Lasers have revolutionized manufacturing, but do you know the top companies driving innovation in this field? In this blog post, we’ll explore the key players shaping the future of laser technology. Our expert team has analyzed the industry landscape to identify the companies making the biggest impact. Discover the cutting-edge advancements and groundbreaking applications that are transforming industries and improving our daily lives.

After decades of development, laser technology has transitioned from laboratory research to widespread industrial and consumer applications. Its impact is evident across diverse sectors, including food processing, textile manufacturing, construction, transportation, advanced manufacturing, and medical aesthetics. The sophistication of a nation’s laser industry serves as a key indicator of its overall industrial manufacturing capabilities and technological prowess.

The laser industry has experienced a complex landscape this year, characterized by divergent performance among companies. While some enterprises have achieved significant growth, others face declining revenues or even financial losses. This variability reflects the industry’s maturation, increasing competition, and the impact of global economic factors on different market segments.

To provide a comprehensive overview of the industry’s current state, we have identified the top 10 laser enterprises based on their annual revenue and market share. These companies exert the most significant influence on the laser industry’s direction, innovation, and market dynamics. Their performance and strategic decisions offer valuable insights into industry trends, technological advancements, and potential future developments in laser applications and manufacturing processes.

Trumpf Group, founded in 1923, stands as a global leader in industrial production machine tools and laser technology. With over nine decades of innovation, Trumpf has transformed from a modest machinery workshop into a laser industry powerhouse, with laser-related products now generating approximately 80% of its revenue.

In 2019, Trumpf made several strategic moves to strengthen its market position and expand its technological capabilities:

Acquisition and Expansion:

Digital Transformation:

International Collaboration:

Technological Milestone:

These strategic initiatives reflect Trumpf’s commitment to innovation, global expansion, and technological leadership in the laser and machine tool industries.

Coherent, established in 1966, initially gained prominence for its pioneering work in CO2 laser technology. This foundation has propelled the company to become one of the world’s foremost photonics innovators and manufacturers.

Over the decades, Coherent has significantly expanded its product portfolio to encompass a wide range of cutting-edge laser technologies. These include high-power fiber lasers, ultrafast lasers for precision micromachining, semiconductor lasers for telecommunications, and excimer lasers for advanced lithography processes. This diverse offering caters to various industries, from fundamental scientific research and advanced medical treatments to high-precision industrial manufacturing and materials processing.

A pivotal moment in Coherent’s growth strategy came in 2016 with the acquisition of Rofin-Sinar Technologies for approximately $942 million. This strategic move substantially bolstered Coherent’s position in the industrial laser market, particularly in the realm of high-power laser cutting and welding systems. The acquisition expanded Coherent’s capabilities in fiber laser technology and strengthened its foothold in key manufacturing sectors such as automotive and aerospace.

Coherent’s subsidiary, Nufern, plays a crucial role in the company’s vertical integration strategy. Specializing in the production of specialty optical fibers and fiber laser modules, Nufern supplies critical components to fiber laser manufacturers worldwide. The subsidiary has placed particular emphasis on serving the rapidly growing Chinese market, where demand for high-power fiber lasers in metal cutting and welding applications has surged in recent years.

IPG was founded by physicist Dr. Valentin P. Gapontsev in Russia in 1991. The company established its global headquarters in the United States in 1998 and went public on NASDAQ in 2006.

Today, IPG is the leading developer and manufacturer of high-performance fiber lasers and amplifiers, commanding a market share significantly larger than its competitors. Its comprehensive range of low-power, medium-power, and high-power lasers and amplifiers find widespread application in advanced fields such as materials processing, telecommunications, entertainment, medical treatments, biotechnology, and scientific research.

In January 2019, IPG strategically acquired Padtec’s submarine network division. This move aimed to leverage IPG’s core pump laser and fiber amplifier technologies to expand its presence in the submarine network systems market, capitalizing on the global surge in submarine optical cable network deployments.

