Are you aware of the pivotal players in the centrifugal pump industry? This article dives into the leading manufacturers revolutionizing the market with innovative and reliable pumping solutions. From Bosch Rexroth’s intelligent motion technologies to Parker Hannifin’s diverse control systems, the piece highlights the top companies driving advancements in efficiency and performance. Readers will gain insights into each company’s unique strengths and their impact on various industries, helping you make informed decisions for your engineering needs.

Hydraulic pumps are essential components in various industrial applications, providing the power needed to operate machinery and equipment. These pumps convert mechanical energy into hydraulic energy, enabling efficient and precise control of motion and force. Understanding the landscape of hydraulic pump manufacturers is crucial for selecting the right supplier for specific needs.

Several companies stand out in the hydraulic pump manufacturing industry due to their extensive product lines, innovation, and commitment to quality. These manufacturers cater to a broad spectrum of applications, from industrial machinery to mobile equipment and aerospace systems.

Country: Germany

About the company:

Bosch Rexroth is globally recognized as a leading supplier of transmission and control technology, dedicated to delivering efficient, powerful, and safe intelligent motion solutions for a wide array of machinery and system equipment.

With a wealth of project experience, Bosch Rexroth excels in several key areas:

Bosch Rexroth’s portfolio includes intelligent components, customized solutions, and comprehensive services designed to foster an optimal application environment for the interconnected industry. This includes:

Country: USA

Founded: 1918

About the company:

Founded in 1918, Parker Hannifin is a diversified global manufacturer specializing in motion and control technologies and systems. The company provides innovative design solutions for various markets, including automotive, industrial, and aviation sectors. Parker Hannifin is committed to meeting customer needs by leveraging its unique engineering expertise and a broad range of core technologies to tackle some of the world’s most challenging engineering problems.

Parker Hannifin’s engineering prowess allows the company to establish strong partnerships with customers, significantly enhancing their productivity and profitability. By working closely with clients, Parker Hannifin ensures that its solutions are tailored to meet specific requirements, thereby optimizing performance and efficiency.

As a leading global motion control manufacturing company, Parker Hannifin offers a wide array of products and services. The company boasts over 1,400 production lines for components and systems, which are distributed across more than 1,000 industrial and aviation fields. Parker Hannifin’s product portfolio includes hydraulic, pneumatic, and electromechanical motion control solutions, catering to a diverse customer base.

Parker Hannifin’s extensive sales network comprises over 7,500 distributors, serving 400,000 customers worldwide. This robust distribution network ensures that Parker Hannifin’s products and services are readily accessible to customers across the globe.

In China, Parker Hannifin offers more than 2,000 product lines, covering over 50 markets. The company provides enterprises with nine technical solutions and services, including aerospace, environmental control, electromechanical, filtration, fluid and gas treatment, hydraulics, pneumatics, process control, and sealing. Parker Hannifin’s product applications and solutions are integral to various industries, such as diesel engines, wind power generation, shipbuilding, marine exploration, steel production, engineering machinery, high-speed railways, and factory automation.

Country: Japan

Founded: 1896

About the company:

Kawasaki Heavy Industries is a prominent player in the hydraulic industry, known for its advanced scale and production capabilities. The company manufactures a wide range of hydraulic machines, including hydraulic pumps, motors, actuators, and hydraulic control valves. Additionally, Kawasaki produces various application-specific machines, such as hydraulic devices, hydraulic deck machinery, electric hydraulic cabin operators, and hydraulic machinery for fishing, offering comprehensive machinery solutions.

Kawasaki’s commitment to innovation is evident through its excellent research team and state-of-the-art test equipment, which are dedicated to developing new technologies and products. This focus on innovation aims to enhance product quality and ensure a stable supply.

Kawasaki’s precision mechanical hydraulic systems are globally recognized, supported by an extensive production network in Japan, the United Kingdom, China, and South Korea. The company’s sales and service networks extend across Japan, the United Kingdom, the United States, China, and South Korea, ensuring worldwide service and support.

Kawasaki Heavy Industries leverages its technological expertise and global infrastructure to deliver high-quality hydraulic solutions, meeting diverse industrial needs worldwide.

Country: Europe

Founded: 1933

About the company:

Founding and Early Vision

Danfoss’s journey began on September 1, 1933, when Mads Clausen founded the company on his parents’ farm in Nordborg, Denmark. From these humble beginnings, Danfoss has evolved into a global leader in providing innovative and energy-efficient solutions.

Commitment to Innovation

Innovation has been a cornerstone of Danfoss’s DNA since its inception. The company’s history is marked by a series of pioneering products that have set industry standards:

Global Impact and Core Philosophy

Mads Clausen’s vision transformed a simple valve into a global enterprise. Today, Danfoss continues to be a benchmark for innovation, driven by its core philosophy of maintaining the “essence” of Danfoss. This philosophy is embodied in the company’s Core&Clear strategy, which emphasizes clarity, focus, and a commitment to excellence.

Danfoss’s unwavering dedication to innovation and energy efficiency has made it a global leader in its field. From its early days on a Danish farm to its current status as a multinational corporation, Danfoss remains true to its founding principles, continually pushing the boundaries of what is possible in the world of engineering and technology.

