How can precise techniques and careful limits transform sheet metal into essential components? In this article, you’ll explore various methods like flattening, 180° U piece bending, and triple folding hemming, which are vital for shaping sheet metal. Discover how to calculate minimum dimensions and avoid common pitfalls, ensuring high-quality results. By the end, you’ll understand the critical factors that impact the effectiveness and precision of these metalworking techniques.

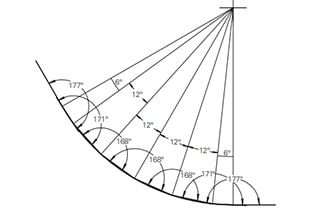

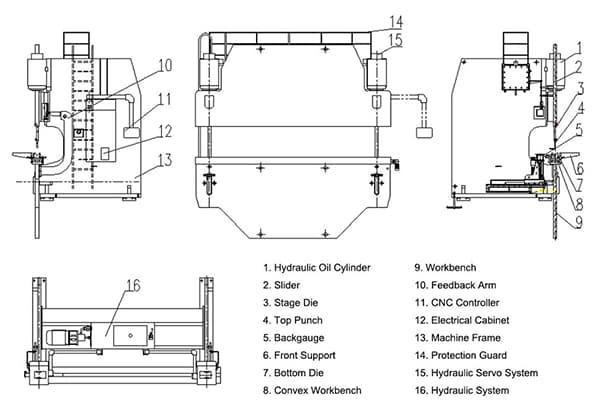

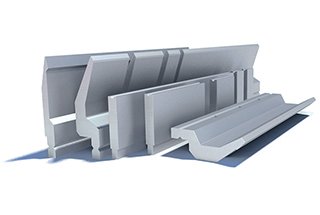

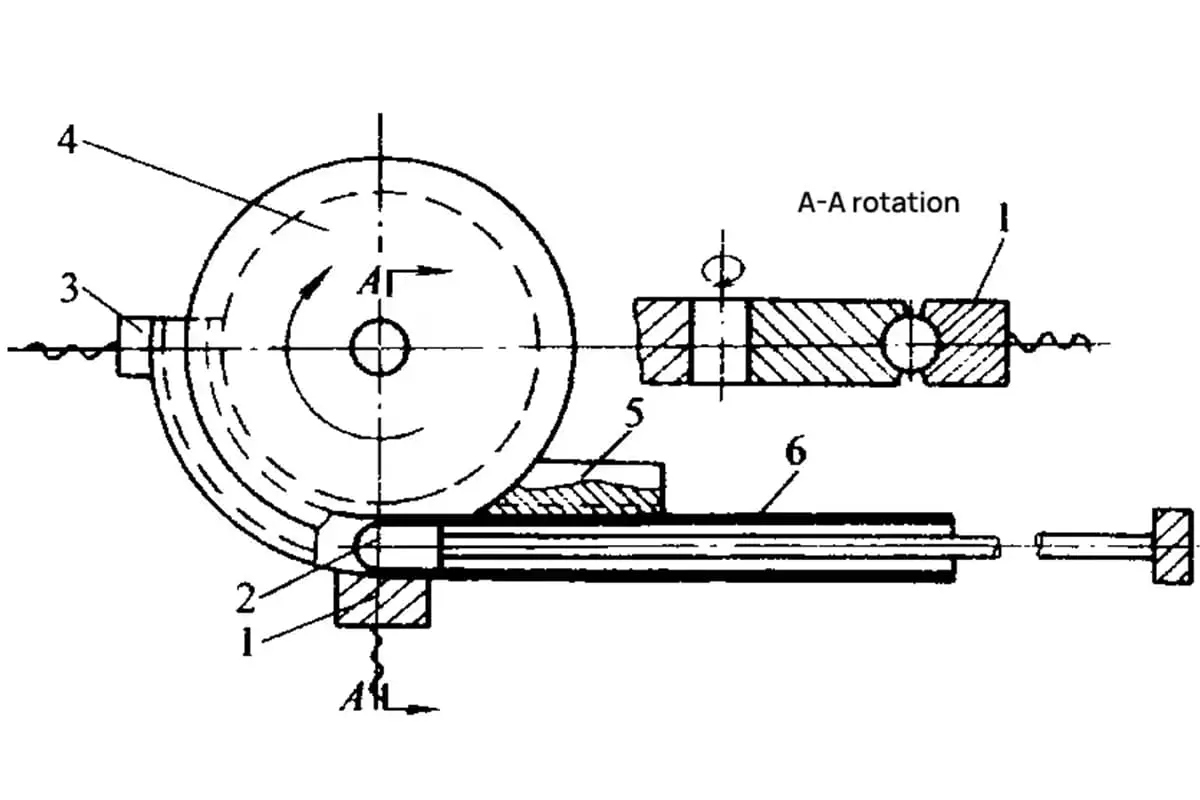

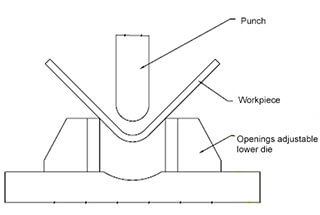

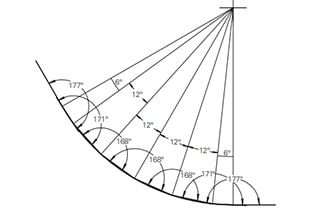

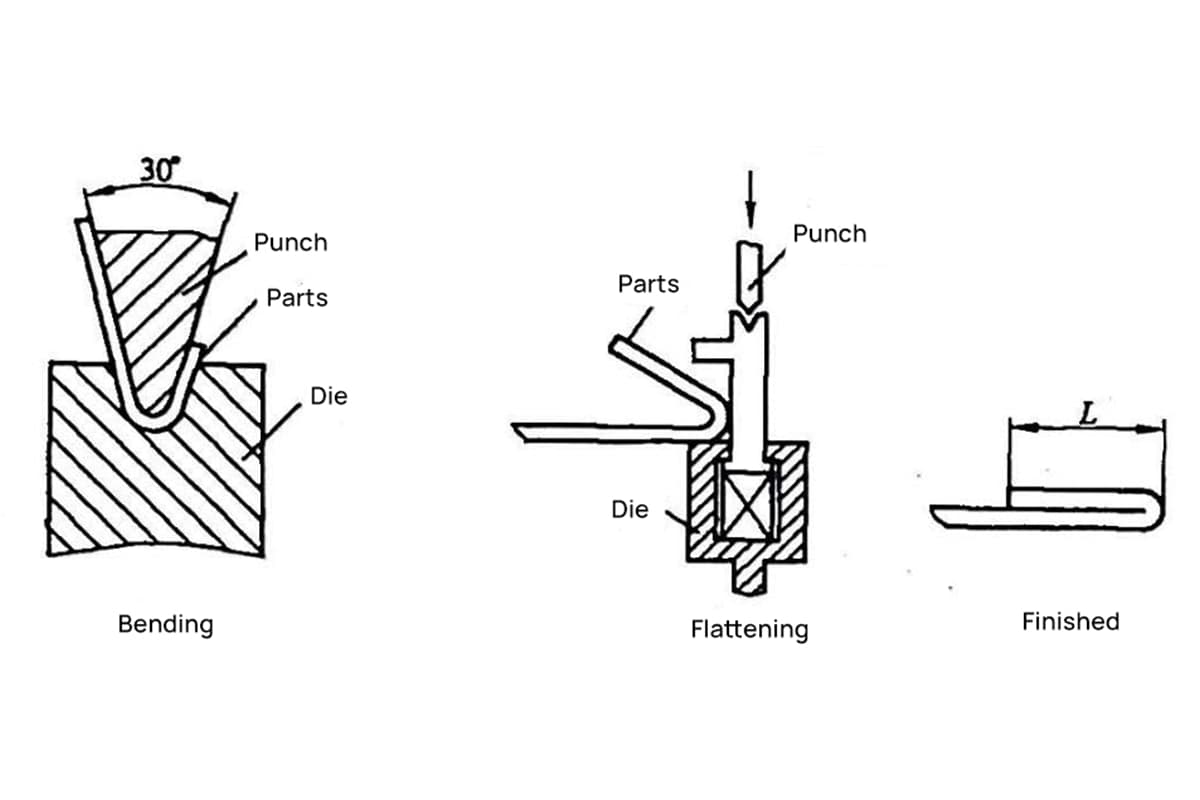

