Ever wondered which companies lead the way in China’s machine tool industry? This article introduces the top 10 boring machine manufacturers, detailing their histories, innovations, and contributions to the field. From SMTCL’s advanced technologies to DMTG’s global collaborations, discover how these industry giants are shaping the future of precision machining. Expect to learn about their flagship products, key achievements, and strategic goals in revolutionizing the sector.

Shenyang Machine Tool, established in 1993 with a heritage dating back to 1933, is a prominent force in China’s machine tool industry. Listed on the Shenzhen Stock Exchange (stock code: 000410), the company emerged from the consolidation of four industry pioneers, including the renowned Shenyang First Machine Tool Factory.

Specializing in high-precision machine tools, Shenyang Machine Tool manufactures a diverse range of lathes and machining centers known for their accuracy and longevity. Since 2010, the company has demonstrated significant innovation by incorporating cutting-edge technologies and advanced materials. A notable example is the integration of LZA4205 microcrystalline alloy in CNC turrets, which has substantially enhanced product performance and cost-efficiency.

Beyond manufacturing, Shenyang Machine Tool offers comprehensive services in the SMTCL lathe machine spare parts sector. These services encompass sales, maintenance, technical consulting, and operator training, all designed to optimize customer experience and maximize value in the selection and utilization of machine tool components.

The company plays a pivotal role in the Shenyang CNC Machine Tool Industrial Park, a state-of-the-art manufacturing complex that brings together nine major enterprises. This strategic initiative underscores Shenyang Machine Tool’s commitment to driving global industry leadership through technological innovation and uncompromising quality standards.

Shenyang Machine Tool’s product portfolio includes advanced CNC lathes, multi-axis machining centers, and specialized tooling systems. The company’s R&D efforts focus on enhancing machining precision, improving energy efficiency, and developing smart manufacturing solutions. Their commitment to Industry 4.0 principles is evident in the integration of IoT technologies and data analytics in their latest machine tool designs, enabling predictive maintenance and real-time performance optimization.

Founded in 1935 and operating as a subsidiary of China General Technology Group, Dalian Machine Tool Company Limited has established itself as a leading innovator and manufacturer of advanced CNC machine tools, flexible manufacturing systems, and comprehensive automation equipment. The company’s expertise in CNC technology has positioned it as a crucial hub for the industrialization of high-precision functional components in China’s manufacturing landscape.

Evolving from its roots as Dalian Machine Tool Factory, the company has undergone strategic expansions through mergers and acquisitions. A significant milestone was reached in 1995 with the consolidation of several state-owned machine tool enterprises in the Dalian region, followed by the integration of the Dalian Combination Machine Tool Research Institute in 2000. This merger enhanced the company’s research and development capabilities, fostering technological innovation. Post-2002, Dalian Machine Tool Group embarked on a global expansion strategy, acquiring international entities such as the American Ingersoll Production Systems and forming joint ventures with partners from the United States, Germany, Japan, Switzerland, and South Korea. These collaborations have facilitated technology transfer and cross-cultural expertise exchange, bolstering the company’s global competitiveness.

Leveraging national policies aimed at revitalizing Northeast China’s traditional industrial base, Dalian Machine Tool has invested in two state-of-the-art production facilities in Dalian Port and Wafangdian. These modern manufacturing centers have propelled the company to the forefront of CNC machine tool and functional component production in China, both in terms of scale and technological sophistication. The company’s diverse product portfolio includes advanced CNC flexible machine tools, intelligent manufacturing units, five-axis machining centers, and high-speed precision centers. Many of these products not only lead the domestic market but also meet or exceed international standards, showcasing the company’s commitment to precision engineering and innovation.

Throughout its 80-year history, Dalian Machine Tool has delivered over 500,000 units to a wide range of industries, including automotive manufacturing, rail transportation, aerospace, and mining sectors, with its machinery operating in more than 100 countries. This global reach underscores the company’s reputation for reliability and performance. Committed to empowering China’s manufacturing sector, Dalian Machine Tool has developed an extensive sales and service network. This infrastructure ensures prompt delivery, responsive after-sales support, and comprehensive customer satisfaction. By adopting an integrated approach to marketing and service, the company aims to forge strong, long-lasting partnerships with its clients, driving mutual growth and innovation in the machine tool industry.