Country: Japan

Founded: 1919

About the company:

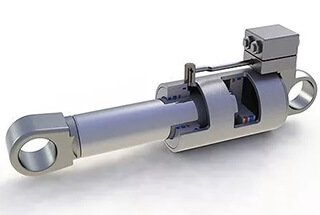

KYB Corporation of Japan is a globally recognized leader in hydraulic equipment manufacturing. The company effectively employs oil pressure technology to produce and sell a diverse range of products, including shock absorbers for various vehicles such as automobiles, motorcycles, trucks, buses, aircraft, and railway vehicles. Additionally, KYB manufactures oil pressure equipment for construction and industrial machinery, agricultural machinery, and system equipment for ships and theater stage devices.

KYB Corporation stands out as one of the world’s largest hydraulic equipment manufacturers. The KYB Group boasts an extensive global footprint, with 32 branches spread across 21 countries. This includes 15 production bases strategically located in Asia, Europe, the United States, and other regions, ensuring efficient and widespread distribution of their products.

KYB combines its professional hydraulic technology with advanced electronic technology. The company’s core competencies lie in its vibration control technology and power control technology. These technologies are continuously evolving, integrating system technology and electronic control technology to enhance comfort and safety across various industries.

KYB’s commitment to innovation is evident in its continuous growth and adaptation to modern technological advancements. By integrating electronic control with hydraulic systems, KYB provides robust support for a wide range of applications, ensuring high levels of comfort and safety. This dedication to quality and innovation has solidified KYB’s position as a trusted name in the hydraulic equipment industry.

In summary, KYB Corporation’s expertise in hydraulic and vibration control technology, combined with its global presence and commitment to innovation, makes it a pivotal player in the industry, providing essential support across multiple sectors.

Country: China

Founded: 1990

About the company:

Over the past 30 years, Hengli Hydraulic has transformed from a hydraulic cylinder manufacturer into a comprehensive enterprise that integrates hydraulic components, precision castings, pneumatic components, hydraulic systems, and other industries. This evolution reflects the company’s commitment to innovation and excellence in the hydraulic field.

Global Presence and Advanced Capabilities

Hengli Hydraulic boasts four hydraulic R&D centers and nine manufacturing bases strategically located in China, Germany, the United States, Japan, and India. These facilities ensure that Hengli’s technical level and production scale remain at the forefront of the global hydraulic industry. The company serves over 2000 customers worldwide, demonstrating its extensive reach and influence.

Diverse Market Coverage

Hengli Hydraulic’s main markets span more than 20 countries and regions. Its products are utilized across various industries, including:

This diverse application of Hengli’s products underscores the company’s versatility and capability to meet the demands of different sectors.

Strategic Expansion and Market Position

Listed on the Shanghai Stock Exchange (stock code 601100), Hengli Hydraulic is headquartered in Changzhou, China. The company operates four internationally advanced manufacturing bases specializing in high-pressure oil cylinders, hydraulic pump valves, precision casting, and pneumatic components.

Hengli’s strategic expansion into the global hydraulic component field has been bolstered by key mergers and acquisitions, including:

These acquisitions have strengthened Hengli’s market position and expanded its technological capabilities.

Commitment to Global Growth and Innovation

To enhance regional service response speed, brand image, and overseas business growth, Hengli Hydraulic has established branches in Japan, the United States, and India. The company has also improved its marketing service network in these regions, ensuring better customer support and engagement.

Hengli is dedicated to enhancing its core competitive advantage by aligning with the “Made in China 2025” initiative. The company actively supports the strategy of building a strong industrial base and aims to reshape the “Made in China” brand through continuous technological innovation.

Customer-Centric Approach

Hengli Hydraulic is committed to improving the global supply chain system and sales service system, providing customers with cutting-edge hydraulic technology solutions and products. The company’s excellent R&D capabilities, stable product quality, and impeccable service have earned it recognition and trust from many well-known customers.

Hengli Hydraulic’s journey from a hydraulic cylinder manufacturer to a global leader in hydraulic solutions is a testament to its dedication to innovation, quality, and customer satisfaction. As the company continues to expand and innovate, it remains a pivotal player in the global hydraulic industry, contributing significantly to the development of hydraulic technology and solutions worldwide.

Country: China

Founded: 2003

About the company:

Yantai Eddie Precision Machinery Co., Ltd is a Sino-foreign joint venture that specializes in developing, producing, and selling hydraulic breakers, quick couplers, hydraulic shears, hydraulic crushers, hydraulic pulverizers, stone/wood grapples, hydraulic compactors, and other attachments for construction machinery.

Established in August 2003, the company successfully landed on the main board of the Shanghai Stock Exchange in January 2017 (Stock Name: Eddie Precision, Stock Code: 603638). The company has a registered capital of CNY 841.55 million, covering an area of 631,400 square meters, and employs over 2500 people.

Yantai Eddie Hydraulic Technology Co., Ltd

Established in October 2009, this subsidiary is mainly engaged in the R&D, production, and sales of hydraulic pumps, swing motors, final drives, and multiple control valves. It offers more than 70 series and over 300 varieties. The company has more than 120 business partners both domestically and internationally and has established strategic cooperative relations with many well-known excavator manufacturing companies.

