In the vast world of manufacturing, one machine stands tall: the press brake. With its ability to bend and shape metal with precision and power, it has become an indispensable tool across industries. But what exactly is a press brake, and who are the top manufacturers driving innovation in this field? Join us as we dive into the fascinating world of press brakes, guided by the insights of seasoned experts in the field.

A few days ago, I had a chat with the sales of a machine tool manufacturing factory, a seasoned professional with over 20 years of experience in the field. He expressed his views on machine tool brands, with which I wholeheartedly agreed. Therefore, I wanted to share his words. Hopefully, it can bring a new perspective to those who are blindly pursuing brands.

In his own words, he said,

“When it comes to machine tools, don’t focus on the brand, but rather on whether the seller is honest and conscientious. Some people, for the sake of money, will sell you refurbished machines or substitute inferior products as superior ones. For instance, if you buy a branded computer for $10,000 or assemble a computer for the same amount, which do you think would be better? Which one would be more practical? What brand could you attribute to the assembled one? I’ve been assembling machine tools since 2004, from after-sales to current sales, and I’ve seen a lot of equipment. They’re indeed good, from workmanship to configuration, precision – I won’t deny that. The price will also surprise you! Nowadays, domestically produced machine tools are very mature. You can buy equipment with the same performance as branded and imported ones at less than half the price. So why pursue the brand? I believe that practicality is the most realistic pursuit. This is just my personal opinion, so if you find it incorrect, please forgive me!“

A press brake, also known as a brake press, is a sophisticated machine tool primarily used for precision bending and forming of sheet metal and plate materials. It is a cornerstone equipment in metalworking, fabrication, and manufacturing industries, enabling the creation of complex geometries and structural components.

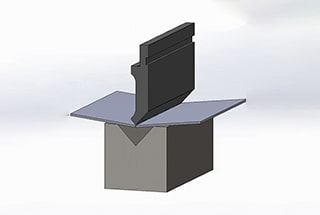

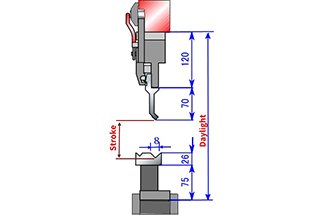

The core structure of a press brake comprises a robust frame with a stationary lower beam and a movable upper beam, known as the ram. The ram houses the punches (upper tooling), while the lower beam secures the corresponding dies. This configuration allows for the precise manipulation of workpieces, typically sheet metal parts, placed between the punch and die.

