Have you ever wondered who leads the way in China’s milling machine industry? This article showcases the top 10 milling machine manufacturers in China, revealing industry giants like WZ Wuhan and Baoji Machine Tool Group. You’ll discover their innovative contributions, extensive product lines, and global influence. Dive in to explore how these companies are shaping the future of CNC technology and high-end equipment manufacturing. Gain insights on the advancements driving China’s dominance in the milling machine market and what it means for the industry worldwide.

China has become a significant player in the global manufacturing industry, particularly in the production of milling machines. Chinese milling machines are known for their cost-effectiveness, diverse range, and increasingly sophisticated technology. Manufacturers in China produce various types of milling machines, including universal milling machines, CNC milling machines, vertical machining centers, and horizontal milling machines.

Chinese manufacturers have invested heavily in advanced manufacturing technologies and infrastructure. This investment has enabled them to produce high-quality milling machines that meet international standards. For instance, companies like Dalian Machine Tool Group and Shenyang Machine Tool Co. have adopted cutting-edge production techniques, resulting in machines that are both durable and precise. The integration of CNC systems from renowned brands such as FANUC, Siemens, and Mitsubishi enhances the precision and reliability of these machines.

One of the key advantages of milling machines from China is their competitive pricing. Chinese manufacturers can offer lower prices due to economies of scale, lower labor costs, and efficient production processes. For example, a CNC milling machine from a Chinese manufacturer can cost up to 30% less than a similar machine from European or American manufacturers. This cost advantage makes Chinese milling machines an attractive option for businesses looking to optimize their investment without compromising on quality.

Chinese milling machines have evolved significantly over the years. Modern machines feature advanced CNC controls, multi-axis capabilities, and robust construction. The availability of 3-axis, 4-axis, and 5-axis machines allows for complex and precise machining tasks, catering to various industrial needs. For instance, the VMC850 vertical machining center from a Chinese manufacturer offers high-speed spindles and automatic tool changers, making it suitable for high-precision manufacturing. Additionally, innovations in spindle technology and table sizes further enhance the versatility and performance of these machines.

The diversity of milling machines available from China is another notable feature. Whether it’s a small workshop looking for a basic milling machine or a large manufacturing plant needing a sophisticated CNC machining center, Chinese suppliers offer a wide range of options to meet different requirements. This variety ensures that buyers can find machines tailored to their specific needs and applications. For example, the X5032 universal milling machine is ideal for educational institutions, while the XK5040 CNC milling machine is designed for industrial production.

Chinese manufacturers have made significant strides in improving the quality and reliability of their milling machines. Many companies have obtained ISO certifications and adhere to stringent quality control processes. This commitment to quality ensures that the machines are durable, efficient, and capable of delivering high-precision results. For example, the ISO 9001 certification held by many Chinese manufacturers is a testament to their adherence to international quality standards.

The global reach of Chinese milling machine manufacturers is expanding rapidly. Companies from various countries import these machines, recognizing their value and performance. Platforms like Alibaba and Made-in-China facilitate the purchasing process, providing access to a wide array of products and suppliers. For instance, the export data from China’s General Administration of Customs shows a steady increase in the export of machine tools, indicating a growing acceptance and demand for Chinese milling machines worldwide.

In conclusion, milling machines from China offer a compelling combination of affordability, advanced technology, and diverse options. These machines are well-suited for various industries, including automotive, aerospace, metalworking, and electronics. As Chinese manufacturers continue to innovate and improve their offerings, the global appeal of their milling machines is expected to grow even further.

Wuhan Heavy Duty Machine Tool Group Co., Ltd., a subsidiary of China North Industries Group Corporation (NORINCO Group), is a preeminent manufacturer of heavy and super-heavy machine tools in China, offering a comprehensive range of products with extreme specifications. Founded during China’s “First Five-Year Plan” as one of the 156 key national projects, the company has evolved into a cutting-edge research and development center for CNC heavy and super-heavy machine tools, as well as a premier international processing collaboration hub in central China following extensive modernization and relocation initiatives.

The company’s diverse product portfolio spans over 10 categories, including advanced CNC-controlled heavy and super-heavy vertical and horizontal lathes, floor-type milling and boring machines, gantry milling and boring machines, gear hobbing machines, rotary tables, tunnel boring machines, and specialized machinery equipment. With more than 400 product variants, all featuring computer numerical control (CNC) and multi-axis functionality, the company offers a wide range of high-precision manufacturing solutions. Additionally, it provides value-added services such as large-scale machine tool retrofitting, equipment remanufacturing, precision mechanical processing, and the production of complex castings and metal structural components. To date, over 20,000 machines developed by the company are operational across various industrial sectors, including energy, transportation, metallurgy, machinery, and railways, with exports reaching more than 40 countries and regions globally.