Yantai Eddie Ruineng Superhard Cutting Tool Co., Ltd

Founded in October 2020, this subsidiary focuses on the design, production, and sales of carbide CNC inserts, solid carbide cutters, gear cutters, tool holders, and tool bodies.

Yantai Eddie Aitron Robotic Technology Co., Ltd

Also established in October 2020, this subsidiary has been dedicated to the independent research and development, production, and sales of industrial robots and RV reducer products. It aims to provide complete sets of industrial robots, integrated applications, and other automation solutions for customers.

Yantai Aolang Machinery Technology Co., Ltd

Established in December 2018, this subsidiary is mainly engaged in the casting production of hydraulic parts.

After 18 years of extraordinary efforts, Yantai Eddie Precision Machinery Co., Ltd has become one of the largest hydraulic attachment manufacturers in the world, exporting products to more than 90 countries and territories.

“Integration, innovation, cooperation, and mutual progress” is the mission of Eddie people. The company sincerely welcomes all friends and partners to join them in creating a prosperous future.

This comprehensive overview highlights the company’s robust growth, diverse product offerings, and strategic global partnerships, underscoring its significant position in the hydraulic attachment manufacturing industry.

Country: Japan

Founded: 2003

About the company:

Nabtesco Co., Ltd. has established itself as a pivotal player in the field of precision reducers, which are essential components in the joints of industrial robots. These reducers are designed to handle high loads while maintaining precision in movement, making them indispensable in advanced industrial applications.

For over two decades, Nabtesco has been at the forefront of this technology, achieving significant success and widespread adoption globally. The company’s precision reducers are renowned for their:

Initially prominent in the industrial robotics sector, Nabtesco’s precision reducers have expanded their reach into other high-tech fields, including machine tools and semiconductor manufacturing.

In 2013, Nabtesco Co., Ltd. partnered with Shanghai Electromechanical Co., Ltd. to form Shanghai Nabtesco Transmission Equipment Co., Ltd. This joint venture focuses on delivering precision reducer RV products and technical services tailored to the Chinese market.

Understanding the unique needs of the Chinese market, Shanghai Nabtesco Transmission Equipment Co., Ltd. leverages its advanced technology and expertise to enhance its technical service capabilities. The company’s objectives include:

Additionally, the company is committed to advancing robot technology and enhancing the user experience in the automation sector.

As China’s manufacturing industry undergoes transformation and upgrades towards increased automation, the demand for industrial robots and automation products is surging. Nabtesco’s precision reducers are well-positioned to capitalize on this growing market, promising expansive opportunities in the Chinese market.

Nabtesco Co., Ltd. continues to lead in the precision reducer market, driven by innovation, quality, and a deep understanding of market needs. With its strategic joint venture in China, the company is set to further strengthen its presence and support the evolving demands of the automation industry.

Country: China

Founded: 1979

About the company:

Beijing Huade Hydraulic Industry Group Co., Ltd., established in 1979, is a prominent domestic supplier specializing in hydraulic basic components and system integration. The company boasts a comprehensive range of products and operates on a large scale. It is a key enterprise under Beijing Jingcheng Electromechanical Holding Co., Ltd.

Huade Hydraulic is renowned for its expertise in research and development (R&D) and manufacturing, holding independent intellectual property rights in hydraulic basic parts. The company’s primary focus areas include:

Additionally, the company produces reducers, oil cylinders, seals, and other related products.

Huade Hydraulic’s products are extensively utilized across various sectors, including:

Notably, the company’s high-end products are integral to defense and other specialized equipment fields.

Huade Hydraulic has established a robust marketing service network, ensuring that its products are available throughout China and internationally. The company’s affiliated enterprises have achieved certifications in national quality management, environmental management, and occupational health and safety management systems.

The leading products of Huade Hydraulic have received several prestigious certifications, including:

Huade Hydraulic adheres to a corporate spirit characterized by “unity, integrity, openness, and innovation.” The company’s mission focuses on creating value for customers, benefiting shareholders, and fostering employee growth. Its business philosophy emphasizes:

Guided by technological innovation, Huade Hydraulic aims to accelerate the development of China’s high-level hydraulic industrial base. The company is committed to advancing towards its grand goal of becoming a global leader in the hydraulic industry.

Beijing Huade Hydraulic Industry Group Co., Ltd. stands out as a key player in the hydraulic industry, with a strong emphasis on innovation, quality, and comprehensive service. Its extensive product range and commitment to excellence position it as a leader both domestically and internationally.

Country: China

Founded: 1964

About the company:

Taiyuan Heavy Machinery Group Yuci Hydraulic Industry Co., Ltd. (Yuci Hydraulic) is a prominent subsidiary of Taiyuan Heavy Machinery Group Co., Ltd., recognized as the largest independent and competitive high-end hydraulic product research, development, and manufacturing base in China.

Founded in 1964 as Yuci Hydraulic Factory, the company is heralded as the “cradle” of China’s hydraulic industry. It integrates research, development, and manufacturing of high-end hydraulic products and is designated as a “high-tech enterprise” by the state. Yuci Hydraulic boasts a national enterprise technology center and a post-doctoral research station, maintaining a leading position in designing high-end hydraulic products and controlling mechanic-electric-hydraulic integration.