Qinchuan Machine Tool Group Co., Ltd. (Stock Code: 000837), established in 1965, has emerged as a preeminent manufacturer of high-precision CNC machine tools and sophisticated metrology instruments in China. As a leading systems integrator and critical component supplier in the advanced equipment manufacturing sector, Qinchuan’s product portfolio encompasses state-of-the-art CNC lathes, multi-axis machining centers, precision cylindrical grinders, gear cutting and finishing machines, thread grinding systems, high-accuracy measuring instruments, and complex CNC tooling solutions.

Recognized as a cornerstone of China’s machine tool industry and a nexus for technological innovation, Qinchuan incorporates several renowned subsidiaries, including Baoji Machine Tools and Hanjiang Machine Tools. The company’s focus on pioneering core technologies for industrial mother machines has garnered numerous accolades, including prestigious national science and technology awards. Moreover, the “Qinchuan” trademark has been distinguished as a well-known Chinese brand, underscoring its reputation for quality and innovation.

Qinchuan’s corporate ethos, “equipping China and reaching the world,” is manifested in its strategic development initiatives. These include spearheading advancements in high-end manufacturing processes, developing and supplying critical components, pushing the boundaries of intelligent manufacturing and CNC technologies, and actively participating in national R&D projects. The company’s ambitious “5221” development framework outlines its aspiration to become a globally recognized provider of comprehensive system integration services and a key supplier of mission-critical components in the realm of advanced equipment manufacturing.

Established in 1937, Jinan Second Machine Tool Group Co., Ltd. (Jinan No.2 Machine Tool) has evolved into a leading manufacturer of stamping equipment, renowned for its extensive capabilities in forging machinery and large heavy-duty metal cutting machine tools. With over 5,000 employees and a 1.23 million square meter campus, the company has been instrumental in China’s industrial advancement, producing the nation’s first gantry planer in 1953 and mechanical press in 1955, earning it the titles “Home of the Gantry Planer” and “Cradle of the Mechanical Press.”

As a backbone enterprise in China’s machine tool industry and one of the “Eighteen Arhats” of the sector, Jinan No.2 Machine Tool offers a comprehensive product portfolio. This state-owned enterprise specializes in forging equipment, CNC metal cutting machine tools, automation systems, casting machinery, and CNC cutting devices. Their products serve critical industries including automotive, aerospace, rail transit, energy, shipbuilding, metallurgy, mold manufacturing, and construction machinery, with exports reaching 67 countries and regions.

The company has developed over 600 products, many pioneering in China, providing crucial support across various industrial sectors. As one of the world’s top three CNC stamping equipment manufacturers, Jinan No.2 Machine Tool dominates the Chinese market for large and heavy-duty mechanical presses. It has supplied hundreds of large-scale stamping production lines and heavy-duty presses to the domestic automotive industry and other sectors, showcasing its technological prowess and market leadership.

Recognized by the State Council for its significant contributions to major technical equipment, Jinan No.2 Machine Tool offers a comprehensive range of services. These include pre-sales consultations, after-sales support, machine tool refurbishment, spare parts supply, and external collaborations on castings, forgings, welded parts, and precision machined components. The company’s product lines are diverse, with mechanical press capacities ranging from 60 to 5000 tons, encompassing various machinery such as production lines, large multi-position presses, CNC hydraulic presses, and CNC bending machines.

Jinan No.2 Machine Tool’s automation equipment, casting machinery, and environmental building material devices have experienced rapid growth, boasting the most extensive product range and specifications in China’s machine tool industry. Since 1997, the company has supplied over ten stamping production lines to renowned global automotive manufacturers. Notably, since 2001, it has been exporting heavy machinery presses with full intellectual property rights to the high-end U.S. market, demonstrating its global competitiveness and technological innovation.

As a foundational enterprise for China’s automotive industry and a global leader in its field, Jinan No.2 Machine Tool continues to drive technological advancements and set industry standards. Its commitment to innovation, quality, and comprehensive solutions positions it at the forefront of the global machine tool and metal forming equipment market.