The company’s workforce of over 3,000 employees includes 600 highly skilled engineering and technical professionals, complemented by numerous national and provincial experts. This robust talent pool has been instrumental in driving significant advancements in China’s equipment manufacturing industry through pioneering research and development efforts. The company has successfully completed several national “863” high-tech research projects, major national scientific and technological initiatives, and numerous provincial and municipal research programs. These endeavors have resulted in the creation of a suite of high-end CNC machine tools with independent intellectual property rights, specifically designed to meet the exacting requirements of critical national projects.

Wuhan Heavy Duty Machine Tool Group’s commitment to innovation has garnered numerous accolades for its groundbreaking products. The company has played a pivotal role in setting and revising 36 heavy machine tool standards, participated in 47 national and industry standard evaluations, and secured over 120 national patents. Its excellence in manufacturing and technological innovation has earned it recognition as a model enterprise in service-oriented manufacturing, integration of informatization and industrialization, and intelligent manufacturing, among other distinctions.

Guided by the principle “Excellence in Mind, Significance in Action,” Wuhan Heavy Duty Machine Tool Group continues to refine its strategic focus on both heavy machine tools and specialized machinery. The company is actively strengthening related industry chains, value chains, and service chains to enhance its competitive edge. By driving the transformation towards “service +,” “product +,” and “Internet +” business models, the company aims to establish itself as a world-class system integrator and critical component supplier in the high-end equipment manufacturing sector. This strategic vision is underpinned by a commitment to sustainable, high-quality development, positioning the company at the forefront of technological innovation and manufacturing excellence in the global machine tool industry.

Founded in 1965, Baoji Machine Tool Group has established itself as a leading developer and manufacturer of CNC machine tools, serving as a crucial R&D and intelligent manufacturing base in China. The company’s mission is to craft superior Chinese machine tools through innovation, employing a management model that integrates intelligent guidance, technology and market-driven strategies, precision manufacturing, and global service. Overseeing 12 subsidiaries, the group boasts total assets of 20 billion yuan and a workforce of 3,500. With an annual output of 20,000 machine tools, Baoji Machine Tool Group generates 3 billion yuan in revenue and has consistently ranked among China’s top machine tool manufacturers, with exports valued at 30 million USD.

Baoji Machine Tool Group’s commitment to innovation is evident in its comprehensive R&D and manufacturing system, encompassing talent development, technological advancement, and brand building. The company’s product portfolio spans 14 major categories, over 200 varieties, and 400 specifications, with a focus on intelligent machine tools, flexible processing units, smart manufacturing cells, and automated production lines. These advanced solutions cater to diverse sectors, including automotive, aerospace, engineering machinery, agriculture, and vocational education. The group is involved in more than 30 national key projects, including the “Brain Replacement Project,” and operates five global marketing service centers, positioning itself as a key equipment supplier driving the intelligent evolution of the industry’s supply chain.

Leveraging the Shaanxi branch of the National CNC System Engineering Technology Research Center, Baoji Machine Tool Group excels in the secondary development of CNC systems and robotics, as well as the optimization of intelligent equipment solutions. The company collaborates on developing next-generation intelligent machine tools and has co-created domestic intelligent production lines for CNC machine tools and robots, ensuring critical automotive components are “Made in China.” By integrating cutting-edge manufacturing technologies with big data and cloud platforms, the group is accelerating its transition to intelligent manufacturing, aiming to establish a fully operational “digital factory” by 2024.

The company’s “talent strengthens enterprise” strategy is exemplified by its highly skilled personnel enhancement project. Baoji Machine Tool Group has implemented a five-tier skill development pathway for technical experts and fostered a multi-level team of artisans and innovators. As a key high-end CNC machine tool R&D and intelligent manufacturing base in China, the company remains dedicated to producing premium Chinese machine tools with a craftsman’s spirit. Its dual-drive approach of technological innovation and market expansion has resulted in a comprehensive R&D and manufacturing system that delivers a wide range of high-end machine tool products for advanced equipment manufacturing.

Baoji Machine Tool Group’s technological prowess is further evidenced by its National CNC System Engineering Technology Research Center and national-level master skill workshops. By leveraging industrial internet, big data, and artificial intelligence, the company continually advances the digitization of production, management, and services, striving to provide comprehensive manufacturing solutions to its customers. The group has cultivated a large team of innovative workers, technical elites, and skilled craftsmen, and regularly hosts national, provincial, and municipal vocational skills competitions.

During the “14th Five-Year Plan” period, Baoji Machine Tool Group is prioritizing high-quality development, accelerating customer-centric transformation towards market and product innovation. This strategy is underpinned by intelligent manufacturing and technological advancements, with a focus on enhancing quality and efficiency. The company aims to establish itself as a premier R&D and manufacturing base for turning-milling compound machines and high-precision machining centers, positioning itself as a leading supplier of high-end equipment in the industry.

