Have you ever wondered why CNC machining tools fail prematurely? Tool damage and wear can disrupt production, leading to costly delays. This article explores common issues like micro-chipping, thermal cracking, and abrasive wear, providing insights into their causes and solutions. By understanding these problems, you can enhance tool longevity and efficiency in your machining processes. Dive in to learn how to identify and mitigate these challenges for smoother operations and better results.

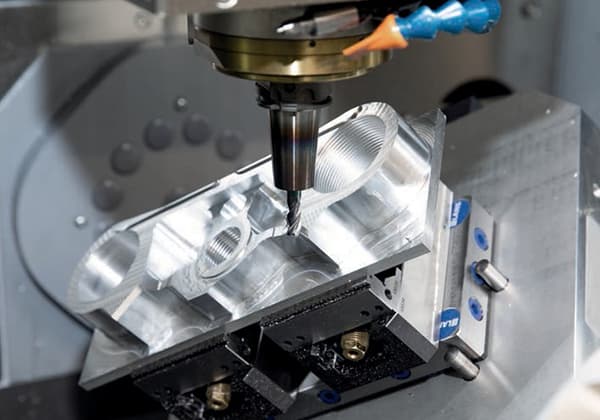

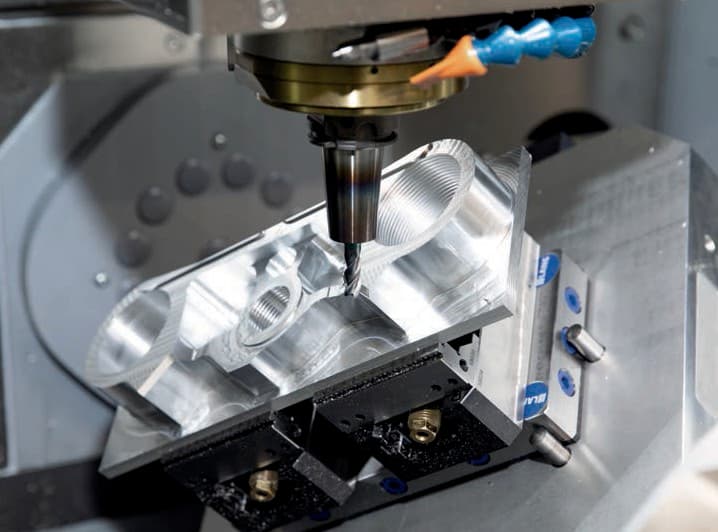

For a machining center, cutting tools are considered consumable tools, and during the machining process, they can experience damage, wear, and chipping.

These occurrences are unavoidable, but they can also be caused by controllable factors such as unscientific and non-standard operation, improper maintenance, etc.

Finding the root cause is key to resolving the issue more effectively.

When the material structure, hardness, and stock of the workpiece are uneven, the front angle is too large, causing the cutting edge strength to be low, the process system rigidity is insufficient, causing vibration, or performing intermittent cutting, and the grinding quality is poor, the cutting edge is prone to micro-chipping, that is, small fractures, gaps, or peelings appear in the edge area.

After this occurs, the tool will lose some of its cutting ability, but it can still continue to work.

During continued cutting, the damaged area of the edge may rapidly expand, leading to greater damage.

2)Breaking of cutting edge or tip

This type of damage occurs under more severe cutting conditions than micro-chipping or as a result of further development of micro-chipping.

The size and range of the breakage is larger than that of micro-chipping, causing the tool to completely lose its cutting ability and have to stop working. Breaking of the tip is commonly referred to as tip breakage.

3)Breaking of blade or tool

Under extremely severe cutting conditions, excessive cutting volume, impact loads, micro-cracks in the blade or tool material, residual stress from welding or grinding, and other factors such as careless operation, the blade or tool may break. After this type of damage occurs, the tool cannot be used anymore and is scrapped.

4)Peeling of the surface layer of the blade

For materials with high brittleness, such as hard alloys with high TiC content, ceramics, PCBN, etc., the surface layer may peel due to defects or potential cracks in the surface layer or residual stress from welding or grinding.

When the surface is not stable enough during cutting or the surface of the tool is subjected to alternating contact stress, peeling is likely to occur.