Founded in 1950, Qiqihar No.1 Machine Tool Plant, now operating as Qiqihar Heavy CNC Equipment Co., Ltd., stands as a pillar in China’s machine tool industry. Recognized as a “Little Giant” by the Ministry of Industry and Information Technology, this enterprise leads the market with its high-precision, heavy-duty CNC machine tools, commanding significant brand influence in the national equipment manufacturing sector.

The company specializes in large-scale vertical and horizontal lathes, with a focus on heavy-duty machining centers. Its comprehensive product portfolio encompasses over 600 variants across 10 major categories, including advanced heavy deep-hole drilling and boring machines, specialized roll lathes, and high-precision vertical grinding machines. Many of these cutting-edge products have filled critical technological gaps in domestic manufacturing capabilities and are exported to more than 30 countries and regions, including advanced markets in Europe, the Americas, Japan, and South Korea.

Qiqihar Heavy CNC Equipment maintains a first-class measurement enterprise status and is designated as a national high-tech enterprise by the Ministry of Science and Technology. The company’s innovation capabilities are bolstered by a state-level enterprise technology center and an R&D team led by industry experts with special government contributions and academic leaders in machine tool engineering. This robust research infrastructure enables the company to stay at the forefront of technological advancements in CNC machining and precision manufacturing.

Adhering to the philosophy of “Lean Manufacturing and Winning by Quality,” the company goes beyond traditional equipment supply to serve as a process advisor, offering integrated machining solutions that optimize production efficiency and product quality for its clients. This customer-centric approach ensures mutual benefit and long-term partnerships. Committed to innovation-driven development, Qiqihar Heavy CNC Equipment is actively pursuing digital transformation and intelligent manufacturing capabilities, aiming to evolve into a smart, service-oriented organization that drives high-quality corporate growth in the era of Industry 4.0.

Established in 1949, Beijing No.1 Machine Tool Co., Ltd. (BMT) stands as a paragon of China’s state-owned enterprises, specializing in the development and manufacture of high-precision CNC machine tools. BMT’s product portfolio encompasses a wide spectrum of advanced machining solutions, including ultra-heavy gantry milling machines capable of handling workpieces up to 600 tons, heavy-duty vertical lathes with cutting diameters reaching 20 meters, floor-type boring and milling machines with X-axis travel up to 50 meters, CNC inverted lathes for large-scale turbine rotor machining, and multi-axis turning-milling compound machine tools for complex part production.

Strategically located in the Zhongguancun Science Park in Shunyi, Beijing, BMT has expanded its global footprint through the acquisition of renowned international brands such as Waldrich Coburg in Germany, known for its heavy-duty machining centers, and C.B. Ferrari in Italy, a leader in high-speed milling technology. This synergy of Eastern and Western engineering expertise has positioned BMT at the forefront of machine tool innovation. The company’s commitment to technological advancement is evidenced by its national-level enterprise technology center and CNAS-certified testing and calibration laboratory, which adhere to ISO/IEC 17025 standards, ensuring the highest level of precision and reliability in their products.

BMT’s machine tools are integral to critical manufacturing processes across diverse industries. In the automotive sector, their five-axis machining centers enable the production of complex engine components with micron-level accuracy. For shipbuilding, BMT’s large-scale portal milling machines facilitate the efficient machining of propeller shafts and rudders. In power generation, their specialized vertical turning lathes are crucial for manufacturing turbine rotors with exceptional concentricity. The rail transport industry benefits from BMT’s floor-type boring mills for precise machining of locomotive frames, while their high-speed machining centers cater to the intricate requirements of mold-making and general machinery production.

The company’s dedication to innovation is reflected in its recent developments in smart manufacturing technologies. BMT has integrated IoT sensors and real-time monitoring systems into its latest machine tool models, enabling predictive maintenance and optimized production scheduling. Their proprietary control software incorporates machine learning algorithms for adaptive machining, significantly reducing setup times and improving overall equipment effectiveness (OEE).

