Have you ever wondered what powers the machines that drive our world? Gearboxes are the unsung heroes behind many industries, from automotive to wind energy. In this article, you’ll explore the top gearbox manufacturers, their innovations, and how they keep the wheels of progress turning. Get ready to uncover the secrets behind these mechanical marvels!

This article provides detailed information about top prominent companies in the gearbox and power transmission industry. These companies are known for their technological advancements, extensive product portfolios, and global reach.

Founded: 1969

Headquarters: Nanjing, China

Stock Listing: Listed in Hong Kong in 2007 under the stock name “China High Speed Drive”

Nangaochi Group is a leading provider of gearbox and power transmission solutions, serving customers worldwide. The company has built a strong reputation for its innovative products and commitment to quality.

Nangaochi Group has established four main business areas:

The company’s brand, “NGC,” is internationally renowned and has been primarily developed and cultivated in Jiangsu Province. NGC stands for quality and innovation in the gearbox industry.

Nangaochi Group adheres to the enterprise philosophy of “step by step, strive for perfection.” The company’s mission is “delivering the impetus of progress for human civilization.” This mission drives Nangaochi Group to continually improve its internal management, specialize and refine its operations, and expand its market development to an international level.

With advanced technology, reliable quality, and considerate service, Nangaochi Group is dedicated to producing products and services that exceed customer expectations. The company’s continuous efforts in innovation and quality assurance have established it as a trusted name in the gearbox and power transmission industry.

Nangaochi Group’s long-standing commitment to excellence and innovation has positioned it as a leader in the gearbox and power transmission market. With a strong focus on quality and customer satisfaction, the company continues to drive progress and deliver superior solutions to its global clientele.

Founded: 1915

Country: Germany

ZF Friedrichshafen AG, commonly known as ZF, is a global technology company that specializes in providing next-generation mobility system products for passenger vehicles, commercial vehicles, and industrial technology. The company is renowned for enabling vehicles to sense, think, and act independently, leveraging its extensive expertise in four key technical areas: vehicle motion control, integrated safety systems, autonomous driving, and electric drives.

ZF’s core competencies are centered around:

ZF offers a wide range of solutions tailored for both traditional automobile manufacturers and new mobility service providers. The company’s product portfolio is designed to:

ZF has been operating in China since 1981 and has achieved steady growth in the country. The company has established its Asia Pacific headquarters in Shanghai and operates two research and development centers. ZF’s presence in China includes:

Caiehu (China) Investment Co., Ltd.: This holding company manages ZF Friedrichshafen AG’s investment business in China. It provides a range of services including market and business development, human resources, finance, information technology, research and development, and supply chain management to ZF’s factories in China. It also supports ZF’s business activities in the Asia Pacific region.

ZF Asia Pacific Group Co., Ltd.: This entity is responsible for the business development of ZF’s Active and Passive Safety Technology Business Unit in the Asia Pacific region and oversees the comprehensive management of its factories.

ZF is committed to driving innovation and sustainability in the automotive industry. By integrating advanced technologies and focusing on environmental protection, ZF aims to shape the future of mobility and contribute to a safer, more efficient, and sustainable world.

With over a century of experience and a strong global presence, ZF continues to lead the way in automotive technology. Its operations in China and the Asia Pacific region are a testament to its commitment to growth and innovation, ensuring that it remains at the forefront of the industry.

Hangzhou ADVANCE Gearbox Group Co., Ltd. is a prominent Chinese enterprise specializing in the design and manufacture of gear transmission devices and powder metallurgy products. Recognized as a national high-tech enterprise, the company has a rich history dating back to its founding in 1960 as Hangzhou Gearbox Factory.

The company is strategically located on the south bank of the Qiantang River in Hangzhou, covering an area of 568,000 square meters. It employs over 1800 employees and operates 19 holding and actual controlling subsidiaries along with 2 joint-stock subsidiaries.

Hangzhou ADVANCE Gearbox Group Co., Ltd. has established a strong market position through its main business of transmission devices. The company emphasizes scientific and technological progress to enhance its core competitiveness. Since the 1980s, it has focused on independent development and the introduction of foreign advanced technology to foster secondary innovation.

The company’s product line has significantly expanded from a single marine gearbox to over 1000 varieties across ten categories:

Hangzhou ADVANCE Gearbox Group Co., Ltd. follows a robust brand development strategy, continuously improving its technology and introducing world-class high-quality equipment. It has established a comprehensive quality management system and built an extensive marketing and service network to ensure customer satisfaction.