The enterprise has garnered numerous prestigious accolades, including the National May Day Labor Award, China Export Quality and Safety Demonstration Enterprise, and Top Ten Enterprises for Independent Innovation in the Chinese Machine Tool Industry. It has also been recognized as a Top Quality Product Enterprise, China Machinery Industry Quality Credit Enterprise, and National Machinery Industry Advanced Manufacturing Integration Backbone Enterprise. In 2021, the Ministry of Industry and Information Technology listed Baoji Machine Tool Group as an “Excellent Intelligent Manufacturing Scenario Enterprise.” The company has also been designated as a machine tool export base in Shaanxi Province, a pilot demonstration enterprise for intelligent manufacturing, and a vocational skills training and competition base. Furthermore, it serves as a provincial-level high-skilled talent training facility, a benchmark for employee vocational ethics, and a pilot unit for industrial worker team construction reform. The group is also recognized as a proactive state-owned enterprise in Baoji’s municipal corporate reform initiative and is among the first batch of unique practice training bases for Baoji’s civil servants.

Founded in 1936, Kunming Machine Tool Co., Ltd., a key enterprise within the General Technology Group, stands as a cornerstone in China’s precision machine tool manufacturing sector. Situated at No. 23 Ciba Road, Kunming, Yunnan Province, this esteemed company has evolved from its origins as the Central Machinery Factory. With a workforce of 940 skilled professionals and total assets of 1.3 billion yuan, the company operates across a 264,000 square meter campus, including 140,000 square meters of advanced manufacturing facilities.

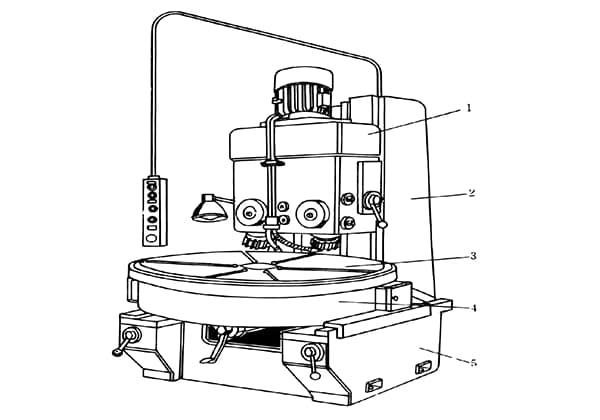

Kunming Machine Tool specializes in the design, production, and distribution of high-precision machining equipment. Their product portfolio encompasses horizontal boring and milling machines, floor-type boring and milling centers, gantry-style milling and boring systems, coordinate boring machines, horizontal machining centers, and critical machine tool components. The company’s diverse product lines, including the KIKI, KITI, KHC-AUTO, and KiMi series, cater to a wide spectrum of industrial applications, offering both CNC and digital display options for enhanced precision and productivity.

As an industry pioneer, Kunming Machine Tool achieved a significant milestone in 1945 by manufacturing China’s first horizontal boring machine. The company has continued to drive innovation, notably developing the nation’s first coordinate boring machine. Their commitment to quality has garnered prestigious recognition, exemplified by the T42100 coordinate boring machine receiving the National Quality Gold Award in 1980, setting a benchmark for precision engineering in the country.

Through strategic evolution, including corporate restructuring and successful stock listings on both the Hong Kong and Shanghai exchanges, Kunming Machine Tool has cemented its position as an industry leader. The company has fostered international collaborations, such as the joint venture with Czech machine tool manufacturer TOS VARNSDORF, facilitating technology transfer and global market expansion. In a move to enhance its manufacturing capabilities, Kunming Machine Tool has initiated the construction of a state-of-the-art CNC heavy-duty precision machine tool manufacturing and casting base in the Songming National Economic and Technical Development Zone, positioning itself at the forefront of advanced manufacturing technologies and Industry 4.0 principles.

Established in October 1950, Qiqihar No.2 Machine Tool (Group) Co., Ltd. has evolved into a leading production base for heavy and ultra-heavy CNC machine tools and large-scale forging and pressing equipment in China. As a subsidiary of China General Technology Group, the company has developed into a modern industrial enterprise offering a comprehensive product portfolio, including advanced metal cutting and forming machine tools, specialized equipment, and high-value technical services.

Throughout its over 70-year history, the company has achieved numerous technological breakthroughs, including the development of China’s first CNC milling machines, automatic cold heading machines, heavy-duty floor-type milling and boring centers, and CNC multi-link press production lines. These innovations have significantly contributed to the advancement of China’s manufacturing capabilities. Serving critical industries such as aerospace, naval engineering, automotive, metallurgy, and rail transit, Qiqihar No.2 Machine Tool has supplied over 2,000 high-precision, large-scale equipment pieces to key domestic enterprises, playing a pivotal role in the nation’s industrial infrastructure development.

The company’s core competency lies in heavy machinery manufacturing, catering to strategic national sectors with a diverse array of sophisticated machine tools and value-added industrial services. These services encompass advanced retrofitting techniques, precision remanufacturing processes, high-tolerance machining operations, and expert technical consultancy. In July 2008, the company’s reintegration into the central enterprise framework under China General Technology (Group) Holding Co., Limited further solidified its central position in China’s advanced manufacturing landscape.