Yuci Hydraulic has played a significant role in formulating 21 national and industrial product standards, secured 24 invention and practical patents, and received 66 awards for technological progress and outstanding new products. The company is equipped with advanced casting, machining, and heat treatment production lines, alongside specialized inspection and testing equipment, ensuring the reliability of its high-end hydraulic products.

The company comprises four branches: the Hydraulic Pump Branch, Hydraulic Valve Branch, Hydraulic System Branch, and Casting Branch. Additionally, it has three subsidiaries focused on R&D and manufacturing in Changzhi, Jinan, and Shanghai. Annually, Yuci Hydraulic produces:

These products include high-pressure piston pumps, vane pumps, gear pumps, hydraulic valves, motors, hydraulic cylinders, hydraulic systems, and castings, serving various industries such as engineering machinery, agricultural machinery, transportation, petroleum machinery, metallurgical steel, coal mines, marine engineering, aerospace, water conservancy and power, machine tool industry, and chemical equipment.

Yuci Hydraulic has supplied products for several national key projects, including the Three Gorges Project, the South-to-North Water Transfer Project, and the localization of metallurgical slab continuous casting and rolling production lines. The company is committed to innovation, making significant breakthroughs in the localization of high-end high-pressure plunger pumps and advancements in high-pressure valve and multi-way valve technology. They have overcome challenges related to operation reliability and sealing technology under high pressure, high temperature, and high frequency, positioning themselves as a leading manufacturer in China.

At the forefront of hydraulic-electro-mechanical technology in China, Yuci Hydraulic has undertaken hydraulic system projects for hoists and ship lifts in national key water conservancy and hydro-power projects, including the Three Gorges Project. They have also addressed challenges related to the main hammer oil cylinder and hydraulic control technology, matching the first set of hydraulic marine pile hammers developed by TZ, and filling the technological gap in hydraulic control technology for pile hammers.

Yuci Hydraulic has implemented a comprehensive quality management system, certified for the “two-oriented integrated management system” of informatization and industrialization. They practice refined management to continuously improve product quality and economic benefits. To better serve their customers, the company has established a nationwide marketing and service network and actively pursued an internationalization strategy, forming strategic partnerships and service agencies in Europe, the Americas, Asia, and Africa.

Guided by core values of “integrity, innovation, leanness, excellence,” Yuci Hydraulic is dedicated to revitalizing China’s hydraulic industry. They vigorously promote independent innovation to support the development of the high-end equipment manufacturing industry, fulfilling their responsibility to advance the sector.

In summary, Taiyuan Heavy Machinery Group Yuci Hydraulic Industry Co., Ltd. stands as a pillar in China’s hydraulic industry, driving innovation and excellence in high-end hydraulic product development and manufacturing.

Choosing the right hydraulic pump manufacturer is crucial for ensuring the performance, efficiency, and reliability of your hydraulic systems. Here are the key factors to consider when selecting a hydraulic pump manufacturer:

The hydraulic pump must meet the specific flow rate and pressure requirements of your system. Calculating the required flow rate and pressure is essential to avoid under-sizing or over-sizing the pump. For example, an under-sized pump can lead to inefficiencies and insufficient power in a construction application, while an over-sized pump can result in unnecessary costs and energy consumption in an industrial setting. Ensure the manufacturer offers pumps that can precisely match your system’s demands.

The hydraulic pump must be compatible with the type of hydraulic fluid used in your system. Factors such as the fluid’s viscosity, temperature range, and chemical properties should be considered to prevent damage and leaks. Manufacturers should provide pumps constructed from materials that can withstand the fluid’s chemical makeup and physical properties, ensuring long-term durability and performance. For instance, a pump used in the automotive industry must be compatible with specific hydraulic oils to maintain optimal operation.

Evaluate the efficiency ratings of the pumps, including both mechanical and volumetric efficiency. Mechanical efficiency refers to the ratio of the actual power output to the input power, while volumetric efficiency measures the pump’s ability to handle the fluid without losses. High-efficiency pumps can lead to significant cost savings over time by minimizing energy consumption and reducing heat generation. For example, a pump with high volumetric efficiency will deliver more fluid per rotation, improving overall system performance and reducing wear.

Understanding the different types of hydraulic pumps and their suitability for your application is vital. The main types include gear pumps, vane pumps, and piston pumps. Gear pumps, commonly used in agricultural machinery, are simple and economical. Vane pumps, often found in industrial applications, offer higher efficiency. Piston pumps, used in high-pressure applications like construction equipment, provide greater precision and power. Choose a manufacturer that offers the appropriate type of pump for your specific needs.

Consider the drive speed and capacity of the pump. The drive speed can range from 1200 to 4000 rpm, depending on the application. The pump’s capacity should match the system’s demands without being oversized or undersized. Proper sizing ensures optimal performance and efficiency. For example, an industrial hydraulic press may require a pump with a higher drive speed to maintain production efficiency, while a mobile hydraulic system might need a lower drive speed to ensure smooth operation.

Opt for a manufacturer with a well-established track record of reliability. The pump should be easy to maintain, with regular maintenance being crucial for prolonged functionality. Look for manufacturers that provide clear maintenance guidelines and support. Reliable pumps minimize downtime and reduce maintenance costs. For instance, a reliable pump used in manufacturing will ensure continuous operation without frequent interruptions.