BMT’s global vision is underpinned by a commitment to sustainable manufacturing practices. The company has implemented energy-efficient designs in its latest machine tools, reducing power consumption by up to 30% compared to previous generations. Additionally, BMT is pioneering the use of eco-friendly cutting fluids and chip recycling systems, aligning with international environmental standards and reinforcing its position as a responsible global manufacturer.

As BMT continues to push the boundaries of machining technology, it remains focused on fostering long-term partnerships with its customers, providing comprehensive after-sales support and customized training programs. This customer-centric approach, combined with its relentless pursuit of technological excellence, positions BMT as a key player in elevating China’s manufacturing capabilities and competing at the highest levels of the global machine tool industry.

Founded in 1950 and now a subsidiary of China General Technology Group, Qiqihar No. 2 Machine Tool (Group) Co., Ltd. is a renowned industrial enterprise specializing in the production of heavy and super-heavy CNC machine tools and large-scale forging and pressing equipment. With over seven decades of continuous innovation, the company has established itself as a cornerstone in China’s advanced manufacturing sector.

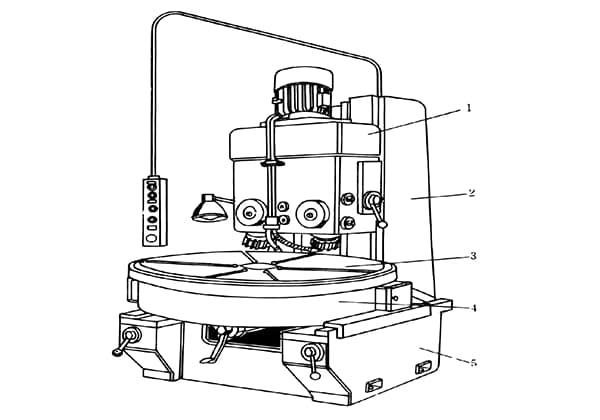

The company’s product portfolio is strategically divided into four main categories: precision metal cutting machine tools, high-performance metal forming equipment, specialized machinery, and comprehensive technical services. Their flagship products include state-of-the-art heavy CNC floor-type boring and milling machines, advanced CNC vertical and horizontal lathes, high-capacity mechanical presses, and custom-engineered machine tools tailored for specific industrial applications. Additionally, they offer value-added services such as machine tool retrofitting, remanufacturing, precision machining, and expert technical consultancy.

Qiqihar No. 2 Machine Tool’s equipment plays a crucial role in critical industries, including aerospace, naval engineering, automotive manufacturing, metallurgical processing, and rail transportation. The company has supplied over 2,000 major pieces of equipment to key domestic enterprises, significantly contributing to China’s industrial infrastructure and technological self-reliance.

With a workforce exceeding 4,500 employees, including a substantial number of professionals holding advanced technical titles and degrees, the company leverages its human capital for continuous innovation. Operating from a 450,000 square meter facility, including 160,000 square meters of advanced manufacturing space, Qiqihar No. 2 Machine Tool utilizes a state-of-the-art production line comprising 1,928 pieces of equipment. This includes 1,005 precision metal cutting machine tools and 225 large-scale, high-precision machines, many of which incorporate internationally advanced technologies and Industry 4.0 principles.

Throughout its history, Qiqihar No. 2 Machine Tool has achieved numerous technological milestones, including the development of China’s first indigenously designed CNC milling machine in 1958. The company has manufactured over 60,000 machine tools, with more than 1,000 units exceeding 100 tons in weight, addressing critical gaps in the national manufacturing capabilities. The “Qiqihar” brand, recognized as a “China Famous Trademark,” has become synonymous with reliability, precision, and innovation in the machine tool industry, solidifying its position as one of the most trusted names in Chinese industrial equipment manufacturing.

Founded in 1936, General Technology Group Kunming Machine Tool Co., Ltd. (formerly Central Machinery Factory) has evolved into a cornerstone of China’s precision machine tool manufacturing industry. Located at 23 Ciba Road, Kunming, Yunnan, the company boasts a 264,000 square meter campus with 140,000 square meters of built-up area. With a workforce of 940 and total assets of 1.3 billion yuan, it stands as a formidable player in the sector.