The method of flattening (also known as hemming) is illustrated in Figure 2-20. Initially, the edge of the sheet metal is bent into a 30° shape using a 30° bending die. Afterward, the bent edge is flattened. Flattening can be conducted on a press machine, hydraulic machine, or a press brake machine.

The minimum flattening width size Lmin for the bending machine can be calculated using Equation (2-3) plus 0.5t (t being the material thickness), as shown in Equation (2-7):

Lmin = (Bvmin – x) / 2 + f + 1.5t (2-7)

Common sheet materials suitable for flattening include stainless steel, galvanized sheet, and aluminum zinc plate. Parts requiring electroplating should not be used, as the flattened areas can cause acid trapping, making treatment difficult.

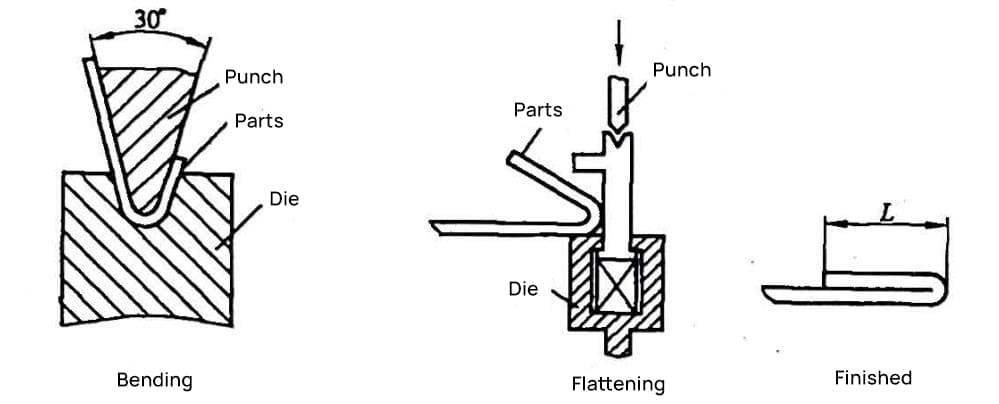

The bending process of a 180° U piece is shown in Figure 2-21. Bend the sheet material to 30° with a 30° bending tool first, then flatten the bent edge and remove the spacer after flattening.

