Have you ever wondered how the industrial world keeps running smoothly? Compressed air is the unsung hero behind countless manufacturing processes. In this blog post, we’ll explore the fascinating world of air compressors and introduce you to some of the top manufacturers in the industry. Discover how these companies are revolutionizing the way we power our factories and learn about the cutting-edge technologies they employ. Get ready to dive into the compelling story of compressed air!

An air compressor is a device used to compress gases. It shares a similar construction with water pumps. Most air compressors are of the reciprocating piston type, rotary vane, or rotary screw variety.

When selecting an air compressor manufacturer, the brand’s market position and product diversity should be the primary considerations.

The qualifications and reputation of the supplier, technical capabilities and product quality, after-sales service and maintenance capabilities, price and cost-effectiveness, and business credit are all important factors to consider. Therefore, when choosing an air compressor manufacturer, it’s recommended to prioritize brands with a good reputation in the market, a rich product line, and high cost-effectiveness. At the same time, based on your specific needs and budget, you should comprehensively evaluate the overall service capabilities of the supplier.

During my research, I came across several top global air compressor manufacturers that are worth mentioning. These companies have a strong global presence and offer a wide range of products to cater to various industries’ needs.

One of the leading air compressor manufacturers is Atlas Copco, a Swedish company founded in 1873. With operations in over 180 countries, they are renowned for their high-quality compressors, including industrial, dental, and workshop compressors. Their extensive product line and continuous innovation have made them a go-to choice for many customers worldwide.

Another key player in the air compressor market is Sullair, a US-based company founded in 1965. As one of the largest professional manufacturers of screw air compressors, they are experts in the research, development, production, and sales of air compressors and related products. In 2017, they became part of the Hitachi Group of Japan, further solidifying their position in the industry.

Country: Sweden

Founded:1873

About the company:

Atlas Copco is a global industrial group founded in 1873 and headquartered in Stockholm, Sweden. With over 41,000 employees and customers in more than 180 countries and regions, Atlas Copco continues to innovate technology, guide industry development, and contribute to all walks of life around the world.

Their excellent products, solutions, and services ensure the reliability of customers’ business operations, improve productivity, reduce costs and carbon dioxide emissions, and help them achieve their sustainable development goals.

Atlas Copco’s compressor technology provides a range of solutions to meet various air and gas needs, including oil injection air compressors, oil-free air compressors, oil-free blowers, cold dryers, suction dryers, air filters, oxygen and ammonia production machines, medical compressed air systems, and high-quality spare parts and services.

The Atlas Copco Vacuum Technology Department provides vacuum and emission reduction solutions for industries worldwide. They develop vacuum pumps and systems with a customer-centric, interconnected, and digitalized approach.

Whether in the semiconductor division, scientific research division, or industrial division, passionate employees at Atlas Copco strive to bring diverse industrial ideas to life.

They support research and development, integrate cutting-edge technologies into equipment, improve energy efficiency, ensure customer safety, and make daily life full of endless possibilities.

The vacuum technology department is a critical force in global manufacturing, research, and production facilities at Atlas Copco. In the industrial technology field, the company transforms industrial creativity into intelligent manufacturing assembly solutions and innovative industrial tools through customer collaboration.

With passionate staff, professional knowledge, and meticulous service, Atlas Copco brings sustainable value to numerous industries worldwide.

In the power business, the company transforms industrial creativity into air, power, and flow solutions.

It offers drainage pumps, hand-held tool high-pressure boosters, light towers, mobile compressors and generators, covering a wide range of industries such as construction, emergency response, large-scale events, manufacturing, mining, power plants, oil and gas, petrochemical, water wells, utilities, and more.

Atlas Copco first entered the Chinese market in the 1920s by importing products from Europe. In 1959, the company established its first subsidiary in Taiwan, China.

Since then, the Atlas Copco Group has expanded into four major business areas in China, including compressor technology, vacuum technology, industrial technology, and power technology, offering innovative products and solutions to customers.

As of the end of 2021, Atlas Copco had established more than 20 companies in China with a workforce of nearly 7,000 employees.

China is an important market for the Group, and Atlas Copco plans to further develop its presence in the country by expanding its market share through innovative industrial solutions and providing sustainable productivity for Chinese customers.

Country: USA

Founded:1871

Products: Air compressors, pumps, blowers, fluid management, loading, power tools and material lifting systems

About the company:

Ingersoll Rand (NYSE code: R) is dedicated to enhancing the quality of life by creating comfortable, sustainable, and efficient environments.