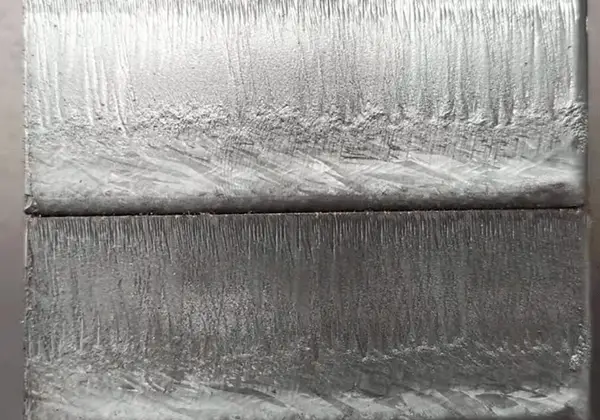

In August of the same year, IPG formed a strategic partnership with Brose North America to advance straight-seam measurement technology for automotive seat guide rails. This collaboration focuses on analyzing performance data generated by In-line Coherent Imaging (ICI), encompassing critical parameters such as penetration depth, weld surface morphology, seam tracking accuracy, and overall equipment effectiveness.

In September 2019, IPG unveiled its groundbreaking 30-kilowatt fiber laser cutting solution at the Shanghai Industry Expo. This system, comprising a 30 kW fiber laser source and a specially designed cutting head, expands the horizons for ultra-high-power laser applications in industrial cutting processes, offering unprecedented capabilities in terms of cutting speed, thickness capacity, and edge quality for a wide range of materials.

Han’s Laser, established in 1996, has emerged as the preeminent manufacturer of industrial laser processing equipment in Asia and globally. The company’s extensive product portfolio encompasses a wide range of advanced laser technologies, including precision laser marking systems, high-power laser welding equipment, and state-of-the-art laser cutting machines. Additionally, Han’s Laser offers demonstration series equipment for research and development purposes, specialized PCB drilling systems for electronics manufacturing, and advanced industrial robots for automation solutions. With over 200 distinct industrial laser equipment offerings and intelligent manufacturing solutions, Han’s Laser caters to diverse industrial needs across multiple sectors.

In 2019, Han’s Laser strategically expanded its technological capabilities and market reach through a series of collaborative agreements. Partnerships were forged with industry leaders such as Huichuan Technology for advanced control systems, Wittenstein for precision drive technology, Tencent for cloud computing and big data integration, Huazhi Intelligence for AI-driven manufacturing solutions, Tanaka for precious metal-based laser applications, and China Unicom for 5G-enabled smart manufacturing. These alliances aim to synergize expertise and drive innovation in laser processing technologies and Industry 4.0 applications.

Simultaneously, Han’s Laser reinforced its commitment to research and development by establishing joint laboratories and talent exchange platforms with prestigious academic institutions. Collaborations with Jinan University, South China Normal University, Shenzhen University of Technology, and Tsinghua Institute of Flexible Electronics focus on fundamental research in laser physics, materials science, and advanced manufacturing techniques. The partnership with a senior vocational college underscores the company’s dedication to nurturing skilled technicians for the laser industry.

Han’s Laser has made significant strides in advancing the laser industry’s technological frontier. The company unveiled a 20kW ultra-high power fiber laser cutting machine, pushing the boundaries of cutting speed, precision, and material thickness capabilities in metal fabrication. This system enables efficient processing of thick-plate materials and enhances productivity in heavy industry applications. Furthermore, Han’s Laser introduced an intelligent welding line for automobile manufacturing, integrating advanced sensors, real-time monitoring, and adaptive control systems to optimize welding quality and efficiency in automotive production. The development of a 10,000-watt laser with independent intellectual property rights marks a milestone in high-power laser source technology, reducing reliance on imported components and strengthening the domestic laser industry chain. These innovations collectively contribute to advancing manufacturing capabilities, improving energy efficiency, and promoting the adoption of smart manufacturing practices across various industries.

II-VI Incorporated, founded in 1971 and headquartered in Saxonburg, Pennsylvania, has transformed from a specialized producer of CO2 laser optical elements into a global leader in engineered materials and optoelectronic components. The company’s vertical integration strategy has enabled it to offer comprehensive manufacturing solutions across multiple high-tech sectors.

In 2019, II-VI undertook several strategic initiatives to strengthen its market position and technological capabilities:

II-VI also introduced several innovative products in 2019, showcasing its commitment to technological advancement:

These product launches underscore II-VI’s dedication to maintaining its competitive edge through continuous innovation in materials science, optoelectronics, and laser technology. The company’s strategic moves in 2019 have solidified its position as a key player in emerging technologies such as 5G, lidar, and advanced manufacturing processes.

Lumentum, a leading provider of optical communication products and laser solutions, was established in 2015 as a spin-off from JDSU (JDS Uniphase Corporation). The company’s roots can be traced back to the 1999 merger of JDS Fitel and Uniphase, which formed JDSU.