Peeling may occur on the front face or the back face of the tool, with peeling material in the form of sheets and a large peeling area. The likelihood of peeling is greater for coated tools.

After slight peeling, the tool can still continue to work, but after severe peeling, it will lose its cutting ability.

5)Plastic deformation of the cutting portion

Due to low strength and low hardness, plastic deformation may occur in the cutting portion of carbon steel and high-speed steel.

When hard alloys work under high temperature and triaxial stress conditions, surface plastic flow may also occur, causing plastic deformation of the cutting edge or tip, leading to collapse.

Collapse usually occurs under conditions of large cutting volume and processing of hard materials. The anti-plastic deformation ability of TiC-based hard alloys is faster or fails more quickly than that of WC-based hard alloys because the former has a lower modulus of elasticity. PCD and PCBN basically do not experience plastic deformation.

6)Thermal cracking of the blade

When the tool is subjected to alternating mechanical loads and thermal loads, repeated thermal expansion and contraction of the cutting portion surface will inevitably generate alternating thermal stress, causing fatigue and cracking of the blade.

For example, when high-speed milling with a hard alloy milling cutter, the teeth are constantly subjected to periodic impact and alternating thermal stress, resulting in comb-shaped cracks on the front face.

Although some tools do not have obvious alternating loads and alternating stresses, temperature differences between the surface and inner layers will also generate thermal stress.

In addition, defects are inevitably present in the tool material, so the blade may also crack. After the formation of cracks, the tool can sometimes continue to work for a period of time, but sometimes the cracks quickly expand, causing the blade to break or the surface to severely peel.

1)Abrasive Wear

The workpiece often contains some extremely high-hardness small particles that can scrape grooves on the tool surface, this is abrasive wear.

Abrasive wear exists on all surfaces and is most obvious on the front cutting edge.

Abrasive wear can occur at all cutting speeds, but when cutting at low speed, other types of wear are not obvious due to the low cutting temperature, so abrasive wear is the main cause. The lower the tool hardness, the more severe the abrasive wear.

2)Cold Welding Wear

During cutting, there is a great pressure and intense friction between the workpiece and the cutting edge, resulting in cold welding.

Due to the relative motion between the friction pair, cold welding causes the fracture to be taken away by one party, resulting in cold welding wear. Cold welding wear is generally more severe at moderate cutting speeds.

According to experiments, brittle metals have better resistance to cold welding than plastic metals; multi-phase metals are smaller than monophase metals; metal compounds have a lower tendency to cold welding than pure metals; the B-group elements in the periodic table and iron have a lower tendency to cold welding.

High-speed steel and hard alloys are more susceptible to cold welding at low cutting speeds.

3)Diffusion Wear

During high-temperature cutting and contact between the workpiece and tool, the two sides’ chemical elements diffuse into each other in the solid state, changing the composition and structure of the tool, making the tool surface brittle and accelerating tool wear.

Diffusion always maintains a deep gradient from the high-gradient object to the low-gradient object.

For example, when cobalt in a hard alloy is cut at 800°C, it quickly diffuses into the chips and workpiece; WC decomposes into tungsten and carbon and diffuses into steel; when cutting steel and iron with a PCD tool, if the cutting temperature is higher than 800°C, carbon atoms in the PCD will transfer to the workpiece surface with a high diffusion strength to form a new alloy and the tool surface will become graphitized.

Cobalt and tungsten have more severe diffusion, while titanium, tantalum, niobium have stronger anti-diffusion ability, so YT-type hard alloys have better wear resistance.

During cutting of ceramics and PCBN, diffusion wear is not significant when the temperature is as high as 1000°C-1300°C.

Due to the material of the workpiece, chips, and tool, a thermoelectric potential will be generated during cutting contact, which promotes diffusion and accelerates tool wear.

This type of diffusion wear under the action of thermoelectric potential is called “thermoelectric wear”.

4)Oxidation Wear

When the temperature rises, the surface of the cutting tool may oxidize, creating a soft oxide that is abraded by the chips and causing wear. This type of wear is called oxidation wear.