The company’s employees and brands, which include Club Car ®, Ingersoll Rand®, Thermo King®, and Trane®, work together to improve air quality and comfort in residential and commercial buildings, transport, and safeguard food and perishables, and increase productivity and efficiency in the industrial sector.

In 2013, Ingersoll Rand achieved annual sales of 12 billion US dollars. The company’s vision is to create a world of continuous progress and an enduring foundation. Founded in 1871, Ingersoll Rand is a global diversified industrial company.

In recent years, Ingersoll Rand has evolved from a heavy machinery manufacturer with high capital requirements into a manufacturing enterprise that offers multiple branded products and serves customers in various industries around the world.

Currently, the company operates 11 strategic business units globally and has offices in all major regions of the world. Ingersoll Rand is prepared to tackle the challenges of an increasingly dense population and scarce resources.

The company believes that exceptional performance is the foundation of long-term success. Ingersoll Rand’s core strategy centers around sustainable development, which includes leveraging innovation, services, and emerging markets for business growth, promoting operational excellence, and building a corporate culture that is diverse, inclusive, and adaptive to the changing times.

Country: USA

Founded:1965

About the company:

Founded in 1965 in the United States, Sullair is the world’s largest professional manufacturer of screw air compressors. The company specializes in the research and development, production, and sales of air compressors and related products. In 2017, Sullair became a part of the Hitachi Group of Japan.

Headquartered in Michigan, Indiana, Sullair has been a leading brand in the air compressor industry for over 50 years, with a focus on screw air compressors.

Sullair Asia’s main production base is located in Suzhou, China, and its sales and after-sales service network covers the entire country, as well as Southeast Asia and other regions in Asia.

Suzhou Shouli Gas Equipment Co., Ltd. produces a range of products, including fixed and mobile screw compressors, screw vacuum pumps, air dryers, precision filters, and vacuum pumps. These products are widely used in various industries such as electronics, thermal power, chemical industry, new energy, steam textile, and medicine.

The company is dedicated to providing stable and excellent gas solutions and effective, high-quality after-sales service to customers from all industries. This is achieved through continuous innovation, practical design, and advanced technology.

In July 2017, Suzhou Sullair Gas Equipment Co., Ltd. became a member of the Hitachi Group.

Country: USA

Founded:1994

About the company:

CompAir, based in the United Kingdom under Gardner Denver, is the world’s leading supplier of compressed air and compressed gas systems. The company is dedicated to providing a wide range of low-pressure and high-pressure compressors, custom blowers, and vacuum pumps.

As a global leader in compressed air solutions, CompAir offers a variety of equipment types, including micro oil screw air compressors, oil-free screw air compressors, centrifuges, water-lubricated air compressors, sliding vane air compressors, mobile air compressors, scroll air compressors, and more.

Through a network of subsidiaries and dealers across continents, CompAir is able to provide global expertise and training, along with local service capabilities, to ensure support for the provision of advanced technology.

CompAir’s breakthrough technologies, such as the Ultima series, are helping compressed air users achieve their sustainability goals, while efficient oil-free compressors can provide a lower environmental impact.

With a complete range of screw, reciprocating, centrifugal, and mobile compressors, as well as compressed air treatment and accessories, CompAir is an innovative and responsive supplier for the compressed air industry.

CompAir’s complete range of compressors have demonstrated their reliability in harsh field conditions, delivering energy efficiency and low maintenance to customers while saving costs.

With a history of 200 years, CompAir continues to provide high-quality products to customers worldwide.

CompAir’s screw air compressors, oil-free air compressors, centrifuges, and sliding vane compressors provide stable and efficient compressed gas to over 100,000 customers around the world.

Country: China

Founded:1956

Products: Screw air compressor, refrigerant compressor, screw expansion generator, process gas compressor, environmental engineering and cold chain industry

About the company:

Kaishan Group Co., Ltd. is a compressor enterprise with over 60 years of history. The company offers screw air compressor products with a power range of 4kW to 630kW, including motor power, diesel power, underground explosion-proof screw air compressors, and two-stage compression screw air compressors.

The screw expansion technology is a world-leading low-grade heat source power generation technology that uses direct expansion of residual pressure and ORC organic Rankine cycle expansion technology. This technology effectively utilizes low-grade residual heat and residual pressure in a ladder manner.

It is efficient, reliable, and widely applied in geothermal power generation, waste heat power generation, bioenergy power generation, residual pressure power generation, and other new energy and renewable energy fields.

