Ever wondered why some metal bends just don’t fit right? From L-bends to Z-bends, mastering these special bends is crucial in metalworking. This article dives into the nuances of different bending techniques, providing essential tips to avoid common pitfalls and enhance precision. You’ll learn how to select the right tools, understand the principles behind each bend, and apply best practices for flawless results. Perfect for both novices and seasoned professionals, this guide ensures your metalwork stands up to the highest standards. Ready to bend with confidence? Keep reading!

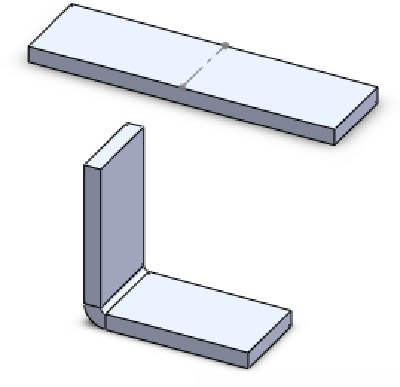

According to the angle, it can be divided into two categories: 90-degree bends and non-90-degree bends.

According to the processing method, it can be divided into two categories: general processing (L > V/2) and special processing (L < V/2).

(1) Based on the principle of two backstops and positioning based on the shape of the workpiece.

(2) When using a back gauge, it is important to consider deflection and ensure it is aligned with the centerline of the bending size of the workpiece.

(3) For small bends, it is more efficient to process them in reverse positioning.

(4) It is recommended to place the back gauge under the middle to prevent lifting when leaning.

(5) It is better to be positioned close to the back gauge.

(6) It is recommended to lean with the long side of the workpiece.

(7) Jigs can be used to assist with irregular positioning and hypotenuse leaning.

When processing, pay attention to the positioning method and the movement of the backstop mechanism in various positioning methods.

When installing the mold, it should be bent and the backstop mechanism should be retracted to prevent deformation of the workpiece during bending.

When bending large workpieces internally, it can be challenging to position the workpiece or prevent damage due to the larger shape and smaller bending area. To avoid this, a positioning point can be added in the longitudinal direction during processing. This method of processing in two directions makes positioning easier, improves safety, prevents damage to the workpiece, and increases production efficiency.

N-bends should use different processing methods based on the shape. When bending, the internal dimensions must be greater than 4mm, and the X dimension size is limited by the mold shape. If the material size is less than 4mm, special processing methods should be used.

(1) Ensure that the workpiece does not interfere with the tools.

(2) Ensure that the leaning angle is slightly less than 90 degrees.

(3) It is best to use two backstop mechanisms for leaning, except in special cases.

(1) After L-bending, the angle should be 90 degrees or slightly less than 90 degrees to facilitate processing and positioning.

(2) During the second bend processing, the workpiece should be positioned in the center of the processing surface.

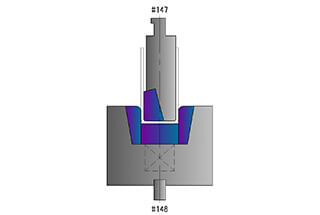

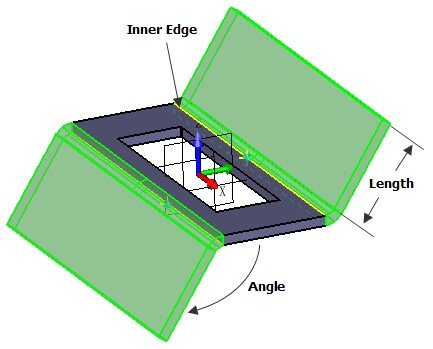

Z-bend, also known as offset bending, refers to bending in the opposite direction. The angle is divided based on the difference between the hypotenuse and straight edge. The minimum size of the bending process is limited by the mold, and the maximum size is determined by the processing machine’s shape. In general, when the inner size of the Z-bend is less than 3.5 times the thickness (T), an offset die is used. When it is larger than 3.5T, the normal processing method is applied.

(1) Convenient leaning position and good stability.

(2) The leaning position is generally the same as the L-bending.

