Ever struggled with creating perfect threads in your workpieces? This article unveils the secrets of tapping, a crucial process in machining. Learn how to enhance tap performance, choose the right tools, and tackle common challenges. Get ready to elevate your tapping skills and achieve flawless results!

Taps are tools used for creating various medium and small internal threads. They have a simple design and are easy to use. They can be operated by hand or on machine tools, making them widely used in production.

Struggling with tapping during the processing process? Don’t worry! Today, I’ll share some tips to help you gain a deeper understanding of tapping.

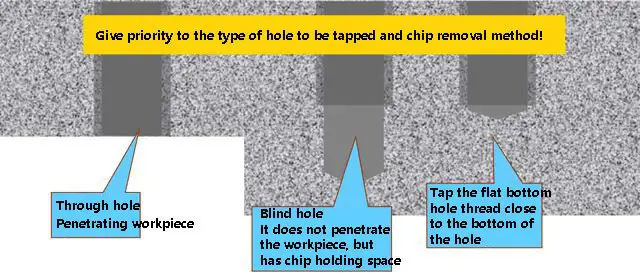

Tapping is the process of cutting an internal thread inside a hole in a workpiece using a tap.

Workpiece material, cutting speed, cutting edge material, tool holder, tap form, hole size, tapping tool holder, cutting fluid and hole depth.

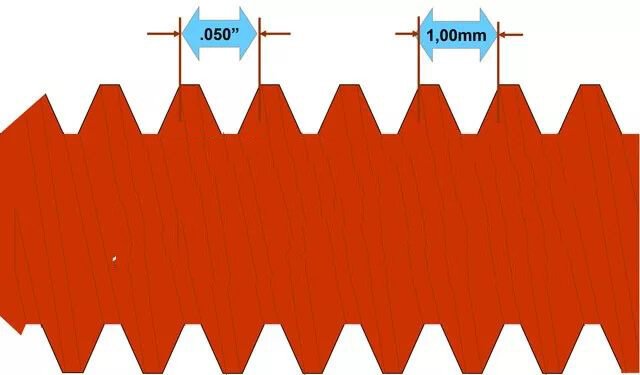

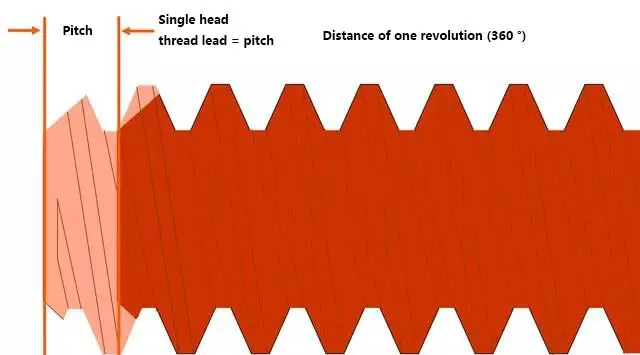

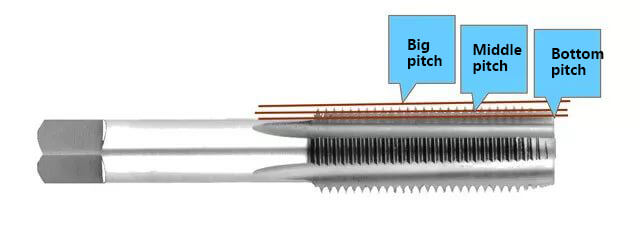

The axial distance between two adjacent teeth on a thread corresponds to two points on the pitch diameter line.

The axial distance between the corresponding points of two adjacent teeth on the same helix is known as the pitch and is denoted by a code.