Boasting a workforce of over 4,500, including a cadre of highly skilled engineers and technicians, Qiqihar No.2 Machine Tool operates from a state-of-the-art manufacturing facility spanning 450,000 square meters. The company’s technological prowess is underpinned by its advanced equipment portfolio, featuring high-precision guide rail grinding systems and large-scale CNC gantry-type boring and milling centers sourced from industry leaders in Germany, Switzerland, Italy, Japan, and Russia. This cutting-edge infrastructure enables the company to maintain its competitive edge in the production of heavy-duty and ultra-heavy-duty machine tools, a specialization that has established Qiqihar No.2 Machine Tool as an industry leader. The company’s commitment to excellence is further exemplified by its “Qiqihar” brand, which has earned the prestigious status of a nationally renowned trademark in China, reflecting its reputation for quality and innovation in the machine tool industry.

Founded in 1949, Beijing No.1 Machine Tool Co., Ltd. (BMT) is a state-owned enterprise specializing in the design, manufacturing, and servicing of high-precision CNC machine tools, with a focus on advanced integration and intelligent manufacturing solutions. Headquartered in the Zhongguancun Science Park Shunyi District, BMT has established a global presence, including strategic acquisitions of renowned manufacturers such as Germany’s Waldrich Coburg and Italy’s C.B. Ferrari.

Aligned with China’s national strategy for technological innovation, BMT has earned recognition as a “National Enterprise Technology Center” and operates a CNAS-accredited testing and calibration laboratory, ensuring adherence to international standards. The company has consistently received national accolades for its significant contributions to the development of high-end CNC machine tools and critical manufacturing equipment.

BMT’s product portfolio encompasses a wide spectrum of advanced machine tool solutions, including:

Furthermore, BMT’s expertise extends to the development of fully integrated automatic production lines and the remanufacturing of machine tools, significantly extending equipment lifecycle. These capabilities cater to diverse industries, including automotive, shipbuilding, power generation, rail transport, precision mold making, and advanced mechanical engineering.

Committed to customer-centric innovation, BMT’s mission is to create sustainable value for shareholders, foster a culture of respect and growth for employees, and provide robust technological support for the global equipment manufacturing industry. By continuously pushing the boundaries of precision engineering and smart manufacturing, BMT aims to solidify its position as a globally competitive machine tool manufacturer and comprehensive service provider, driving the evolution of intelligent production systems.

Founded in 1950, Qiqihar No.1 Machine Tool Plant, now operating as Qiqihaer Heavy CNC Equipment Co., Ltd. (QHNC), stands as a cornerstone in China’s precision manufacturing sector. Recognized as a specialized, innovative “Little Giant” enterprise by the Ministry of Industry and Information Technology, QHNC has established itself as a premier manufacturer of advanced heavy-duty CNC machine tools.

QHNC’s product portfolio is anchored by its vertical and horizontal lathes, encompassing over 600 variants across 10 major categories. This diverse range includes high-precision heavy-duty deep-hole drilling and boring machines, specialized roll lathes for metalworking industries, and advanced vertical grinding machines for surface finishing. Many of these cutting-edge products have not only filled technological gaps in the domestic market but have also been exported to over 30 countries and regions, including advanced manufacturing hubs in Europe, the United States, Japan, and South Korea.

As a national first-class metrology enterprise and a state-recognized key high-tech entity, QHNC houses a national-level enterprise technology center. The company’s research and development efforts are spearheaded by a team of industry-leading experts, including scholars who have made significant contributions to government initiatives and are recognized as thought leaders in the machine tool sector. This concentration of expertise drives QHNC’s continuous innovation in CNC technology, machining processes, and smart manufacturing solutions.

QHNC’s operational philosophy centers on “lean manufacturing and quality-driven success,” emphasizing process optimization and precision engineering. The company positions itself not just as a equipment supplier, but as a strategic process consultant, offering comprehensive integrated solutions that enhance productivity and efficiency for its clients. This approach ensures mutual benefit and fosters long-term partnerships across the manufacturing value chain.

Committed to innovation-driven development, QHNC is at the forefront of promoting digital transformation and upgrading within the industry. The company is actively integrating intelligent manufacturing principles and service-oriented operations, aiming to set new benchmarks for high-quality, sustainable development in the machine tool sector.

QHNC’s brand influence in China’s equipment manufacturing landscape is substantial. Its heavy vertical and horizontal lathes are widely acclaimed as industry-leading products, while the “Qi Yi” branded machine tools have achieved the prestigious status of famous Chinese products, underscoring the company’s reputation for excellence and reliability in precision engineering.

Established in 1937, Jinan Second Machine Tool Group Co., Ltd. (Jinan No.2 Machine Tool) has evolved into a leading manufacturer of metal forming and cutting equipment, renowned as one of China’s largest forging equipment and heavy-duty machine tool production bases. Spanning 1.23 million square meters and employing over 5,000 skilled workers, the company has significantly contributed to China’s advanced manufacturing capabilities.

