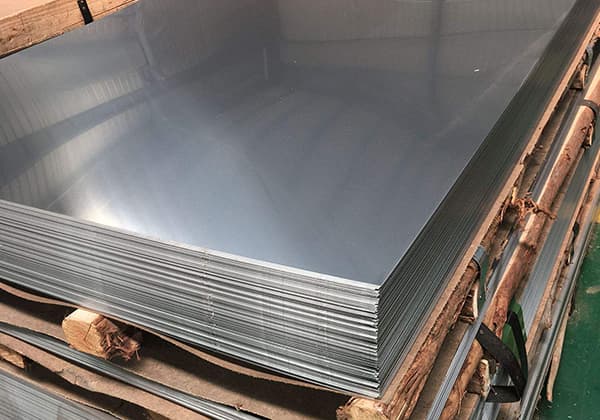

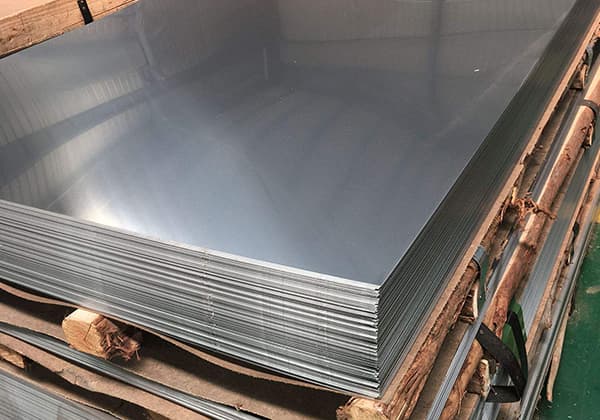

Did you know that a 5mm thick stainless steel plate isn’t always exactly 5mm thick? The actual thickness typically ranges between 4.5mm and 5.2mm, depending on whether it’s hot-rolled or cold-rolled. This article delves into national standards for these deviations, explaining the allowable tolerances and how they vary by plate width and manufacturing process. Readers will gain a clear understanding of the precise tolerances defined by standards like GB/T24511-2017, ensuring accuracy in their engineering projects.

According to GB/T24511-2017, the Chinese national standard for Stainless Steel and Heat-Resisting Steel Plates and Strips for Pressure Equipment, the actual thickness of a nominal 5mm thick stainless steel plate falls within a specific tolerance range. This standard distinguishes between hot-rolled and cold-rolled products, each with its own tolerance specifications.

For hot-rolled stainless steel plates with a nominal thickness of 5mm, the tolerance range is -0.35mm to +0.45mm. This means the actual thickness can vary from 4.65mm to 5.45mm. For cold-rolled plates of the same nominal thickness, the tolerance is tighter, typically ±0.20mm, resulting in an actual thickness range of 4.80mm to 5.20mm.

It’s important to note that these tolerances are critical for various engineering applications, affecting factors such as weight calculations, fitting precision, and overall structural integrity. In practice, manufacturers often aim for the middle of the tolerance range to ensure consistent quality. For precise applications, it’s advisable to specify the exact thickness requirements or consult with the supplier about their manufacturing capabilities and quality control measures.

The error of 5mm of the non inductive steel plate is as follows:

Allowable thickness deviation of hot rolled steel plate and strip

According to national standard (G5/T24,511-2017)

| National standard for actual thickness of 5mm thick stainless steel plate | Accuracy class | Width range (mm) | |||

| ≤1200 | >1200~1500 | >1500~1800 | >1800~2100 | ||

| PT.A | +0.31 -0.30 | +0.33 -0.30 | +0.36 -0.30 | +0.38 -0.30 | |

| PT.B | ±0.28 | ±0.30 | +0.33 -0.30 | +0.35 -0.30 | |

Note:

Allowable thickness deviation of cold rolled steel plate and strip

According to national standard GB/T24511-2017

| National standard for actual thickness of 5mm thick stainless steel plate | Width range (mm) | |||

| ≤1000 | >1000~1300 | >1300~2100 | ||

| Accuracy | ±0.14 | ±0.15 | ±0.15 | |

2. According to GB/T4237-2015 Hot Rolled Stainless Steel Plate and Strip, 5mm stainless steel plate can be divided into thick steel plate, steel strip and coiled steel plate, as follows:

Allowable thickness deviation of thick steel plate

According to the national standard GB/T4237-2015

| 5mm thick stainless steel plate | Accuracy class | Width range (mm) | ||||

|---|---|---|---|---|---|---|

| 1000 | >1000~1500 | >1500~2000 | >2000~2500 | >2500~4800 | ||

| National standard for actual thickness | PT.A | ±0.31 | ±0.33 | ±0.36 | ±0.41 | ±0.65 |

| PT.B | ±0.28 | ±0.30 | ±0.34 | ±0.36 | ||

Note:

Allowable thickness deviation of steel strip and rolled steel plate

According to national standard GB/T4237-2015

| National standard for actual thickness of 5mm thick stainless steel strip | Accuracy class | Width range (mm) | |||

| 1200 | >1200~1500 | >1500~1800 | 1800~2500 | ||

| PT.A | ±0.33 | ±0.33 | ±0.36 | ±0.38 | |

| PT.B | ±0.31 | ±0.30 | ±0.33 | ±0.35 | |

Note:

Allowable thickness deviation of wide steel strip and rolled steel plate

According to national standard GB/T3280-2015

| National standard for actual thickness of 5mm thick stainless steel plate and strip | Width range (mm) | ||

| <1250 | 1250-2100 | ||

| Accuracy requirements | ±0.4 | ±0.45 | |

Note:

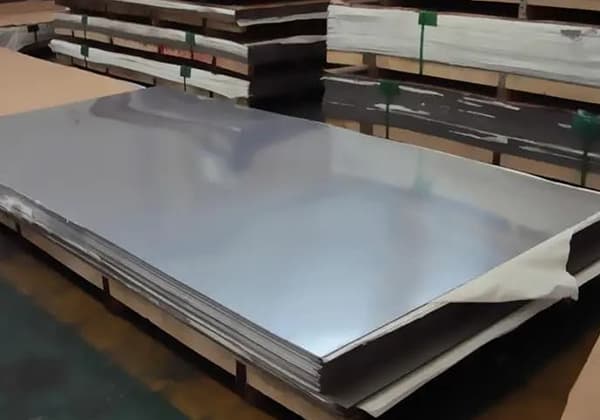

Example: What is the National Standard Tolerance for 5mm Thick 304 Plate?

The national standard tolerance for 5mm thick 304 stainless steel plate is governed by GB/T 24511-2017, “Stainless Steel and Heat-Resistant Steel Plates and Strips for Pressure Equipment.” This standard specifies thickness tolerances based on the manufacturing process and plate dimensions.

For hot-rolled 304 stainless steel plate with a nominal thickness of 5mm and width of 1500mm, the lower thickness tolerance is -0.3mm. This means the actual thickness should not be less than 4.7mm (5mm – 0.3mm).

In the case of cold-rolled 304 stainless steel plate with the same nominal thickness (5mm) and width (1500mm), the standard specifies a tighter tolerance. The lower thickness tolerance for cold-rolled plate is -0.15mm, resulting in a minimum allowable thickness of 4.85mm (5mm – 0.15mm).

It’s crucial to note that these tolerances represent the minimum acceptable thickness. The upper tolerance is typically not specified, allowing for slight overages in thickness. However, excessive thickness can impact weight calculations, material costs, and downstream fabrication processes.

When sourcing or working with 304 stainless steel plate, it’s essential to consider these tolerances for quality control, design calculations, and manufacturing processes. Proper measurement and verification of plate thickness using calibrated instruments are necessary to ensure compliance with GB/T 24511-2017 and maintain consistent product quality.