The “ADVANCE” brand products are widely sold across 31 provinces, municipalities, and autonomous regions in China, and in 47 countries and regions globally.

Aligned with the national manufacturing power strategy, the company is committed to upholding its enterprise spirit of “loyalty, dedication, unity, and excellence.” It aims to promote the construction, transformation, and upgrading of intelligent manufacturing, striving for sustainable development with higher quality, efficiency, and benefits.

Hangzhou ADVANCE Gearbox Group Co., Ltd. stands as a testament to innovation, quality, and strategic growth in the gear transmission industry. With its extensive product range, robust quality management, and global market presence, the company is well-positioned to continue its legacy of excellence and technological advancement.

Founded: 1966

Location: Jiangjin District, Chongqing, China

Area: Over 900,000 square meters

Employees: More than 2000

Total Assets: Over 7 billion yuan

Chongqing Gearbox Co., Ltd., commonly referred to as “Chongchi,” is a prominent state-owned military enterprise specializing in the research, development, and production of high and low-speed heavy-duty gearboxes. The company is a key component of the China Shipbuilding Group (CSSC).

Chongchi’s core business revolves around hard-surface gear transmission devices. Their products serve a wide array of industries, including:

As a key military enterprise within the shipbuilding system, Chongchi manufactures ship gearboxes, couplings, and shock absorbers. It stands as one of the largest R&D and manufacturing bases for hard-surface gears in China and is the primary research base for rear transmission devices of naval ships in the country.

Chongchi is actively expanding into electromechanical and hydraulic system integration, leveraging its strong foundation in mechanical transmission. The company adheres to a high-quality development strategy that emphasizes military-civilian integration. This strategy is underpinned by:

Chongchi aims to become a world leader in gear transmission, earning respect and recognition globally. Their focus areas include:

By aligning with the requirements of military-civilian integration management, Chongchi seeks to establish itself as a respected and leading entity in the gear transmission industry.

Chongqing Gearbox Co., Ltd. is a pivotal player in the gear transmission sector, with a rich history and a forward-looking strategy. Its commitment to innovation, quality, and integration positions it well for continued growth and leadership in the industry.

Flender is a renowned technical expert and supplier of high-quality products and services in the fields of mechanical and electrical transmission. The company’s innovation and efficiency are driven by its professional and dedicated employees, strong consulting capabilities, and an extensive product portfolio.

Flender operates under two distinct brands: Flender and Winergy. This strategic division allows the company to cater to different market segments with specialized products and services.

Flender focuses on providing transmission technology products for a variety of industries. These products include gear units, couplings, and other mechanical and electrical transmission components. Flender’s expertise in these areas makes it a reliable partner for industries such as:

In 2001, Flender launched the Winergy brand to better serve the unique needs of the wind power industry. Winergy specializes in providing gearboxes, generators, and wind power services. This focus allows Winergy to deliver tailored solutions that enhance the efficiency and reliability of wind turbines. Key offerings include:

The dual-brand strategy of Flender and Winergy offers several advantages:

Flender’s strategic use of the Flender and Winergy brands enables the company to leverage its extensive technical expertise and production capabilities to serve a wide range of industries effectively. This approach not only enhances customer satisfaction but also solidifies Flender’s reputation as a leader in mechanical and electrical transmission technology.

Founded: 1956

Headquarters: Italy

Bonfiglioli is a globally recognized, family-owned business that has been a pioneer in the field of power transmission and control solutions for over six decades. The company is structured into three primary business departments:

These departments are dedicated to providing comprehensive and professional support to meet the diverse development needs of their customers.

Bonfiglioli boasts a robust global network, ensuring that customers receive timely and efficient support regardless of their location. This extensive network underscores the company’s commitment to delivering high-quality service and tailored solutions for various industrial applications.

Bonfiglioli designs, manufactures, and markets a wide array of products tailored to meet the specific needs of industrial automation, engineering machinery, and renewable energy sectors. Their product offerings include:

These products are integral to numerous aspects of daily life, impacting industries such as food production, infrastructure, textiles, and home lighting.

With five influential brands in the power transmission market, Bonfiglioli is well-positioned to serve a global clientele. The company has a rich history of embracing change and driving innovation, which has been a cornerstone of its success. Over the past 60 years, Bonfiglioli has consistently pursued technological advancements with enthusiasm, solidifying its reputation as a leader in the industry.

Bonfiglioli’s commitment to quality and sustainability is evident in its product design and manufacturing processes. The company strives to create solutions that not only meet but exceed the demanding requirements of their applications, ensuring reliability, efficiency, and environmental responsibility.