For example, in the temperature range of 700-800°C, oxygen in the air reacts with cobalt and carbides in cemented carbides, and with carbide titanium, forming a softer oxide. At 1000°C, PCBN reacts with water vapor.

1)Front Cutting Edge Wear:

During cutting with a larger speed of plastic materials, the front cutting edge near the cutting force will wear into a crescent shape due to the effect of chips, thus it is also called crescent groove wear.

In the early stage of wear, the front angle of the tool increases, improving the cutting conditions and helping to bend and break the chips.

However, as the crescent groove becomes larger, the cutting edge strength weakens, and finally the cutting edge may break.

Crescent groove wear does not occur when cutting brittle materials or when cutting plastic materials with a lower cutting speed and a thinner cutting thickness.

2)Cutting Tip Wear:

Cutting tip wear is the wear on the back cutting edge and the adjacent side of the back cutting edge of the cutting tip arc.

It is a continuation of the wear on the back cutting edge of the tool. Due to the poor heat dissipation conditions here, the stress concentrates, and therefore the wear rate is faster than the back cutting edge.

Sometimes, a series of grooves with a spacing equal to the feed rate will be formed on the side of the back cutting edge, called groove wear.

They are mainly caused by the hardening layer and cutting pattern on the machined surface.

Groove wear is most likely to occur when cutting difficult-to-cut materials with a high hardening tendency.

Cutting tip wear has the greatest impact on the surface roughness and machining accuracy of the workpiece.

3)Back Cutting Edge Wear:

When cutting plastic materials with a large cutting thickness, the back cutting edge of the tool may not be in contact with the workpiece due to the existence of built-up edge.

In addition, the back cutting edge usually comes into contact with the workpiece, forming a wear band with a back angle of 0.

Usually, in the middle of the working length of the cutting edge, the back cutting edge wear is relatively uniform, so the degree of back cutting edge wear can be measured by the width of the wear band VB on this section of the cutting edge.

Since almost all types of tools will experience back cutting edge wear under different cutting conditions, especially when cutting brittle materials or cutting plastic materials with a smaller cutting thickness, the main wear of the tool is back cutting edge wear.

And the measurement of the width of the wear band VB is simple, so VB is often used to represent the degree of tool wear.

The larger VB is, the more cutting force will increase, causing cutting vibration, and also affecting the wear at the cutting tip arc, thus affecting the machining accuracy and surface quality.

Based on the characteristics of the material and parts being machined, select the type and grade of blade material reasonably. Ensure that the blade material has necessary toughness under the premise of having a certain hardness and wear resistance.

Select the blade geometry parameters reasonably. Adjust the front and back angles, main and secondary relief angles, and rake angles to ensure that the cutting edge and tip have good strength. Grinding a negative rake on the cutting edge is an effective measure to prevent blade breakage.

Ensure the quality of welding and grinding, and avoid various defects caused by poor welding and grinding. The key blades used in the process should be ground to improve surface quality and checked for cracks.

Choose the cutting amount reasonably to avoid excessive cutting force and high cutting temperature and prevent blade breakage.

Make the process system as rigid as possible to reduce vibration.

Use the correct operation method to minimize the blade’s exposure to sudden loads.

1. Improper selection of tool blade specification and grade, such as blade being too thin or using a blade with too high hardness and brittleness during rough machining.

Countermeasures: Increase the thickness of the blade or install the blade vertically and select a grade with higher bending strength and toughness.

2. Improper selection of tool geometry parameters (such as excessive front and back angles).

Countermeasures:

Redesign the tool from the following aspects:

1)Reduce the front and back angles appropriately.

2)Adopt a larger negative blade inclination angle.

3)Reduce the main inclination angle.

4)Adopt a larger negative rake or blade edge circular arc.

5)Grind the transitional cutting edge to strengthen the tool tip.

3. Incorrect tool blade welding process, resulting in excessive welding stress or welding cracks.

Countermeasures:

1)Avoid using a blade slot structure with three-side enclosure.

2)Select the correct welding material.

3)Avoid using oxygen-acetylene flame heating and keep the blade warm after welding to eliminate internal stress.

4)Replace the structure with mechanical clamping as much as possible.