Ensure the pump is suitable for the environment in which it will operate. This includes considerations such as protection from freezing temperatures, dust, or explosive vapors. Different industries, such as industrial, automotive, and construction, have unique requirements that the manufacturer should be able to address. Select a manufacturer that can provide pumps tailored to your specific environmental and application needs. For example, a pump used in a mining operation must withstand harsh conditions and abrasive fluids.

Evaluate both the initial upfront cost and the long-term cost of ownership. This includes maintenance expenses, energy consumption, and potential replacement costs. While the initial cost may be higher for a more efficient pump, it can lead to substantial savings in the long run. Consider the total cost of ownership to make an informed decision. For instance, a high-efficiency pump might have a higher initial cost but will reduce energy bills and maintenance costs over its lifespan.

Investigate the manufacturer’s reputation for producing reliable and efficient pumps. Check for any necessary certifications, such as compliance with industry standards or regulatory requirements. Certifications, such as ISO or FDA guidelines for food industry applications, indicate the manufacturer’s commitment to quality and adherence to industry standards. For example, a manufacturer with ISO certification ensures that their products meet international quality standards.

Ensure the manufacturer offers adequate customer support, including technical assistance, maintenance advice, and troubleshooting services. Prompt and effective customer support is crucial for addressing any issues and minimizing downtime. Choose a manufacturer known for excellent customer service and support. For instance, a manufacturer with a dedicated support team can quickly resolve any operational issues, ensuring minimal disruption to your processes.

By carefully considering these criteria, you can select a hydraulic pump manufacturer that provides a pump tailored to your specific needs, ensuring optimal performance, efficiency, and longevity of your hydraulic system.

Bosch Rexroth, a leading German manufacturer, excels in producing high-tech and durable hydraulic pumps. Their A10VO series axial piston pumps are distinguished by their high power density and efficiency, making them ideal for demanding industrial applications such as manufacturing and automation. Bosch Rexroth’s commitment to research and development ensures that their products incorporate the latest technological advancements, offering superior performance and reliability. For example, their hydraulic pumps are often utilized in high-precision CNC machines, where consistent and reliable performance is crucial.

Parker Hannifin, an American leader in hydraulic pump manufacturing, provides a broad range of products suitable for industrial machinery, mobile equipment, and aerospace systems. Their PGP505 series gear pumps are known for their high performance and durability, while the PVP series piston pumps offer exceptional efficiency and reliability. Parker Hannifin’s global presence and comprehensive product lines make them a trusted choice for various hydraulic needs. Their hydraulic pumps are commonly used in construction equipment, where robustness and reliability are essential.

Eaton Corporation, another prominent American manufacturer, is recognized for its robust and reliable hydraulic pumps. Their Vickers V10 and V20 series vane pumps are renowned for their high efficiency and long service life, making them ideal for industrial and mobile applications. The PVM series piston pumps are designed for high performance in mobile equipment, ensuring Eaton’s products meet rigorous demands. Eaton’s innovative solutions and strategic acquisitions have solidified their strong market presence, particularly in heavy machinery and agricultural equipment.

Danfoss, based in Denmark, excels in producing hydraulic pumps for refrigeration, heating, water treatment, and transmission control. Their D1P series axial piston pumps are designed for high efficiency and low noise levels, making them suitable for both mobile and industrial applications. Danfoss’s SNP series gear pumps are known for their reliability and performance. The company’s focus on energy efficiency and sustainability sets it apart, providing solutions that reduce environmental impact while maintaining high performance. For instance, their pumps are widely used in renewable energy systems like wind turbines.

Linde Hydraulics, headquartered in Germany, specializes in modular hydraulic systems, including high-pressure and high-efficiency pumps for heavy machinery such as excavators. Their HPV series axial piston pumps offer high efficiency and a compact design, while the HPR series is tailored for heavy-duty applications. Linde’s modular approach allows for customization and flexibility, meeting the specific needs of various applications. Their products are highly regarded in the mining and construction industries, where reliability and efficiency are paramount.

HAWE Hydraulik, also based in Germany, has over 50 years of experience in developing high-pressure hydraulic components and systems. Their V30D series axial piston pumps provide high efficiency and reliability, while the MPN series radial piston pumps are known for their robust construction. HAWE’s expertise in high-pressure technology makes them a preferred choice for industrial and mobile applications requiring durable and precise hydraulic solutions. Their pumps are often used in high-precision applications such as injection molding machines.

Kawasaki Heavy Industries, a Japanese manufacturer, produces hydraulic pumps widely used in construction, ships, oil and gas, and other hydraulic equipment fields. Their K3V series axial piston pumps are known for high efficiency and reliability, and the K7VG series is designed for high-pressure applications. Kawasaki’s products are renowned for their robustness and reliability, making them suitable for heavy-duty applications in harsh environments, such as offshore drilling rigs.

As part of the Eaton Group, Vickers is a well-known brand in the hydraulic industry, producing a wide range of hydraulic pumps, motors, cylinders, and hydraulic valves. Their VQ series vane pumps offer high efficiency and long service life, while the PVH series piston pumps are designed for high performance in demanding environments. Vickers’ long-standing reputation underscores their commitment to quality and innovation. Their pumps are widely used in aerospace and defense applications, where reliability is critical.