In 2009, Kaishan established the “Kaishan North America R&D Center” in Seattle, United States, and developed many high-tech products with independent intellectual property rights according to the model of “North America R&D Made in China”.

Kaishan’s core value is to “make contributions to saving the earth”, and the company aims to become a renowned compressor manufacturer on an international scale.

Its product distribution network covers the entire country, with over 2,000 marketing outlets and high-quality sales services. The products are sold to more than 60 countries and regions worldwide, including the United States, Germany, Japan, South Korea, Russia, and others.

Country: China

Founded:1953

About the company:

Since its establishment as a joint-stock company in 1953, Fusheng has weathered more than half a century of challenges, accumulating extensive manufacturing experience and advanced automation equipment.

With a complete product line and a focus on market demand, Fusheng is committed to providing energy-efficient and environmentally-friendly products. Its products cover fixed air compressors, mobile air compressors, refrigeration compressors, new energy vehicle air compressors, diesel generators, Roots blowers, and more.

Fusheng places great emphasis on providing considerate and effective services to its customers. The company currently has three production bases and three sales and service departments in mainland China, located in Beijing, Shanghai, and Zhongshan.

Fusheng’s sales headquarters are located in Shanghai, and over 30 branches and offices are distributed throughout major cities in the country. The company’s special dealers and service providers are located nationwide.

Fusheng is committed to providing quality services to its customers through strictly trained maintenance personnel who hold certificates and have access to ample factory spare parts. This enables the company to provide timely and efficient services that prioritize the rights and interests of its customers.

Regardless of where its products are used, Fusheng’s special dealers provide nearby inspections, local branches offer technical support, and the sales service department provides strong support. This makes Fusheng the go-to compressor and power expert for its customers.

Fusheng prioritizes the profitability, low total operating costs, and equipment availability of its customers. To achieve these goals, Fusheng collaborates and interacts with its customers, taking into account their process flow, needs, and goals, to ensure the continuous operation of their production.

Fusheng’s organizations and personnel are dedicated to improving the operational availability and efficiency of its customers’ compressed air network. With specialized technology, ample supply of factory spare parts, and nearby services, Fusheng can not only respond in a timely manner but also quickly resolve any problems that may arise.

Country: Japan

Founded:1910

About the company:

Hitachi, a large integrated motor manufacturer, was founded in Japan in 1910. It is an enterprise group that focuses on air conditioners and refrigerators while integrating research, development, production, and sales of household appliances, computer products, semiconductors, industrial machinery, and other products.

As a global leader in social innovation, Hitachi carries out businesses involving electricity, energy, industry, circulation, water, urban construction, public, medical, and health. It provides high-quality solutions through collaboration with customers.

Currently, Hitachi is accelerating its social innovation globally to solve various social issues. It aims to become an innovation partner in the IoT era and to achieve further development in the global market.

It leverages its advantages in control technology at the beginning of its business and half-century-old IT technology. It integrates big data analysis, AI, and other digital technologies to provide high-quality solutions.

Hitachi has always adhered to the entrepreneurial spirit of “harmony, honesty, and pioneer spirit” and the corporate philosophy of “contributing to society through excellent independent technology and product development” to achieve the inheritance and continuous growth of its cause in more than 100 years of development.

In the context of rapid changes in the world economy, Hitachi has formulated a new vision, that is, “Hitachi, with innovation to open the way to solutions, with excellent teams and rich global market experience, to inject new vitality into the world.” Hitachi built up the core values of its group, with a view to making greater contributions to social development with a new spirit.

In China, Hitachi has carried out extensive business activities with the goal of being “The Most Trusted Partner in China.”

Additionally, Hitachi pays close attention to environmental protection and is committed to the development and upgrading of energy conservation and emission reduction based social infrastructure systems. It aims to solve China’s social problems and make positive contributions to the sustainable development of China’s society.

Country: China

Founded:1991

About the company:

Jaguar, a supplier of air compressor solutions, was established in 1991 under Taiwan Risheng Industry. The company mainly engages in the production and sales of air compressors, precision filters, and other related products. It is currently a brand of Xiamen East Asia Machinery Industry Co., Ltd.

Xiamen East Asia Machinery Industry Co., Ltd. is a large air compressor manufacturer established in 1991 with nearly 30 years of experience. The company is focused on providing energy-saving and stable compressed air system solutions, integrating independent research, development, production, sales, and service. It is one of the few domestic enterprises that master the core technology of screw air compressor and a significant volume air compressor manufacturer in China.