As a leader in the power transmission and control industry, Bonfiglioli continues to innovate and expand its product offerings to meet the evolving needs of its customers. With a strong global presence and a commitment to excellence, Bonfiglioli remains a trusted partner for industrial automation, engineering machinery, and renewable energy solutions.

Ningbo Donly Co., Ltd. (referred to as “Ningbo Donly” hereafter) was established in 1997 and became publicly listed on the Shenzhen SME Board in 2007. The company is a prominent player in China’s gear industry, listed as an A-share.

After more than two decades of growth, Ningbo Donly has developed a diverse and professional business model focusing on transmission equipment, door control systems, and engineering technology services. The company operates production and manufacturing facilities located in the Ningbo Jiangbei Industrial Zone, Ningbo National High-Tech Zone, and Sichuan Chuandeyang, covering a total area of 320,000 square meters.

Located in the Jiangbei Industrial Zone, Ningbo Donly Transmission Equipment Co., Ltd. is a high-tech enterprise dedicated to the research and development (R&D), production, and service of gearboxes, motors, and transmission devices. The company is equipped with high-precision and comprehensive gear processing, box processing, heat treatment, physical and chemical testing, and experimental equipment.

Ningbo Donly’s product range includes:

These products cater to power capacities ranging from 0.12 KW micro gearboxes to 10,000 KW high-power heavy-duty gearboxes. The company has established partnerships with many Fortune 500 companies and maintains a global sales network. In the metallurgical industry, Ningbo Donly has held a significant domestic market share for many years.

Ningbo Donly Transmission focuses on serving the high-end market with its transmission equipment offerings, providing comprehensive and high-quality transmission solutions to its customers. The company adheres to the values of “loyalty, trust, respect, and perfection,” prioritizes value creation, and strives to be a value-leading listed company that integrates manufacturing, industrial management, and capital management.

The company’s facilities are equipped with state-of-the-art technology for:

Ningbo Donly Co., Ltd. stands out as a leader in the gear industry in China, with a strong focus on innovation, quality, and customer satisfaction. Through its comprehensive product offerings and robust partnerships, the company continues to expand its market presence both domestically and internationally.

The NORD Group, a renowned transmission equipment manufacturer, was founded in 1965 and is headquartered in Hamburg, Germany. The company specializes in the production and sales of reducers, motors, and frequency converter equipment. With a robust global presence, NORD Group operates eight advanced production bases across five continents, ensuring the delivery of high-quality drive parts to customers worldwide.

NORD Group’s extensive network includes 36 branches worldwide, providing ample inventory, assembly services, technical support, and customer service. The company employs approximately 4,000 individuals who are dedicated to offering customized drive solutions to meet the diverse needs of their global clientele.

NORD entered the Chinese market in 2005, establishing modern assembly and production bases in key cities such as Suzhou and Tianjin. By 2019, NORD China had grown to employ 700 people, maintaining the same high standards of quality and service as the parent company. NORD China adheres to a professional business philosophy, ensuring swift and reliable service.

NORD China boasts advanced facilities, including a high-precision motor laboratory and a modern frequency converter studio for equipment debugging, testing, and maintenance. The company also operates two technical service centers and 25 sales offices in major industrial cities across China.

NORD’s products are utilized in a wide array of industries, demonstrating their versatility and reliability. Key sectors include:

The NORD Group’s commitment to innovation, quality, and customer service has solidified its position as a leading global provider of transmission equipment. With a strong presence in China and a diverse range of industry applications, NORD continues to drive forward with its mission to deliver exceptional drive solutions worldwide.

Chongqing Wangjiang Industry Co., Ltd. (referred to as “the Company”) is a prominent Class I enterprise directly owned by China Ordnance Equipment Group Co., Ltd. The company has a rich history, originally founded in Qingyuan County, Guangdong Province, in 1933, and later relocated to Guojiatuo in Chongqing City in 1938. In 2003, the company underwent a system reform, resulting in its current form as Chongqing Wangjiang Industry Co., Ltd.

The company boasts a robust infrastructure with more than 2,500 sets of processing and testing equipment, which supports its strong comprehensive machining manufacturing and production testing capabilities. This extensive setup enables the company to maintain high standards in both production and quality assurance.

Since the founding of the People’s Republic of China, Chongqing Wangjiang Industry Co., Ltd. has developed and produced numerous special equipment, earning over 100 awards for its contributions to national defense construction. The company’s equipment has been prominently featured in significant national events, including:

These contributions have earned the company recognition and honor from the Party and the people of China.