Jinan No.2 Machine Tool’s history is marked by groundbreaking innovations, including the development of China’s first gantry planer in 1953 and mechanical press in 1955. These achievements earned the company the prestigious titles “Home of Gantry Planing” and “Cradle of Mechanical Presses.” Over the decades, it has pioneered more than 600 national first-set products, providing critical equipment support across diverse industrial sectors.

The company’s comprehensive product portfolio encompasses state-of-the-art forging equipment, CNC metal cutting machine tools, advanced automation systems, foundry machinery, and precision CNC cutting equipment. These products serve key industries such as automotive, aerospace, rail transport, energy, shipbuilding, metallurgy, mold manufacturing, and construction machinery. Jinan No.2 Machine Tool holds a significant domestic market share, particularly in heavy-duty machinery presses, and has become an indispensable supplier for China’s burgeoning automotive industry. The company’s global reach extends to 67 countries and regions, solidifying its position in the international market.

Recognized by the State Council for its outstanding contributions to major technical equipment development, Jinan No.2 Machine Tool is acclaimed as one of the world’s top three CNC stamping equipment manufacturers. As a state-owned enterprise of national importance in the machine tool industry, it plays a crucial role in China’s industrial advancement. In September 2019, the company was selected by four ministries, including the Ministry of Education, as one of the first national vocational education teacher enterprise practice bases, underscoring its commitment to fostering industry talent.

Jinan No.2 Machine Tool offers a comprehensive suite of services, encompassing pre- and post-sale technical support, machinery equipment maintenance and modernization, spare parts supply, and collaborative manufacturing for castings, forgings, welded assemblies, and precision-machined components. Its diverse product range caters to varied customer requirements, featuring mechanical presses, multi-station transfer presses, high-precision CNC hydraulic machines, five-axis machining centers, integrated automation solutions, and environmentally-friendly manufacturing equipment. This holistic approach ensures that Jinan No.2 Machine Tool remains at the forefront of metal forming and cutting technology, driving innovation and efficiency in global manufacturing processes.

Founded in 1965, Qinchuan Machine Tool Group Co., Ltd. (stock code: 000837) is a cornerstone in China’s high-end equipment manufacturing sector, specializing in precision CNC machine tools and advanced tooling systems. As a national high-tech enterprise and innovation leader, Qinchuan is committed to elevating China’s manufacturing capabilities while expanding its global footprint.

Qinchuan’s comprehensive portfolio encompasses a wide range of CNC machinery, including multi-axis lathes, 5-axis machining centers, high-precision cylindrical and thread grinders, and gear processing equipment. Their precision measuring instruments ensure micron-level accuracy across manufacturing processes. The company has also diversified into industrial robotics, manufacturing high-performance reducers and specialized gearboxes that meet the exacting demands of automation and precision engineering.

Beyond traditional machine tools, Qinchuan produces critical components for various industries. Their expertise in rolling functional components, automotive parts, and precision gears demonstrates mastery of complex geometries and tight tolerances. The company’s precision casting capabilities, utilizing advanced metallurgy and controlled solidification techniques, enable the production of high-integrity components for demanding applications.

At the forefront of Industry 4.0, Qinchuan has developed a suite of intelligent manufacturing solutions. Their smart machine tools incorporate adaptive control systems and real-time monitoring capabilities, while their proprietary high-grade CNC systems offer advanced interpolation and predictive maintenance features. The Qinchuan Cloud platform integrates IoT technologies with manufacturing execution systems, enabling data-driven optimization and remote diagnostics.

Qinchuan’s strategic focus on core technologies and high-end manufacturing is exemplified by their participation in national R&D initiatives. Their “5221” development plan aims to position the company as a world-class integrated service provider and key component supplier in the high-end equipment sector. By driving original innovation in areas such as ultra-precision machining, additive manufacturing integration, and AI-enhanced process control, Qinchuan is poised to shape the future of industrial machinery technology on a global scale.

Founded in 1935 and now a subsidiary of China General Technology Group, Dalian Machine Tool Group Co., Ltd. has established itself as a leading manufacturer of CNC machine tools, flexible manufacturing systems, and automated equipment in China. The company is particularly renowned for its advanced CNC machine tools and innovative manufacturing solutions.

Originally established as Dalian Machine Tool Factory, the company played a pivotal role in China’s post-1949 machine tool industry development. In 1995, it underwent a strategic merger with Dalian’s primary state-owned machine tool enterprises, forming the Dalian Machine Tool Group Co., Ltd. The group’s capabilities were further enhanced in 2000 with the integration of the Dalian Combined Machine Tool Research Institute, formerly under the Ministry of Machinery. This consolidation of research and manufacturing expertise significantly boosted the company’s technological prowess.

Through a series of strategic acquisitions and joint ventures with industry leaders from the United States, Germany, and other countries, Dalian Machine Tool Group has expanded its global footprint and technological capabilities. This international collaboration has facilitated knowledge transfer, allowing the company to incorporate cutting-edge manufacturing techniques and design principles into its product lineup.