Over the past three decades, Xiamen East Asia Machinery Industry Co., Ltd. has developed into a modern factory with 70,000 square meters based on its business philosophy of continuous innovation.

The company has collaborated with SRM of Sweden and NREC of the United States to enhance its technology research and innovation ability and resource integration, allowing it to master high-quality air compressor technology.

Jaguar’s permanent magnet frequency conversion series, with dozens of models, meets the “national first-class energy efficiency standard” in recent years.

Through continuous efforts and innovation, Xiamen East Asia Machinery Industry Co., Ltd. provides users in over 40 countries with a complete set of compressed air system solutions, relying on high-quality teams, testing equipment, scientific management system, and strong research and development capabilities.

Millions of Jaguar devices are currently operating in various countries and regions worldwide, serving end customers such as China Railway, CRRC, PetroChina, Dongfeng Motor, BYD, Zhengxin Tire, Fangtai, Bull, and many other enterprises.

Jaguar has a worldwide marketing network with over 300 convenient Jaguar service centers established in central cities in China. The company’s strong sales team and professional technical service team always provide users with a comprehensive service system.

Country: Chian

Founded:1999

About the company:

Bolatie has been focused on designing, producing, and selling screw air compressors since its establishment. The company is committed to continuous technological innovation and providing high-quality products and services.

In 2006, Bolatie was wholly acquired by Atlas Copco Group, a supplier of air compressors. The company has inherited advanced technology, equipment, and production management modes from the Group, and is widely praised and used in machinery, steel, mining, chemical industry, textile, automobile, environmental protection, new technology, and energy fields.

Bolaite has a dedicated marketing team, a perfect agent management system, and an agent business support DBS system. The company assigns special management personnel to track each stage of the order in real-time through the BPCS system. Additionally, the CRM system is used to directly and effectively manage the information and data of all authorized agents.

The company has established a comprehensive agent training system and provides specialized training, consulting, and guidance services, as well as a full range of solutions for compressed air systems. The aim is to help and support agents to actively develop local business and achieve win-win cooperation.

Bolatie offers five product series, three cold dryer lines, and four compressor production lines. The compressor products’ power ranges from 4.0kW to 560kW.

Bolaite is committed to meeting the differentiated needs of different customers and strictly follows the CTP development process of the Group. Each new product goes through 122 development processes, 33 test items, and a 2000 hour durability test to control product quality from the source and meet user needs with reliable performance.

The company implements lean production in the process of transforming design into products. The production workshop of Bolaite products has precision machining equipment and manufacturing processes such as Gaobo suspension hoisting system and Atlas Copco torque control and recording system to strictly control every link of production.

Bolaite has a high-quality laboratory with the capacity to conduct high and low voltage testing from 4KW to 355kW. The laboratory can perform vibration, noise, oil content, flow, energy consumption, and other performance tests on new products.

Bolaite provides customers with perfect after-sales service. The company’s sales and service outlets cover more than 200 cities nationwide, providing a 24-hour service hotline and WeChat repair service.

Bolaite offers original spare parts with excellent performance and a complete variety to extend the service life of air compressors, reduce maintenance costs, improve operating efficiency, and protect customers’ investments even under severe working conditions.

In addition to air compressor after-sales service, Bolaite provides customers with a range of after-sales service products such as compressed air system detection, analysis, and optimization, air compressor centralized control, waste heat recovery, frequency conversion transformation, dryer energy-saving transformation, and Jieneng pipeline. These services help customers reduce production costs, improve operating efficiency, and contribute to protecting the environment.

In Shanghai, Bolaite has an overhaul workshop that can achieve unconditional rotor exchange and ensure 24-hour delivery. Additionally, the company has a modern warehousing and logistics center that integrates adjustment, detection, packaging, and distribution functions. This center provides various spare parts and optional kits to meet customers’ specific needs.

Bolaite’s strictly trained service personnel are equipped with service vehicles and special inspection and maintenance tools to provide customers with timely and professional services and support their production.

Country: China

Founded:1997

About the company:

Founded in 1997, Hongwuhuan Group has become one of China’s leading manufacturing enterprises of air power equipment and engineering tunneling equipment.

The Group, with a total registered capital of 245 million yuan and holding 10 subsidiaries, is a modern machinery and equipment manufacturing enterprise that integrates technology research and development, production and manufacturing, sales, and service. It covers an area of 476 mu and has more than 1100 employees.

