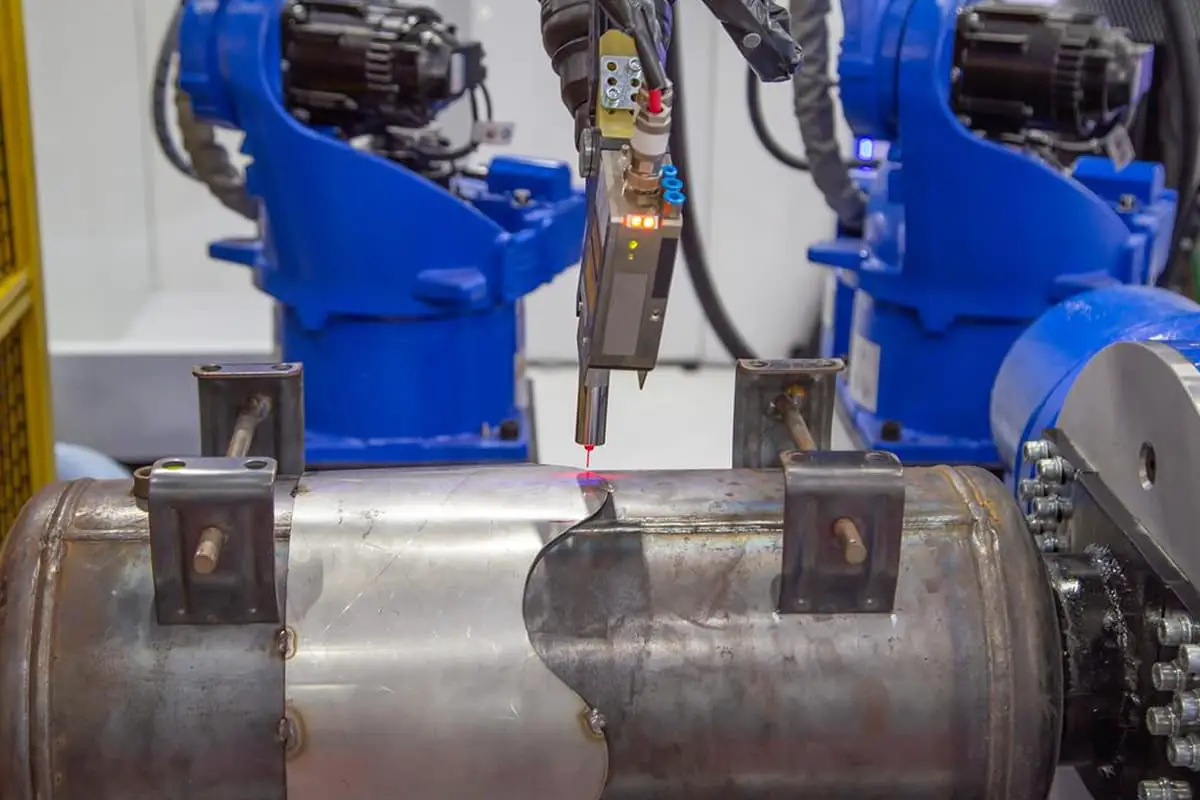

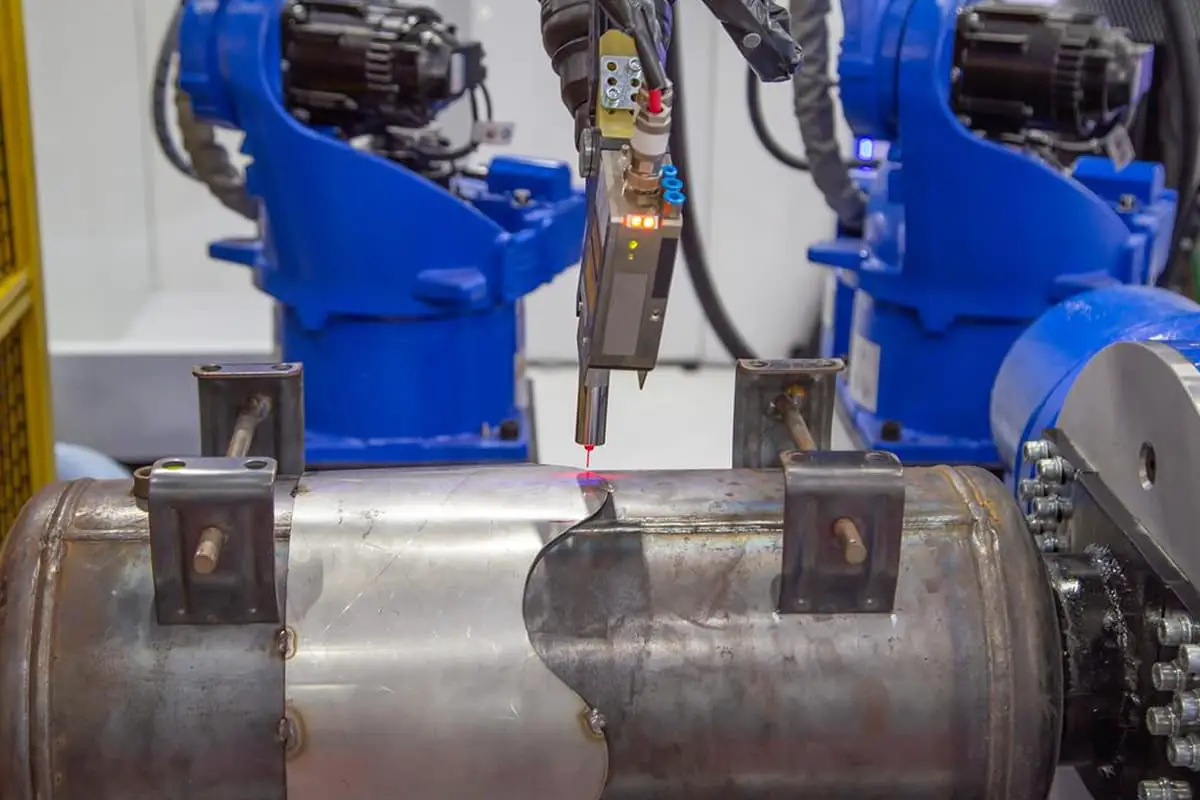

How do you achieve the perfect weld on a titanium tube, balancing precision with efficiency? This article dives into the intricacies of titanium tube laser welding, exploring techniques to minimize weld width and increase production speeds. Readers will gain insights into selecting the right laser and understanding the critical factors affecting weld quality, from beam quality to seam alignment. Discover how advanced welding methods can enhance manufacturing outcomes in this comprehensive guide.

In the welding process of titanium alloy pipes at the factory, the depth of the weld is determined by the thickness of the titanium pipe.

Therefore, the production goal is to improve formability by reducing the weld width and achieving higher speeds simultaneously. When selecting the most suitable laser, one cannot solely consider the beam quality but must also take into account the precision of the tube rolling machine.

Furthermore, before the dimensional inaccuracies of the rolling machine come into play, one must first consider the constraints encountered when reducing the beam spot size.

There are many unique size-related issues in titanium tube welding, yet the primary factor affecting the welding process is the seam on the welding box.

Once the titanium plate is ready for welding after forming, characteristics of the weld seam include: gaps between titanium plates, severe or minor welding misalignment, and changes in the seam centerline. The gap determines the amount of material needed to form the weld pool.

Excessive pressure can lead to surplus material at the top or the inner diameter of the titanium alloy welded pipe. On the other hand, severe or minor welding misalignment can result in poor welding appearance.

In both these scenarios, the titanium plate is cut and cleaned, rolled up, and then brought to the welding point. Additionally, a coolant is used for cooling the induction coil used during the heating process.

Finally, some coolant will be used in the extrusion process. Here, a large force is applied on the extrusion roller to avoid porosity in the welding area; however, using greater extrusion force could lead to an increase in burrs (or weld beads). Therefore, specially designed tools are used to remove burrs from the inside and outside of the tube.