Leveraging national policies aimed at revitalizing Northeast China’s industrial base, the company has undergone substantial modernization. Two state-of-the-art production facilities were established in the Dalian Development Area and Wafangdian, featuring advanced manufacturing equipment and Industry 4.0 principles. These modern bases have propelled the company to the forefront of CNC machine tool and functional component manufacturing in China, with capabilities rivaling international standards.

Dalian Machine Tool Group’s product portfolio encompasses a wide range of high-precision manufacturing solutions, including:

The company’s commitment to innovation and integration of international technologies has maintained its position at the cutting edge of China’s machine tool industry. Many of its products now meet or exceed international standards in terms of precision, efficiency, and reliability.

Over its eight-decade history, Dalian Machine Tool Group has supplied more than 500,000 machine tools to diverse industries, including automotive, aerospace, rail transit, and mining. Its global reach extends to over 100 countries and regions, testament to the quality and competitiveness of its products in the international market.

The company continues to prioritize customer satisfaction, market development, and the provision of a robust sales and after-sales service network. This customer-centric approach, combined with its technological expertise, positions Dalian Machine Tool Group as a key player in advancing China’s manufacturing capabilities and supporting the country’s transition towards high-end, precision manufacturing.

Founded in 1993 and building on a legacy dating back to 1933, Shenyang Machine Tool stands as a pioneer in the Chinese machine tool industry. This publicly listed company (stock code 000410 on the Shenzhen Stock Exchange) emerged from the strategic merger of four industry leaders, including the renowned Shenyang First Machine Tool Factory.

Shenyang Machine Tool is acclaimed for its comprehensive portfolio of high-precision machine tools, featuring a diverse range of lathes and machining centers known for their exceptional accuracy and durability. Since 2010, the company has been at the forefront of innovation, particularly in materials science. A notable advancement is the integration of LZA4205 microcrystalline alloy in their CNC turrets, significantly enhancing both product quality and cost-effectiveness through improved wear resistance and thermal stability.

The company’s expertise extends beyond manufacturing to encompass a full spectrum of services for SMTCL lathe machine spare parts. Their holistic approach includes sales, preventive and corrective maintenance, technical consulting, and comprehensive operator training programs. This integrated service model is designed to optimize the customer experience in selecting, implementing, and maintaining machine tool components, ultimately maximizing equipment uptime and productivity.

Shenyang Machine Tool plays a pivotal role in the Shenyang CNC Machine Tool Industrial Park, a state-of-the-art manufacturing ecosystem that synergizes nine major enterprises. This strategic involvement underscores the company’s commitment to maintaining its leadership in the global machine tool industry. By fostering collaborative innovation, leveraging advanced manufacturing techniques such as digital twin technology and AI-driven process optimization, and adhering to stringent quality control standards like ISO 9001:2015, Shenyang Machine Tool continues to drive the evolution of precision engineering and smart manufacturing solutions.

When selecting a milling machine manufacturer in China, several critical factors should guide your decision. The following are key considerations to ensure you choose a reliable and high-quality supplier:

Machine Quality and Performance

The quality and performance of the milling machines should be your paramount concern. Opt for manufacturers with a proven track record of producing machines that not only meet but exceed industry standards. Key quality indicators include:

Thoroughly research the manufacturer’s reputation, analyze technical specifications, and review customer feedback. If possible, request sample parts or arrange a site visit to witness the machines in operation.

Total Cost of Ownership

While initial price is important, focus on the total cost of ownership (TCO) when evaluating different manufacturers. Consider factors such as:

A higher upfront investment in a quality machine often translates to lower long-term costs and improved profitability.

Technical Support and After-Sales Service

Robust technical support and after-sales service are crucial for minimizing downtime and maximizing machine productivity. Evaluate the manufacturer’s capabilities in:

Choose a manufacturer with a strong local presence or reliable service partners in your region.

Manufacturing Capacity and Delivery Time

Consider the manufacturer’s production capacity and ability to meet your delivery requirements. Factors to assess include:

Request a detailed production and delivery schedule before placing an order to ensure alignment with your operational needs.

Technological Innovation and Industry 4.0 Readiness

In today’s rapidly evolving manufacturing landscape, choose a milling machine manufacturer that demonstrates a commitment to technological innovation and Industry 4.0 principles. Look for features such as:

Selecting a forward-thinking manufacturer ensures your investment remains competitive in the long term.

In conclusion, when choosing a milling machine manufacturer in China, carefully evaluate machine quality, total cost of ownership, technical support, manufacturing capacity, and technological innovation. By conducting thorough due diligence and prioritizing these factors, you can identify a supplier that not only meets your immediate needs but also supports your long-term manufacturing goals and competitiveness.

Purchasing milling machines from China can be a cost-effective and strategic decision, offering a variety of benefits. Chinese manufacturers often provide high-quality machines at competitive prices, meeting international standards. This chapter will guide you through the process of purchasing milling machines from China, focusing on different platforms and important considerations.