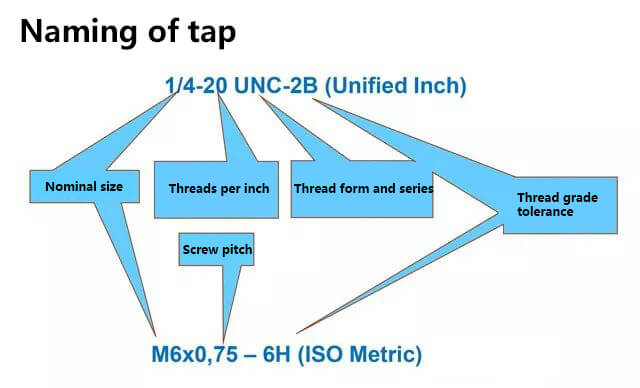

The nominal diameter of a pipe thread is the inner diameter of the through pipe (measured in inches), while the nominal diameter of other threads is the major diameter of the thread (measured in metric units).

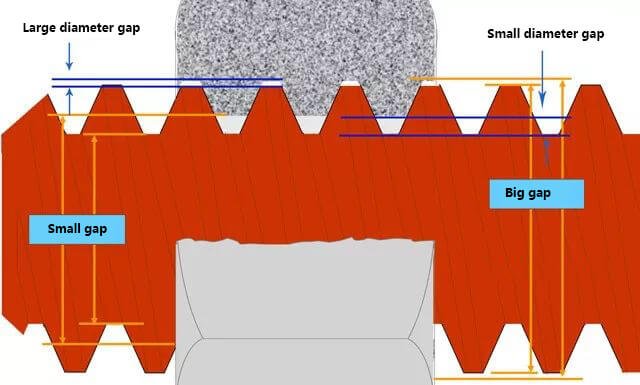

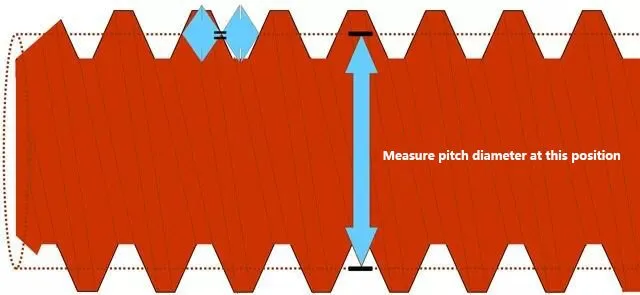

The pitch diameter is the most crucial aspect as it determines the fit and strength of all threaded assemblies. It is located on the pitch line, and the width of the tooth at this point is equal to the width of the adjacent tooth slot.

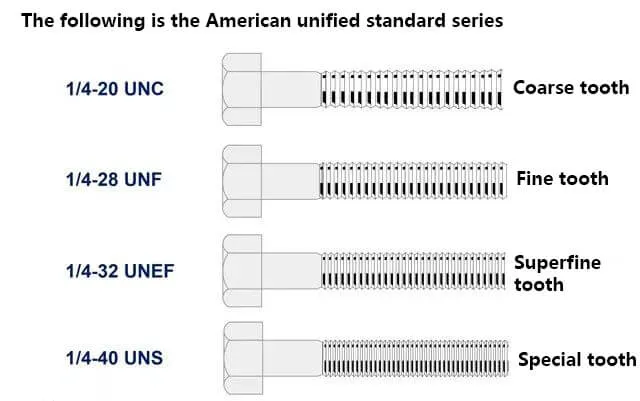

English thread: The English thread is a type of thread dimension that is marked in the English system. It was developed jointly by the United States, Britain, and Canada to provide a unified system.

Metric thread: The Metric thread is a type of thread developed according to the ISO (International Organization for Standardization) system. It is the global standard for metric threads.

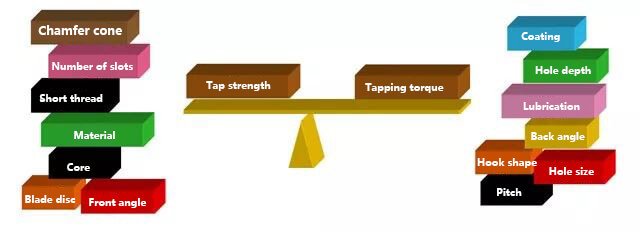

In the tapping process, several factors must be considered, including the design of the workpiece, the design of the tap, and its intended application. The objective is to minimize cutting force and maximize the strength of the tap.