One of the main advantages of the high-frequency welding process is its ability to process titanium tubes at high speeds. However, a typical situation in most solid-phase forging is that the welding points of high-frequency welding are not easily tested reliably using conventional non-destructive techniques.

Welding cracks may appear in the thin flat areas of low-strength joints, which traditional methods cannot detect, potentially compromising reliability in some high-demand automotive applications.

Traditionally, titanium tube manufacturers opt for Gas Tungsten Arc Welding (GTAW) to complete the welding process. GTAW generates an electric welding arc between two non-consumable tungsten electrodes.

Concurrently, an inert shielding gas is introduced from the torch to shield the electrodes, create ionized plasma flow, and protect the molten weld pool.

This is an established and well-understood process that consistently delivers high-quality welding outcomes. Therefore, the success of the titanium alloy tube welding process depends on the integration of all individual techniques, necessitating its treatment as a comprehensive system.

In all titanium tube welding applications, the edges of the titanium sheet are melted, and upon squeezing together the edges of the titanium tube using a clamping bracket, solidification occurs. However, laser welding is characterized by its high-energy beam density.

The laser beam not only melts the surface of the material but also creates a keyhole, resulting in a narrow weld profile. To weld titanium alloy tubes, a flat titanium sheet is first formed and subsequently shaped into a cylindrical tube.

Once formed, the seams of the titanium alloy tube must be welded together. This seam significantly influences the part’s formability. Therefore, choosing the appropriate welding technique is crucial to achieve a weld profile that can meet the stringent testing requirements of the manufacturing industry.

Undoubtedly, Gas Tungsten Arc Welding (GTAW), High Frequency (HF) welding, and laser welding have each found their applications in the manufacturing of titanium alloy tubes.

As the founder of MachineMFG, I have dedicated over a decade of my career to the metalworking industry. My extensive experience has allowed me to become an expert in the fields of sheet metal fabrication, machining, mechanical engineering, and machine tools for metals. I am constantly thinking, reading, and writing about these subjects, constantly striving to stay at the forefront of my field. Let my knowledge and expertise be an asset to your business.