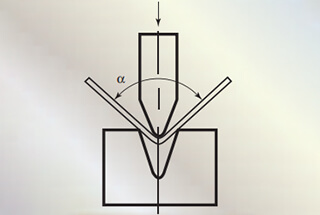

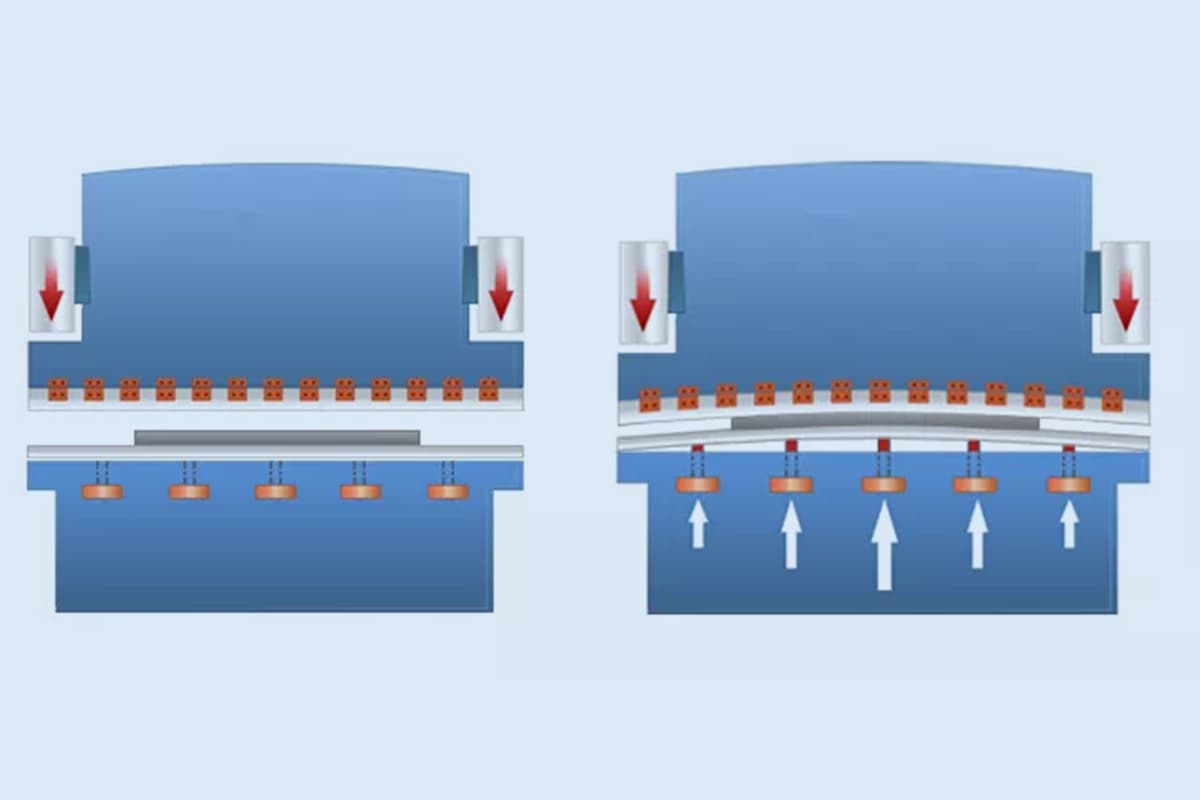

During operation, the press brake applies controlled force—either hydraulic, mechanical, or servo-electric—to the ram. This action drives the punch into the die, causing the workpiece to conform to the tooling geometry. The resulting bend or form is determined by several factors, including the punch and die profiles, material properties, and applied force. Modern press brakes often incorporate advanced force distribution systems to ensure uniform pressure along the entire bending length, crucial for maintaining consistent bend angles and preventing distortion in large parts.

Press brakes exhibit remarkable versatility, capable of executing a wide array of bending and forming operations:

State-of-the-art press brakes are equipped with sophisticated CNC (Computer Numerical Control) systems, revolutionizing the bending process. These advanced controllers enable precise programming of bend angles, sequences, and ram positions. Many systems now incorporate real-time angle measurement and correction capabilities, ensuring unprecedented accuracy. This level of automation not only boosts productivity and consistency but also facilitates complex multi-bend parts production with minimal operator intervention.

Press brake capacities vary widely to accommodate diverse manufacturing needs. Bending forces typically range from 20 to 2,000 tons, with bed lengths spanning from 4 to over 20 feet. High-end models may offer even greater capacities for specialized applications. The selection of an appropriate press brake depends on factors such as material thickness, bend length, and required tonnage, which can be calculated using specific formulas considering material properties and bend parameters.

In the evolving landscape of Industry 4.0, modern press brakes are increasingly integrated with IoT (Internet of Things) sensors and data analytics platforms. This connectivity allows for real-time monitoring of machine performance, predictive maintenance, and seamless integration with broader manufacturing execution systems (MES).

The sheet metal fabrication industry employs several types of press brakes, each with distinct characteristics suited to specific applications:

Mechanical Press Brakes

Hydraulic Press Brakes

Pneumatic Press Brakes

Electric Servo Press Brakes

Hybrid Press Brakes

The selection of an appropriate press brake type depends on various factors, including:

Modern press brakes increasingly incorporate advanced CNC controls, automated tool changing systems, and can be integrated into smart manufacturing environments. This allows for highly optimized bending processes, reduced setup times, and improved overall efficiency in sheet metal fabrication operations.

The press brake manufacturing sector has witnessed remarkable advancements, with numerous companies establishing themselves as industry leaders. Press brakes play a pivotal role in metal fabrication, enabling precise sheet metal bending and significantly impacting production quality and efficiency. Several manufacturers have distinguished themselves through their commitment to innovation, quality, and customer service.