(3) During the second leaning, the workpiece should be flush with the lower die.

(1) The processing angle of the L-bending must be in place, and the general requirement is 89.5 to 90 degrees.

(2) Pay attention to the workpiece deformation when retracting.

(3) The processing order must be correct.

(4) For special processing, the following methods can be used:

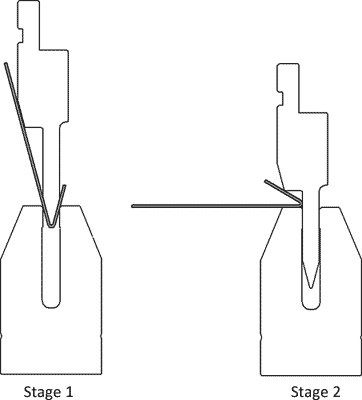

The processing steps for acute bending and hemming are:

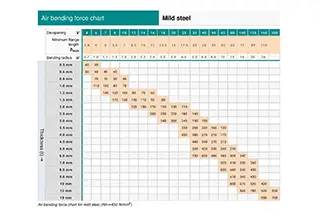

Based on 5 to 6 times the material thickness, select the V groove width of the lower die with a depth of 30 degrees. Choose the upper die based on the specific conditions of the flattening edge.

The flattening side should pay attention to the parallelism of both sides. For longer flattening edges, it is recommended to bend first and then flatten. For shorter flattening edges, padding processing can be used.

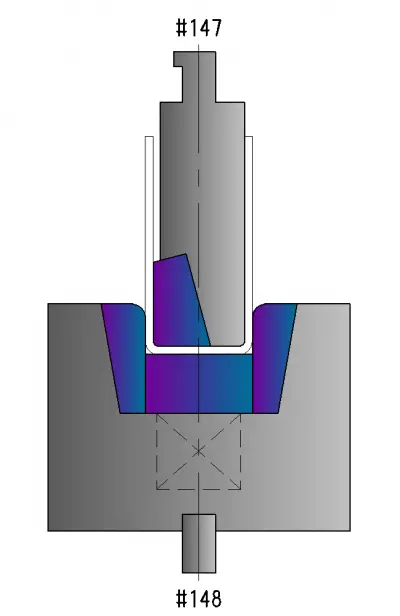

The use of a press brake to press riveted hardware usually requires the use of concave molds, fixtures, and other auxiliary mold processing tools. Common hardware items include crimp nuts, studs, screws, and others.

Precautions:

When the shape of the workpiece needs to be protected, avoidance processing must be done.

After processing, inspect the torque, verify that the thrust meets the standard, and ensure that the hardware and workpiece are flat and close.

When pressing the hardware next to the machine after bending and riveting, pay attention to avoiding processing and maintaining parallelism between the mold and workpiece.

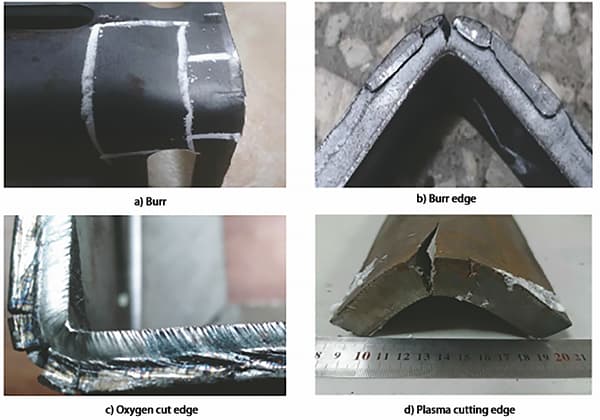

If bulging occurs, make sure there are no cracks on the bulging edge, and that the bulging edge is not higher than the surface of the workpiece.

The processing of general special mold forming includes:

Small offsets, hooks, draw bridges, draw bags, squashes, and some irregular shapes.

Special molds are generally positioned using back gauge fingers or self-positioning.

The most important aspect of processing with special molds is to ensure that their functions and assembly requirements are not impacted and that their appearance is normal.