Have you ever wondered about the secrets hidden within the gleaming surfaces of metals? In this fascinating article, we delve into the intricacies of metal composition analysis. Our expert author, with years of experience in mechanical engineering, takes you on a journey to unravel the mysteries of ferrous and non-ferrous metals. Discover the cutting-edge methods used to test and analyze these materials, and gain valuable insights that will enhance your understanding of this crucial field.

Metal materials encompass a diverse array of options, including pure metals, alloys, and specialized composites. These materials find extensive applications across various industries, from aerospace and automotive to machinery manufacturing and advanced electronics.

The increasing demand for high-performance metal materials has led to the development of sophisticated alloys and metal matrix composites. These intricate materials are engineered to meet specific requirements in terms of strength-to-weight ratio, corrosion resistance, thermal stability, and other critical properties.

The composition of metals is fundamental in determining their mechanical, physical, and chemical properties. Elements such as carbon, chromium, nickel, and molybdenum, when added in precise quantities, can dramatically alter the characteristics of base metals, resulting in materials tailored for specific applications.

A comprehensive understanding of metal composition and properties is essential for materials engineers and product designers. This knowledge enables the optimal selection of materials for various applications, ensuring that components meet performance requirements while considering factors such as cost-effectiveness, manufacturability, and sustainability.

During manufacturing processes, two critical challenges frequently arise: accurate identification of metal materials and verification of their conformity to specified requirements. These issues are particularly pertinent in industries with stringent quality control standards, such as aerospace and medical device manufacturing.

By employing advanced analytical techniques such as spectrometry, X-ray fluorescence (XRF), or inductively coupled plasma mass spectrometry (ICP-MS), it becomes possible to precisely determine the elemental composition of metal materials. This capability is crucial for:

Nature provides over 90 types of metals, including iron, copper, aluminum, tin, nickel, gold, silver, lead, and zinc, among others.

An alloy is a combination of two or more metals, or a metal with a non-metal, exhibiting metallic properties. Common examples include steel (iron and carbon), stainless steel (iron, chromium, and nickel), and brass (copper and zinc).

Metal materials are generally classified into three categories: ferrous metals, non-ferrous metals, and specialty metal materials.

Ferrous metals, or iron and steel materials, encompass pure iron, cast iron (2-4% carbon), carbon steel (<2% carbon), and various specialized steels such as structural, stainless, heat-resistant, tool steels, superalloys, and precision alloys. Broadly, ferrous metals may also include chromium and manganese alloys.

Iron, being the most abundant and cost-effective metal on Earth, serves as a fundamental material across industries. Its applications range from household appliances (refrigerators, kitchenware, washing machines) to transportation (cars, railways, ships), infrastructure (bridges, electric towers, buildings), and industrial equipment.

Non-ferrous metals comprise all metals and their alloys except iron, chromium, and manganese. They are typically categorized as light metals, heavy metals, precious metals, semi-metals, rare metals, and rare earth metals. Compared to pure metals, alloys generally exhibit superior mechanical properties, including higher strength and hardness, coupled with lower electrical resistance and temperature coefficients.

Common non-ferrous alloys include those based on aluminum, copper, magnesium, nickel, tin, titanium, and zinc. These materials find extensive use as structural and functional components in diverse sectors such as machinery manufacturing, construction, electronics, aerospace, and nuclear energy applications.

The selection of appropriate metal materials for specific applications requires careful consideration of their unique properties, including strength-to-weight ratio, corrosion resistance, thermal and electrical conductivity, and fabrication characteristics. Advanced manufacturing techniques, such as additive manufacturing and powder metallurgy, are expanding the possibilities for creating custom alloys with tailored properties to meet specific industry needs.

Related reading: Ferrous vs Non-ferrous Metals

The methods for analyzing and testing the composition of metal materials have evolved over time, moving from traditional titration and spectrophotometry to more advanced techniques such as plasma emission spectrometry and spark direct reading spectrometry. The testing process has also changed, allowing for simultaneous analysis of multiple elements, which has improved efficiency and accuracy.

The principles and characteristics of different test methods are as follows:

Spectrophotometry is a fundamental analytical technique widely employed for quantifying metal elements in various industries, including metallurgy, environmental monitoring, and materials science. This method relies on measuring the absorbance or transmittance of electromagnetic radiation by a sample within a specific wavelength range, typically spanning from ultraviolet to infrared regions of the spectrum.

The principle of spectrophotometry is based on the Beer-Lambert law, which relates the attenuation of light to the properties of the material through which it is traveling. For metal analysis, this technique often involves forming colored complexes with specific reagents, allowing for both qualitative identification and precise quantitative determination.