In the new era, the company has adopted a market-oriented approach, diversifying its product offerings to include:

These products are sold in over 10 regions, including the Southwest, Northwest, and North China, with the company’s production and sales volume ranking among the highest in Southwest China.

Chongqing Wangjiang Industry Co., Ltd. has experienced continued and rapid growth, leading to an increase in its economic scale and overall strength. This growth has significantly enhanced the company’s contribution and influence in the industry, positioning it as a key player in China’s industrial landscape.

In summary, Chongqing Wangjiang Industry Co., Ltd. is a well-established and influential enterprise with a strong historical foundation, extensive capabilities, and a diverse product portfolio. Its contributions to national defense and its market-oriented approach ensure its continued relevance and success in the industry.

Dalian Huarui Heavy Industry Group Co., Ltd. (commonly referred to as “Dalian Heavy Industry”) is a prominent publicly listed holding company under the umbrella of Dalian Heavy Industry & Crane Group Co., Ltd., with the stock code 002204. As a significant player in China’s national heavy machinery industry, Dalian Heavy Industry stands out as a large-scale key enterprise.

The company boasts a robust workforce of over 10,000 employees and manages total assets valued at nearly 20 billion yuan. This substantial asset base enables Dalian Heavy Industry to provide comprehensive technical equipment, high-tech products, and services across various foundational sectors of the national economy.

Dalian Heavy Industry serves a diverse range of industries, including:

The company has developed nine distinct product structures:

Dalian Heavy Industry has established a comprehensive research and development framework, known as “one headquarters and five research and development bases,” spanning over 2 million square meters. This infrastructure supports the company’s capability for independent R&D of major technical equipment and the integration of electromechanical and hydraulic systems, encompassing design, manufacturing, installation, commissioning, and general contracting.

The company has a strong international presence, exporting products to over 90 countries and regions. It has been recognized by the Ministry of Science and Technology of the People’s Republic of China as the “National Wind Power Transmission and Control Engineering Technology Research Center.” Dalian Heavy Industry has garnered 24 national, provincial, and municipal product awards, with many of its technologies achieving world-class standards.

To bolster its R&D efforts, Dalian Heavy Industry has established a National Technology Center, which includes:

Additionally, the company has set up a German Technology Research and Development Center, a postdoctoral workstation, and an academician workstation, forming a comprehensive scientific research and development system.

Dalian Huarui Heavy Industry Group Co., Ltd. exemplifies a leading enterprise in China’s heavy machinery sector, with extensive capabilities in R&D, manufacturing, and international operations. Its diverse product offerings and strong focus on innovation and technology position it as a key contributor to various critical industries both domestically and globally.

When evaluating gearbox manufacturers, the reputation and experience of the company are crucial factors. A well-established manufacturer with a strong reputation is likely to have a proven track record of delivering high-quality products and services. For instance, a company recognized with awards such as the “Industry Excellence Award” or holding certifications like ISO 9001:2015 demonstrates credibility and expertise. Positive customer testimonials, such as those from large automotive or industrial clients, can also provide insights into the manufacturer’s reliability and customer satisfaction levels. Companies with decades of experience, like those founded in the early 20th century, often have extensive knowledge and a deep understanding of market needs and technological advancements.

The quality of the gearboxes produced by a manufacturer is paramount. High-quality gearboxes ensure reliability, efficiency, and longevity in various applications. For example, gearboxes made from hardened steel or aluminum alloys are known for their durability. Advanced manufacturing techniques, including precision machining and heat treatment processes, contribute to the production of robust and reliable gearboxes. Gearboxes that meet or exceed industry standards such as ISO 9001:2015 and ANSI B11.19-2019 are more likely to be of high quality. Data supporting the longevity of these materials, such as a 20% increase in lifespan compared to standard materials, can further validate their use.

Excellent customer service and support are essential for ensuring that any issues or queries are promptly addressed. Manufacturers offering 24/7 technical support can assist with installation, maintenance, and troubleshooting. Comprehensive after-sales services, including warranty coverage of up to five years, repair services, and availability of spare parts, are significant advantages. The ability to provide customized solutions tailored to specific application requirements, such as bespoke gear ratios or housing designs, enhances the manufacturer’s appeal.

A manufacturer’s commitment to research and development (R&D) indicates its dedication to innovation and continuous improvement. For example, manufacturers investing 10% of their annual revenue into R&D are more likely to develop advanced and efficient gearbox solutions. Innovative products, such as smart gearboxes with Internet of Things (IoT) capabilities, demonstrate a forward-thinking approach. A portfolio of patents and proprietary technologies, such as a patented noise reduction mechanism, underscores the manufacturer’s innovative capabilities.

A manufacturer’s global presence can provide insights into its ability to serve diverse markets and meet international standards. A wide distribution network, including warehouses and service centers in multiple continents, ensures timely delivery and availability of products. International partnerships, such as collaborations with leading automotive companies, enhance a manufacturer’s credibility and reach. Understanding local market needs and regulatory requirements, demonstrated by compliance with regional standards like the European CE mark, is crucial for providing effective solutions.

Reviewing case studies and references from previous projects can provide valuable insights into a manufacturer’s capabilities and performance in real-world applications. Successful implementations, such as a gearbox solution for a major wind turbine project that resulted in a 15% efficiency improvement, showcase the manufacturer’s expertise. Client references from industries such as aerospace or heavy machinery can provide firsthand information on the manufacturer’s reliability and product performance. For instance, a testimonial from a leading mining company highlighting the reduced downtime and increased productivity due to the manufacturer’s gearboxes can be highly persuasive.

By thoroughly evaluating these factors, you can make an informed decision when selecting a gearbox manufacturer that meets your specific needs and ensures high-quality, reliable, and efficient solutions.

When selecting a gearbox manufacturer, the reputation and experience of the company are critical factors that can greatly influence the quality and reliability of the products. A manufacturer’s reputation is built over time through consistent delivery of high-quality products, excellent customer service, and a commitment to innovation. Experience reflects the company’s longevity in the industry and its ability to adapt to changing market demands and technological advancements.

When purchasing a gearbox, several critical factors must be taken into account to ensure you select the most suitable product for your specific needs.

Choosing a manufacturer with extensive experience in gearbox design and manufacturing is crucial. For example, a manufacturer with over 50 years in the industry is likely to provide reliable, high-quality products and offer valuable insights. Experienced manufacturers are more likely to understand the complexities of different applications and provide solutions that are tailored to your unique requirements.

The reliability of a gearbox is paramount. A reliable gearbox ensures consistent performance, reduces downtime, and lowers maintenance costs. Evaluate the manufacturer’s history of delivering high-quality products. For instance, products that meet ISO 9001 certification standards are likely to be more durable and efficient. Consider their use of high-grade materials and advanced manufacturing processes.

Excellent customer service is essential for addressing any issues that may arise. Manufacturers should offer comprehensive technical support, including installation guidance and troubleshooting assistance. Robust after-sales support, such as warranty services and availability of spare parts, is crucial for ensuring long-term reliability. For example, a manufacturer that provides a 24/7 customer support hotline can significantly reduce downtime in critical situations.

The ability to customize gearboxes to meet specific application requirements is a significant advantage. Manufacturers should offer flexible solutions and be able to adapt to changing business needs. For instance, the option to choose special gear ratios or unique housing designs ensures that the gearbox is perfectly suited to your application, enhancing performance and efficiency.

Consider the total cost of ownership when selecting a gearbox. This includes the initial purchase price, maintenance costs, repair expenses, and potential downtime. While some gearboxes may have a higher upfront cost, their long-term efficiency and reduced maintenance costs can lead to significant savings. For example, a gearbox with an energy-efficient design can lower operational costs over time.

Innovative gearbox technologies can significantly improve performance and efficiency. Look for manufacturers that invest in research and development and use advanced materials and design techniques. Features such as IoT capabilities provide real-time performance data, enabling predictive maintenance and reducing downtime. Predictive maintenance uses data analytics to anticipate and address issues before they lead to failures.

For businesses committed to sustainability, the environmental impact of the gearbox and its manufacturing process is an important consideration. Manufacturers that use eco-friendly materials and sustainable manufacturing practices can help align with your environmental goals. For instance, gearboxes designed for energy efficiency can reduce the overall environmental footprint of your operations.

Ensure that the gearbox meets the specific technical requirements of your application. Key specifications to consider include:

A good warranty and robust post-sales support are indicative of a manufacturer’s confidence in their product. This support can be invaluable in the event of unforeseen issues. Ensure that the manufacturer offers comprehensive warranty coverage and reliable post-sales support services. For example, a five-year warranty can provide peace of mind and reduce long-term costs.

The regional market share and growth of the manufacturer can influence your choice. Understanding the regional dynamics, such as the presence of local service centers and support networks, can help in selecting a manufacturer with a strong presence and ability to provide timely assistance. For instance, a manufacturer with a well-established network in your region can offer faster support and service.

The physical dimensions and housing styles of the gearbox should be compatible with your system. Considerations for space constraints and the need for compact designs are particularly important in manufacturing plants where space is limited. Ensure that the gearbox fits seamlessly into your existing setup. For example, a compact gearbox design can be advantageous in tight spaces.

By carefully evaluating these factors, you can make an informed decision when purchasing a gearbox, ensuring that it meets your specific needs, enhances efficiency, and provides long-term reliability.

Below are answers to some frequently asked questions:

The leading gearbox manufacturers for the automotive industry include several prominent companies known for their innovation, quality, and extensive market presence. ZF Friedrichshafen AG is a global leader in driveline and chassis technology, producing a range of transmissions for various vehicle types and maintaining supply agreements with major automakers like Volkswagen, Renault, BMW, and Toyota. Schaeffler AG, another key player, manufactures high-precision components and systems for transmissions and has a significant global footprint with numerous manufacturing facilities.

Magna International Inc., through its subsidiary GETRAG, offers a variety of gearboxes including manual, dual-clutch, and hybrid transmissions, and operates across many countries. Aisin Seiki Co., Ltd., a Japanese manufacturer, produces a wide range of transmissions, including CVTs and hybrid options, making it a crucial player in the market. BorgWarner Inc. specializes in propulsion systems and components, including automatic and dual-clutch transmissions, and has a substantial presence in North America, Europe, and Asia.

Allison Transmission Inc. focuses on high-performance transmissions for commercial and military applications, while Eaton Corporation is recognized for its transmission products for commercial vehicles. JATCO Ltd. specializes in automatic transmissions and CVTs, supplying many major automobile manufacturers. Continental AG produces various transmission components and systems, and Hyundai Transys Inc. is noted for its innovative automatic transmission technologies. These companies lead the automotive gearbox market through their extensive operations, technological advancements, and strong partnerships with major car manufacturers.

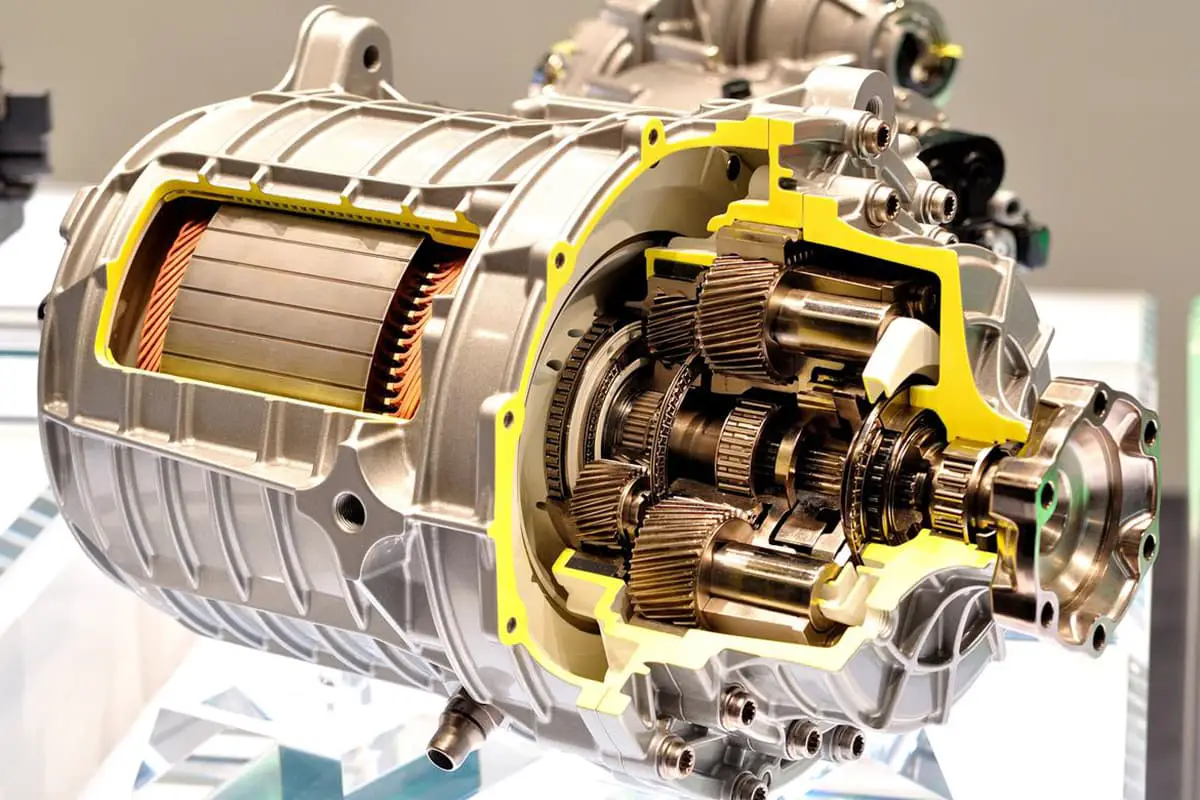

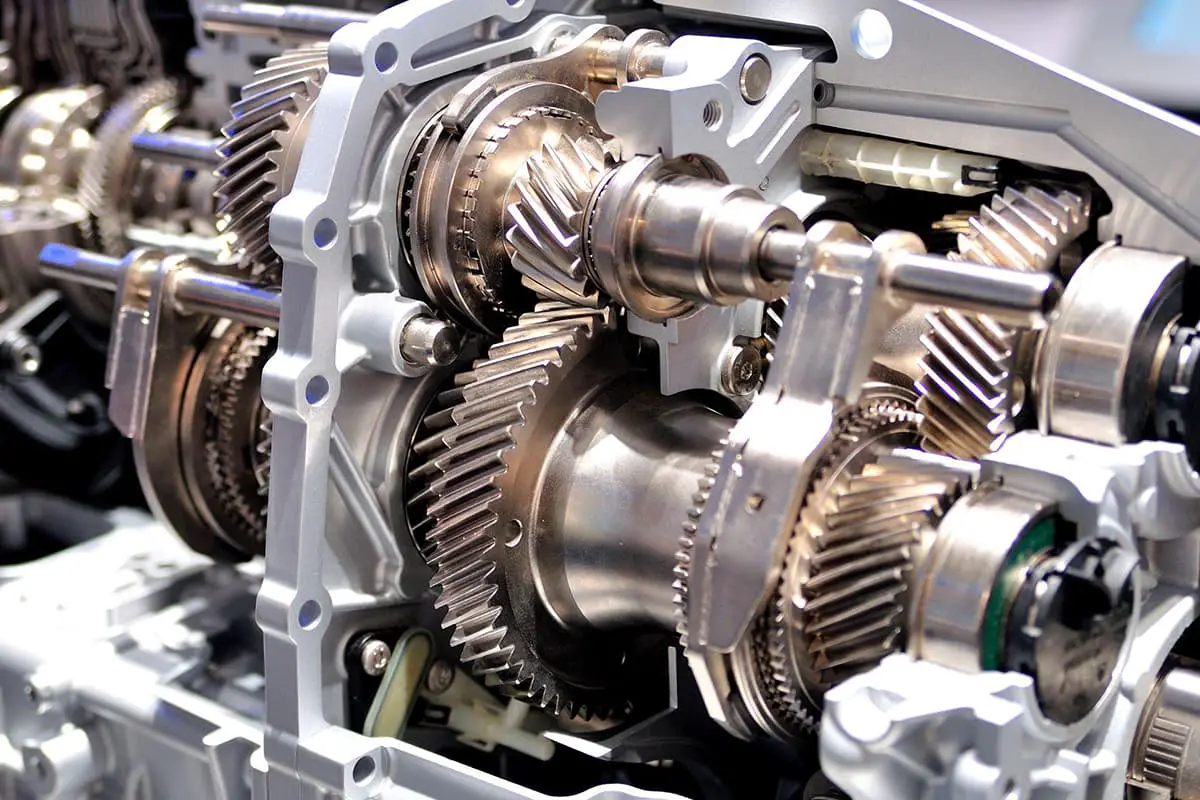

Gearboxes are mechanical devices used to transfer power from one component to another and to change the speed, torque, and direction of this power. There are several types of gearboxes, each with specific uses across various industries:

In the automotive sector, different types of gearboxes are used to enhance performance and efficiency:

Each type of gearbox is tailored to meet specific operational needs, such as high torque, shock load resistance, or space constraints, making them essential across a wide range of industrial and automotive applications.

Evaluating the quality of a gearbox manufacturer involves a thorough analysis of several critical factors. Firstly, consider the quality of materials and manufacturing processes. A reputable manufacturer should use durable materials and advanced manufacturing techniques, adhering to industry standards such as ANSI/AGMA for gear design and manufacturing. Reliability and performance are also crucial; look for manufacturers with a proven track record of delivering high-quality, reliable products backed by warranties and robust quality control measures, including testing and inspection.

Customer service and support are essential; the manufacturer should offer technical support, installation guidance, and troubleshooting assistance through a knowledgeable and experienced team. Expertise and customization capabilities are important, especially for industries requiring specialized gearboxes. A manufacturer with extensive experience can provide tailored solutions and valuable insights.

Research the manufacturer’s reputation by reading reviews and testimonials from other businesses on platforms like Google Reviews, Yelp, and Trustpilot, and ask for references directly from the manufacturer. A strong reputation is indicative of quality products and excellent service.

Ensure the manufacturer has stringent quality control and inspection protocols, including visual, functional, and acoustical inspections. Compliance with internationally recognized standards like IEC 61400-4 and AGMA is essential for specific applications. Warranty and after-sales support are also crucial; a reliable manufacturer will offer extended warranties and dedicated customer support services to protect customers in case of breakdowns.

Finally, consider the availability of maintenance and repair services. A manufacturer that offers comprehensive maintenance and repair services, along with a healthy supply of spare parts and a nationwide maintenance network, can help minimize production downtime and ensure efficient operation. By evaluating these factors, you can select a gearbox manufacturer that provides high-quality, reliable, and efficient products with excellent customer service and support.

Yes, there are several leading manufacturers that specialize in offering custom gearbox designs to meet specific application requirements. These manufacturers provide tailored solutions to ensure that the gearboxes meet the unique needs of their clients in terms of material selection, size, speed, torque, and performance specifications.

Prominent manufacturers such as Ondrives.US, Superior Gearbox Company, WM Berg, Riley Gear Corporation, and Horsburgh & Scott are known for their expertise in custom gearbox design. These companies offer extensive engineering support, including design services and reverse engineering capabilities, to create gearboxes that align precisely with the customer’s requirements.

Ondrives.US, for example, offers a wide range of custom configurations, including right angle, parallel shaft, and crossed axis gearboxes, designed to meet specific needs such as low backlash and high output torque. Superior Gearbox Company provides custom solutions tailored to various torque, horsepower, and power consumption requirements, working closely with customers to meet their timelines and budgets.

WM Berg uses advanced 3D CAD design and encourages on-site meetings with engineers to ensure precise customization for unique torque, material, and speed/backlash specifications. Riley Gear Corporation leverages its over 70 years of experience to produce high-quality custom gearboxes for industries such as commercial, marine, defense, and energy, adhering to AGMA standards.

Horsburgh & Scott designs and manufactures custom gearboxes for light to heavy-duty applications, utilizing modern manufacturing processes to produce efficient units that can handle high torque and power requirements.

These manufacturers highlight the importance of customization, engineering support, adherence to quality standards, versatile applications, and advanced manufacturing techniques to deliver reliable and high-performance custom gearboxes.

When purchasing a gearbox for industrial applications, several critical factors must be considered to ensure the selection of the most appropriate and efficient gearbox. Firstly, the service factor is essential; it accounts for the ratio between the gearbox’s rated horsepower and the horsepower demanded by the application, considering variables like input type, daily usage hours, and shock or vibration levels. Higher service factors are necessary for applications with non-uniform loads, frequent starts or stops, and extreme vibration.

Next, evaluate the load characteristics and torque requirements by determining the torque and speed needed for the load and the overall speed ratio from the motor to the load. Ensure the gearbox can handle the required output torque and decide if constant horsepower or constant output torque is necessary at all speeds. The gearbox ratio and any additional reduction mechanisms should also be determined to meet the required ratio.

Overhung load calculations are crucial; the gearbox must have an overhung load rating that exceeds the calculated load to prevent premature wear and failure. Consider the operating conditions and environment, including ambient temperature and the need for special materials like corrosion-resistant coatings or stainless steel housing.

Mounting and configuration needs must be determined, such as shaft input or hollow bore input, shaft output or hollow bore output, and the gearbox orientation. Compatibility with the motor is also vital; ensure the motor and gearbox combination meets the system requirements, and consider if the manufacturer offers integrated motor services.

Calculate the design horsepower by multiplying the service factor by the actual input horsepower required, and use appropriate formulas to determine torque requirements. Choose the correct type of gearbox based on your application needs, considering options like helical gearboxes, coaxial helical inline gearboxes, spiral bevel gearboxes, planetary gearboxes, and worm gearboxes, each suited for different applications.

Additional considerations include ensuring proper lubrication and seals, especially for vertical shaft applications, and determining if special materials are needed based on the application environment. Refer to the manufacturer’s catalog or website for detailed dimensional and mounting information to ensure proper installation. By carefully evaluating these factors, you can select a gearbox that meets your specific industrial application needs, ensuring optimal performance, efficiency, and longevity.