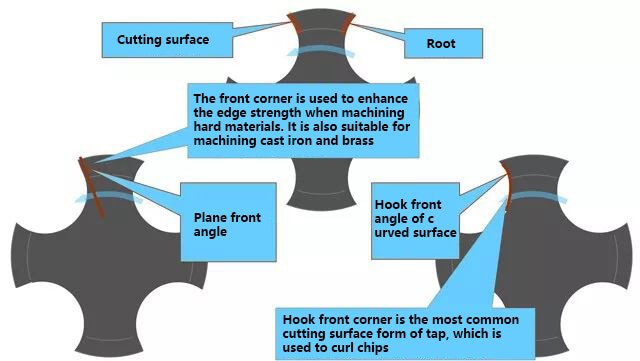

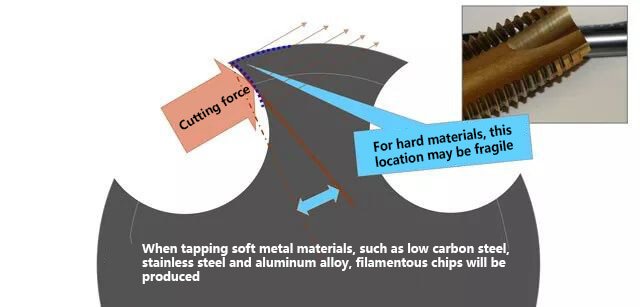

(1) For softer, more viscous materials that produce long chips, the tap should have a simple design, a large front angle and hook angle, a large rear angle, and measures to avoid voids. It should also be designed for easy cutting, with a tendency to collapse at the edges, a fragile overall structure, and a large space for holding chips.

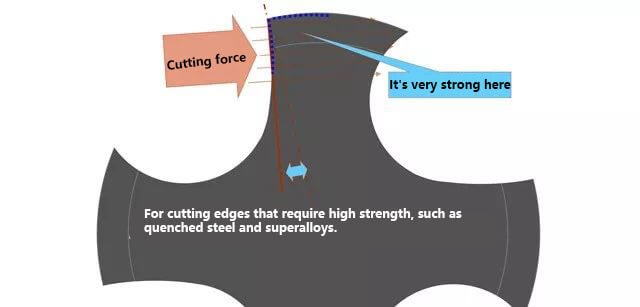

(2) For harder materials, the tap should have a heavy-duty design, a small front angle and hook angle, a small back angle and shovel back, and be able to withstand high cutting pressure. It should also have a strong edge design to reduce edge collapse and have a large cross-section and limited chip holding space.

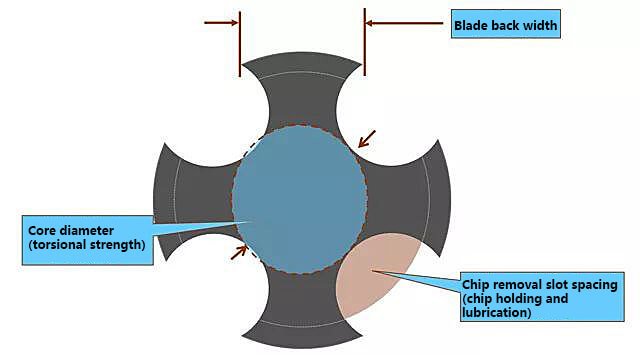

(3) Factors to consider in tap design include the type of tap groove, the material used for the tool, and surface strengthening treatments. These design features must be balanced to ensure proper cutting, chip control, lubrication, and torsional strength.