Hongwuhuan Group has established close cooperation with Tsinghua University, China University of Geosciences, Zhejiang University, Xi’an Jiaotong University, China General Machinery Research Institute, and other scientific research institutes, providing the Group with strong product research and development capabilities.

The Group’s main business areas include air compressors, open-air down-hole drilling rigs, underground rock drilling rigs, hand-held drilling equipment, tea making equipment, pressure vessels, and other related products.

Hongwuhuan Group offers more than 200 products across six series, making it one of the best-performing enterprises in the air power and engineering tunneling industries in China.

The Group has over 1500 sales outlets at home and abroad, and its products are exported to Southeast Asia, the Middle East, Africa, Europe, America, and other countries.

Hongwuhuan Group has established joint ventures and cooperation projects with enterprises such as American Ingersoll Rand and Sweden Atlas Copco.

The Group has obtained the 1S09001:2008 quality management system certification and the 1S014001:2004 environmental management system certification.

The Group aims to build the Red Five Ring brand into a world-famous brand and has set a development goal of becoming a “100-year-old enterprise” and a 10-billion enterprise.

With a focus on its two main businesses of aerodynamics and engineering tunneling, Hongwuhuan Group aims to establish its place in the global manufacturing industry.

Below are answers to some frequently asked questions:

To compare different air compressor brands effectively, you need to consider several key factors and specifications. First, evaluate the tank capacity, which is measured in gallons. Larger tanks provide more continuous airflow but are heavier and less portable. Next, consider the power output, measured in Cubic Feet per Minute (CFM) at a specific pressure, as higher CFM ratings are better for more demanding tools.

Noise level is another critical factor, expressed in decibels (dBA). For quieter work environments, opt for compressors with lower dBA ratings. The maximum pressure, measured in pounds per square inch (PSI), is important for more powerful tools, with higher PSI being more suitable for such needs. Additionally, running power, indicated by horsepower (HP) and current draw, affects the compressor’s power and electrical requirements, with higher HP models offering more power but needing more electrical support.

Portability is crucial, especially if you need to move the compressor frequently. Consider the weight, dimensions, and features like handles and wheels. The type of compressor also matters; reciprocating compressors are suitable for smaller applications and are often more affordable, while rotary screw compressors are more powerful and used in industrial settings.

Top manufacturers like Ingersoll Rand, Makita, DeWalt, Kaeser, Atlas Copco, Quincy, and Bostitch each have their specializations, from reliability and durability to high-quality industrial models. Consider certifications and quality standards like ISO 9001 for consistent quality, and check user reviews for real-world performance insights. Maintenance requirements and long-term costs should also be considered, as some models are maintenance-free while others require regular upkeep. Finally, evaluate the price in relation to the features and performance to ensure you get the best value for your investment.

When choosing an air compressor, several key technical specifications need to be considered to ensure the compressor meets your specific needs. Here are the crucial factors, particularly relevant when evaluating products from top air compressor manufacturers:

Pressure and PSIG: The pressure rating of the compressor, measured in pounds per square inch gauge (PSIG), is critical. Most pneumatic tools require around 90 PSIG, but some applications may need higher pressures.

Capacity and CFM: The capacity of the air compressor, measured in cubic feet per minute (CFM), indicates the amount of air it can produce at a specific pressure. This is one of the most important specifications, as it determines whether the compressor can support the airflow requirements of your tools and applications.

Horsepower (HP): While horsepower is a measure of the motor’s power, it is not as straightforward in air compressors as in other machinery. It is essential to ensure the horsepower is sufficient to deliver the required pressure and capacity, but it should be considered in conjunction with other specifications to avoid overpowered and inefficient compressors.