The thickness H of the spacer should be chosen from common sheet sizes (such as 0.5mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm), and it is not advisable to choose a too large sheet thickness. When the opening of the 180° U piece is large, a special mold should be used for bending.

The minimum bending edge size Lmin of the bending width can be calculated with Equation (2-3) plus H. The equation is as follows:

Lmin = (Bvmin – x) / 2 + f + H (2-8)

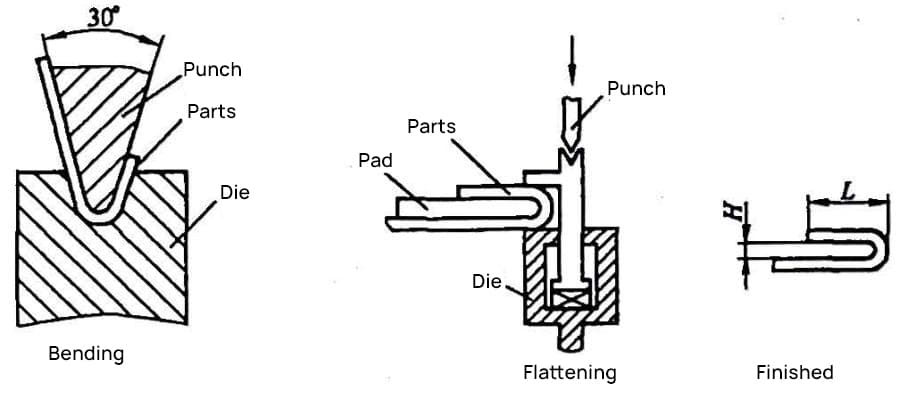

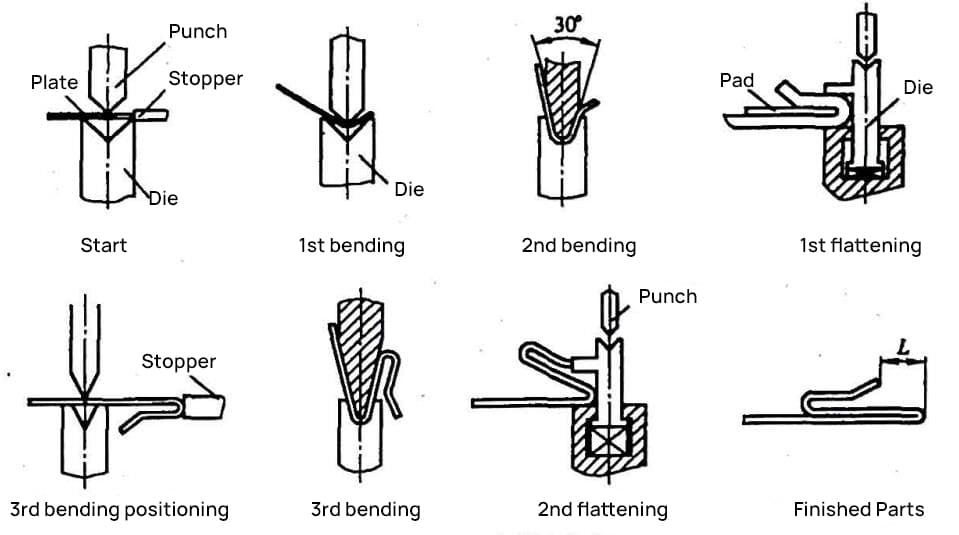

Triple folding hemming is shown in Figure 2-22. The bend should first be made on the smaller side shown in the figure, then the U-shaped part is formed using the previously mentioned 180° U piece bending method, and finally, the triple folding hemming piece is formed using the flattening method.

When designing and preparing the processing technology for the parts that require a triple folding dead edge, attention should be paid to the structural dimensions of all parts.

The structural dimensions should meet the minimum bending dimensions required by each step and the minimum width dimension Lmin of the final flattened compressed edge, avoiding unnecessary post-processing or manufacturing of special fixtures.

The recommended value of the minimum width dimension Lmin of the flattened compressed edge is shown in Table 2-5.

Table 2-5 Minimum Width Dimension of the Final Flattened Compressed Edge for Triple Folding Hemming (Unit: mm)

| Material Thickness t | 0.5 | 0.6 | 0.8 | 1.0 | 1.2 | 1.5 | 2.0 | 2.5 |

| Minimum Compressed Edge Dimension Lmin | 4.0 | 4.0 | 4.0 | 4.0 | 4.5 | 4.5 | 5.0 | 5.0 |

Note: