Are you struggling to perfect your fillet processing techniques? This article provides five essential tips for rounding off rough edges in sheet metal parts, focusing on cost efficiency, reducing man hours, optimizing deburring processes, ensuring accuracy, and integrating advanced cutting technology. By following these guidelines, you’ll not only enhance safety and quality but also streamline your manufacturing workflow. Dive in to learn how to save time, reduce costs, and improve your overall production process.

Whether it involves manual operations or equipment processing, an increasing number of sheet metal processing enterprises are now integrating fillet processing into their parts processing process chain.

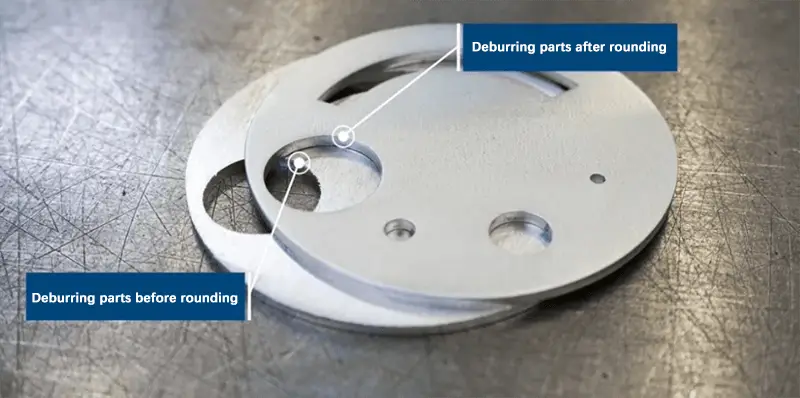

Rounding off the rough edges of parts is crucial not only to prevent industrial accidents but also to ensure the smooth follow-up processing of parts, particularly after accurate rounding off.

Here are five practical tips for fillet machining:

In recent times, sheet metal processors have become increasingly aware of the advantages of fillet machining in simplifying subsequent machining processes.

Some parts are manually polished, brushed, and polished, while others use deburring machines for these operations. But which method is better?

Firstly, it is essential to calculate the cost of consumables involved in burr processing for your enterprise. Although many enterprises have integrated fillet treatment into their process chains, they are often unaware of the actual costs, such as labor, abrasive tools, and machine energy consumption.

Therefore, it is important to ask several critical questions, such as the amount of labor and man-hours required for deburring and whether deburring is necessary for both sides of the parts.

If you need to integrate the deburring process into your production process, you must also consider how to optimize the logistics process before and after the fillet machining.

For instance, you need to reasonably arrange processes such as material flow, manipulator, online operation, or rotary conveying of parts.

It is also essential to save on labor hours and resources and reduce the labor intensity of operators, as lifting and turning parts weighing less than 25 kg requires considerable physical strength.

Furthermore, manual deburring can cause workers’ hands to vibrate for an extended period, which can adversely affect their health.

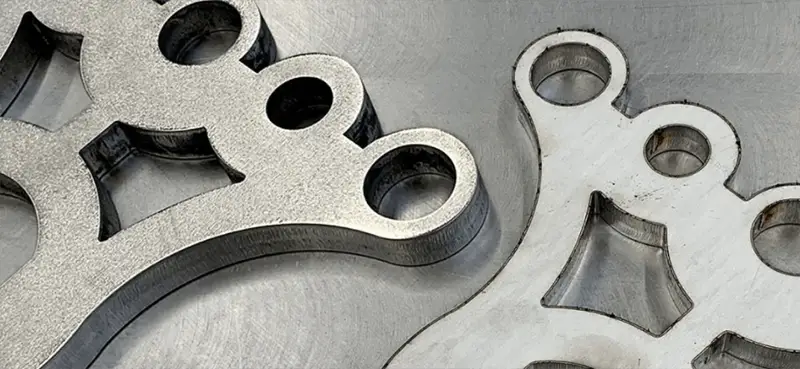

The term “deburring” often encompasses various sheet metal processing operations, including removing slag, burrs, fillets, and oxide layers from sections, as well as providing final surface treatments for parts.

Therefore, it is crucial to accurately define the deburring process requirements before selecting equipment.

For instance, if you require deburring and slight filleting of 80% of the parts, you should prioritize this core requirement while formulating the processing process. It is not advisable to integrate the remaining 20% of the surface treatment requirements into the production chain simultaneously.

If you aim to manufacture high-quality sheet metal parts, rounding off the rough edges of the sheet metal is an essential process. This process ensures that the burr is removed, thereby reducing the risk of industrial injury during operation, and optimizing the next processing steps, such as welding or spraying.

Before beginning the fillet treatment, it is necessary to determine the fillet machining accuracy of the workpiece. For instance, you can determine the specific machining accuracy based on the required anti-corrosion performance. Generally, fillet machining can be carried out as per the actual needs.

However, it is important to follow the principle of “less is more” when meeting the machining requirements. This is because doubling the machining depth would require four times the cutting capacity, resulting in an increase in the cost of grinding consumables.

The application of deburring technology in sheet metal processing has led some processors to mistakenly believe that they can operate carelessly when cutting or stamping plates, assuming that deburring treatment will take care of any burrs that may occur. However, this view is a big mistake.

In reality, careful cutting and stamping processes can reduce the occurrence of burrs in parts, ultimately saving subsequent working hours and reducing the wear and tear on deburring machinery.

For instance, an advanced plasma cutting machine can produce sheet metal parts with fewer burrs, but only if the cutting speed, operating current, and plate spacing are set correctly. Therefore, deburring treatment should be seen as a supplementary step rather than a corrective one.

Sheet metal processing enterprises should not only focus on integrating advanced cutting technology into their production process but also include deburring and fillet treatment in their process chain planning.

By integrating deburring technology that is perfectly adapted to their production needs, enterprises can improve product quality and sustainability at a low cost. This technology can be seamlessly integrated into their processing line to play a positive role in the overall production process.