Why does laser cutting thick steel plates present such a challenge? This article explores the technical hurdles faced when using high-power lasers to cut plates over 10mm thick. Learn about the issues with maintaining a stable combustion process, the impact of oxygen purity on cutting quality, and potential solutions for overcoming these difficulties. Discover practical insights into achieving precision and efficiency in thick plate laser cutting.

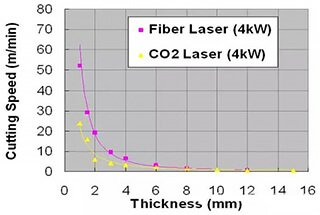

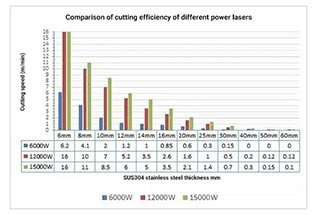

Cutting steel plates below 10mm is not an issue with a laser cutter. However, for thicker plates, a high-power laser with a power output of over 5kW is often required. This results in a significant decrease in the quality of the cut.

The high cost of high-power laser equipment makes the laser cutting output mode less favorable. As a result, traditional laser cutting methods do not have an advantage in cutting thick plates.

The technical challenges in cutting thick plates with a metal laser cutting machine are:

The metal laser cutter has limitations on the thickness of plates that can be cut during the actual cutting process. This is linked to the instability of the iron cutting edge’s combustion.

The temperature at the top of the slit must reach the ignition point to maintain the continuous combustion process. The energy released from the iron oxide combustion reaction alone does not guarantee the continuation of the combustion process.

On one hand, the cutting edge temperature is decreased by the constant cooling of the oxygen flow from the cutting nozzle. On the other hand, the iron oxide layer formed after combustion covers the surface of the workpiece, blocking the diffusion of oxygen. When the oxygen concentration decreases to a certain level, the combustion process will be extinguished.

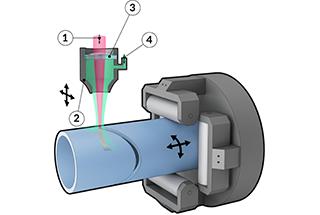

In traditional convergent beam laser cutting, the laser beam focuses on a small area on the surface. The high laser power density causes the surface temperature of the workpiece to reach the ignition point not only in the laser radiation area but also in a wider area due to heat conduction.

The diameter of the oxygen flow on the surface of the workpiece is larger than the diameter of the laser beam, resulting in a strong combustion reaction not only in the laser radiation area but also outside of it.

When cutting thick plates, the cutting speed is slow. The surface of the workpiece is burning faster than the moving speed of the cutting head. After burning for some time, the combustion process is extinguished due to the decrease in oxygen concentration. When the cutting head moves to that position, the combustion reaction starts again.

The burning process of the cutting edge occurs periodically, leading to temperature fluctuations and poor incision quality.

The decrease in oxygen purity also plays a crucial role in determining the cutting quality of thick plates using a laser cutter. The purity of the oxygen flow has a significant impact on the cutting process.

A decrease in oxygen flow purity by 0.9% leads to a 10% decrease in the iron-oxygen combustion rate. A decrease in purity by 5% results in a 37% decrease in the combustion rate. This decrease in combustion rate greatly reduces the energy input into the cut seam and slows down the cutting speed.

Additionally, the iron content in the liquid layer of the cutting surface increases, causing the viscosity of the slag to increase and making it difficult to discharge the slag. This results in significant slag buildup in the lower part of the incision, making the incision quality unacceptable.

To maintain cutting stability, the purity of the cutting oxygen flow in the direction of the plate thickness and pressure should be kept constant.

In traditional laser cutting, a conventional taper nozzle is used, which is suitable for cutting thin plates. However, when cutting thick plates, a shock wave is formed in the nozzle’s flow field as the supply pressure increases. The shock wave poses several hazards to the cutting process, such as reducing the oxygen flow purity and affecting the incision quality.

There are three solutions to this problem:

(1) Adding a preheating flame around the cutting oxygen flow.

(2) Adding an auxiliary oxygen flow around the cutting oxygen flow.

(3) Reasonable design of the internal walls of the nozzle to enhance the airflow field.