Key advantages of spectrophotometry include:

However, spectrophotometry does have limitations:

Spectrophotometric instruments used in metal analysis include:

Recent advancements in spectrophotometry for metal analysis include the development of portable and handheld devices for field testing, integration with automated sample preparation systems, and the use of multivariate calibration techniques to improve accuracy and potentially overcome some single-element limitations.

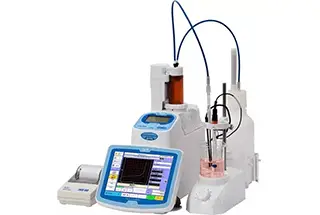

Titration is a quantitative analytical technique used to determine the concentration of metal ions in a solution by reacting them with a standard solution of known concentration (titrant). In this process, the metal ions are systematically neutralized or complexed by the titrant until the reaction reaches its endpoint, signaled by a detectable change (e.g., color shift, precipitate formation, or electrode potential).

This method is particularly effective for analyzing metal content exceeding 1% in a sample. Titration offers high accuracy and precision, especially when using potentiometric or spectrophotometric endpoint detection. Common titration techniques for metal analysis include complexometric titration using EDTA and redox titration.

While titration provides reliable results, it has some limitations:

To enhance efficiency, automated titrators can be employed, allowing for higher throughput and reduced human error. Additionally, combining titration with other techniques, such as spectrophotometry or electrochemistry, can improve both speed and sensitivity for metal content determination.

Atomic Absorption Spectrometry (AAS) and Atomic Emission Spectrometry (AES) are fundamental analytical techniques employed in the quantitative and qualitative analysis of metallic elements in various materials.

AAS operates on the principle of measuring the absorption of specific wavelengths of light by ground-state atoms in the gaseous phase. When light of a characteristic wavelength passes through a cloud of atomized sample, the atoms absorb energy, transitioning to an excited state. The amount of light absorbed is proportional to the concentration of the element present. This technique offers high sensitivity, excellent selectivity, and a wide dynamic range, making it particularly useful for trace metal analysis in complex matrices.

Key advantages of AAS include:

However, AAS does have some limitations:

AES, conversely, analyzes the characteristic emission spectra produced when atoms or ions are excited by thermal or electrical energy. As excited electrons return to their ground state, they emit light at specific wavelengths unique to each element. This method allows for simultaneous multi-element analysis, offering advantages in speed and efficiency.

Notable features of AES include:

Limitations of AES encompass:

Recent advancements in atomic spectrometry, such as Inductively Coupled Plasma Mass Spectrometry (ICP-MS) and High-Resolution Continuum Source AAS (HR-CS AAS), have addressed many of these limitations, offering improved sensitivity, multi-element capabilities, and enhanced matrix tolerance. These modern techniques are increasingly employed in metallurgical analysis, environmental monitoring, and quality control in metal manufacturing processes.

X-ray fluorescence (XRF) spectrometry is a powerful, non-destructive analytical technique widely employed for the rapid determination of elemental composition in metal materials. This method leverages the principle of atomic excitation and subsequent emission of characteristic secondary X-rays to provide both qualitative and quantitative analysis of metallic samples.

When atoms in a sample are irradiated with high-energy X-rays or gamma rays, electrons from inner orbitals are ejected, creating vacancies. As electrons from higher energy levels fill these vacancies, they release energy in the form of fluorescent X-rays. The wavelength and energy of these emitted X-rays are unique to specific elements, serving as a “fingerprint” for elemental identification.

XRF analysis offers several advantages in metallurgy:

Quantitative analysis is achieved by comparing the intensities of characteristic X-ray lines from the sample to those of calibration standards. Modern XRF systems employ sophisticated algorithms and matrix correction methods to account for inter-element effects, enhancing accuracy.

While XRF is primarily used for bulk analysis, recent advancements have expanded its capabilities:

It’s important to note that while XRF is highly effective for most metals, it has limitations in detecting light elements (Z < 11) and achieving extreme precision for trace elements. For these cases, complementary techniques such as optical emission spectroscopy (OES) or inductively coupled plasma mass spectrometry (ICP-MS) may be employed.

In summary, X-ray fluorescence spectrometry stands as a cornerstone analytical method in metallurgy, offering rapid, multi-element analysis with minimal sample preparation, making it invaluable for quality control, material verification, and research applications in the metal industry.

Inductively Coupled Plasma Atomic Emission Spectrometry (ICP-AES), also known as Inductively Coupled Plasma Optical Emission Spectrometry (ICP-OES), is currently the most widely used analytical technique for metal analysis in industrial applications. Its principle relies on the excitation of metal atoms in a high-temperature plasma (typically 6,000-10,000 K), causing electronic transitions which result in the emission of element-specific spectral lines. The intensities of these emission lines are then used to determine both the presence and concentration of metallic elements in the sample.

This method offers several distinct advantages:

In metal manufacturing and processing, ICP-AES is invaluable for quality control, alloy verification, and impurity analysis. It can rapidly test a batch of samples and determine multiple elements under one calibration, making it ideal for high-throughput industrial environments. Recent advancements in ICP-AES technology, such as axial viewing and advanced detector systems, have further improved detection limits and expanded its applications in trace element analysis for high-purity metals and advanced materials.

Spark Direct Reading Spectrometry (SDRS) employs high-energy electric arcs or sparks to vaporize and excite elements within a solid sample, inducing the emission of element-specific spectral lines. This advanced analytical technique offers rapid, multi-elemental analysis with exceptional accuracy and precision.

In the SDRS process, a controlled spark discharge, typically ranging from 100 to 1000 Hz, generates temperatures exceeding 10,000 K. This extreme thermal energy causes surface atoms to transition into a plasma state, where they emit characteristic wavelengths of light. The emitted radiation is then dispersed by a high-resolution diffraction grating, creating a spectrum arranged by wavelength.

The dispersed light passes through precisely positioned exit slits, each corresponding to a specific element’s spectral line. Photomultiplier tubes (PMTs) or charge-coupled devices (CCDs) detect these isolated spectral lines, converting the optical signals into electrical impulses. The intensity of each spectral line correlates directly with the concentration of the corresponding element in the sample.

A sophisticated control and measurement system, often employing advanced signal processing algorithms, integrates and analyzes these electrical signals. Modern SDRS instruments utilize powerful computer systems and specialized software to perform real-time data acquisition, background correction, and matrix effect compensation, ensuring highly accurate quantitative results.

Key advantages of SDRS include:

While SDRS excels in metallic sample analysis, it does have some limitations:

Despite these constraints, Spark Direct Reading Spectrometry remains an indispensable tool in metallurgical quality control, alloy verification, and materials research, offering unparalleled speed and accuracy in elemental analysis of conductive materials.

In metal materials, particularly steels, carbon and sulfur are critical elements requiring precise quantification, which conventional methods often fail to accurately measure. Consequently, a specialized carbon-sulfur analyzer is employed for their determination.

The analysis process involves high-temperature combustion of the sample in an oxygen-rich environment. This oxidizes carbon and sulfur into carbon dioxide (CO2) and sulfur dioxide (SO2), respectively.

These combustion gases are then directed through dedicated infrared absorption cells. As CO2 and SO2 absorb specific wavelengths of infrared radiation, the attenuation of the infrared beam is detected and converted into electrical signals. These signals are subsequently processed by integrated software to calculate and display the carbon and sulfur content.

This combustion infrared absorption method offers several advantages:

The technique is particularly valuable in quality control for steel production, where precise carbon content influences mechanical properties, and sulfur levels must be strictly controlled to prevent embrittlement. It’s also crucial in other metallurgical applications, such as cast iron analysis and the assessment of non-ferrous alloys.

The oxygen and nitrogen analyzer is a sophisticated instrument used to precisely quantify oxygen and nitrogen content in a wide range of materials, including various grades of steel, non-ferrous metals, and advanced materials. This analytical technique employs the principle of inert gas fusion, where the sample is rapidly heated in a high-purity graphite crucible under an inert atmosphere, typically helium or argon.

During the analysis, the sample undergoes pulse heating, which causes it to melt and release gases. The liberated oxygen reacts with the carbon from the crucible to form CO and CO2, while nitrogen is released as N2. These gases are then carried by the inert carrier gas to specific detectors:

This method is renowned for its exceptional attributes:

The oxygen and nitrogen analyzer plays a crucial role in quality control, research and development, and process optimization in metallurgy and materials science. It is particularly valuable in industries where the precise control of these interstitial elements is critical, such as in the production of high-purity metals, advanced alloys, and semiconductor materials.

Introduction to testing items

| Metal category | Project | ||

| Iron and steel | Element analysis | Grade identification(to identify whether it conforms to a standard or a grade)Request) | Coating composition analysis (test coating composition and elementElement content) |

| Copper alloy / high purity copper | |||

| Lead free solder / lead solder | |||

| Aluminium alloy | |||

| Magnesium alloy | |||

| Kirsite | |||

| Titanium alloy | |||

| Precious metals (gold, silver, palladium, platinum) | |||

| High pure metal | |||

| Brazing filler metal | |||

| Powder metallurgy | |||