What sets top hydraulic press machine manufacturers apart in today’s market? This article ranks the leading companies globally, highlighting their specialties and innovations. By exploring the offerings of these industry giants, readers will gain insights into the latest advancements and discover which manufacturers best meet their needs. Whether you’re interested in deep drawing presses, forging technology, or high-speed forming machines, this guide provides a comprehensive overview to help you make informed decisions. Dive in to learn about the companies shaping the future of hydraulic press technology.

The following is a ranking of the top 15 hydraulic press machine manufacturers and the best forging equipment suppliers in the world.

Asai Sangyo Co., Ltd. was founded in 1947 and has a workforce of 100 employees. The company specializes in the manufacture and sale of press machines.

They offer a range of products including hydraulic press machines, die spotting press machines, and related components, as well as inspection services for press machines. Additionally, the company provides machine assembly and parts manufacturing contracting services.

Beckwood, an American company established in 1976, provides press and automation equipment to manufacturers around the world.

Their product line includes temperature-controlled presses for compression molding and hot forming/SPF, triple-sheet hydroforming presses, hydraulic ring expanders, hot joggle presses, and stretch forming machines.

To maximize productivity, Beckwood has developed several strategic technologies for their custom thermoforming solutions.

Dees, established in 1976 in Taiwan, specializes in the manufacture of customized hydraulic machinery with a reputation for excellence in the metal forming industry.

Their primary products include deep drawing presses, clamping machines, bending machines, and other related hydraulic presses.

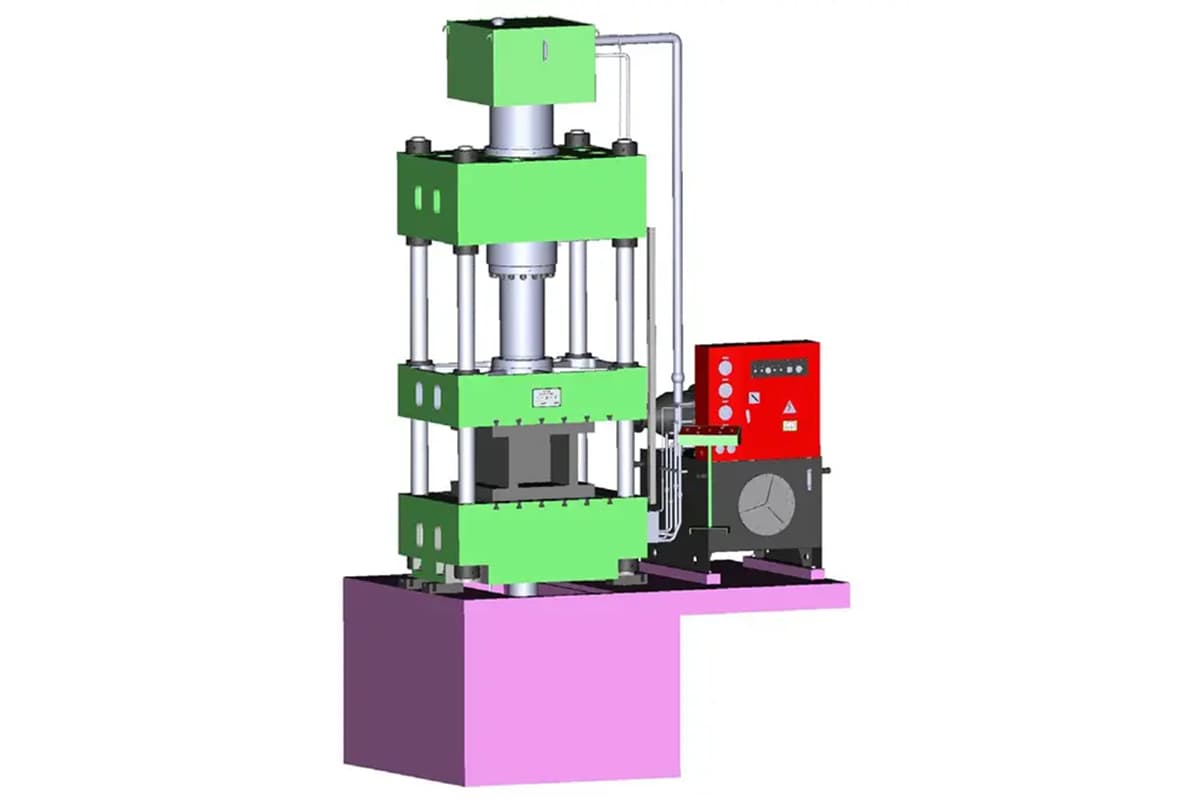

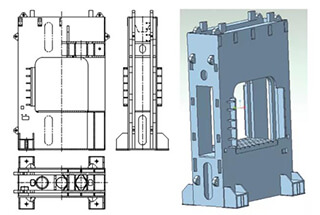

Doerfer Companies, an American company with a workforce of 580 employees and a production area of over 650,000 square feet, provides hydraulic press system technology through its subsidiary, Williams White & Company.

Williams White is a leading supplier of hydraulic press technology and presses in North America, offering solutions ranging from 500 to 13,000 tons for various applications such as aerospace, forging, hydroforming, laminating, metalworking, and forming.

Headquartered in the United States, Gasbarre was established in 1973 and has a workforce of over 200 employees across seven locations.

The company designs and manufactures complete powder pressing and sizing presses for the powder metallurgy industry. They offer equipment and services for all applications related to powder compaction and heat treatment and have established a global reputation for their comprehensive services in the powder metallurgy, granular materials, and heat treatment industries.

Currently, 20% of Gasbarre’s products are exported, including mechanical powder presses, hydraulic powder presses, isostatic powder presses, sintering and brazing furnaces, vacuum and atmosphere furnaces, industrial heat treatment equipment, and more.

Kojma, founded in 1809 as a foundry, built Japan’s first hydraulic press in the early 19th century. Since then, the company has been at the forefront of developing and incorporating the latest technology and has accumulated extensive experience as a manufacturer of pressure mechanisms.

Their product offerings include a ring rolling mill, hydraulic forging press, hydraulic long plate forming press, plate forming press, hydraulic straightening press, high-speed stamping press, high-speed tryout press, scratch deep drawing press, tryout press, die spotting press, rim forming press, and more.

Lasco, established in Germany in 1863, boasts over 160 years of machinery manufacturing experience and has served over 1000 users in over 50 countries worldwide.

The company offers users the most advanced forging equipment and forging production lines. With a workforce of over 300 employees, about 20% of whom are involved in design and development, Lasco is well-positioned to meet the needs of the market. In 1952, Lasco produced the world’s first hydraulic die forging hammer and has since established itself as a pioneer in the forging hammer industry.

Over the past few decades, Lasco has continued to develop and improve their products, resulting in the new generation of high-efficiency and high-speed electro-hydraulic hammers. These products are ideal for hot forging, warm forging, cold forging, various extrusion processes, and sheet forming.

Macrodyne is a Canadian company established in 1996, specializing in the design and manufacture of heavy-duty hydraulic presses with capacities up to 20,000 tons.

The company also offers automatic hydraulic press production lines, automation systems, and mold processing equipment for molds weighing more than 100 tons.

As the main manufacturer and supplier of power presses, hydraulic presses, press production lines, and die processing equipment, Macrodyne’s products are used for a wide range of metal forming applications, including hot stamping, deep drawing, compression forming, forging, extrusion, embossing, die clamping, hydraulic forming, elastic forming, superplastic forming, rubber forming, and laminating and wood processing.

Founded in 1978, Sanki Seiko is a technology-focused oil press manufacturer. Its main products include a Reversing Type Die Spotting Press, a Die Spotting Press, a Tryout Press, a Trimming Press, a Molding Press, a Hemming Press, a Hot Press, and a High-Speed Deep Drawing Press.

These products are exported to 17 countries and regions across the world, including North America, South America, the European Union, and Asia.

The company’s products have a worktable that can be processed up to 5000mm x 2500mm and the mold test pressure can be adjusted steplessly and variably up to 1000 tons.

Schuler, a German company founded in 1839, is a technology pioneer in the field of metal and composite forming equipment.

The company operates production bases in Germany, Switzerland, Brazil, the United States, and China, and has branches in 40 countries/regions as well as its own sites and representative offices. As of 2016, the company employed over 6,600 people and holds more than 600 patents.

Siempelkamp, founded in 1883 in Germany, focuses on three main divisions: machine and plant engineering, foundry technology, and engineering and services.

Its machine and plant engineering division is a systems supplier of press lines and complete plants for the wood-based panel industry, metal forming industry, as well as the composite and rubber industries.

SMS Meer is a subsidiary of the SMS Group. Founded in 1872 and headquartered in Germany, SMS Meer is a leading global manufacturer of metallurgical equipment.

The equipment is utilized in the industrial processing of metal materials such as steel, aluminum, and non-ferrous metals. With a workforce of 2400 employees, over half of whom are based at the German headquarters, SMS Meer has grown through organizational expansion and strategic mergers and acquisitions to become a top equipment supplier in the metal forming and processing industry.

The company offers comprehensive technical support and services for all its products, providing its customers with all-around technical assistance after equipment acceptance.

Tianduan Press is a Chinese company established in 1966. The company specializes in the production of plate shears, bending machines, hydraulic presses, plate rolling machines, and complete JCOE large-diameter longitudinal submerged arc welded pipe equipment.

The company offers 20 series and over 200 specifications that are categorized into five categories.

These products are utilized in a variety of industries, including machinery manufacturing, metallurgy, petrochemical, electric power, wind power generation, aerospace, defense, military, automobile, railway, shipbuilding, oil and gas transportation, and more.

Xuduan Group is a Chinese company established in 1951. They offer a variety of products such as mechanical presses, CNC servo presses, and hydraulic presses. With 21 marketing branches and 40 offices nationwide, the company employs over 100 people directly involved in marketing and after-sale services.

Founded in 1966, Yangli Group is a Chinese company committed to the research and development (R&D) and manufacturing of various medium and high-end sheet metal processing equipment and intelligent production lines. The group spans across an area of 1670 Mu and employs over 4000 people.

It is one of the largest, most comprehensive, and strongest medium and high-end metal forming equipment manufacturers in China. The group has three manufacturing bases and five production divisions, and boasts a modern standard workshop of 600,000 square meters and various high-precision and cutting-edge processing equipment. With an annual production capacity of 30,000 sets of complete machines, Yangli Group has the ability to provide complete solutions for medium and high-end sheet metal processing.