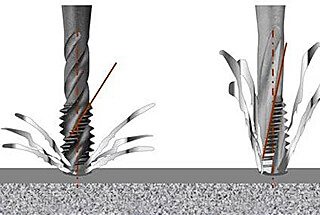

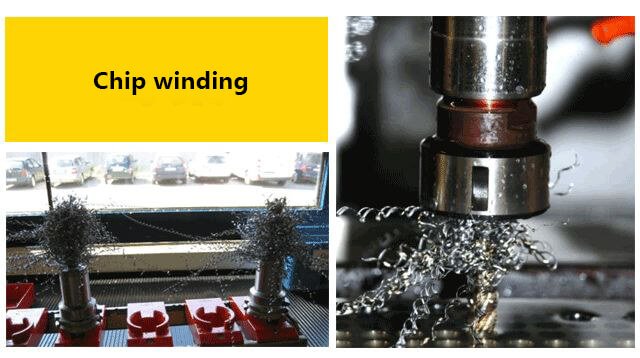

When cutting, it is important to stop in the middle of the cut and reverse the direction of the hole, while keeping the cutting in the groove. This presents the biggest challenge in tapping and tap design in metal processing.

① Correct selection of positive hook tap

② Correctly select the tap with small or negative hook angle

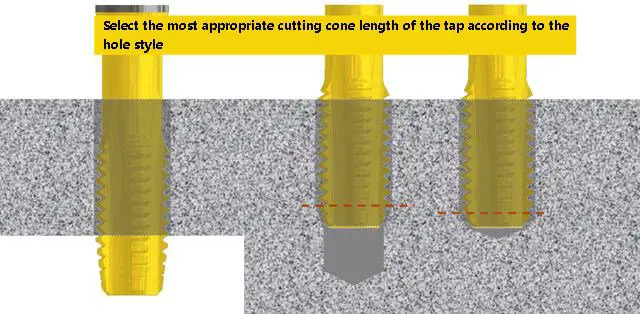

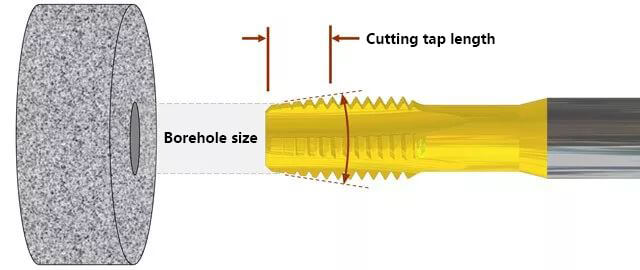

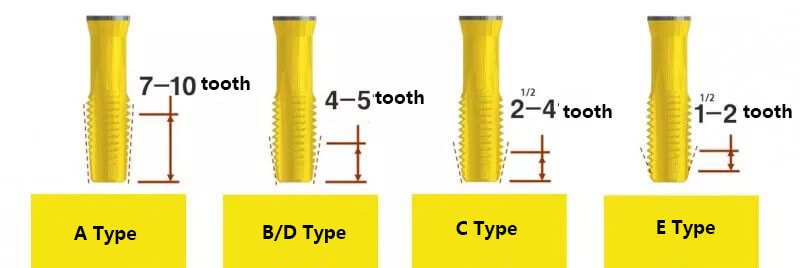

The service life of a tap can be significantly extended with each additional cutting tap tooth. Tests have shown that the tool’s lifespan can be doubled for every half of the cutting tooth thread.

Unlike other tools, the chip load of a tap can only be altered by the number of chip removal slots and the length of the cutting tap.

Similar to all other tools, the tap is also slightly inverted.

Advantages of using a thread shovel back include less heat buildup on the tap and less plastic build-up on the back of the workpiece, which can help mitigate the accumulation of chips on the thread.

Disadvantages of using a thread shovel back include the cutting edge becoming brittle and prone to collapse, insufficient rigidity of the main shaft and clamping (including a floating tool handle), and the possibility of small chips becoming embedded during reverse rotation, leading to the collapse of the cutting edge.