Chinese manufacturers are known for their cost efficiency and adherence to international quality standards. For example, many buyers have reported cost savings of up to 30% compared to purchasing from other countries. Additionally, Chinese suppliers often hold certifications such as ISO9001 and CE, ensuring the quality and safety of their products.

Alibaba is a popular platform for sourcing milling machines from China. It offers a vast array of suppliers and products, making it easy to compare options.

A case study highlights a buyer who successfully purchased a milling machine by negotiating directly with a supplier on Alibaba. They secured a 20% discount by ordering in bulk and confirming the machine specifications via video call.

Made-in-China is another reputable platform for purchasing milling machines. It provides a comprehensive directory of manufacturers and suppliers.

Purchasing directly from manufacturers can offer better prices and personalized service.

When purchasing milling machines from China, consider the following:

When importing milling machines from China, be aware of legal and regulatory requirements. This includes customs duties, import regulations, and compliance with local standards. Tools like third-party inspection services and trade associations can help verify supplier credibility and ensure compliance with regulations.

By following these guidelines and conducting thorough research, buyers can make informed decisions and successfully purchase milling machines from China, benefiting from the cost-effectiveness and quality that Chinese manufacturers offer.

Evaluating the credibility of a supplier is crucial when sourcing milling machines from China. A systematic approach helps ensure you partner with reliable suppliers, minimizing risks and ensuring product quality. Here are key criteria and methods to evaluate supplier credibility effectively.

Quality Management System: Verify the supplier’s compliance with ISO 9001 standards, which indicate robust quality management practices. For instance, a supplier with an ISO 9001 certification has established processes to consistently meet customer and regulatory requirements. This can be illustrated by a case where a supplier’s implementation of ISO 9001 significantly reduced defect rates, enhancing their credibility.

Documentation: Request quality control documentation, including part inspection reports and material certifications, to confirm the supplier’s adherence to quality standards. Detailed documentation provides transparency and traceability, crucial for maintaining high quality.

Performance History: Review the supplier’s performance metrics, such as defect rates and corrective actions taken for past quality issues. For example, a supplier with a low defect rate and a robust corrective action plan demonstrates a strong commitment to quality.

Current Production Levels: Assess the supplier’s ability to meet your demand by evaluating their current production levels, resource allocation, personnel, and materials. A supplier with high production capacity can accommodate large orders and scale operations as needed.

Flexibility: Determine if the supplier can handle rush orders and adjust to changes in order quantities. A flexible supplier can adapt to your business needs, ensuring continuous supply without disruptions.

Delivery Times: Evaluate the supplier’s on-time delivery rate and assess potential risks associated with delays. Timely deliveries are crucial for maintaining your supply chain efficiency. For instance, a supplier with a 95% on-time delivery rate is likely to be reliable.

Service Level Agreements (SLAs): Ensure the supplier meets contractual requirements for delivery times and product quality by reviewing their SLAs. SLAs provide a clear framework for expectations and accountability, ensuring both parties are aligned.

Total Cost Analysis: Conduct a comprehensive cost analysis, considering not just the product price but also costs related to returns, defective goods, inventory holding, and delays. This approach provides a holistic view of the supplier’s value proposition.

Financial Health: Assess the supplier’s financial stability to ensure they can remain a reliable long-term partner. This includes evaluating their ability to withstand economic fluctuations. Financially stable suppliers are less likely to experience disruptions in their operations.

Customer Service: Evaluate the level of customer service and support offered by the supplier, including their responsiveness to inquiries and complaints. Strong customer service can significantly enhance the overall business relationship.

Assistance: Assess their capability to provide assistance and support when needed, ensuring a smooth and efficient business relationship. For instance, a supplier with a dedicated support team can promptly address any issues that arise.

Below are answers to some frequently asked questions:

Buying milling machines from China offers several advantages. Firstly, Chinese manufacturers have significantly improved the quality and precision of their products, often using advanced equipment and stringent quality control measures to meet international standards. This ensures that buyers receive high-quality machines capable of performing complex tasks with accuracy.

Cost-efficiency is another major benefit. Due to lower labor and manufacturing costs in China, milling machines are more affordable compared to those from other regions, without compromising on quality. This makes them an attractive option for businesses looking to reduce expenses.

Chinese manufacturers are also leaders in material innovation, utilizing advanced materials such as high-performance alloys and smart materials that enhance durability and reduce maintenance costs. Additionally, China’s well-developed supply chain infrastructure and proximity to raw material suppliers ensure efficient production and reduced transportation costs, further enhancing affordability.

Many Chinese companies comply with international quality and safety standards, including EU regulations and CE marking, facilitating smoother import processes and ensuring regulatory compliance. This compliance is crucial for businesses operating in regions with stringent safety and quality requirements.

Moreover, Chinese suppliers offer customization and flexibility, allowing buyers to tailor milling machines to specific needs, whether in terms of material, design, or functionality. This customization ensures that the machines meet the exact requirements of the buyer’s operations.