Headquartered in San Jose, California, Lumentum has solidified its position as a global leader in photonics technology. The company maintains a robust network of R&D facilities, manufacturing plants, and sales offices worldwide, enabling it to serve diverse markets efficiently.

Lumentum’s core focus lies in developing and delivering cutting-edge optoelectronic solutions that cater to both consumer and industrial applications. Its product portfolio includes advanced optical components, modules, and subsystems that are crucial for high-speed data transmission, cloud computing infrastructure, and next-generation communication networks.

In the industrial sector, Lumentum’s laser technologies play a pivotal role in advanced manufacturing processes, including precision material processing, 3D sensing applications, and emerging fields such as autonomous vehicles and augmented reality. The company’s commitment to innovation drives the continual enhancement of data transmission speeds, processing capabilities, and sensing accuracies across various technological domains.

HGTECH, founded in July 1999, achieved a significant milestone by listing on the Shenzhen Stock Exchange in June 2000. This listing established HGTECH as the pioneering publicly traded high-tech company with academic roots in Central China, showcasing the region’s growing technological prowess.

In a strategic move to expand its technological capabilities and global presence, HGTECH successfully acquired Farley and Laserlab in September 2000. These Australian companies were renowned for their expertise in advanced laser and plasma cutting systems, bringing valuable know-how and international market access to HGTECH’s portfolio.

A landmark achievement in China’s manufacturing sector occurred in July 2004 when HGTECH, through its subsidiary Huagong Laser, successfully developed and produced the country’s first domestic high-performance laser cutting machine. This breakthrough, validated through rigorous inspection in Wuhan, marked a significant step towards technological self-reliance in China’s advanced manufacturing industry. The development of this cutting-edge laser cutting technology not only demonstrated HGTECH’s innovative capabilities but also positioned China as a emerging player in the global high-precision metal fabrication market.

Founded in 1964, the Swiss Bystronic Group has evolved into a global leader in sheet metal processing solutions. The company’s integration with the Swiss Conzzeta holding company in 1994 marked a significant milestone in its growth trajectory, solidifying its position as one of Switzerland’s most prestigious industrial conglomerates. Bystronic’s foray into laser technology began in 1983 with the production of its first CO2 laser cutting machine, a pivotal moment that set the stage for its future innovations in precision metal fabrication.

In June 2019, Bystronic expanded its global footprint by establishing a state-of-the-art plate processing center in Johannesburg, South Africa. This strategic move not only enhanced the company’s manufacturing capabilities but also enabled direct sales and comprehensive after-sales support for the burgeoning South African market, demonstrating Bystronic’s commitment to localized service excellence. Later that year, in December, Bystronic forged a strategic partnership with Spanish software specialist Kurago, accelerating the development of intelligent factory solutions. This collaboration underscores Bystronic’s dedication to Industry 4.0 principles, integrating advanced software capabilities with its cutting-edge hardware to drive the next generation of smart manufacturing processes in sheet metal fabrication.

Founded by Dr. Yan Dapeng in 2007, Raycus Laser has established itself as a leading national high-tech enterprise, distinguished by its commitment to independent innovation and robust intellectual property portfolio. The company specializes in the research, development, manufacturing, and distribution of fiber lasers, along with their critical components and materials.

Raycus Laser’s core competency lies in the development of both pulsed and continuous wave (CW) fiber lasers, which form the backbone of their product lineup. These laser systems cater to a wide range of industrial applications, from precision cutting and welding to marking and surface treatment. The company’s technological prowess extends beyond these mainstay offerings to include:

This comprehensive product portfolio positions Raycus Laser at the forefront of photonics technology, enabling the company to address the evolving needs of advanced manufacturing, materials processing, and emerging industrial applications. By maintaining a strong focus on research and development, Raycus continues to push the boundaries of laser technology, contributing to the advancement of high-precision manufacturing processes and Industry 4.0 initiatives.

Castech, founded on July 8, 1988 by the Fujian Institute of Material Structure of the Chinese Academy of Sciences, has established itself as a leader in the research, development, production, and commercialization of advanced optical materials and components. The company specializes in crystals, precision optical components, and sophisticated laser devices, positioning itself at the cutting edge of the laser industry supply chain.

With a global market share exceeding 80%, Castech’s nonlinear crystals, laser crystals, and magneto-optical crystals consistently dominate international sales. These high-performance materials are crucial for applications in laser technology and optical communication systems, where precision and reliability are paramount.

