Are you curious about the cutting-edge technology revolutionizing manufacturing? In this blog post, we’ll dive into the world of laser cutting machines, exploring their advantages and the top manufacturers dominating the industry. Our expert mechanical engineer will guide you through the intricacies of this fascinating technology, revealing how it’s transforming the way we cut and shape materials. Get ready to discover the power and precision of laser cutting!

Laser cutting machines are advanced devices that leverage high-powered laser beams to precisely cut, engrave, or etch various materials. These machines are pivotal in modern manufacturing due to their accuracy, speed, and versatility. Understanding their components, operating principles, and applications is essential for optimizing their use in different industries.

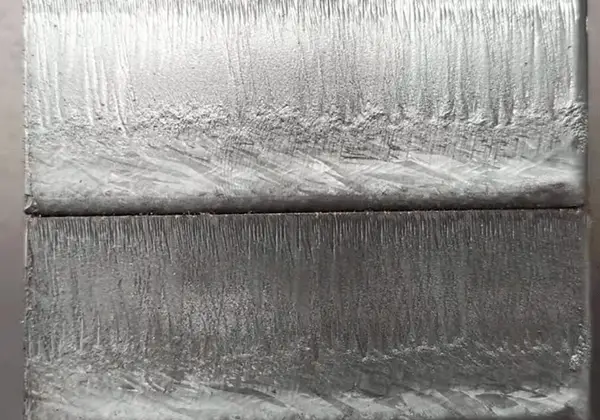

Laser cutting machines function by generating a focused laser beam that irradiates the workpiece. This high-density beam rapidly heats the material, causing it to melt, vaporize, or burn away. The process involves several critical steps:

A typical laser cutting machine comprises several key components:

Assist System: Includes cooling systems, smoke exhaust systems, and gas supply systems to ensure stable and efficient operation.

Laser Generator: The core of the machine, responsible for producing the high-power laser beam. Common types include CO2 lasers, Nd lasers, and Nd:YAG lasers, each suited for different applications.

Optical System: This system includes mirrors, focus lenses, and other components that direct and focus the laser beam precisely onto the workpiece.

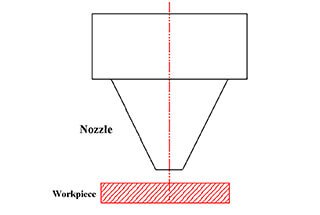

Cutting Head: The cutting head emits the laser beam and cutting gases, controlling their position relative to the workpiece. It often includes a height follower system to maintain an optimal distance.

CNC Control System: This system controls the movement paths and speed of the cutting head, allowing for precise and automated cutting based on CAD/CAM data.

See also:

Laser cutting machines can primarily be categorized into three types based on the different lasers used: fiber laser cutting machines, CO2 laser cutting machines, and YAG laser cutting machines. YAG laser cutting machines are widely used due to their high precision and the fact that they don’t require any processing gas, allowing them to process various materials.

It’s worth noting that YAG laser cutting machines have been phased out, with fiber laser cutting machines currently dominating the market.

In conclusion, the common types of laser cutting machines on the market include fiber laser cutting machines, CO2 laser cutting machines, and YAG laser cutting machines, with fiber laser cutting machines being the current market leader.

The following post will also provide guidance on selecting the best fiber laser cutting machine.

What are the leading laser cutting machine manufacturers in this era of advanced technology? Let’s examine the top 10 laser cutting machine brands of 2023.

Let’s evaluate the pros and cons of laser cutting machines produced by the following brands.

Founded in 1923 and headquartered in Ditzingen, Germany, TRUMPF boasts over 90 years of history in machine tool production and is a global market and technology leader in the fields of industrial machine tools and lasers.

With the evolution of the market, TRUMPF, following multiple transformations and innovations, has grown from a small mechanical factory at its inception to a large multinational corporate group with approximately 13,500 employees worldwide.

In the 2021/22 fiscal year, TRUMPF’s sales revenue reached 4.223 billion euros (equivalent to approximately 29.6 billion RMB).

Throughout its history, Trumpf has established itself as a leader in international markets and technologies across various business fields.

If you’re working with relatively homogeneous materials in large quantities, Trumpf is a good option. The cutting head can be easily replaced, and cleaning the cutting lens is convenient.

However, the manual operation function may not be as user-friendly.

Founded in Switzerland in 1964, Bystronic is a company that focuses on the automatic control of the entire material and data flow in the cutting and bending process chain.

It offers solutions for sheet metal processing, including laser cutting systems, press brake machines, automation, and software solutions.

With over 30 branches worldwide responsible for sales and technical support, Bystronic is a global provider of sheet metal processing solutions.

In terms of manual operation, Bystronic is known for its user-friendly processing parameter adjustments, but the manual adjustment methods may not be suitable for materials with unstable quality, such as hot-rolled sheets.

TANAKA and Koike specialize in producing gantry-type, large-table structured laser cutting machines.

One advantage of these machines is their large work surface, which can reach several meters in length and 3-6 meters in width, making them ideal for cutting medium-sized plates.

For instance, a metal plate measuring 3×9 meters or 2×6 meters can be placed directly on the workbench for cutting.

However, a disadvantage is that the laser generator moves along with the machine, which can make it quite heavy.

Additionally, the cutting speed for thin plates (3 mm or less) is slower compared to that of desktop laser cutting machines.

TANAKA laser cutting machines, made in Japan, are known for their ability to cut thick plates up to 30mm.

They are mainly used in the processing of structural parts and are one of the few options available for processing large workpieces and thick plates.

Amada is a well-known multinational company that specializes in sheet metal processing machinery, such as numerical control punch presses, press brake machines, plate shearing machines, and laser cutting machines.

In 1946, Isamu Amada established Amada Co., Ltd., initially focusing on sheet metal machinery and cutting product businesses. Today, Amada has become a large multinational corporation specializing in the production of sheet metal processing machinery, boasting an array of such products.

In 2022, the total revenue of the Amada Group reached 365.687 billion yen, approximately 18.9 billion RMB.

The company focuses on direct sales and services, and is a comprehensive manufacturer of metal processing equipment, contributing to the growth of the world economy in four areas of expertise: sheet metal, stamping, cutting, and machine tools.

Mazak, established in 1919 in Japan, specializes in offering comprehensive solutions for compound machining, five-axis machining, milling, turning, CNC systems, and automation.

It is one of the few machine tool manufacturers that have established a global production system.

Mazak produces the world’s most intelligent laser machine, capable of cutting not only 3D workpieces but also providing special profile cutting and software.

Additionally, it comes equipped with devices for tapping and chamfering after laser cutting.

Salvagnini, founded in 1963, specializes in the research and development, manufacture, and sale of flexible equipment and systems such as sheet metal flexible production lines, optical fiber laser cutting machines, robots, panel benders, and automated logistics warehouses.

It has established itself as a leading example in the field of global sheet metal flexible processing technology and is dedicated to providing intelligent solutions for sheet metal factories.

As a well-known brand in the field of sheet metal processing machinery and systems, PrimaPower is recognized for its extensive range of 3D laser cutting equipment.

Their product offerings encompass all aspects of laser processing, including stamping, shearing, bending, and automation, covering every stage of sheet metal processing.

PrimaPower is one of the manufacturers with the broadest range of products in the industry.

In addition to its extensive product range, PrimaPower is also known for its highly complete servo-electric solutions for stamping, bending, and integrated processing, available globally.

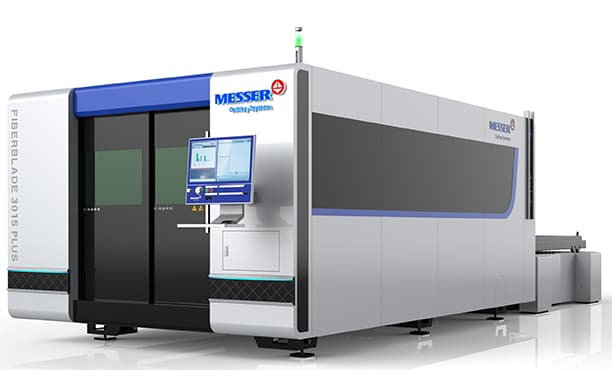

Started in 1898 in Germany, Messer Cutting Systems is a global supplier of comprehensive solutions for the metal processing industry. They offer reliable cutting technology, flexible services, and intelligent software solutions.

Their product range includes flame, plasma, and laser cutting systems that cater to a wide range of applications, from manual cutting to shipbuilding.

They also offer machines and equipment for oxygen gas welding, cutting, soldering, brazing, and heating.

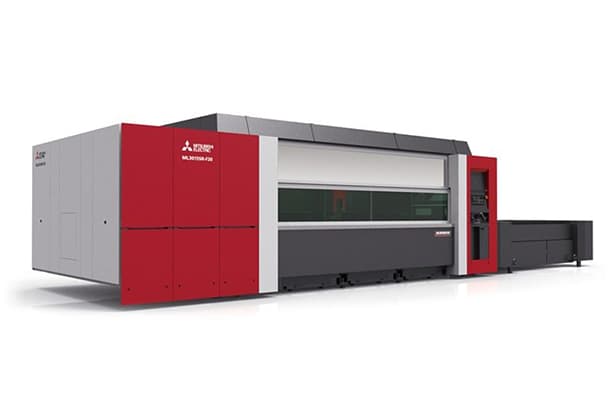

Started in 1871 in Japan, Mitsubishi is a globally renowned manufacturer of non-ferrous metals. Its CNC tools and hardware products have gained recognition worldwide.

Since entering China in the 1990s, the Mitsubishi Integrated Materials Group has established manufacturing companies, sales companies, and representative offices in many locations.

Currently, its business encompasses a wide range of fields, including automotive parts, electronic components, processing tools, environmental protection, energy, metals, ceramics, compounds, and more.

| Laser Sheet Metal Cutting Equipment Revenue Scale | Laser Equipment Integrators (Cutting Business Division) |

| Revenue > 1.5 billion yuan | Han’s Laser, HSG Laser |

| Revenue between 1 billion yuan and 1.5 billion yuan | Bodor Laser, Suzhou Quick Laser, and others |

| Revenue between 500 million yuan and 1 billion yuan | Bystronic DNE Laser, Shandong Leiming (Senfeng Technology), Huagong Tech, Penta Laser, Gweike Laser, Leading Laser, Cheeron Laser, and others |

| Revenue between 300 million yuan and 500 million yuan | Yawei, Hymson etc. |

Han’s Laser, established in Shenzhen, China in 1996, has established itself as a top player in China’s laser machine manufacturing industry.

The company boasts of its global competitiveness and has multiple subsidiaries selling laser cutting machines.

With a robust research and development team of hundreds of employees and numerous international invention patents, domestic patents, and software copyrights,

Han’s Laser offers a full range of laser processing solutions and supporting facilities to customers both domestically and abroad.

Their product portfolio includes over 200 industrial laser equipment and intelligent equipment, including laser marking machines, welding machines, cutting machines, new energy laser welding equipment, industrial robots, and automation solutions.

In 2004, Han’s Laser was listed on the Shenzhen Stock Exchange and has since grown to employ over 10,000 individuals worldwide, with assets worth over 7 billion yuan.

As of the end of June 2023, the total assets of Han’s Laser were valued at 3,526,392.43 million yuan, with net assets amounting to 1,787,450.99 million yuan. The company’s operating income for the year 2022 stood at 1,496,118.50 million yuan, with a net profit of 128,179.19 million yuan.

Wuhan Huagong Laser Engineering Co., Ltd. operates under two brand names, Huagong Laser and FARLEY LASERLAB.

HuaGong Technology was established on July 28, 1999, with a primary product line that includes laser marking machines, laser engraving on bamboo slips, laser welding machines, laser processing machines, and laser cutting machines. HuaGong Technology was publicly listed on the Shenzhen Stock Exchange on June 8, 2000. As of the end of June 2023, HuaGong Technology’s total assets amounted to 1,745,842.82 million yuan, with net assets standing at 874,890.09 million yuan. The company’s operating income for 2022 was 1,201,102.88 million yuan, and the net profit was 89,056.64 million yuan.

As a pioneer in the application of laser industrialization in China, Huagong Laser has five product lines.

They are widely used in a variety of industries, including iron and steel metallurgy, non-ferrous metals, automobiles and parts, aerospace, military electronics, precision instrumentation, machinery manufacturing, molds, hardware tools, integrated circuits, semiconductor manufacturing, solar energy, education, communication, measurement, packaging, shoes, leather, plastics, jewelry, craft gifts, medical equipment, and more, and contribute to the improvement of the world’s equipment manufacturing level.

Wuhan Chutian Laser (Group) Co., Ltd. was founded in Wuhan in 1985 and is the key enterprise of Wuhan’s Optics Valley.

The company employs over 1,000 individuals and has received attention from both domestic and international leaders, with 22 national and 5 foreign leaders visiting the company.

Chutian Laser has been designated as a laser application service provider for the Shenzhou spacecraft series, from Shenzhou-1 to Shenzhou-8, and has earned recognition as a “Shenzhou Six Aerospace Engineering Meritorious Unit.”

With over 400 national patents, the company operates in various industries, including aerospace, aviation, electronics, healthcare, metallurgy, and culture.

Its laser products offer a wide range of applications, such as welding, marking, cutting, drilling, heat treatment, and resistance, making it a full-spectrum laser manufacturer.

Leading Laser specializes in research and development, manufacturing, and sales of high-power laser processing equipment, showcasing their strength.

However, the high power laser comes with a high cost. The company was among the first batch of high-tech enterprises established in high-tech development zones.

Bystronic DNE was founded in Shenzhen and has gained significant market influence, unique service appeal, and market share in the field of laser cutting machines in China through years of dedicated research, development, production, and sales of metal laser cutting machines.

Their main products include high-power fiber laser cutting machines (ranging from 2000W to 12000W) and medium-power fiber laser cutting machines (<2000W).

These machines are widely used in industries such as electric power, automotive manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, precision parts, hardware products, and others.

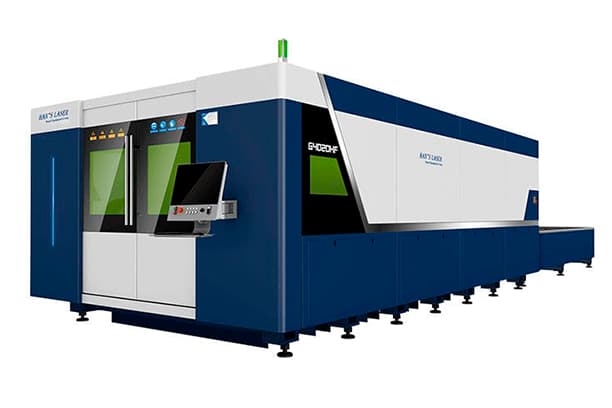

Foshan HSG Laser is a high-tech company that provides global customers with laser intelligent equipment solutions.

It has been dedicated to the manufacturing of laser intelligent equipment and focuses on efficiency, intelligence, environmental friendliness, and compatibility in product development.

Established in 2006, HSG Laser has seen rapid growth and now operates four standardized intelligent equipment manufacturing facilities with a total area of 40,000 square meters or more.

It specializes in flexible manufacturing and digital hierarchical management in areas such as laser robots, multi-axis linked professional cutting tubes, and precision welding intelligent automatic production lines.

HSG Laser’s intelligent equipment operates successfully in more than 100 countries and has a wide range of prestigious customers in various industries, including precision instruments, auto parts, kitchen and bathroom hardware, electronics and electricals, and smart homes.

The company has a professional R&D team and a well-established after-sales technical support department, providing a customer-centric service experience.

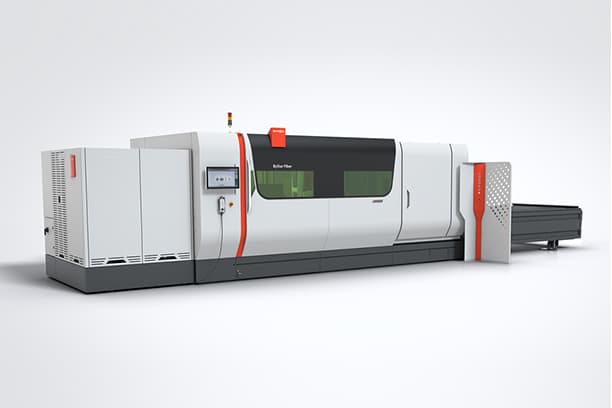

Jinan Bodor Laser was established in 2008 and follows a brand development strategy that emphasizes both employee development and product innovation.

Hymson Laser is a nationally recognized high-tech enterprise that specializes in the field of lasers and automation.

Founded on April 3, 2008, Hymson primarily engages in the research, design, production, and sales of laser and automation equipment for industries such as consumer electronics, power batteries, and sheet metal fabrication. On September 9, 2020, it was listed on the Science and Technology Innovation Board of the Shanghai Stock Exchange. As of the end of June 2023, Hymson’s total assets amounted to 10,172,808.85 ten thousand yuan, with net assets of 2,130,873.9 ten thousand yuan. Its operating income in 2022 was 4,105,415.55 ten thousand yuan, with a net profit of 375,493.2 ten thousand yuan.

The company is recognized as one of the best providers of comprehensive laser and automation equipment solutions in the industry.

Its products range from lithium battery automation equipment, air-cooled UV laser equipment, large-scale automatic production lines, large-scale laser cutting equipment, sapphire cutting equipment, and PCB marking equipment.

Hymson Laser is dedicated to continuously improving and delivering more efficient and high-quality solutions to its customers in the lithium battery, 3C, and sheet metal industries.

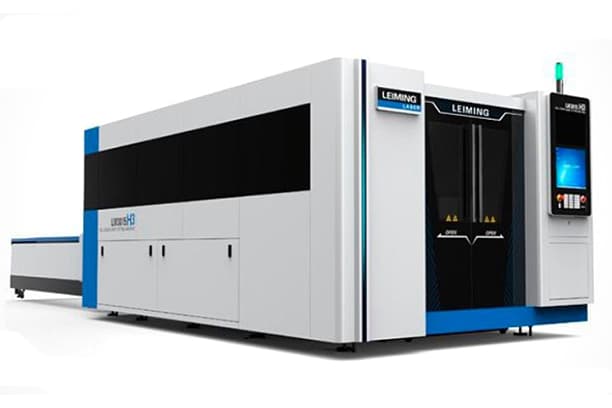

Shandong Leiming Laser is dedicated to developing, producing, and selling fiber laser cutting machines.

The company provides a complete range of fiber laser cutting machines, laser processing and welding equipment, and cleaning equipment.

These machines are widely used in industries such as steel metallurgy, non-ferrous metals, automotive, aerospace, military electronics, precision instrumentation, machinery manufacturing, hardware tools, integrated circuits, and solar energy.

Headquartered in the Jiangsu Free Trade Zone in China, Quick Laser is dedicated to the development, production, and sales of laser equipment.

The company provides a comprehensive range of laser application solutions and equipment customization services to global manufacturers, including laser cutting machines, laser welding machines, laser pipe cutting machines, laser micro-machining, and automotive welding workstations.

With over 100 invention patents, Quick Laser has developed innovative laser production lines independently, such as a cup and pot welding and cutting line, a five-axis linkage instrument welding machine, a wafer and fan automatic cutting machine, and a zero-tail material cutting machine with three parallel chucks.

Founded in 1923 in Germany, Trumpf is one of the most experienced companies in the laser cutting industry. With over 14,000 employees, Trumpf operates globally, providing a wide range of laser cutting, welding, marking, and other machine solutions. Their extensive history and global presence make them a leading player in the market.

Established in 1964 in Switzerland, Bystronic has grown into a leading manufacturer of laser cutting machines, press brakes, and related software. Employing over 3,000 people, Bystronic has service subsidiaries in 30 countries, enhancing their global reach and customer service capabilities.

Founded in 1946 in Japan, Amada is a multinational company specializing in sheet metal processing machinery, including laser cutting machines. Amada’s long history and reputation for reliable and versatile machines have established them as a significant player in the industry.

Founded in 2008 in China, Bodor has rapidly expanded to become a global player with a significant presence in over 150 countries. With 3,000 employees and a robust global service network, Bodor’s rapid growth and innovation have made them a notable contender in the laser cutting market.

Trumpf offers a broad range of machines, including 2D and 3D laser cutters, mechanical and automated machines, and VCSEL solutions. Their TruLaser series, for example, features advanced technologies like BrightLine and SpeedMark, which enhance cutting speed and quality, making them suitable for diverse industrial applications. Trumpf continually invests in research and development to introduce state-of-the-art technologies such as laser welding and additive manufacturing.

Bystronic specializes in fiber laser cutting machines and press brakes, with their ByStar Fiber model being particularly noted for its efficiency and ability to cut various materials, including thick metals. Bystronic’s innovative BySoft software suite enhances the user experience, allowing for seamless integration and management of production processes. Their focus on automation and digitization positions them as a leader in advanced manufacturing solutions.

Bodor manufactures a wide range of laser machines, including CO2 and fiber laser cutting machines, handheld laser welding machines, and high-power models up to 40,000W. Their innovative features include an automatic focusing system and a unique dust removal system that improves cutting quality and reduces maintenance needs. Bodor’s commitment to research and development is evident in their introduction of the world’s first 22,000W laser cutting machine, which significantly increases productivity.

Bodor is recognized for its extensive customer support, including a three-year warranty, free maintenance for three years, and 24/7 online service. They also provide consumable parts at agency prices and have 30 overseas spare part centers, ensuring comprehensive support for their global customer base. Their adherence to international quality standards such as CE, FDA, SGS, and ISO9001 is complemented by advanced quality control measures like laser interferometers and optical microscopes.

Trumpf invests heavily in customer support, offering software, tools, and maintenance services. Their products are known for reliability and durability, backed by a strong support network that ensures customer satisfaction. Trumpf’s commitment to quality is reflected in their rigorous testing protocols, ensuring that every machine meets high-performance standards before delivery.

Bystronic emphasizes customer digitization and offers highly intelligent yet user-friendly laser-cutting systems. Their dedicated R&D department and service subsidiaries in many countries ensure that customers receive top-notch support and innovative solutions. Bystronic also meets high-quality standards, continuously improving technology to maintain their competitive edge.

Trumpf has achieved significant market leadership through a series of acquisitions and innovations, particularly in ultrafast lasers. Their continuous investment in research and development keeps their products at the cutting edge of technology, enabling them to meet the evolving needs of industries such as automotive and aerospace.

Bystronic has dominated the laser-cutting industry for the past decade, continuously innovating with highly intelligent laser-cutting systems. Their strong global presence and revenue generation reflect their market leadership, supported by a growing portfolio of automated solutions that enhance productivity.

Bodor has rapidly risen to become a key player in the global laser cutting market, known for its technological advancements and innovation. With numerous groundbreaking products and patents, Bodor’s commitment to innovation positions them as a formidable competitor in the industry, particularly in cost-effective solutions for small to medium-sized enterprises.

Laser cutting machines are sophisticated tools that utilize laser technology to cut materials with high precision. Different types of laser cutting machines are designed for specific applications, each offering unique capabilities. This chapter explores the various types of laser cutting machines, their working principles, materials they can cut, and their applications.

Laser cutting technology involves the use of a laser beam to melt, burn, or vaporize material, creating precise cuts with minimal waste. The laser beam is directed through a cutting head, which focuses the energy onto the material’s surface. This technology is widely used in various industries due to its accuracy, speed, and versatility.

Working Principle: CO2 laser cutters utilize a gas mixture containing carbon dioxide, helium, and nitrogen as the active laser medium. The gases are electrically stimulated to produce a laser beam with a wavelength of 10.6 micrometers, which falls in the infrared range.

Materials: CO2 lasers are highly effective for cutting non-metallic materials such as glass, plastics, leather, wood, and acrylic. They can also cut metals, particularly sheet metals with thicknesses less than 10 mm.

Applications: CO2 lasers are extensively used in the textile industry for cutting and engraving fabrics with intricate designs. For example, in garment manufacturing, CO2 lasers are employed to cut precise patterns, reducing material waste and improving efficiency. In the woodworking industry, CO2 lasers are used to create detailed engravings on wood products, enhancing their aesthetic appeal.

Efficiency and Statistics: CO2 laser cutters are known for their efficiency and lower operating costs. They typically have cutting speeds ranging from 20 mm/s to 300 mm/s, depending on the material and thickness. The lifespan of CO2 laser tubes can vary from 1,000 to 3,000 hours, making them a reliable choice for many applications.

Working Principle: Crystal laser cutters use neodymium-doped yttrium aluminum garnet (Nd:YAG) or neodymium-doped yttrium ortho-vanadate (Nd:YVO) crystals as the gain medium. These lasers operate at a wavelength of approximately 1064 nm, allowing for higher intensity and better focus.

Materials: Crystal lasers are suitable for cutting thicker metals, as well as materials like plastics, ceramics, and glass. Their high energy output and precision make them versatile for various cutting applications.

Applications: In the electronics manufacturing industry, crystal lasers are used for cutting and scribing ceramics and metals. For instance, Nd:YAG lasers are employed in the production of printed circuit boards (PCBs) to cut precise shapes and patterns. This technology is also used in the medical device industry for cutting intricate components with high precision.

Efficiency and Statistics: Crystal laser cutters offer high precision and energy efficiency. Their cutting speeds can range from 50 mm/s to 500 mm/s, depending on the material. Crystal lasers typically have a lifespan of around 8,000 to 15,000 hours, making them a durable option for demanding applications.

Working Principle: Fiber lasers utilize a bank of diodes to generate the laser beam, which is then amplified and transmitted through a fiber-optic cable. This technology is known for its high efficiency and reliability, with a typical wavelength around 1.064 micrometers.

Materials: Fiber lasers are versatile and capable of cutting both metals and non-metals. They excel in cutting reflective and conductive metals like copper and aluminum and are highly efficient for materials with thicknesses less than 5 mm.

Applications: Fiber laser cutters are widely used in the automotive industry for cutting metal components with high precision. For example, they are employed to cut intricate shapes and parts for car bodies and frames, ensuring accuracy and reducing production time. In the aerospace industry, fiber lasers are used to cut lightweight materials like aluminum, contributing to the manufacturing of aircraft components.

Efficiency and Statistics: Fiber lasers are known for their high cutting speeds and precision. They can achieve cutting speeds of up to 1,000 mm/s, depending on the material and thickness. Fiber lasers have a long lifespan, often exceeding 100,000 hours, and require minimal maintenance, making them a cost-effective choice for industrial applications.

Understanding the different types of laser cutting machines and their specific applications helps in choosing the right technology for your needs, ensuring optimal performance and efficiency in various industrial tasks.

Choosing the right laser cutting machine is crucial for optimal performance and efficiency in manufacturing operations. Several factors must be evaluated to match the machine’s capabilities with your specific needs.

Consider the type of material you plan to cut. Different laser cutting machines handle various materials such as mild steel, stainless steel, aluminum, copper, brass, and non-metals like plastics and composites. Ensure the machine is compatible with the materials you will be working with regularly. Additionally, consider the thickness of the materials, as this influences the required laser power and cutting speed.

For applications requiring intricate designs or tight tolerances, cutting accuracy and precision are paramount. Look for machines offering high precision and repeatability. Factors such as laser quality, machine rigidity, and advanced control systems play significant roles in achieving consistent and accurate cuts. High-precision machines reduce material waste and ensure the quality of finished products.

Laser power directly impacts the machine’s cutting speed and its ability to cut through materials. Higher power lasers can cut through thicker materials more quickly, but they may come at a higher cost. Balance the machine’s power with your specific cutting needs, considering both the material types and thicknesses you will handle. Evaluate the overall cutting speed, especially if you need to meet high production demands.

Modern laser cutting machines often come with various automation features that enhance productivity and reduce manual labor. Features such as automatic loading and unloading systems, nesting software, and automated nozzle change systems streamline the cutting process, minimize human error, and increase production efficiency. These features are particularly beneficial for high-volume production environments.

The user interface and software compatibility are important for ease of use and integration with existing systems. Look for machines with intuitive controls and user-friendly software compatible with your existing CAD/CAM systems. The software should support various file formats and offer advanced features like nesting and cutting path optimization. Additionally, training and support from the manufacturer can be invaluable for smooth operation and maximizing the machine’s capabilities.

Consider the reputation of the manufacturer and the warranty period offered. A reputable manufacturer with a history of producing reliable machines is more likely to provide a quality product. Look for reviews and testimonials from other users to gauge the manufacturer’s reliability and customer satisfaction. Ensure the warranty covers parts and labor for a specified period, providing peace of mind and support in case of any issues.

The bed size of the laser cutting machine determines the maximum size of the material you can cut. Ensure the bed size matches the largest piece you plan to fabricate. For added flexibility, consider machines that can cut both tubes and sheet metal, beneficial for small batches or job shops. Efficient material handling systems can improve productivity by reducing setup times and facilitating easier material loading and unloading.

Laser cutting machines generate significant heat, so proper cooling and ventilation are essential. The machine should have an efficient cooling system to prevent overheating and ensure stable operation. Proper ventilation is necessary to allow heat and fumes to escape, maintaining a safe and comfortable working environment.

The quality of operation is influenced by the distance between the nozzle and substrate, the intensity and speed of the laser beam, and the precision and accuracy of the cutting head movement. Advanced cutting heads with sensors can automatically adjust the focus position and diameter of the laser beam, ensuring ideal cutting speed and quality on different materials and thicknesses. These features contribute to achieving high-quality cuts with minimal defects.

Laser machines can be a significant investment, so having a clear budget in mind is crucial. Compare prices from different dealers and consider financing options to make the acquisition more accessible and financially sustainable. Evaluate the total cost of ownership, including maintenance, consumables, and potential downtime, to ensure the machine provides a strong return on investment.

Consider the machine’s versatility in cutting different types of materials and its ability to integrate with other systems such as ERP, production analysis, and system monitoring. A versatile machine that supports various materials and integrates seamlessly with other systems can enhance overall manufacturing efficiency and support everyday decision-making.

Understanding the maintenance and operational costs associated with a laser cutting machine is essential. Regular maintenance ensures the machine operates efficiently and extends its lifespan. Consider the availability and cost of consumables such as lenses, nozzles, and gases. Implementing a preventive maintenance schedule can reduce unexpected downtime and repair costs. Additionally, energy consumption and the cost of spare parts should be factored into the overall operational budget.

By carefully evaluating these factors, you can select a laser cutting machine that meets your specific needs, supports your production goals, and provides a strong return on investment.

Laser cutting technology has undergone significant advancements in recent years, driven by the need for enhanced efficiency, precision, and versatility. This chapter explores the latest innovations and technological advancements that are shaping the future of laser cutting.

High-power lasers have become increasingly common, with machines now available at 6 kW, 10 kW, and even higher power outputs. For example, the BOLT VII 6025 30kW laser cutting machine by Penta can cut 12mm carbon steel at speeds up to 11 meters per minute and maintain excellent verticality when cutting 20mm carbon steel at 5.5 meters per minute. These high-power lasers significantly improve cutting speed and performance, making them ideal for heavy-duty industrial applications.

Fiber lasers are favored for their high efficiency, precision, and lower maintenance requirements. They offer higher cutting speeds, especially for thin materials, and are effective for cutting a wide range of materials, including metals and plastics. Fiber laser technology provides superior beam quality, resulting in finer cuts and less material waste. Additionally, fiber lasers have longer lifespans and require less frequent maintenance, making them a cost-effective solution for various industries.

Innovations in beam shaping technology have improved control over the laser’s focus and intensity. This enhancement leads to better edge quality and reduced heat-affected zones, resulting in more precise cuts and optimized material usage. Advanced beam shaping allows manufacturers to tailor the laser beam’s characteristics to specific cutting tasks, ensuring optimal performance for various materials and thicknesses.

Hybrid laser systems combine different laser technologies, such as CO2 and fiber lasers, in a single machine. This combination offers versatility in handling a broader range of materials and thicknesses. Hybrid systems optimize performance by leveraging the strengths of each laser type, providing manufacturers with a flexible and efficient cutting solution. For instance, these systems are particularly useful in industries that require cutting diverse materials with varying properties.

The integration of automation technologies with laser cutting systems has advanced significantly. Modern laser cutters now feature automated loading and unloading, real-time monitoring and adjustments, and seamless integration with CAD/CAM systems. These enhancements reduce downtime, increase throughput, and streamline the design-to-production workflow. Automation not only improves efficiency but also minimizes human error, ensuring consistent and high-quality cuts.

Advancements in 3D laser cutting technology enable the cutting of complex geometries and structures. This capability is particularly beneficial in aerospace and automotive applications, where precision and intricate designs are essential. Additionally, micro laser cutting technology allows for extremely fine and precise cuts, which are crucial for manufacturing intricate components in medical devices and microelectronics. These technologies expand the possibilities for laser cutting, allowing for more complex and detailed designs.

Green lasers are increasingly used for cutting non-metal materials such as glass and ceramics. They offer high-quality cuts with minimal damage to surrounding areas, making them effective for electronics manufacturing. Green laser technology provides precise control and reduces the risk of thermal damage, ensuring high-quality results for delicate materials.

The integration of IoT and smart technologies allows laser cutting machines to connect to the internet and communicate with other systems. Real-time monitoring software provides instant feedback, helping to prevent mistakes, reduce waste, and increase safety and efficiency. Smart technologies enable predictive maintenance, allowing manufacturers to address potential issues before they lead to downtime, further enhancing productivity and operational efficiency.

New laser cutters come equipped with advanced software that simplifies setup and operation. This software can automatically adjust settings for different materials, ensuring optimal cutting conditions. Additionally, dashboards provide real-time monitoring and analytics, accessible from computers or mobile devices, enhancing operational convenience and safety. User-friendly interfaces make it easier for operators to manage cutting tasks, reducing training time and improving overall efficiency.

Modern laser cutters are designed to consume less energy while maintaining high performance. This focus on energy efficiency aligns with ecological standards, making the machines more environmentally friendly and cost-effective in the long run. Manufacturers are increasingly adopting sustainable practices, such as using recyclable materials and reducing emissions, to minimize the environmental impact of their operations.

Penta’s BOLT VII 6025 30kW ultra-high power laser cutting machine exemplifies the industry’s commitment to high-performance and precision cutting, featuring patented self-mixing gas cutting technology. Stealth Laser’s 2024 lineup includes machines that integrate the latest laser technology advances, offering ease of use, robustness, and the ability to adapt to different materials and complexities effortlessly. Their fiber laser cutting machines are powered by state-of-the-art fiber laser technology, ensuring high precision and efficiency.

These innovations collectively drive the laser cutting industry towards greater efficiency, precision, and versatility, opening up new possibilities across various sectors, from manufacturing and design to aerospace and automotive.

The global presence and customer support offered by leading laser cutting machine manufacturers are critical factors for users when choosing a supplier. These aspects ensure that customers have access to timely support, training, and maintenance, which are essential for maintaining operational efficiency and productivity. Here is an overview of the global presence and customer support strategies of some of the top manufacturers in the laser cutting industry.

Global Presence: Bystronic, headquartered in Switzerland, has a strong presence in Europe, the Americas, and Asia. The company has established service subsidiaries in 30 countries and employs over 3,000 people worldwide. This extensive network ensures that Bystronic can provide localized support and services to its customers across the globe.

Customer Support: Bystronic is known for its customer-centric approach, offering comprehensive training programs and tailored solutions to meet specific customer needs. The company emphasizes modular automation systems and advanced software integration. For instance, the BySoft 7 software allows for seamless CAD/CAM workflow integration, enhancing operational efficiency. Bystronic also provides sustainable manufacturing solutions with energy-efficient designs and offers 24/7 support to ensure continuous operation and minimize downtime.

Global Presence: Mazak, founded in Japan in 1919, boasts an extensive global manufacturing network with subsidiaries present worldwide. The company has a significant presence in Asia and North America and is expanding its market share in Europe and emerging economies. Mazak employs around 7,000 people globally, which highlights its capacity to support a wide range of customers.

Customer Support: Mazak is committed to providing unparalleled customer support through its extensive network of over 80 customer support bases worldwide. The company offers advanced CNC controls with AI-assisted cutting parameter optimization, which automatically adjusts settings for optimal cutting performance. Mazak also provides devices that can be chamfered and tapped after laser cutting, enhancing versatility. Their global manufacturing network ensures consistent quality and localized support, enhancing customer satisfaction and operational efficiency.

Global Presence: Amada, headquartered in Japan, has a worldwide presence with over 83 branches across continents and more than 8,000 employees. The company has a strong presence in Europe and North America and is growing its influence in the shipbuilding and heavy machinery sectors globally.

Customer Support: Amada offers a comprehensive global service network with rapid response times and predictive maintenance capabilities. The company provides proprietary beam control technology for superior cutting quality and an IoT-enabled VPSS 3i software suite for integrated production management, allowing for real-time monitoring and optimization of production processes. Amada also delivers high-durability machines with proven longevity in demanding industrial environments, ensuring that customers receive reliable and efficient support.

Global Presence: Han’s Laser, based in China, has a strong presence in Asia and is expanding its market share in Europe and North America. The company has a network of over 50 global partners and service centers, which facilitates effective customer support and service delivery.

Customer Support: Han’s Laser offers a wide range of laser equipment and provides significant support through its global network. The company is known for its fast cutting speeds, good cutting effects, and stable operations. Maintenance tasks like cleaning the cutting lens and replacing the cutting head can be done quickly, though the manual operating function of their devices is somewhat complex. Han’s Laser’s support infrastructure ensures that customers can maintain optimal machine performance with minimal disruption.

Global Presence: Trumpf, headquartered in Germany, has a dominant global presence with approximately 13,000 employees. The company has a strong footprint in Europe, North America, and Asia, making it one of the most widely recognized names in the laser cutting industry.

Customer Support: Trumpf is recognized for its robust global service network, which includes 24/7 support and remote diagnostics. The company offers comprehensive training programs to ensure that customers can fully utilize their machines’ capabilities. Trumpf’s products are known for their ease of maintenance, such as quickly cleaning the cutting lens and replacing the cutting head. This support infrastructure is particularly suitable for large-volume production with single material types, ensuring consistent performance and customer satisfaction.

Global Presence: Tanaka, based in Japan, is a pioneer in the global laser industry but has a more focused presence compared to some of the other giants. The company is known for its high-end feature cutting machines, including plasma and gas cutting machines, and is widely used in structural parts processing.

Customer Support: While specific details on Tanaka’s customer support network are less detailed, the company’s commitment to innovation and delivering cutting-edge solutions suggests a strong focus on customer needs. Tanaka’s machines are designed to handle thick plates up to 30 mm, indicating a robust support system for demanding applications. This ensures that customers can rely on Tanaka for high-performance solutions and effective support.

Global Presence: Prima Power, based in Finland, covers more than 80 countries with eight plants spread over three continents. The company is a leading provider of Industry 4.0 sheet metal manufacturing solutions, which underscores its extensive global reach.

Customer Support: Prima Power offers a comprehensive range of services, including laser drilling, punching, 2D and 3D laser cutting, welding, and bending. The company’s focus on combined technologies and automation ensures that customers receive integrated solutions. Prima Power’s global presence and service network support a wide range of industrial applications, ensuring that customers have access to the necessary resources for maintaining and optimizing their machines.

Global Presence: Messer Cutting Systems, based in Germany, has an international presence and contributes significantly to the global metal processing industry. The company offers a variety of cutting options, including oxyfuel, plasma, and laser cutting systems, which highlights its versatile capabilities.

Customer Support: Messer provides quality production and delivers high standards in heavy machinery. The company’s laser cutting machines focus on precision and reliability, and Messer’s global network ensures localized support and service. This extensive support infrastructure ensures that customers can maintain high productivity and efficiency, regardless of their location.

These leading manufacturers emphasize a strong global presence, innovative technology, and comprehensive customer support to meet the diverse needs of the laser cutting industry. Their commitment to quality, efficiency, and customer-centric solutions underscores their positions as industry leaders, ensuring that customers receive the best possible products and services.

Below are answers to some frequently asked questions:

The top laser cutting machine manufacturers are renowned for their innovation, quality, and global presence. Trumpf, based in Germany, is a leader in electronic technology and industrial machine tools, offering high-quality beams and cutting efficiency. Bystronic from Switzerland focuses on high-performance machines for sheet metal processing with a strong emphasis on automation and efficiency. Han’s Laser, a prominent Chinese company, offers an extensive range of laser machines, including welding and engraving models. Bodor Laser, also from China, is recognized for its technological advancements and high-power fiber laser machines. Mazak from Japan provides versatile laser cutting machines capable of performing multiple tasks, while Mitsubishi, another Japanese giant, is known for its pioneering CO2 laser technology. AMADA, a multinational company from Japan, specializes in precision and flexible machines for various applications. HGTECH, a Chinese leader, offers intelligent manufacturing solutions and high-speed laser cutting platforms. Epilog Laser from the USA focuses on CO2 and fiber laser technology with high-speed capabilities. Accurl Technologies from Italy provides customizable solutions for metal processing, and Prima Power, also from Italy, is known for its reliable and precise laser machines in the sheet metal sector. These companies are distinguished by their commitment to excellence and customer satisfaction, making them leaders in the laser cutting machine market.

When choosing a laser cutting machine, several key factors should be carefully evaluated to ensure it aligns with your specific needs. First, consider the power of the laser, as this determines the thickness and types of materials you can cut or engrave. Higher power lasers are capable of cutting thicker materials more efficiently. Next, examine the speed and efficiency of the machine, as faster cutting can significantly reduce production time, particularly for high-volume operations.

Performance quality and precision are also crucial, as they directly affect the quality of the output. Factors like cut depth and focal point play a significant role, so investing in a machine with high-quality components is important. The bed size of the laser cutter should match the dimensions of the materials you plan to work with; larger bed sizes accommodate bigger pieces, while smaller sizes are suitable for more compact projects.

Software compatibility is another vital consideration. A user-friendly software interface can enhance your experience, especially if it integrates well with existing design programs. Additionally, look for features that facilitate automation and scalability, which can improve efficiency and lower labor costs, particularly in industrial settings.

Safety features, including effective ventilation and cooling systems, are essential to ensure a safe working environment. Budget constraints will also play a role in your decision, as they affect the power, size, and features of the machine. It’s important to balance cost with the quality and reliability of the equipment.

Lastly, consider the maintenance requirements and service life of the machine, as well as the reputation of the manufacturer. A manufacturer with extensive experience and strong customer support can provide valuable assistance throughout the machine’s lifecycle, ensuring optimal performance and longevity. By thoughtfully weighing these factors, you can select a laser cutting machine that best fits your requirements.

When comparing different types of laser cutting machines, several key factors come into play, including the type of laser, material compatibility, cutting accuracy, speed, and maintenance costs.

CO2 laser cutting machines operate at a wavelength of 10.6 micrometers and are primarily used for cutting non-metallic materials such as wood, plastic, glass, and paper. They offer medium cutting speed, particularly fast for thin sheet materials, with a process accuracy around ±0.1mm. However, they have higher maintenance costs due to the need for aggressive cooling and frequent replacement of laser tubes.

Fiber laser cutting machines, on the other hand, work at a wavelength of 1.06 micrometers and are ideal for cutting metals like stainless steel, carbon steel, and aluminum alloys. They provide high cutting speed and superior accuracy, reaching ±0.02mm. Fiber lasers have low maintenance costs, with long service life and minimal upkeep required, making them highly efficient and cost-effective for metal cutting applications.

YAG solid laser cutting machines also operate at a wavelength of 1.06 micrometers and are used mainly for cutting metals, similar to fiber lasers but with lower efficiency. They offer lower cutting speeds and process accuracy around ±0.05mm, with medium maintenance costs.

Diode laser cutting machines, which vary in wavelength, are generally used in lower power settings. They are suitable for cutting thinner materials like paper, cardboard, and occasionally wood and plastic. Diode lasers are slower and less powerful compared to CO2 and fiber lasers and are typically used for small-scale, home-based projects.

Ultimately, the choice of a laser cutting machine depends on the specific needs of the user, including the types of materials to be cut, desired cutting speed and accuracy, and budget. Each type of laser cutter has its unique advantages and disadvantages, making it essential to select the right machine based on these factors.

In 2024, laser cutting technology has advanced significantly, with several key innovations leading the way. Higher power and speed are major trends, with high-power lasers (6 kW, 10 kW, and higher) enhancing the ability to cut thicker materials with superior quality and smoother edges. Precision and accuracy have also improved due to advanced control and motion systems, resulting in detailed cuts and reduced material waste.

Fiber laser technology continues to dominate due to its efficiency, precision, and lower maintenance needs, offering faster cutting speeds for thin materials and versatility for various materials. Advanced beam shaping technology allows for better control over the laser’s focus and intensity, improving edge quality and minimizing heat-affected zones, which optimizes material usage.

Hybrid laser systems, combining CO2 and fiber lasers, provide greater versatility and performance for different materials and thicknesses. Automation and integration have also progressed, with features like automated loading/unloading, real-time monitoring, and integration with CAD/CAM systems, reducing downtime and enhancing throughput.

The integration of IoT and smart technologies allows for real-time monitoring, predictive maintenance, and optimized resource allocation, improving operational safety and efficiency. Adaptive optics dynamically adjust the laser beam’s focus to ensure consistent cutting quality across various materials and thicknesses.

3D laser cutting technology enables the creation of complex three-dimensional shapes, particularly beneficial in industries like aerospace and automotive. Green laser technology is gaining traction for cutting non-metal materials such as glass and ceramics, providing high-quality cuts with minimal surrounding damage, especially useful in electronics manufacturing.

Micro laser cutting technology allows for extremely fine and precise cuts, crucial for producing intricate components in medical devices and microelectronics. There is also a growing emphasis on sustainability, with efforts to reduce energy usage, material waste, and improve recycling processes. Laser cutting specialists are exploring eco-friendly technologies to enhance environmental sustainability.

Lastly, laser cutting is increasingly being integrated with other technologies like milling, waterjet cutting, and additive manufacturing (3D printing) to efficiently produce intricate and complex parts, which is expected to become more prevalent in aerospace, automotive, and healthcare industries. These innovations collectively drive the laser cutting industry towards greater efficiency, precision, and versatility, opening up new possibilities across various sectors.

When evaluating which manufacturers offer the best global support and service in the laser cutting machine industry, several companies stand out due to their extensive networks and commitment to customer satisfaction.

TRUMPF, a leading German manufacturer, is recognized for its robust global presence and comprehensive customer support. With over 14,000 employees and operations in numerous countries, TRUMPF provides a wide array of services, including maintenance, leasing, and inspection, while investing heavily in innovation through its strong R&D department.

Bystronic, based in Switzerland, has established a significant global footprint with service subsidiaries in 30 countries. The company focuses on digitization and automation, offering intelligent laser-cutting systems along with reliable customer support, making it a dependable choice for clients worldwide.

Amada, a prominent Japanese manufacturer, operates 83 branches globally and sells products in over 100 countries. They provide a complete range of sheet metal processing solutions, including software and maintenance services, ensuring comprehensive support through their extensive network.

Mazak, also from Japan, has more than 80 service centers around the world. Their offerings include CNC turning centers, machining centers, and laser processing machines, all supported by a strong commitment to customer service and a robust global reach.

Han’s Laser, a major player from China, is known for its wide range of laser equipment and a strong R&D focus. They maintain a significant global presence and offer extensive support services, particularly in China.

Finally, Prima Power, headquartered in Finland, covers more than 80 countries with eight manufacturing plants. They provide comprehensive solutions for sheet metal processing and ensure reliable customer support through their extensive network.

These manufacturers excel in global support and service due to their vast service networks, comprehensive offerings, continuous innovation, and strong commitment to customer satisfaction.

After reading this article, many readers may have the question of which laser manufacturer is the best.

Every manufacturer presents unique strengths, underscoring the importance of aligning purchase decisions with individual needs and expectations. Hence, diligent research is recommended, taking note of user reviews and post-purchase support availability for a well-informed choice.

However, it’s important to note that determining the best manufacturer requires a set of criteria, such as product quality, cost-effectiveness, and customer service. The criteria for determining the best manufacturer can vary, and so the conclusion of who is the best will also change. In addition, the best manufacturers are constantly evolving.

Therefore, the answer to the question of how to choose the best manufacturer lies in your own research and comparison.

You can also read the laser cutting machine buyer’s guide for assistance in making a decision for your business. A comprehensive comparison is necessary to find the best laser cutting machine supplier for your needs. If you would like to receive a quote for a fiber laser cutting machine, please feel free to contact us.