4. Improper grinding method, resulting in grinding stress and grinding cracks. For PCBN milling tools, excessive tooth sway after grinding can cause individual teeth to bear excessive loads and cause breakage.

Countermeasures:

1)Use intermittent grinding or diamond abrasive grinding.

2)Select a softer abrasive wheel and frequently sharpen it.

3)Pay attention to the grinding quality and strictly control the tooth sway of the milling tool.

5. Improper selection of cutting amount, such as excessive cutting force and temperature, causing tool breakage.

Countermeasures: Re-select the cutting amount.

6. Structural reasons for mechanical clamping type tools, such as uneven bottom of tool slot or blade protruding too long.

Countermeasures:

1)Repair the bottom of the tool slot.

2)Arrange the cutting fluid nozzle position reasonably.

3)Increase the hardness of the alloy spacer under the blade by quenching the shank.

7. Excessive tool wear.

Countermeasures: Change the blade or change the cutting edge in time.

8. Insufficient cutting fluid flow or incorrect addition method, causing blade to overheat and break.

Countermeasures:

1)Increase the flow of cutting fluid.

2)Arrange the cutting fluid nozzle position reasonably.

3)Use effective cooling methods such as spray cooling to improve cooling efficiency.

4)Use interrupted cutting to reduce the impact on the blade.

9. Incorrect tool installation, such as cut-off tool installed too high or low, end mill using asymmetrical milling, etc.

Countermeasures: Reinstall the tool.

10. Poor rigidity of the process system, causing excessive cutting vibration.

Countermeasures:

1)Increase auxiliary support for the workpiece and improve the clamping rigidity of the workpiece.

2)Reduce the tool’s overhang length.

3)Reduce the tool’s back angle appropriately.

4)Adopt other vibration-damping measures.

11. Unsafe operation, such as too rough when cutting into the workpiece from the center, or stopping the machine before retracting the tool.

Countermeasures: Pay attention to the operating method.

1. Formation

In the area close to the cutting edge, where the tool-chip contact occurs, due to the high downward pressure, the metal at the bottom of the chips gets embedded into the microscopic peaks and valleys on the front of the cutting tool, forming a tight metal-to-metal contact that results in bonding.

This part of the tool-chip contact area is known as the bonding area. In the bonding area, a thin layer of metal material from the chips accumulates on the front of the cutting tool, which undergoes severe deformation and strengthening at appropriate cutting temperatures.

As the chips continue to flow out, this accumulated material is pushed away from the subsequent cutting flow and becomes the foundation for the built-up edge.

Then, a second layer of accumulated cutting material will form on top of it, and this process will continue to accumulate, forming a built-up edge.

2. Characteristics and Impact on Cutting Process

1)The hardness of the built-up edge is 1.5 to 2 times higher than the workpiece material, and it can substitute for the front of the cutting tool, protecting the cutting edge and reducing wear on the front of the cutting tool, but fragments of the built-up edge that fall off can cause wear on the back of the cutting tool when they flow through the tool-workpiece contact area.

2)After the built-up edge is formed, the working front angle of the tool increases, which actively reduces the deformation of chips and cuts down on cutting force.

3)Due to the built-up edge protruding from the cutting edge, the actual cutting depth increases, affecting the dimensional accuracy of the workpiece.

4)The built-up edge causes a “plowing” effect on the surface of the workpiece, affecting its surface roughness.

5)The fragments of the built-up edge can adhere or embed into the surface of the workpiece, causing hard points and affecting the quality of the machined surface of the workpiece.

From the above analysis, it can be seen that the built-up edge is detrimental to cutting processing, especially to precision machining.

3. Control Measures

To avoid the formation of built-up edge, the following measures can be taken to prevent metal at the bottom of the chips from bonding or strengthening with the front of the cutting tool:

1)Reduce the roughness of the front of the cutting tool.

2)Increase the front angle of the tool.

3)Reduce the cutting thickness.

4)Use low-speed or high-speed cutting to avoid cutting speeds that are prone to forming built-up edge.

5)Heat treat the workpiece material appropriately to increase its hardness and reduce its plasticity.

6)Use cutting fluids with good anti-bonding properties (such as extreme pressure cutting fluids containing sulfur and chlorine).