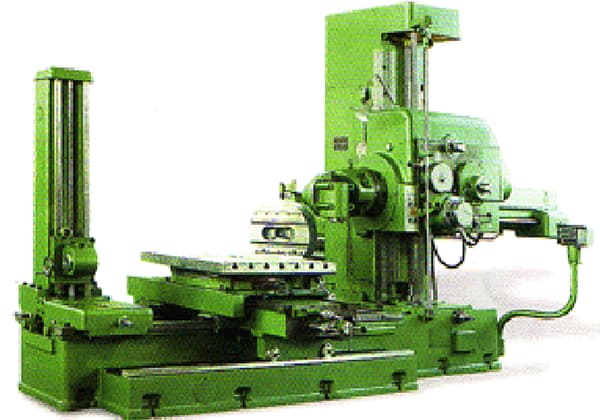

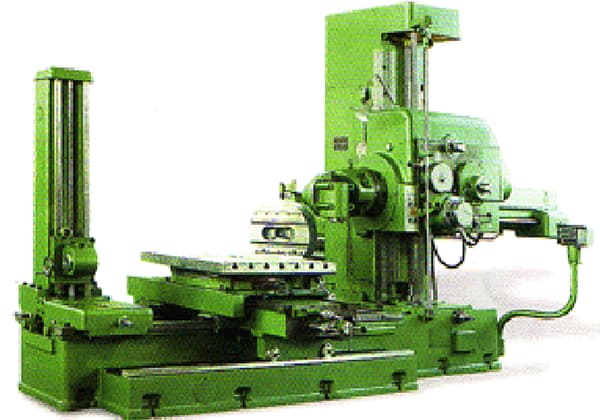

Kunming Machine Tool’s product portfolio encompasses a wide range of high-precision machine tools, including the KIKI Smart Series, KITI Series, KHC-AUTO Series, and advanced THM/TGK and KiMi Series. Their offerings include horizontal boring and milling machines, floor-type boring and milling machines, gantry milling and boring machines, coordinate boring machines, horizontal machining centers, and critical machine tool components. Each series is designed to meet specific industrial needs, incorporating cutting-edge CNC technology and advanced materials for optimal performance and longevity.

The company’s legacy of innovation dates back to 1945 when it produced China’s first horizontal boring machine, followed by the country’s inaugural coordinate boring machine in 1958. These milestones underscore Kunming Machine Tool’s pivotal role in China’s industrial development. The firm’s commitment to excellence culminated in winning the National Quality Gold Award for their T42100 coordinate boring machine in 1980, a testament to their precision engineering capabilities and stringent quality control measures.

As a subsidiary of the General Technology Group, Kunming Machine Tool continues to push the boundaries of precision manufacturing. Their R&D efforts focus on enhancing machine accuracy, developing smart manufacturing solutions, and improving energy efficiency. The company’s products now incorporate features such as adaptive control systems, real-time monitoring, and predictive maintenance capabilities, aligning with Industry 4.0 trends.

Kunming Machine Tool’s global presence has expanded, with their machines exported to over 30 countries. They have established strategic partnerships with international technology leaders, facilitating knowledge exchange and continuous improvement in their manufacturing processes. This global outlook, combined with their deep understanding of domestic market needs, positions the company to meet the evolving demands of both Chinese and international customers in sectors ranging from aerospace and automotive to energy and general machinery.

Founded in 1965, Baoji Machine Tool Group has established itself as a premier developer and manufacturer of CNC machine tools in China. As a critical hub for CNC machine tool research, production, and intelligent manufacturing, the company is spearheading industry advancements with its intelligent machine tools, flexible machining cells, smart manufacturing systems, and automated production lines.

Driven by a mission to craft high-quality Chinese machine tools through precision engineering and smart manufacturing, Baoji Machine Tool Group operates under a management philosophy that synergizes intelligent guidance with the dual drivers of craftsmanship and global service excellence. The company’s impressive portfolio includes 12 subsidiaries, total assets valued at 2 billion yuan, a skilled workforce of 3,500, an annual production capacity of 20,000 machine tools, revenues of 3 billion yuan, and export trade generating 30 million USD.