In recent years, Castech has expanded its product portfolio to include innovative acousto-optic Q-switch and holographic grating technologies. These advancements have gained significant traction in ultraviolet laser, fiber laser, ultrafast laser, and optical communication sectors, transitioning successfully from development to large-scale production and distribution. The company’s proprietary magneto-optical isolator products have also secured a dominant position in the Chinese market, underscoring Castech’s commitment to innovation and its ability to meet evolving industry demands.

Castech’s continued success in developing and manufacturing critical components for photonics applications reinforces its role as a key enabler in the advancement of laser and optical communication technologies. The company’s focus on research-driven product development and its ability to scale production of complex optical materials position it well to address future challenges in emerging photonics applications.

The laser industry features a moderately concentrated market, dominated by several key players with significant shares in various segments.

Major companies stand out through diverse products and continuous innovation:

These companies’ geographic presence and industry focus reveal their market strategies:

Strategic collaborations and acquisitions are key to maintaining competitive advantage:

This comparative analysis highlights how top laser companies leverage market presence, product innovation, and strategic collaborations to maintain leadership in a competitive and evolving industry.

Below are answers to some frequently asked questions:

The leading companies in the laser industry include IPG Photonics Corporation, TRUMPF, Han’s Laser Technology Industry Group Co., Ltd., Coherent Corp., and Lumentum Operations LLC. These companies are recognized for their significant contributions to various segments of the laser market, including industrial processing, medical applications, and telecommunications. They offer a wide range of laser products and services, maintain strong global presences, and are at the forefront of innovation and market share.

The top laser companies offer a diverse range of products and services that cater to various industrial, scientific, and commercial applications.

IPG Photonics Corporation specializes in high-performance fiber lasers and amplifiers used in materials processing, communications, entertainment, medical treatment, and biotechnology. TRUMPF provides machine tools and laser systems, including disk, fiber, diode, short, ultrashort, and CO2 lasers for marking, cutting, welding, and surface treatment. Han’s Laser Technology Industry Group Co., Ltd. offers laser marking, welding, cutting, sub-surface engraving, and display series equipment, along with industrial robots and intelligent solutions. Coherent Corp. manufactures CO2, fiber, ultrafast, semiconductor, and excimer lasers, as well as laser machines, systems, and beam delivery components. Lumentum Operations LLC produces laser optics and accessories, high-power fiber and direct-diode laser optics, solid-state lasers, and high pulse energy UV nanosecond lasers.

These companies are pivotal in driving advancements and meeting the growing demands in sectors such as manufacturing, telecommunications, healthcare, and scientific research.

The top laser companies differ significantly in market share and innovation based on their focus areas and strategies. IPG Photonics Corporation leads the global fiber laser market with a dominant share and is known for high-performance fiber laser technology and subsea network innovations. Coherent Corp. excels in a diverse range of lasers, including ultrafast and semiconductor lasers, bolstered by strategic acquisitions like Rofin. Han’s Laser holds a strong presence in Asia with innovative industrial solutions, such as ultra-high-power fiber laser cutting machines. TRUMPF is recognized for cutting-edge technologies like EV battery recycling lasers. Meanwhile, Lumentum Operations LLC is influential in telecommunications and nonlinear optics. These companies demonstrate leadership through market dominance in specific segments and groundbreaking advancements across industries.

Several top laser companies specialize in specific applications like laser cutting and laser communication. In laser cutting, notable companies include TRUMPF, which offers a wide range of laser systems for cutting, welding, and surface treatment; Han’s Laser Technology Industry Group Co., Ltd., known for its industrial laser processing equipment including laser cutting machines; and IPG Photonics Corporation, recognized for its high-performance fiber lasers and amplifiers used in material processing applications. For laser communication, Coherent Corp. is a key player, providing laser systems for communication through wireless technology, including laser communication terminals. Additionally, IPG Photonics has a segment focused on communications, utilizing their fiber lasers and amplifiers in advanced laser communication systems.

The laser industry is experiencing significant advancements driven by growing applications across sectors, including telecommunications, manufacturing, and defense. Key trends include the adoption of green and fiber lasers for renewable energy and space exploration, as well as the development of high-power lasers for industrial and medical uses. Artificial intelligence is increasingly integrated into laser systems, enhancing precision and efficiency, particularly in defense applications. Quantum technologies and optical networks are gaining momentum, supporting innovations in 5G and optical communication. Companies like IPG Photonics, TRUMPF, and Coherent are leading these advancements, while startups focus on ultrashort pulse lasers and sustainable laser solutions. These developments underscore the laser market’s dynamic growth and expanding global impact.