HYDAC, a German multinational, provides technologically advanced hydraulic system solutions. Their HPP series piston pumps are known for high efficiency and reliability, while the HPK series gear pumps offer robust performance. With a strong global presence and more than 70 subsidiaries worldwide, HYDAC is recognized for its innovative solutions that enhance the efficiency and performance of hydraulic applications. Their products are commonly used in industrial automation systems, where precision and efficiency are essential.

Moog Inc., an American company, manufactures high-quality, cost-effective hydraulic pumps suitable for various excavator models and other applications. Their products are known for their reliability and efficiency, making them a trusted choice for diverse hydraulic needs. Moog’s commitment to innovation and quality ensures their products meet the stringent requirements of different industries. Their hydraulic pumps are often used in aerospace applications, where precision and reliability are crucial.

Custom and specialty hydraulic pump manufacturers provide tailored solutions that meet complex and unique requirements across various industries. These manufacturers leverage advanced technologies and innovative approaches to deliver high-performance, reliable hydraulic pumps designed for specific applications.

Eaton Hydraulics, headquartered in Eden Prairie, MN, offers a comprehensive line of hydraulic systems and components. Eaton excels in customizing hydraulic pumps and systems to meet specific customer needs, serving markets such as industrial, mobile, and aerospace. For example, Eaton’s custom hydraulic pumps are widely used in agricultural machinery, where precise control and high efficiency are critical for operations like planting and harvesting.

Linde Hydraulics, with a strong presence in Germany and the USA, specializes in modular hydraulic systems that can be customized for various applications, including construction, agriculture, and industrial sectors. Their hydraulic pumps are known for their efficiency and durability. In the construction industry, Linde’s custom hydraulic solutions are essential for heavy machinery like excavators and cranes, providing reliable performance under demanding conditions.

Bosch Rexroth, a renowned German company, develops and manufactures hydraulic transmission products for industries such as engineering, oil and gas, and mining. Bosch Rexroth’s custom hydraulic pumps are designed to handle high-pressure applications, making them ideal for oil drilling operations where robust and precise hydraulic systems are necessary to manage the extreme conditions of deep-sea exploration.

Parker Hannifin, an American global company, offers a wide range of hydraulic pumps for industrial, mobile, and aerospace applications. Parker Hannifin is particularly noted for its capability to customize products to meet specific customer requirements. For instance, in the aerospace industry, Parker’s custom hydraulic pumps are used in aircraft landing gear systems, where reliability and performance are paramount.

Based in Germany, HAWE Hydraulik has over 50 years of experience in developing high-pressure hydraulic components and systems. HAWE specializes in custom hydraulic solutions for complex applications. Their high-pressure hydraulic pumps are used in industrial presses, where precision and power are required to shape and form materials under extreme pressure.

Hydac, with over 50 years in the hydraulic system industry, offers technologically advanced hydraulic system solutions. With more than 70 subsidiaries worldwide, Hydac provides customized hydraulic pumps and components to various industries. In the renewable energy sector, Hydac’s custom hydraulic solutions are used in wind turbines to control blade pitch and yaw, ensuring optimal energy capture.

Dynex/Rivett, Inc., based in Pewaukee, WI, manufactures hydraulic pumps capable of handling both standard and specialized applications. Their high-pressure pumps, which can handle pressures from 3,000 to 15,000 psi, are suitable for a variety of custom applications. For example, in the defense industry, Dynex/Rivett’s hydraulic pumps are used in military vehicles for steering and braking systems, where high reliability and performance are critical.

Located in Katy, TX, Hydro Leduc N.A., Inc. has developed over 100 patents due to their passion for innovation in hydraulics. They provide solutions for complex applications involving piston pumps, hydraulic motors, and hydro-pneumatic accumulators. In the automotive industry, Hydro Leduc’s custom hydraulic pumps are used in advanced suspension systems, providing smooth and controlled rides in high-performance vehicles.

Star Hydraulics & Pneumatics, LLC, based in River Grove, IL, is an ISO 9001 certified manufacturer that produces standard and custom pumps, cylinders, and lift jacks. They offer custom product design, engineering, and testing for unique use cases. In the manufacturing industry, Star Hydraulics’ custom hydraulic solutions are used in automated assembly lines, ensuring precise and efficient movement of components.

These manufacturers are well-equipped to handle custom and specialty hydraulic pump needs, offering a range of products and services that cater to complex and demanding applications across various industries. Their expertise in innovation, customization, and high-performance solutions ensures that clients receive hydraulic pumps designed to meet their specific operational challenges.

Below are answers to some frequently asked questions:

The top hydraulic pump manufacturers include several industry leaders known for their quality, innovation, and broad range of applications. Parker Hannifin, based in the United States, is renowned for its extensive product line across industrial, mobile, and aerospace sectors. Bosch Rexroth, a German company, excels in high-tech hydraulic solutions for engineering, oil and gas, and mining applications. Another key player is Eaton, also from the U.S., which offers reliable and efficient hydraulic systems and components tailored to various markets.

Danfoss, a Danish manufacturer, stands out for its advancements in refrigeration, heating, and hydraulic technologies. Linde Hydraulics, known for its innovative approaches, serves sectors like construction and agriculture with high-quality hydraulic systems. HAWE Hydraulik, another German firm, has a strong reputation for high-pressure hydraulic components, while Vickers, part of Eaton’s Fluid Power Division, specializes in a wide range of hydraulic products.

Hydac, with over five decades in the industry, provides advanced hydraulic solutions worldwide. Kawasaki, a Japanese manufacturer, is known for its robust hydraulic pumps used in heavy industries. Finally, Enerpac leads in high-force tools and equipment, emphasizing safety and productivity in industrial applications.

Other notable manufacturers include Nike Hydraulics, Hydro Leduc, Gator Pump, and Star Hydraulics, all recognized for their specialized products and commitment to quality in the hydraulic pump sector. These companies collectively contribute to the diverse applications of hydraulic pumps across various industries, ensuring performance and reliability in demanding environments.

To choose the best hydraulic pump manufacturer for your needs, consider several critical factors. First, evaluate the quality and standards of the manufacturer’s products by looking for certifications like ISO 9001, which ensure consistent quality and customer satisfaction. Next, assess the material and build quality, favoring manufacturers that use durable materials such as iron or steel. Testing and performance benchmarks are also essential; select manufacturers whose pumps meet or exceed industry standards in pressure ratings, operational efficiency, and temperature stability.

Technical expertise and support are crucial, especially for complex applications that may require customized solutions. Opt for manufacturers with experienced engineers who can offer expert advice. Additionally, ensure the manufacturer offers a wide range of products and customization options to meet your specific needs.

Performance and efficiency factors, such as flow rate requirements, pressure ratings, and volumetric efficiency, should also be evaluated. A high-efficiency pump can reduce energy consumption and operating costs. Reliability and reputation matter too; choose manufacturers with a proven track record of dependability to avoid costly downtime.

Consider the initial cost and long-term cost of ownership, including maintenance and energy consumption. While higher upfront costs may seem expensive, they often result in long-term savings. Robust after-sales support, including warranties and maintenance services, is essential for the longevity of your hydraulic system.

Timely delivery is another critical factor; select a manufacturer that can meet your delivery schedules to maintain project timelines. Lastly, consider application-specific requirements and ensure the manufacturer has experience in your industry, whether it’s industrial, automotive, or construction.

By carefully evaluating these factors, you can select a hydraulic pump manufacturer that offers high-quality products, reliable performance, and comprehensive support tailored to your needs.

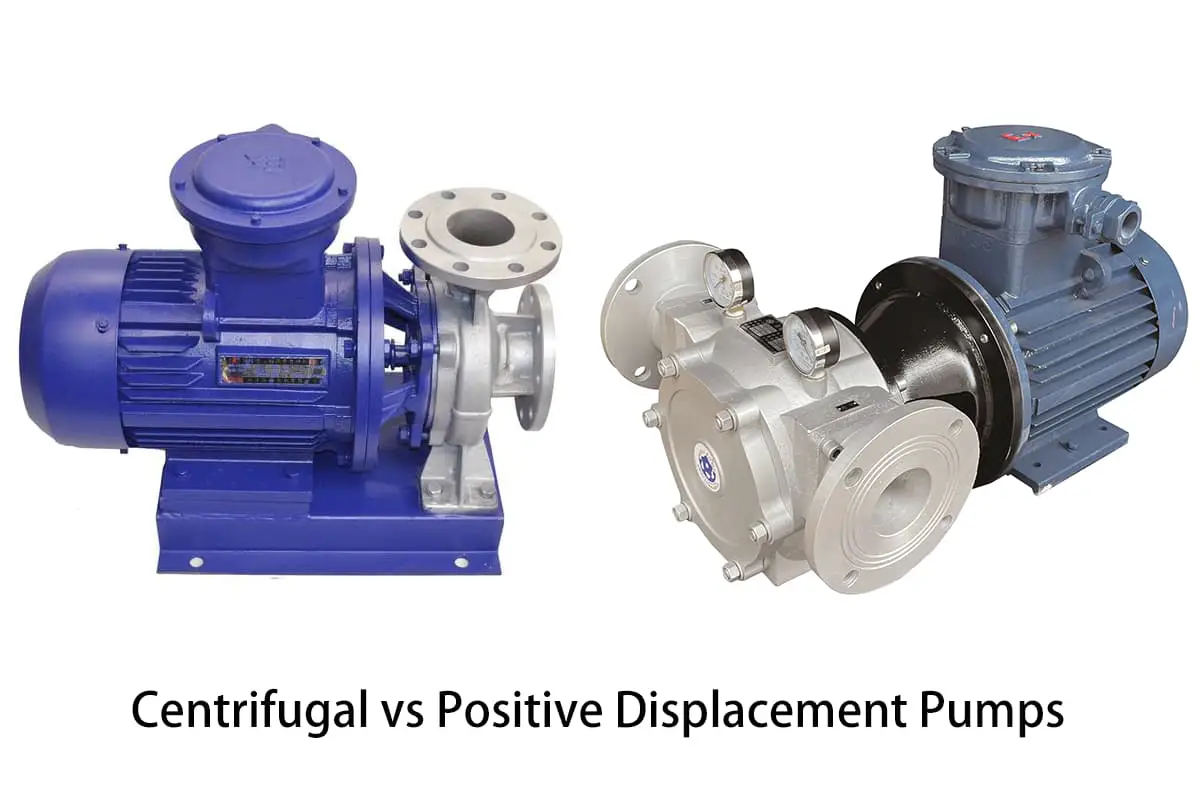

Hydraulic pumps come in various types, each suited for specific applications based on their construction and operational characteristics.

Gear pumps are the most common type, known for their simplicity and efficiency. They use interlocking gears to drive fluid flow and are suitable for low to medium pressure applications. They are widely used in truck-mounted hydraulic systems and various industrial and commercial applications due to their tolerance of contamination and ease of service.

Piston pumps, or reciprocating pumps, use pistons and high-pressure seals to move fluid and can operate under high pressure without significantly affecting the flow rate. These pumps can be fixed or variable displacement and are commonly used in high-pressure applications like manufacturing, water irrigation systems, and delivery systems. Bent axis hydraulic pumps, a type of piston pump, are used where variable flow rates are needed.

Vane pumps are positive displacement pumps that use a rotor with vanes to move fluid. They are suitable for lower-pressure applications requiring high flow rates and are less common but straightforward in design.

Specialized pumps include dump pumps, designed for dump trailers and trucks with built-in pressure relief and directional control valves, and live pak pumps, used on refuse equipment and driven by engine crankshafts with flow limiting valves. Electric pumps, driven by electric motors, are ideal for small to medium-sized hydraulic tools and are easily transportable. Hydraulic hand pumps use manual force to generate pressure, suitable for water pumping and fluid distribution. Air hydraulic pumps use compressed air to trigger pump action, often used for lifting heavy goods and transporting materials.

Other types include rotary pumps, such as lobe and screw pumps, which use different mechanisms to move fluid, and centrifugal pumps, which use a rotating impeller to create high-speed fluid flow for applications requiring high flow rates and heads.

In summary, the choice of hydraulic pump depends on the specific application’s pressure, flow rate, and system configuration needs. Each pump type has unique characteristics and advantages, making them essential in various industrial, commercial, and mobile hydraulic applications.

Yes, there are several manufacturers that specialize in providing custom or specialty hydraulic pumps to meet specific industry needs and unique applications. These manufacturers offer tailored solutions that standard off-the-shelf pumps may not be able to provide.

Star Hydraulics & Pneumatics, LLC (SHP) offers custom product design, engineering, and testing for clients with unique use cases, manufacturing a variety of hydraulic pumps and accessories for industries such as transportation, military, and offshore sectors.

Tri-Rotor, with a history dating back to 1930, produces positive displacement rotary piston pumps and offers customized solutions, serving a diverse clientele including blue-chip and Fortune 500 companies.

Hydra-Tech Pumps, Inc. specializes in hydraulic drive submersible pumps and provides custom design services to meet specific customer needs, offering a range of hydraulic pumps, gear pumps, and power units.

Dynex/Rivett, Inc. creates hydraulic pumps for both standard and specialized purposes, focusing on high-pressure pumps that handle various fluids and pressures, tailored to specific customer requirements.

Cascon, Inc. manufactures hydraulic pumps for a wide range of applications, including aircraft, aerospace, and industrial markets, providing solutions that off-the-shelf pumps cannot address.

MAXPRO Technologies, Inc. offers Maximator® air-driven hydraulic pumps that can deliver a wide range of pressures, providing standard or customized high-pressure pump systems along with repair services.

High Pressure Technologies, LLC provides air-driven high-pressure hydraulic pumps customizable to match specific customer requirements, ensuring tailored solutions for various pressure ranges.

Perfection Hydraulics, Inc. is known for manufacturing and servicing hydraulic components for heavy equipment, offering reliable custom solutions for heavy-duty hydraulic needs.

Linde Hydraulics Corporation, a global leader in hydraulic technology, provides innovative and custom solutions for various industries, focusing on meeting specific industry requirements.

These manufacturers demonstrate the availability and capability of custom and specialty hydraulic pumps designed to cater to the unique needs of different industries and applications.

When evaluating hydraulic pump manufacturers, several key factors should be considered to ensure you select a reliable and suitable provider. Firstly, reputation and experience are crucial; established companies like Parker, Bosch Rexroth, and Eaton are known for their expertise and reliability. Quality standards and certifications, such as ISO 9001, indicate a commitment to consistent quality and customer satisfaction.

Material and build quality are important; pumps made from durable materials like iron or steel generally offer better longevity and resistance to wear. Technical specifications and performance, including pressure ratings, flow capacity, and efficiency metrics, should align with your operational requirements. Efficiency metrics such as volumetric, mechanical, and overall efficiency are essential for minimizing energy wastage and optimizing performance.

Customization options can be beneficial for specialized applications, and a manufacturer with a broad product range can better cater to diverse industrial needs. Ensuring fluid compatibility is vital to prevent accelerated wear and extend the pump’s lifespan. Consider the ease of installation, maintenance requirements, and the availability of support services to ensure ongoing functionality and minimize downtime.

Power and efficiency ratings should be compared to ensure the pump meets your system’s requirements, with higher efficiency potentially leading to long-term cost savings. Finally, evaluate the manufacturer’s warranty and support services, as comprehensive coverage can be critical for maintaining continuous operation. By carefully assessing these factors, you can make an informed decision and select hydraulic pumps that meet your specific needs while providing optimal performance and reliability.