Each tap has its own unique pitch diameter.

Taps marked with H or D tolerance (mainly American taps) indicate the thread size of the tap through the H/D tolerance. The letter indicates whether the tap size is greater than (H = imperial, D = Metric) or lower than (L = imperial, DU = Metric) the basic pitch diameter. The actual tap size is expressed in relation to the basic pitch diameter, such as H2, D3, L1, or DU2.

Taps are also often marked with a thread grade. For example, a general HP tap series indicates that the tap is the correct size for the fitting grade of the part. A grade 3B tap is suitable for a grade 2B part, and a tap marked with an “X” grade indicates that it has a large tolerance and is used for precision taps, electroplated or heat-treated parts, or materials with close to an elastic memory.

For electroplated tapping threads, it’s necessary to select a tap with a larger tolerance grade for internal threads. A larger pitch diameter will result in a slightly larger thread size, and the increase after electroplating will bring the thread size back to the specified value.

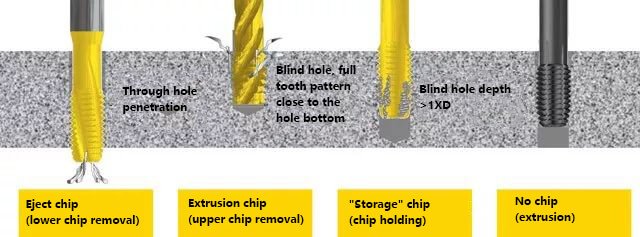

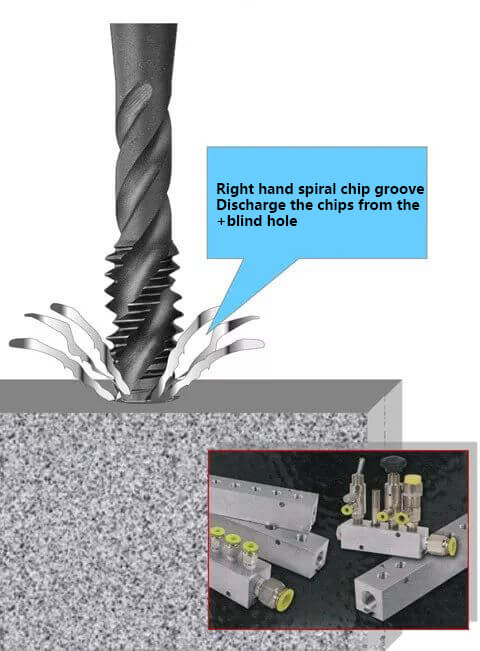

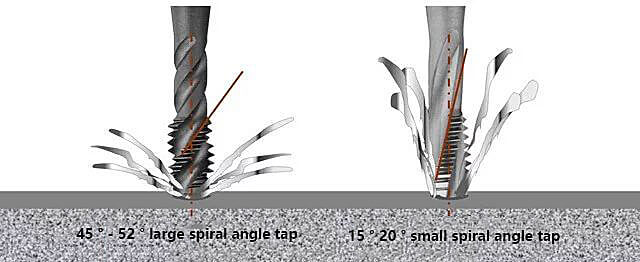

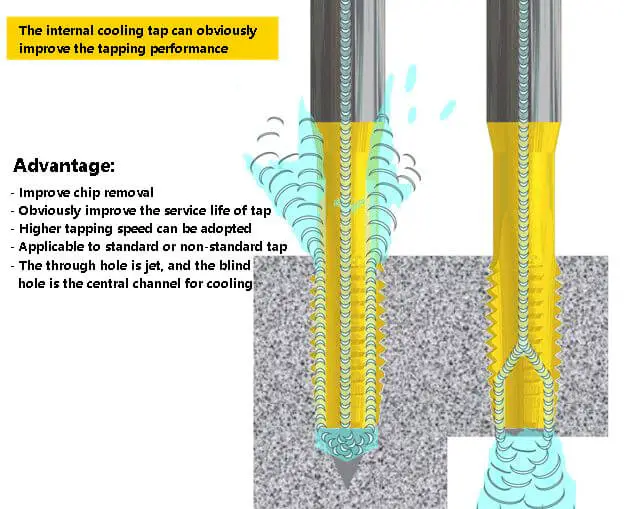

The spiral chip removal slot tap is best suited for blind hole and deep hole processing. It is recommended to use materials that produce sticky chips, making it ideal for intermittent cutting.

The taper core of the spiral chip removal slot tap is very thin, making it the most vulnerable part of the tap design. To avoid breakage, the speed should be 30% to 40% lower compared to that of a straight chip removal slot tap.

For materials that are prone to breaking chips, such as brass, cast iron, or hardened steel, it is recommended to use a tap with high strength. Coolant or gas is usually needed to flush chips from the chip removal groove.

Taps can come in a variety of cutting forms, including:

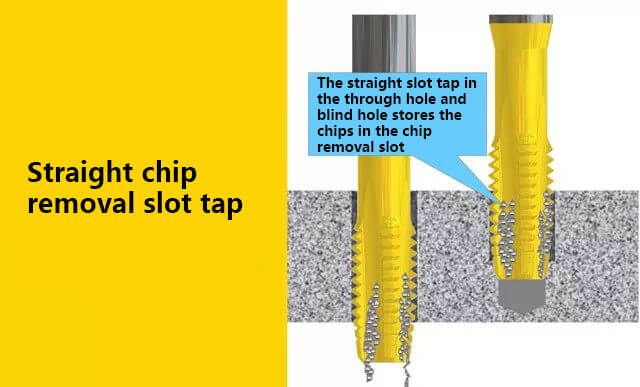

Its processing feature is that there is no chip in the through hole or blind hole.

① Surface Treatment: Improves the appearance of HSS taps without changing their size.

② Improved Tap Life: Offers high wear resistance, reduces friction and power consumption, reduces blade collapse and breakage, and slightly increases surface hardness.

③ Improves Surface Quality and Dimensional Accuracy of Screw Holes: Maintains a sharp cutting edge with a lubricating effect, reduces load and scratches, and minimizes chip buildup.

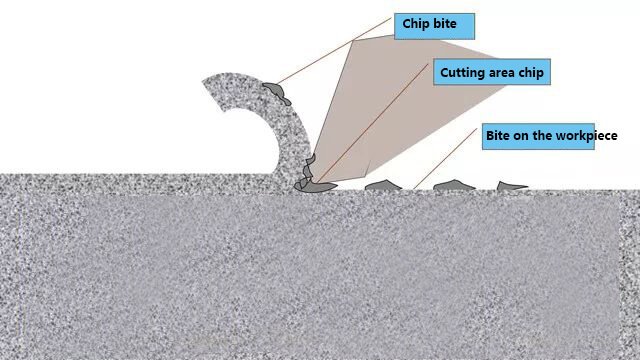

The workpiece material is welded or bitten on the chip edge.

At the start of cutting, a chip buildup forms and grows throughout the cutting process.

When chip buildup becomes severe, the cutting pressure causes it to break apart and the fragments become embedded in the workpiece, leading to a poor finish and deviations from the desired size.

When the chip buildup fragments, the tool material particles break down, leading to tool wear.

Oxidation treatment:

Nitriding treatment:

Oxynitride treatment:

(TIN) titanium nitride coating

(TiCN) titanium carbonitride coating

(TiAIN) titanium nitride aluminide coating

(CRN) chromium nitride coating

Diamond film

Tin + CRC / C composite coating

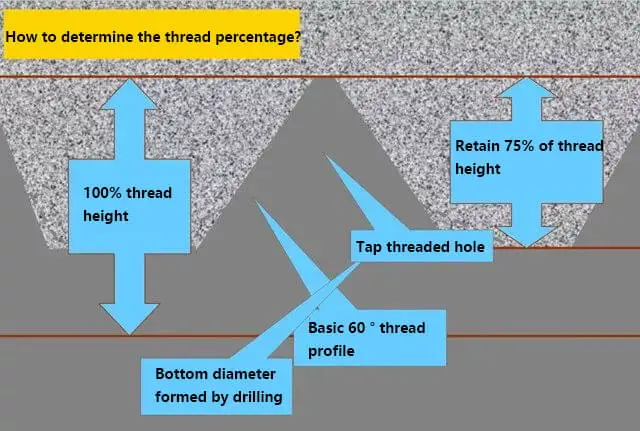

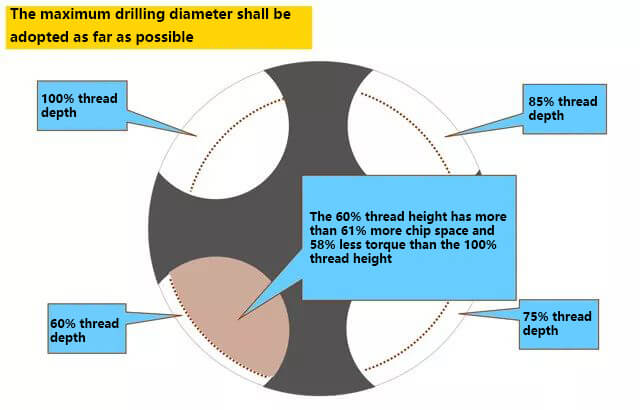

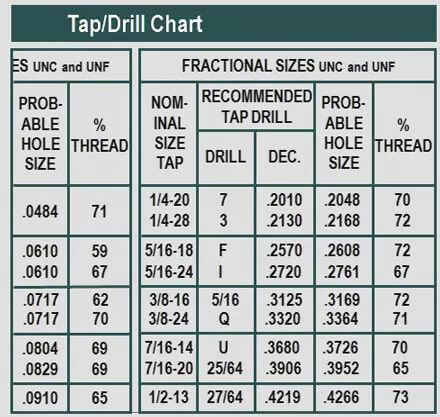

The size of the drilled hole determines the percentage of the thread bottom diameter and the thread height.

The larger the drill diameter used, the smaller the ratio of thread height achieved.

Typically, a thread height ratio of 65% to 70% is preferred.

While a thread strength of 83% height is only 2% higher than that of 65% height, the tapping torque is more than double.

① Causes of tap top cutting

Manual tapping: the manual feed is not coordinated, and the feed is too fast or too slow.

Machine tapping: asynchronous tapping cycle is not programmed properly.

Lead Screw Machine Tool: Backlash caused by a worn lead screw or loose lead screw adjusting nut.

Cam Feed Machine: Incorrect or worn cam profile.

Pneumatic or Hydraulic Machine Tools: Uncontrollable pressure, either too high or too low.

Gear Feed Machine: Backlash caused by improper gear adjustment or wear.

② Solve the problem of tap top cutting

For the most accurate threads, the feed rate should be synchronized with the spindle speed.

The feed rate and spindle rotation must match the thread pitch.

Thread depth control, consistent hole-to-hole size, elimination of roof cutting, and retapping when necessary are important factors in tapping.

Question: If a CNC machine programmed with the G84 tapping cycle is operated manually, does it mean that rigid tapping can be performed?

Answer: No! Many CNC machine tools have a fixed tapping program with a feed rate in the form of drilling. These programs cannot be synchronized with the spindle.

Beware! The machine tool data must indicate whether the machine tool has “synchronous” or “rigid” tapping capabilities.