Lastly, Chinese milling machines are versatile and compatible with a wide range of materials, making them suitable for various industrial applications such as aerospace, medical, and electronics industries. This versatility, combined with affordability, precision, and innovation, makes milling machines from China a highly attractive option for manufacturers looking to optimize their production processes.

To find reliable milling machine suppliers in China, you can follow these steps:

Start by researching and identifying reputable manufacturers listed on well-known platforms like Alibaba, Made-in-China, and industry-specific websites. These platforms usually verify the business licenses and credentials of suppliers, ensuring a level of trustworthiness. Look for suppliers with relevant certifications such as ISO 9001 and CE, which indicate a commitment to quality standards.

Evaluate the company’s profile and experience by selecting suppliers with a long history and strong track record in manufacturing milling machines. Companies with extensive experience, like SHANDONG XILI MACHINE TOOL CO., LTD. and TAICNC, demonstrate stability and expertise in the field. Additionally, consider suppliers that offer a wide range of milling machines and can handle custom orders to meet your specific needs.

Assess the manufacturing capabilities and technology used by the suppliers. Opt for those who invest in advanced equipment and technology to ensure high precision and quality. A skilled workforce and ongoing employee training are also crucial factors that contribute to the production of high-quality machines.

Customer service and support are essential aspects to consider. Look for suppliers known for their reliable delivery times and good customer service. Ensure that they provide adequate technical support, including user manuals, maintenance plans, and guidance.

Check customer feedback and ratings on platforms like Made-in-China and Alibaba to gauge the reliability and satisfaction of previous clients. Customer reviews can provide valuable insights into the supplier’s performance and credibility.

Lastly, compare prices among different suppliers to ensure you are getting a competitive deal without compromising on quality. Consider the long-term value of the machine, including its durability and maintenance costs, to make a well-informed purchasing decision.

By thoroughly evaluating these factors, you can identify reliable milling machine suppliers in China who can meet your requirements for quality, reliability, and support.

Chinese manufacturers offer a diverse range of milling machines, each designed for specific applications and characterized by their layout, structure, and control modes. The commonly available types include:

These milling machines cater to various industrial needs, including precision machining, heavy-duty operations, and specialized applications, making Chinese manufacturers a reliable source for a wide range of milling solutions.

When purchasing a milling machine, particularly from Chinese manufacturers, several technical specifications should be considered to ensure you select the right machine for your needs.

Firstly, assess the base and structural components. The base should be made of rigid materials like cast iron to support the machine’s weight and absorb shock during operations. The column and knee should provide stable vertical movement and support for the worktable, with the knee typically containing a guideway and screw mechanism for height adjustment.

Next, consider the table and work surface. The table size should match your workpiece dimensions, and the T-slots’ number, width, and distance are crucial for clamping workpieces securely. Also, ensure the table can handle the maximum load of your workpieces.

Movements and travel are also important. Check the longitudinal, cross, and vertical travel ranges of the table, as well as the feed speed and rapid feed speed, which affect the machine’s efficiency and precision.

Spindle specifications are critical. Examine the spindle speed range, motor power, and spindle taper type, such as ISO50 or ISO40, to ensure compatibility with your tooling needs.

Control and automation features should also be evaluated. Decide between manual, semi-automatic, or fully automatic control systems. Machines with CAD/CAM software support and digital readout can enhance precision. An automatic tool changer can facilitate multiple operations without manual intervention.

Additional features like a rotary table can provide extra axes of movement, and an adequate coolant system is necessary to prevent overheating during prolonged use.

Power and electrical specifications, including the main drive motor and coolant motor, should match your facility’s capabilities. Finally, consider the machine’s overall dimensions and weight to ensure it fits within your available workspace and meets your operational requirements.

By carefully evaluating these technical specifications, you can select a milling machine that meets your specific needs for precision, capacity, and operational efficiency.

To verify the credibility of a Chinese milling machine supplier, you should undertake a thorough and multi-faceted approach. Start by checking the supplier’s business license and registration details through the National Enterprise Credit Information Publicity System (NECIPS) to confirm their legal status. Cross-check this information with government databases to ensure authenticity. Conduct an on-site factory audit, if possible, to assess their manufacturing capabilities and quality standards, or hire a local agent or third-party company to perform the audit on your behalf.

Examine the supplier’s business scope on their license to confirm they are a manufacturer, not just a trading company. Request a 17% Value Added Tax (VAT) invoice, which only factories can issue, to further confirm their status. Evaluate product samples to ensure the quality meets your standards and implement stringent quality control measures.

Verify any claimed certifications, such as ISO 9001, and request factory auditing reports to check their credibility. Review the supplier’s website for a legitimate physical address in China and ensure it is professionally presented. Search for any negative reviews or scam reports and contact previous customers for references, if possible.

Maintain clear and transparent communication with the supplier, requesting regular updates and detailed reports throughout the verification process. Finally, review the supplier’s product catalog to see if they specialize in specific products, as a factory typically does, compared to a trading company. By following these steps, you can ensure the credibility of a Chinese milling machine supplier, facilitating a reliable business partnership.