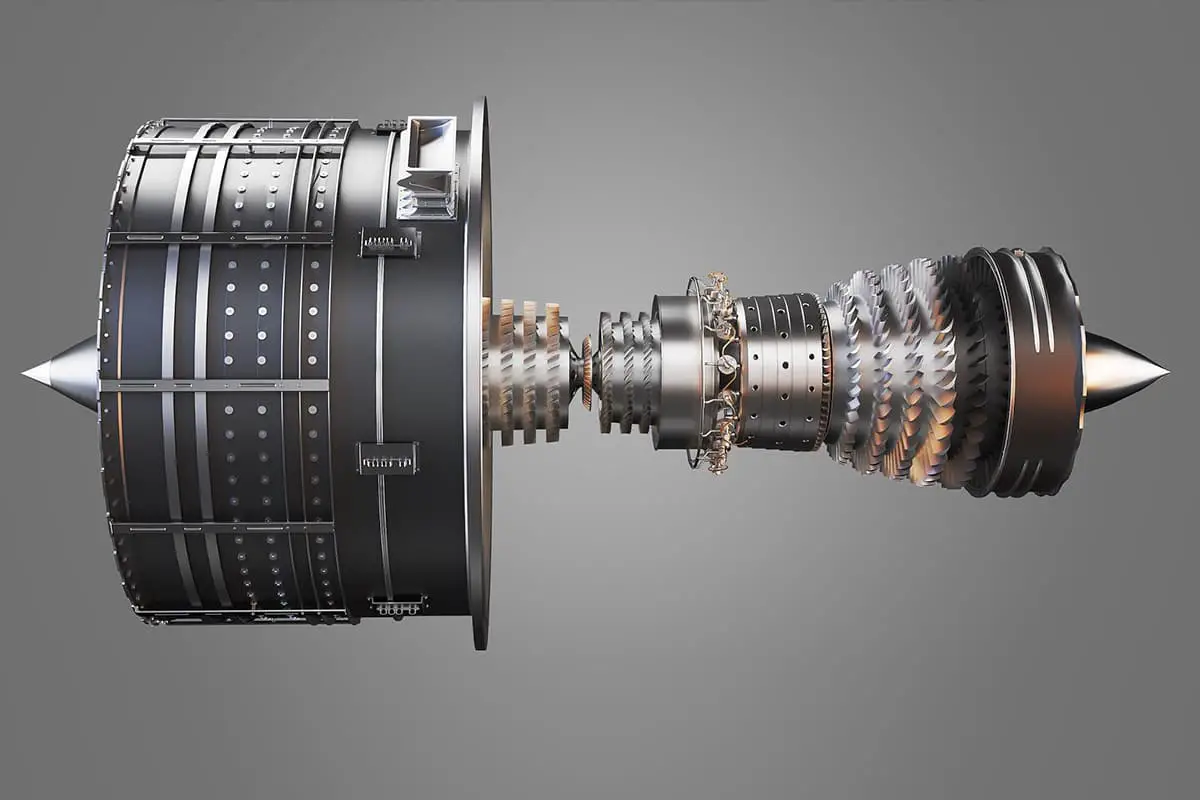

Compressor Technology: Different technologies include rotary screw, reciprocating piston, centrifugal, diaphragm, and other types such as axial, blower, and linear compressors. Each type has unique characteristics and applications, with rotary screw and reciprocating piston being the most common for general use.

Motor Type and Power Source: The type of motor and power source can vary. AC single phase is typical for smaller compressors, AC three phase is common in industrial settings, gasoline or diesel engines are used for mobile or remote use, and natural gas is for specific industrial applications.

Lubrication Style: Compressors can be oil-lubricated, which requires regular oil changes and maintenance, or oil-free, which is suitable for applications requiring clean air, such as food processing or medical use.

Cooling System: The cooling system is essential for maintaining the compressor’s performance and longevity. Air-cooled compressors use fans to cool the unit, while water-cooled compressors are more efficient for high-power compressors but require a water supply.

Integral Components: Some compressors come with integral components such as integrated dryers to remove moisture from the compressed air, and intercoolers and aftercoolers to improve efficiency by cooling the air between stages and after compression.

Duty Cycle: The duty cycle refers to the percentage of time the compressor can operate at full capacity without overheating or failing. This is crucial for continuous use applications.

Tank Size: The tank size affects the compressor’s ability to store compressed air and meet intermittent demand. Larger tanks can handle more tools and applications.

Mounting and Portability: Consider whether the compressor needs to be fixed or portable. Fixed compressors are often used in stationary applications, while portable compressors are necessary for mobile or variable work environments.

Air Filtering and Purification: For applications requiring clean air, appropriate air filtering and purification systems are essential. This includes suction and discharge air filtering systems and replaceable filters.

Regulation and Control: The compressor’s regulation system maintains constant pressure. Options include load/no load control, modulation control, and manual or automatic regulators, depending on the need for constant pressure and energy conservation.

By carefully evaluating these technical specifications, you can select an air compressor that meets your specific requirements and ensures optimal performance and efficiency.

The top air compressor manufacturers include Ingersoll Rand, Atlas Copco, Gardner Denver, Sullair, Kaeser Kompressoren, Hitachi, and Mitsubishi Heavy Industries (MHI). These companies are globally recognized for their high-quality products, innovative technologies, and comprehensive services. Ingersoll Rand is known for its reliable industrial air compressors and power tools, serving industries such as manufacturing and construction. Atlas Copco focuses on sustainable productivity with a presence in over 180 countries. Gardner Denver is renowned for its engineering excellence and serves various industries, including manufacturing and transportation. Sullair specializes in rotary screw compressors, providing clean and dry solutions for medical and automotive industries. Kaeser Kompressoren, a family-owned company, is known for efficient and reliable compressors. Hitachi, a multinational conglomerate, emphasizes technological innovation and energy efficiency. MHI has a significant impact on the aerospace and heavy industrial sectors, known for quality and innovation in manufacturing processes. These manufacturers are integral to various industries, including manufacturing, construction, automotive, and more, due to their advanced technologies and comprehensive service offerings.

Choosing the right type of air compressor for your needs involves evaluating several key factors that influence its performance and suitability for your specific applications. First, consider the air pressure (PSI) requirements of your tools. Most tools operate effectively around 90 PSI, but it’s advisable to choose a compressor that can produce at least 120 PSI to maintain consistent pressure.

Next, assess the air flow (CFM) needed. Different tools have specific CFM requirements, and it’s crucial to ensure your compressor can handle the combined CFM of all the tools you’ll be using simultaneously. For example, a framing nailer might require 3.0 – 5.0 CFM, whereas a paint sprayer could need 5.0 – 7.0 CFM.

The tank size of the compressor also matters. Smaller tanks (1-6 gallons) are suitable for light to medium usage, while larger tanks (over 26 gallons) are ideal for heavy usage and powering multiple tools. A larger tank means the motor runs less frequently, reducing wear and noise.

Consider the noise level and electrical needs of the compressor. Oil-less compressors tend to be noisier but require less maintenance. Ensure the compressor matches the electrical capacity of your work area; some larger models may need a dedicated 20-amp circuit.

Choose the type of compressor based on your work environment. Portable jobsite compressors are great for mobility and light to medium usage, while stationary workshop compressors with larger tanks are better for continuous use and powering a variety of tools. Gas jobsite compressors are useful for remote locations without electricity.

Additional features such as an oil-free pump, belt-drive system, thermal protection, adjustable exhaust, multiple couplers, and suitable hose and accessories can enhance usability and efficiency.

Finally, consider the specific tools you will be using. Determine the highest CFM and PSI requirements among your tools and select a compressor that exceeds these needs by about 50% to ensure reliable performance. By carefully evaluating these factors, you can choose an air compressor that meets your needs and optimizes the performance of your tools.

When evaluating air compressor manufacturers, it is important to look for several key certifications and standards that ensure the quality, safety, and performance of their products. Here are some crucial certifications to consider:

ISO 9001: This certification indicates that the manufacturer has a robust quality management system in place, ensuring consistent product quality and customer satisfaction.

ISO 1217: This standard specifies the requirements for the performance of air compressors, including air capacities and performance metrics.

ISO 8573: This standard defines the purity classes of compressed air, which is critical for applications requiring high air purity, such as in the medical industry.

ISO 22000: For the food and beverage industry, this certification ensures the manufacturer has implemented a food safety management system, including Hazard Analysis Critical Control Point (HACCP) principles.

ASME and CE-PED: Compliance with these standards ensures the safety and integrity of pressure vessels and equipment, which is crucial for high-pressure applications.

CE and UL Approval: These certifications ensure that the electrical components of air compressors meet safety and performance standards.

LEAN Manufacturing: Certification in LEAN manufacturing indicates a commitment to efficient and quality-oriented production processes, reflecting positively on the manufacturer’s ability to deliver high-quality products consistently.

CAGI: Certifications from the Compressed Air and Gas Institute (CAGI) ensure the expertise of personnel involved in designing, servicing, and installing compressed air systems.

ASERCOM: This certification is important for compressors used in commercial refrigeration and air conditioning systems, ensuring reliable performance data and aiding in product selection based on verified metrics.

By ensuring that an air compressor manufacturer holds these certifications, you can be confident in the quality, safety, and performance of their products.

Air compressors are widely used across numerous industries due to their versatility and efficiency in providing reliable power for various applications. In the automotive industry, air compressors are essential for vehicle assembly, painting, sanding, and powering pneumatic tools such as nailers and wrenches. The agricultural sector utilizes air compressors for tasks like powering tools, greenhouse ventilation, and maintaining irrigation systems. In the food and beverage industry, clean, contaminant-free compressed air is crucial for moving products on assembly lines, packaging, and maintaining product quality.

Manufacturing processes heavily rely on air compressors to power pneumatic tools and automate tasks like stamping, mixing, and clamping. The aerospace industry uses air compressors for precise and reliable production, ensuring high-quality standards. Woodworking and furniture manufacturing benefit from air compressors for operating air drills, nail guns, and other tools.

The pharmaceutical industry demands clean, dry, and oil-free compressed air for conveyor systems, packaging, and maintaining high sterility standards. In the textile industry, air compressors power equipment like air-jet looms and spinning machines, enhancing precision and reducing waste. The oil and gas industry relies on air compressors for maintaining pipeline pressure, gas injection, and petrochemical synthesis.

Additionally, air compressors play a crucial role in HVAC systems for climate control, dry cleaning facilities, mining operations, and breweries. They provide clean air, power pneumatic tools, and ensure efficient and safe operations in these industries. The consistent and reliable power provided by air compressors makes them indispensable across these varied sectors.

When buying an air compressor, several key features should be considered to ensure you select the right unit for your needs. Firstly, identify the type of compressor that suits your application: reciprocating compressors are ideal for intermittent use, rotary screw compressors for continuous use, and centrifugal compressors for high-volume applications.

Next, assess the air quality requirements. Compressors with integrated dryers and filters are essential for removing moisture and contaminants, crucial in industries like food processing and semiconductor manufacturing.

Consider the power source and size; compressors can be powered by electricity, gasoline, or diesel. Ensure the horsepower is sufficient to meet your needs without being excessive, which can lead to inefficiency. Evaluate the compressor’s capacity, measured in CFM, to ensure it can handle your tools and applications’ demand.

Check the required pressure, typically measured in PSIG, to match the needs of your pneumatic tools. The duty cycle, indicating the operational time before needing a break, is crucial for continuous industrial use.

Mobility and installation requirements should also be considered. Decide whether you need a portable compressor or a fixed one, and ensure you have the necessary space and installation setup, including electrical connections and ventilation.

Efficiency and maintenance are vital; look for compressors that meet efficiency standards and consider the maintenance needs of different types. Lastly, factor in industry-specific requirements, as different applications may have unique demands for air quality, pressure, and flow rate.

By carefully evaluating these features, you can choose an air compressor that meets your specific needs and ensures optimal performance and efficiency.

When selecting an air compressor manufacturer, the importance of after-sales service and support cannot be overstated. After-sales service plays a critical role in maintaining customer satisfaction and loyalty, ensuring that the equipment operates efficiently and reliably over its lifespan. Manufacturers that provide robust after-sales support, including maintenance contracts, genuine spare parts, and comprehensive customer service, significantly enhance the customer experience and foster long-term relationships.

Prompt and reliable after-sales service minimizes downtime, which is essential for maintaining business operations and profitability. Quick responses to maintenance needs and equipment repairs help prevent costly interruptions and ensure continuous production. This is particularly crucial in industries where air compressors are integral to daily operations, such as manufacturing, construction, and automotive sectors.

Regular maintenance facilitated by after-sales services can lead to substantial cost savings. Annual maintenance contracts (AMCs) help maintain the compressor’s efficiency, reduce energy consumption, and prevent expensive repairs by identifying potential issues early. This proactive approach extends the equipment’s lifespan and reduces overall maintenance costs.

Access to advanced tools and expertise is another significant benefit of strong after-sales support. Certified service providers use specialized equipment and diagnostic technologies to perform maintenance and repairs more efficiently, ensuring optimal performance of the air compressor system. This expertise is invaluable in minimizing the risk of unexpected breakdowns and ensuring compliance with industry standards.

A positive after-sales experience also enhances the manufacturer’s brand reputation. Satisfied customers are more likely to provide positive reviews and recommendations, contributing to a strong brand image. Conversely, poor after-sales service can lead to negative feedback and damage the brand’s reputation.

Furthermore, outsourcing air compressor maintenance to professional service providers allows businesses to focus on their core activities, such as production and innovation, without being distracted by maintenance tasks. Customized service agreements offered by manufacturers can be tailored to meet specific customer needs, providing additional value through emergency services, protection plans, and expert recommendations.

In summary, after-sales service and support are vital when selecting an air compressor manufacturer. They ensure customer satisfaction, reduce operational costs, minimize downtime, enhance brand reputation, and allow businesses to concentrate on their primary functions. Top manufacturers recognize the importance of integrating comprehensive after-sales services into their offerings, making it a key factor in the competitive landscape of air compressor manufacturing.