Baoji Machine Tool Group excels in innovation, having developed a comprehensive R&D and manufacturing ecosystem that integrates talent, cutting-edge technology, and brand strength. Its diverse product range encompasses over 200 varieties across 400 specifications in 14 major categories, catering to high-demand sectors such as automotive, aerospace, engineering machinery, agricultural equipment, and educational institutions. The company has successfully undertaken more than 30 national key projects and the strategic “Brain Replacement Project,” while operating five global marketing and service centers, solidifying its position as an influential supplier in the intelligent evolution of the industry’s supply chain.

With a strong emphasis on talent development, the company has implemented a “High-Skill Talent Quality Improvement Project,” creating a multi-tiered talent development pathway from technical experts to “Baoji Craftsmen.” This strategic initiative has fostered a multi-level team of skilled artisans and innovators, crucial for maintaining the company’s technological edge.

Baoji Machine Tool Group is at the forefront of second-level development and optimization of CNC systems and robotics, collaborating on the creation of next-generation intelligent machine tools. By seamlessly integrating advanced manufacturing technologies with big data analytics and cloud computing platforms, the company is accelerating its transformation towards intelligent manufacturing, with the ambitious goal of establishing a fully digital factory by 2024.

The company’s commitment to excellence has earned it numerous accolades, including national awards and recognition for its outstanding contributions to quality, innovation, and integrity within the machine tool industry. Looking ahead, Baoji Machine Tool Group remains dedicated to high-quality development, customer-centric innovation, market and product transformation, and the establishment of a state-of-the-art R&D and manufacturing base for complex turning and milling centers. Through these initiatives, the company is poised to solidify its position as a top-tier supplier of high-end equipment in the global market.

Wuhan Heavy Duty Machine Tool Group Co., Ltd., a subsidiary of China North Industries Group Corporation, stands as a cornerstone enterprise in China’s machine tool industry, offering an extensive range of heavy and super-heavy machine tools. Originally established as one of the 156 key projects during China’s First Five-Year Plan, the company has undergone a comprehensive relocation and transformation to emerge as a leading research and development base for CNC heavy and super-heavy machine tools.

With a workforce exceeding 3,000 employees, including over 600 engineering and technical experts—seven of whom are recognized as national-level specialists—the company boasts a formidable knowledge base. Its product portfolio encompasses more than 400 varieties across 50+ series, including advanced heavy and super-heavy vertical and horizontal lathes, floor-type milling and boring machines, gear hobbing machines, and specialized equipment for sectors such as mining and railways. The company has fully embraced the integration of numerical control systems and multifunctional capabilities, positioning itself at the forefront of smart manufacturing trends.

The enterprise has made significant contributions to China’s manufacturing sector by developing high-end CNC machine tools with proprietary intellectual property rights, supporting critical national projects. Through the execution of various national and provincial research initiatives, the company has garnered numerous awards for its innovative products. Notable examples include the DL250 super-heavy CNC horizontal boring machine, featuring advanced thermal compensation and high-precision spindle technology, and the CKX5680 CNC seven-axis five-linkage turning and milling compound machine, which integrates complex machining operations into a single setup, dramatically improving efficiency and accuracy.

Moreover, the company has played a pivotal role in shaping industry standards, having set and revised 36 heavy machine tool standards. This commitment to standardization ensures interoperability and quality across the sector. The accumulation of over 120 national patents underscores the company’s dedication to innovation and technological advancement in areas such as adaptive control systems, high-speed spindle design, and energy-efficient machining processes.

The Wuhan Heavy Duty Machine Tool Group is strategically focused on integrating machine tools with specialized machinery, aiming to build comprehensive industry, value, and service chains. By concentrating on high-end, intelligent, and niche equipment, the company is positioning itself as a world-class systems integrator and provider of key components in the high-end equipment manufacturing sector. This approach is driven by a commitment to innovation, sustainable development, and Industry 4.0 principles, including the implementation of IoT technologies for predictive maintenance and real-time production optimization.