Leading press brake manufacturers are characterized by their extensive industry experience, robust engineering practices, and dedication to technological advancement. For instance, Amada, founded in 1946, has been at the forefront of sheet metal processing machinery innovation, consistently pushing the boundaries of press brake technology. Another notable leader, Trumpf, established in 1923, is renowned for its cutting-edge solutions in machine tools, laser technology, and electronics applied to press brake systems. These companies have demonstrated their ability to adapt to changing market demands and set new industry standards.

The diversity of press brake manufacturers in the market offers a wide range of specialized solutions to meet various fabrication needs. Top-tier manufacturers excel in delivering a combination of reliability, advanced features such as CNC controls and automated tool changing systems, and responsive customer support. They align their products with evolving business requirements and operational demands, often incorporating Industry 4.0 principles for enhanced connectivity and data-driven manufacturing.

When evaluating the leading players in the press brake domain, several factors are considered, including technological innovation, build quality, energy efficiency, safety features, and after-sales support. The best manufacturers consistently demonstrate their ability to adapt to the evolving demands of modern metalworking, offering solutions that enhance productivity, precision, and versatility in sheet metal forming operations.

The following list of top press brake manufacturers is presented in alphabetical order and does not reflect a specific ranking. Each of these manufacturers brings unique strengths to the market, catering to diverse customer needs across various industries and applications.

Amada, founded in 1946, is a global leader in the design and manufacture of advanced sheet metal processing machinery. With over seven decades of innovation, the company has established itself as a pioneer in precision metalworking technologies.

Amada’s comprehensive product portfolio encompasses a wide range of cutting-edge solutions, including:

The company’s commitment to research and development has resulted in numerous technological breakthroughs, such as their proprietary AMNC 3i control system, which enhances machine performance and user experience through intuitive interfaces and IoT connectivity.

As a publicly traded entity, Amada offers a holistic approach to sheet metal fabrication, providing comprehensive services that span the entire manufacturing lifecycle:

This end-to-end service model, coupled with their high-performance machinery and effective management systems, has solidified Amada’s position as a trusted partner for metalworking businesses worldwide, from small job shops to large-scale industrial manufacturers.

AccurPress, established in Canada in 1973, has emerged as a premier manufacturer of high-precision CNC machine tools in North America. Their core competency lies in the design and production of advanced CNC press brakes and shearing machines, catering to the evolving needs of the metal fabrication industry. With a robust manufacturing footprint comprising six state-of-the-art factories and a cutting-edge research and development center strategically located across Canada, the United States, and China, AccurPress has solidified its position as an industry leader in sheet metal forming technology.

In a strategic move to expand its global presence and tap into the burgeoning Asian market, AccurPress founded a wholly-owned subsidiary in China in 2003. This facility serves as a comprehensive hub for research and development, manufacturing, and after-sales support, specifically tailored to meet the unique demands of the Asia Pacific region. Leveraging its advanced engineering capabilities and commitment to quality, AccurPress has successfully delivered over 6,000 high-performance machine tools to a diverse customer base across the Asia Pacific market since the establishment of this subsidiary.

These CNC machines, known for their precision, reliability, and innovative features, have played a crucial role in enhancing the manufacturing capabilities of various industries in the region, including automotive, aerospace, electronics, and general fabrication. AccurPress’s success in the Asia Pacific market underscores its ability to adapt its technology to local manufacturing requirements while maintaining the high standards of quality and performance that have been the hallmark of its North American operations.

Bystronic, founded in Switzerland in 1964, has established itself as a global leader in advanced sheet metal processing solutions. The company specializes in automating and optimizing the entire material and data flow for cutting and bending processes, leveraging state-of-the-art technologies to enhance manufacturing efficiency.

Their comprehensive product portfolio encompasses high-precision laser cutting systems, CNC-controlled press brakes, and sophisticated automation and software solutions. This integrated approach allows Bystronic to offer end-to-end solutions for sheet metal fabrication, from raw material handling to finished part production. Their laser cutting systems utilize fiber laser technology, enabling high-speed, high-quality cutting of various materials and thicknesses. The press brakes feature advanced bending technology with real-time angle measurement and correction systems, ensuring consistent accuracy in complex forming operations.

Bystronic’s commitment to innovation extends to their Industry 4.0-ready software suite, which facilitates seamless integration of machines, processes, and data management. This digital ecosystem enables real-time production monitoring, predictive maintenance, and adaptive manufacturing strategies.

With sales and technical service subsidiaries strategically located in more than 30 countries worldwide, Bystronic provides localized support and expertise to meet diverse market needs. This global presence allows them to offer tailored solutions and rapid response times, ensuring optimal performance and productivity for their customers across various industries and regions.

Located on an expansive 80-acre campus near Cincinnati, Ohio, they operate a state-of-the-art 500,000-square-foot manufacturing facility and advanced technical center. This strategic location in the heart of the Midwest provides excellent access to key industrial markets and a skilled workforce.

Their comprehensive product portfolio encompasses cutting-edge metal fabrication technologies, including high-power fiber laser cutting systems, robotic automation cells, precision CNC press brakes, heavy-duty shears, high-tonnage powder metal compaction presses, and industrial-scale additive manufacturing machines. Each product is meticulously engineered and robustly constructed to meet the demanding requirements of the North American market, emphasizing durability, precision, and long-term reliability. The equipment is designed to withstand continuous operation in harsh industrial environments while maintaining tight tolerances and high productivity levels essential for competitive manufacturing operations.

As a global leader in metal sheet processing machinery, Durma stands at the forefront of the industry in Turkey, boasting a workforce of 1,500 highly skilled professionals. Their cutting-edge production facility encompasses an impressive 150,000 square meters, equipped with state-of-the-art technology and advanced manufacturing processes.

Durma’s global reach is exemplified by its extensive distribution network, which includes 80 strategic distributors and partners across 120 countries. This robust international presence has enabled the company to establish a significant market share in industrialized nations, with 80% of their machinery exports destined for advanced economies such as the United States, European Union member states, and Australia. These markets demand high-precision, technologically advanced sheet metal processing equipment, reflecting Durma’s commitment to innovation and quality.

The remaining 20% of Durma’s exports cater to emerging markets and companies in developing countries, often in collaboration with foreign investors. This diversified market approach allows Durma to adapt its product offerings to varying technological needs and economic conditions, while also fostering industrial growth in developing regions. By engaging with foreign investors, Durma facilitates technology transfer and helps elevate manufacturing capabilities in these markets, further solidifying its position as a global industry leader.

As a market leader in CNC bending and forming technology, LVD offers a comprehensive range of press brakes engineered to optimize sheet metal fabrication processes. Their portfolio spans from cost-effective manual and CNC-controlled models to advanced multi-axis machines featuring LVD’s proprietary adaptive forming system and intuitive touchscreen interfaces. The company also provides custom-designed solutions to meet specific manufacturing requirements.

LVD’s press brakes are meticulously engineered to streamline programming processes, significantly reduce setup times, and eliminate the need for trial bending. This is achieved through advanced features such as real-time angle measurement, automatic tool recognition, and intelligent bend sequencing algorithms. The result is consistently accurate forming, even with complex parts or challenging materials, leading to improved productivity and reduced material waste.

Key innovations in LVD’s press brake technology include:

These features collectively ensure that LVD’s press brakes deliver precise, repeatable results across a wide range of bending applications, from simple brackets to complex, multi-bend components in various industries such as aerospace, automotive, and HVAC.

Prima Power is a division of the Prima Industrie Group, a global leader in high-technology laser systems, sheet metal processing machinery, and industrial electronics. The group is publicly traded on the Milan Stock Exchange (BIT: PRI), reflecting its significant market presence and financial transparency.

Established in 1977, the Prima Industrie Group marked a significant milestone in 2017 by celebrating 40 years of innovation and excellence in the sheet metal working industry. Over these four decades, the company has consistently pioneered advanced manufacturing solutions, integrating cutting-edge technologies such as laser cutting, punching, bending, and automation systems. This long-standing expertise has positioned Prima Power at the forefront of Industry 4.0 initiatives, driving the digital transformation of sheet metal fabrication processes worldwide.

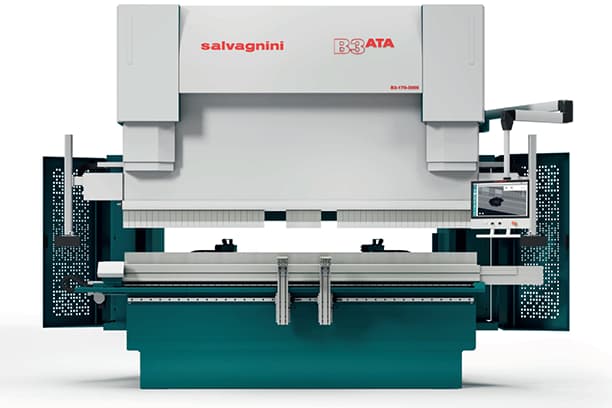

Flexible automation and process efficiency form the cornerstone of Salvagnini’s innovative product portfolio. Their cutting-edge solutions leverage advanced robotics and Industry 4.0 principles to revolutionize metal fabrication workflows.

These state-of-the-art systems offer intelligent, autonomous, and self-optimizing capabilities, featuring intuitive programming interfaces and user-friendly operation. The integration of machine learning algorithms enables adaptive processing, ensuring optimal performance across diverse manufacturing scenarios.

Salvagnini’s interconnected machines form a cohesive ecosystem, utilizing real-time data exchange and IoT connectivity to synchronize operations seamlessly. This smart factory approach facilitates dynamic production scheduling, predictive maintenance, and automated material handling, resulting in a highly streamlined and agile manufacturing process. The system’s ability to efficiently produce a wide variety of components in sequence, with minimal setup time, significantly enhances overall productivity and reduces lead times in modern sheet metal fabrication environments.

TruBend machines epitomize the convergence of extensive press brake expertise and cutting-edge innovations, enabling precision fabrication of components with unparalleled complexity and cost-efficiency. These advanced bending systems incorporate state-of-the-art features such as adaptive crowning, multi-axis backgauges, and real-time angle measurement to ensure consistent accuracy across diverse material types and thicknesses.

Renowned for their exceptional versatility, TruBend machines excel in handling a wide spectrum of bending applications, from intricate small parts to large, heavy-duty components. The machines’ high-precision servo-electric drives and robust frame design contribute to superior finished part quality, maintaining tight tolerances and eliminating springback issues common in traditional press brakes.

Furthermore, TruBend systems offer an attractive cost-benefit ratio through their energy-efficient operation, reduced setup times, and minimized material waste. Advanced software integration, including offline programming capabilities and automated tool selection, significantly enhances productivity and reduces operator dependency, making these machines a strategic investment for modern sheet metal fabrication facilities aiming to optimize their bending processes and maintain a competitive edge in the industry.

Ursviken specializes in advanced machinery for heavy plate metal fabrication, offering solutions that combine power, precision, and productivity. Their equipment portfolio encompasses a wide range of capabilities, from robust systems for thick plate processing to high-speed, flexible lines for lighter gauge materials. Each machine is engineered to deliver optimal performance in terms of efficiency, accuracy, and output quality, catering to the diverse and exacting requirements of modern metal fabrication industries.

The company’s heavy plate processing solutions feature high-tonnage press brakes, large-format shears, and specialized forming equipment capable of handling materials up to 400mm thick. These machines incorporate advanced CNC systems, real-time adaptive bending technologies, and automated material handling to ensure consistent accuracy and reduced cycle times in demanding applications such as shipbuilding, heavy construction, and large-scale industrial manufacturing.

For lighter gauge materials, Ursviken offers highly flexible production systems that combine multiple processes – such as punching, forming, and laser cutting – into integrated manufacturing cells. These solutions leverage state-of-the-art servo-electric drives, high-speed tool changing systems, and intelligent process optimization software to maximize throughput and material utilization while maintaining tight tolerances and superior surface finish.

Across their entire product range, Ursviken emphasizes modularity and scalability, allowing customers to configure systems that precisely match their production needs and easily adapt to changing market demands. This customer-centric approach, coupled with ongoing R&D investments in areas such as Industry 4.0 connectivity and predictive maintenance, ensures that Ursviken machines remain at the forefront of metal fabrication technology, delivering long-term value and competitive advantage to their users.

When choosing a press brake manufacturer, consider the following critical factors to ensure you acquire a high-quality, reliable machine that aligns with your specific production requirements:

Experience and Reputation

Prioritize established manufacturers with extensive experience in press brake design and fabrication. Longevity in the industry often correlates with consistent production of dependable machines.

Conduct thorough due diligence by analyzing customer reviews, case studies, and testimonials. A consistent pattern of positive feedback, particularly regarding machine performance and longevity, is crucial.

Machine Quality and Capabilities

Assess the manufacturer’s press brakes in terms of structural integrity, component quality, bending accuracy, and long-term reliability. Evaluate key aspects such as frame rigidity, hydraulic system efficiency, and precision of the backgauge system.

Ensure the manufacturer offers press brakes with the appropriate tonnage capacity, bed length, and specialized features tailored to your specific bending applications and material requirements. Consider factors like maximum bending force, working length, and throat depth.

Technology and Innovation

Seek manufacturers that integrate cutting-edge press brake technologies to enhance performance, accuracy, efficiency, and ease of use. Key features to look for include:

Evaluate the manufacturer’s commitment to R&D and their track record of continuous improvement in press brake design and functionality.

Service and Support

Select a manufacturer offering responsive, expert technical service to minimize downtime and quickly resolve any issues. Consider their global service network and availability of remote diagnostics.

Verify the availability and accessibility of spare and replacement parts, including lead times and inventory management systems.

Assess the quality and scope of operator training programs, technical documentation, and ongoing support resources provided by the manufacturer to optimize machine utilization and maintenance.

Price and Value

Compare pricing among leading manufacturers, but prioritize overall value rather than upfront cost savings. Consider the total cost of ownership, including energy efficiency, maintenance requirements, and potential productivity gains.

Evaluate the long-term value proposition in terms of:

The global market for CNC press brakes is diverse, with manufacturers from various countries competing for market share. While many are intrigued by rankings of top-tier press brake manufacturers, it’s crucial to understand that the most expensive machines don’t always equate to the best quality or value for your specific needs. The high cost of some press brakes often reflects factors such as labor costs, raw material prices, and component sourcing, rather than solely indicating superior performance.

For those seeking cost-effective solutions without compromising on quality, Chinese press brake manufacturers merit serious consideration. China’s dominance in steel production, coupled with its extensive machine tool consumption and manufacturing capabilities, allows these manufacturers to offer competitive pricing while maintaining high standards of quality. Many renowned press brake brands either operate their own facilities in China or engage in OEM partnerships with Chinese manufacturers, leveraging the country’s manufacturing expertise and cost advantages.

This global manufacturing ecosystem means that press brakes sourced from Germany, Italy, or China often share similar quality standards and components. The primary differentiator frequently lies in branding and pricing strategies rather than fundamental differences in machine capabilities or build quality.

When selecting a press brake, it’s essential to focus on factors that directly impact your production needs:

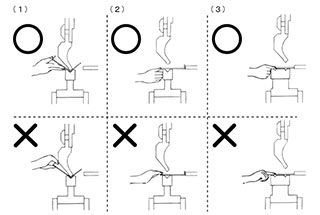

Additionally, consider the specific demands of your sheet metal fabrication processes when selecting press brake tooling. The choice of punches and dies significantly influences the range of parts you can produce, the achievable tolerances, and overall productivity. Factors such as material types, thickness ranges, and desired bend angles should guide your tooling decisions.

By carefully evaluating these aspects and aligning them with your production goals and budget constraints, you can make an informed decision that optimizes your investment in press brake technology. Remember, the best press brake for your operation is one that balances performance, reliability, and cost-effectiveness to meet your unique fabrication requirements.

When choosing a press brake machine, there are several factors to consider, and this buying guide is meant to provide insight into making an informed decision.

Additionally, the press brake dies guide can help you choose the right punches and dies for your sheet metal fabrication needs.