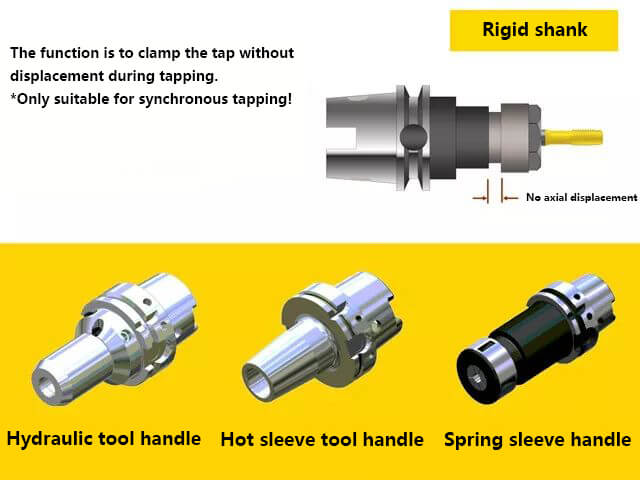

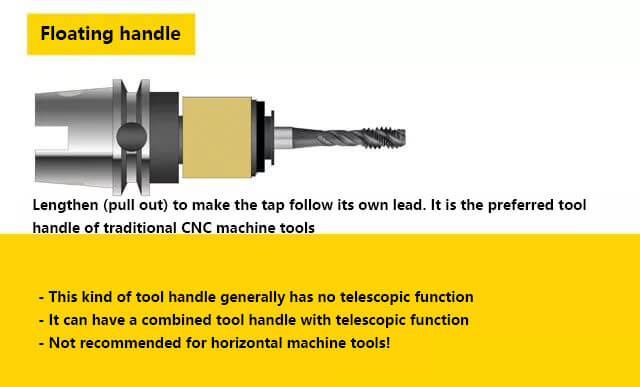

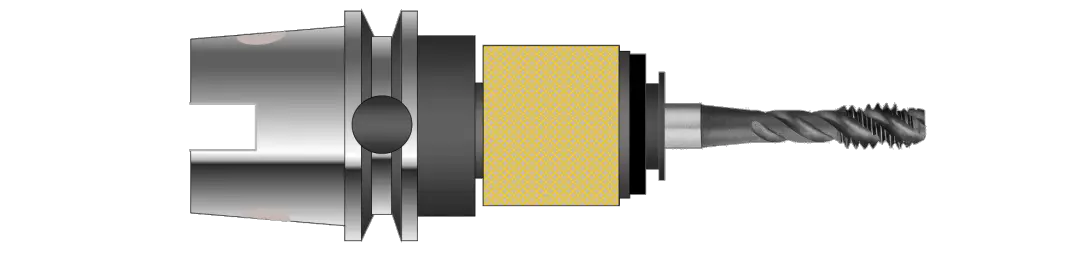

For asynchronous tapping:

For synchronous tapping:

Proper tool holder maintenance is crucial for producing high-quality threads and extending the service life of taps.

The internal mechanism should be kept free of chips and debris.

Lubricate regularly to ensure smooth movement of components and prevent rust.

Frequently check the tool handle, especially when using water-soluble coolants.

Tapping NC setting

When tapping with CNC machine tools without a rigid tapping cycle:

When tapping on CNC machine tools with a rigid tapping cycle:

If the end of the thread gauge is exceeded during topping:

→ straight groove

→ smaller helix angle

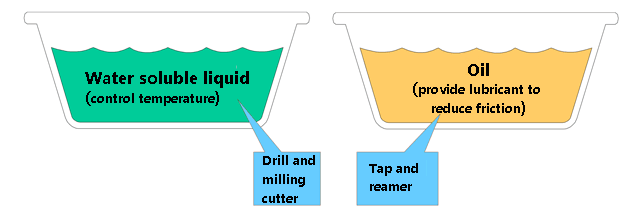

The purpose of lubrication in tapping is to reduce friction.

Therefore, lubricants are generally used for tapping, not coolants.

If a coolant is used, add EP (ultra-high pressure) or HP (high pressure) additives.

The tap has a fixed, large feed rate that is controlled by the tap pitch, while the drilling feed can be adjusted to control the load.

Before selecting a tap, we need to understand: