.

Cold roll repaired by surfacing technology

Roller tyre and roller skin repaired by surfacing technology

(2) Wear and corrosion-resistant surfacing:

Wear and corrosion are the main factors that cause the failure of metal materials. In order to improve the wear and corrosion resistance of metal workpiece surfaces, meet the requirements of working conditions, and extend the service life of the workpiece, one or more layers of wear or corrosion-resistant material can be deposited on the surface.

Materials with different properties can be selected for the substrate and surfacing layer of the workpiece, which can produce a bimetallic workpiece. This is because only the surface layer of the workpiece needs to have the required special properties in terms of wear and corrosion resistance. By doing so, it maximizes the role and potential of the material, saving a considerable amount of precious metals.

(3) Create New Parts

Bimetal machine parts with comprehensive properties can be created by surfacing an alloy onto a metal substrate.

The substrate and the surfacing alloy layer of these parts have different properties, which can fulfill various performance requirements.

This approach fully unleashes the potential of materials.

For instance, in the case of hydraulic turbine blades, carbon steel is used as the base material, and a layer of stainless steel is welded onto the parts (mostly the lower back of the blades) that are susceptible to cavitation. This produces cavitation-resistant bimetallic blades.

When manufacturing metal abrasive tools, the matrix needs to be strong and tough. Therefore, carbon steel and low-alloy steel with a relatively low cost are selected for the manufacturing process.

On the other hand, cutting edge molds require high hardness and wear resistance. Using wear-resistant alloy surfacing on the cutting edge mold can significantly reduce the consumption of precious alloy and significantly extend the mold’s service life.

Hardfacing wear-resistant or corrosion resistant layer II on workpiece surface

Mold manufacturing

Surface roughening of plastic molds enhances both aesthetic appeal and service life. For repairing parting surfaces of helmet plastic molds, surfacing welding is recommended. Surface strengthening is essential for diffuser cones in aluminum alloy die casting dies. When mold cavities become worn, scratched, or fall out of tolerance, repair and strengthening should be performed to restore functionality.

Plastic and rubber components

Surfacing techniques are employed to repair mechanical parts made of rubber and plastic, addressing issues such as mold-induced tolerance deviations and wear in rubber and plastic components.

Aerospace applications

In the aerospace sector, surfacing is crucial for:

Automotive manufacturing and maintenance

Surfacing techniques are utilized for compensating and repairing various automotive components, including:

Ship and electric power industries

Surfacing applications in these sectors include:

Machinery industry

Surfacing techniques are employed for:

Foundry industry

Surfacing is utilized to:

Address wear on aluminum molds, extending their service life and maintaining product quality

Repair defects such as sand holes and air pockets in iron, copper, and aluminum castings

Surfacing welding is a process that involves welding overlay materials with specific properties onto the surface of weldments.

The goal is not to join the weldment, but to acquire a deposited metal layer on the surface of the weldment that possesses unique characteristics, including wear resistance, heat resistance, and corrosion resistance. This technique can also be used to restore or increase the size of the weldment.

The surfacing method is widely used in manufacturing and repair processes.

In general, the deposited metal for surfacing welding must first meet the service conditions of the weldment. After that, consideration is given to selecting surfacing metal with better weldability and greater economy.

The following are some common surfacing metals used in various working environments:

Iron-based surfacing metal is widely used due to its various products, wide range of performance capabilities, good balance of toughness and wear resistance, and low cost.

There are roughly four categories of iron-based surfacing metals:

(1) Pearlitic steel surfacing metal:

This type of alloy has good weldability, strong impact resistance, low hardness, and is mainly used to repair mechanical parts such as shafts.

(2) Austenitic steel surfacing metal:

Austenitic manganese steel surfacing metal has high impact toughness and work hardening properties but is prone to hot cracks. It is generally used to repair parts that are severely impacted by metal-to-metal wear and abrasives, such as mine skip cars and railway turnouts.

Austenitic chromium-manganese surfacing metal has better weldability, corrosion resistance, heat resistance, and heat crack resistance than austenitic manganese steel. It is mainly used to repair manganese steel and carbon steel parts that are severely impacted by metal-to-metal wear.

(3) Martensitic steel surfacing metal:

The structure of this type of surfacing metal is mainly martensite. The hardfacing layer has high hardness, yield strength, high wear resistance, and can withstand moderate impact, but its impact resistance is lower than that of pearlitic and austenitic steel. It is mainly used to repair worn parts between metals such as gears and tractor chassis.

(4) Alloy cast iron surfacing metal:

This type of surfacing layer has high abrasive wear resistance, heat resistance, corrosion resistance, good oxidation resistance, and light impact resistance, but it is prone to cracking during surfacing, so welding must be done with caution. It is mainly used for surfacing agricultural machinery, mining equipment, and other parts.

Nickel base surfacing metal

The most widely used alloy among them is the nickel chromium boron silicon series alloy. It exhibits excellent resistance to low-stress abrasive wear and wear between metals, and has good corrosion resistance, heat resistance, and high-temperature oxidation resistance. However, its resistance to high-stress abrasive wear and impact resistance is slightly poor. This alloy is typically used in corrosive media or occasions subject to low-stress abrasive wear in high-temperature environments.

Nickel-based alloys containing intermetallic compounds, such as Ni-32Mo-15Cr-3Si, have high-temperature hardness, excellent resistance to intermetallic wear, and moderate abrasive wear, but poor impact resistance. This alloy is more suitable for gas tungsten arc surfacing or plasma arc surfacing, and is commonly used for surfacing valve sealing surfaces that work in severely corrosive media.

The price of nickel-based alloys containing carbide is much lower than that of cobalt-based alloys. From an economic point of view, it has been widely used as a substitute for cobalt-based surfacing metals.

Cobalt-based surfacing metals mainly refer to cobalt chromium tungsten alloys, which can maintain high strength and hardness at about 650 ℃, have certain corrosion resistance, and excellent adhesion wear resistance. Cobalt-based alloys have the best comprehensive performance among various surfacing metals and are commonly used for surfacing parts under high-temperature working conditions.

Copper base surfacing metal

There are generally four types of copper-based surfacing alloys: bronze, brass, white copper, and pure copper. These alloys exhibit good corrosion resistance, cavitation resistance, and wear resistance between metals. They can be welded onto iron-based materials to make bimetallic parts and can also be used to repair worn parts.

However, copper-based surfacing metals have poor resistance to sulfide corrosion, wear of wear-resistant materials, and high-temperature creep, low hardness, and are not easy to weld. They are only suitable for environments below 200 ℃. This type of surfacing metal is mainly used for the surfacing of bearing shells, low-pressure valve sealing surfaces, and other similar applications.

Carbide surfacing metal

This type of surfacing metal is mainly used for the surfacing welding of oil well bits and road construction machinery parts under severe wear conditions.

Oxygen acetylene surfacing

This method is mainly used for surfacing parts that require a smooth surface and high quality, particularly small and medium-sized weldments produced in small batches, such as valves, oil well bits, and ploughshares.

The oxygen acetylene equipment is simple to use, has low costs, and can be used with gas welding equipment. However, the welding torch nozzle hole diameter is larger than that of gas welding.

Hardfacing materials of any shape, including leftovers, can be used. This method offers high visibility, making it possible to carry out surfacing on a small area, producing a thin and smooth surfacing layer.

The dilution ratio is low, and the depth of melting layer can be controlled within 0.1mm, making it easy to ensure the quality of the surfacing layer.

Using a reducing flame and carbonizing flame for carburization can reduce the toughness of the hardfacing layer, but can improve the wear resistance of the hardfacing layer with carbide as the primary wear-resistant phase.

This method is characterized by high labor intensity, low production efficiency, and a requirement for welders with certain technical skills.

Oxygen acetylene surfacing typically involves using a carbonization flame, and the flame properties are related to the type of surfacing metal:

Most steel parts can be overlayed without flux. However, when overlaying cast iron, flux must be used, and measures must be taken to prevent white microstructure and cracks.

Preheating and slow cooling can significantly reduce the possibility of cracking in the surfacing layer and also help to reduce the dilution ratio.

Small workpieces can be heated directly using a welding torch, while large workpieces are usually heated in a furnace, with enough time to ensure the temperature is uniform.

The maximum thickness of each layer of surfacing welding should be around 1.6mm, and multi-layer surfacing welding can be performed.

For oxygen acetylene spray welding (spray melting), self-fusing alloy powder is typically used.

The spray welding process can be divided into “one-step method” and “two-step method” based on the order of powder spraying and remelting.

The “one-step” spray welding method involves simultaneous powder spraying and remelting, where fine powder is preheated, pre-sprayed, and then sprayed onto the working surface before being melted.

In contrast, the “two-step” spray welding method involves two separate steps of powder spraying and remelting using a remelting gun after preheating.

Common defects in oxygen acetylene surfacing include lack of fusion and pores, which can be caused by improper operation or poor quality surfacing materials.

Electrode arc surfacing

Welding rod arc equipment is an inexpensive and versatile option that is suitable for field surfacing.

Common power sources include arc welding transformers, arc welding rectifiers, arc welding generators, and arc welding inverters. This equipment is particularly well-suited for surfacing irregularly shaped parts and parts that are difficult to access.

The concentrated arc heat results in minimal deformation and high productivity. However, it also has a high penetration rate and dilution rate, which can reduce the hardness and wear resistance of the surfacing layer.

Generally, 2-3 layers are welded, and multi-layer welding is prone to cracking.

Electrode arc surfacing is primarily used for small-batch production and repairing worn parts. The surfacing electrodes available in China include D10×-24×, D25×-29×, D30×-49×, D50×-59×, D60×-69×, D70×-79×, D80×-89×, and so on.

Electrodes with titania calcium type, ilmenite type, and low hydrogen type coatings should preferably adopt DC reverse connection for surfacing. Electrodes with graphite type coatings should preferably adopt DC positive connection or AC power supply.

Before surfacing, the electrode should be dried at the temperature specified in the electrode manual. Acid electrodes should be dried at 150℃ for 0.5-1 hour, and alkaline electrodes should be dried at 250-350℃ for 1-2 hours.

The preheating temperature for surfacing primarily depends on the carbon equivalent. For example, with a carbon equivalent (%) of 0.4, 0.5, 0.6, 0.7, and 0.8, the preheating temperature (℃) is 100, 150, 200, 250, and 300, respectively.

Slow cooling after surfacing can be accomplished in a furnace or asbestos, or it can be achieved by proper heating to ensure that the cooling process is slow.

See Fig. 1 for process parameters of electrode arc surfacing.

Fig. 1 Surfacing welding process parameters of shielded metal arc welding

| Thickness of surfacing layer mm | <1.5 | <5 | ≥5 |

| Electrode diameter mm | 3.2 | 4-5 | 5~6 |

| Number of surfacing layers | 1 | 1~2 | ≥2 |

| Surfacing welding current A | 800~100 | 140~200≥ | 180~240 |

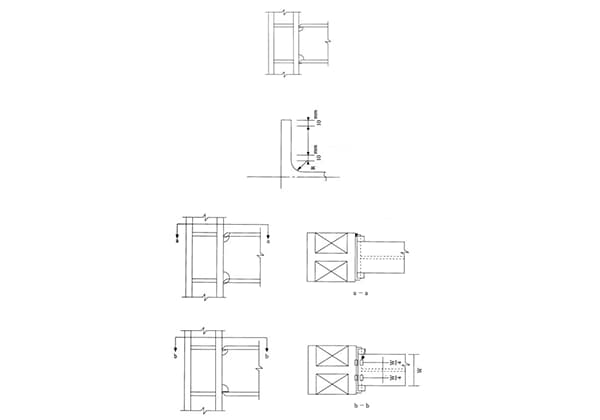

Submerged arc surfacing

Submerged arc surfacing is an automatic production method with high current and efficiency. It does not emit light radiation, providing good working conditions. However, the submerged arc heat can be excessive, leading to a high dilution rate.

To ensure the required performance, typically 23 layers of surfacing are applied. Preheating and slow cooling measures are often taken to avoid cracking.

Submerged arc surfacing is mainly used for horizontal surfacing and is most suitable for large parts that are not easily deformed, such as the surfacing of corrosion-resistant layers on the inner walls of large diameter containers, or the surfacing of wear-resistant layers on steel rolling mill rolls. It is not suitable for small parts.

DC or AC power supply can be used for submerged arc surfacing. However, DC reverse connection is mostly used to improve surfacing quality and production efficiency.

Increasing welding current will lead to a higher dilution ratio, penetration depth, and overlay thickness. The influence of welding arc voltage on dilution ratio is not significant. The arc voltage is typically set at 30-35V, and the extension length of welding wire is 8 times the diameter of the welding wire.

To reduce the dilution ratio and improve deposition speed, multi-wire and strip electrodes (in tandem) can be used to improve the electrode.

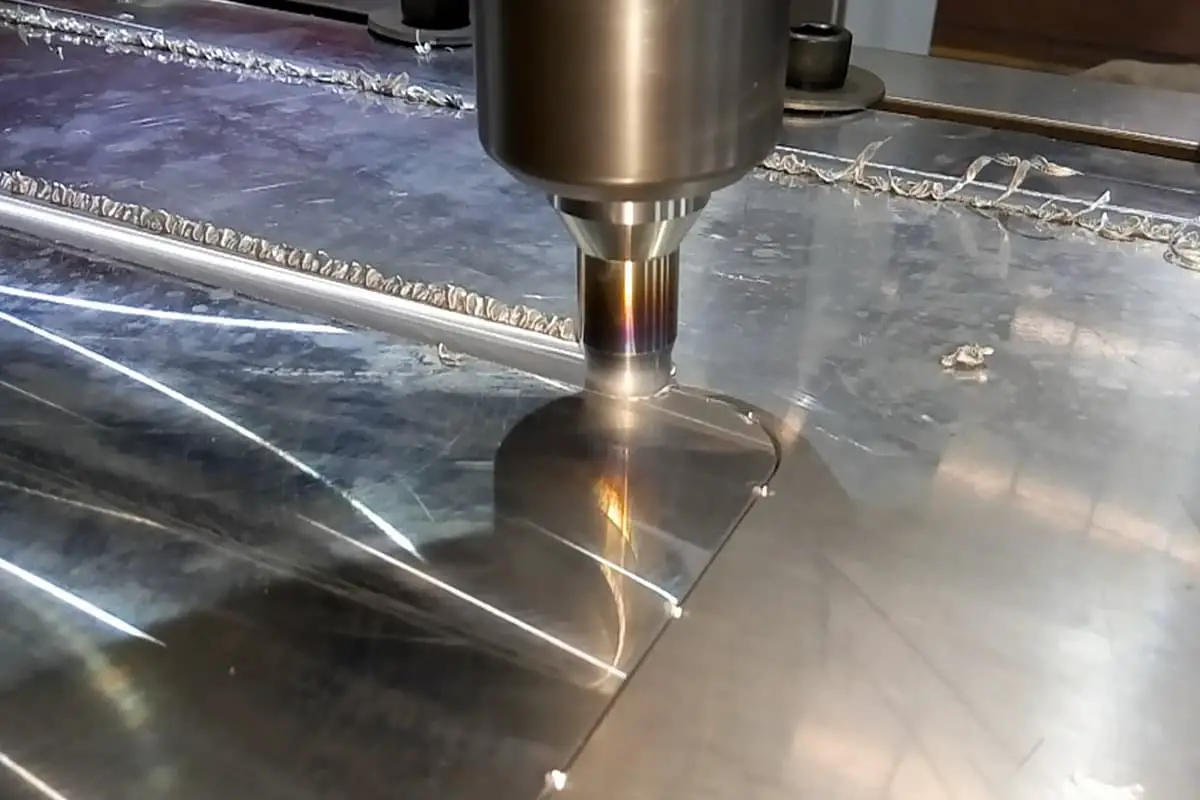

Other surfacing methods

There are several surfacing methods available, such as gas metal arc surfacing, tungsten argon arc surfacing, plasma arc surfacing, electroslag surfacing, laser surfacing, friction surfacing, and others.