Have you ever wondered how the machines that shape our world are made? This blog takes you on a journey through the top punch press machine manufacturers. You’ll learn about industry leaders like Aida, Chin Fong, and Schuler, and discover what sets them apart. Get ready to explore the technology powering everything from cars to electronics!

Punch press machines are critical components in various manufacturing processes, utilized for their ability to punch holes and create shapes in metal sheets with high precision and efficiency. A wide range of manufacturers around the globe specialize in producing these machines, each contributing unique technologies and innovations to the market.

Aida was established in 1917 by Mr. Yokei Aida in Tokyo, Japan. The company has since grown to become a leading global supplier specializing in the manufacture of servo and mechanical stamping presses. These presses boast a capacity ranging from 30 to 4,000 tons and can operate at speeds from 1 to 1,500 strokes per minute.

Aida offers a diverse range of equipment to meet various industrial needs. Their product lineup includes:

The company has established a robust sales and service network, spanning nearly 40 cities across 20 countries. To date, Aida has installed over 80,000 press machines in more than 60 countries and regions worldwide, underscoring its extensive global reach and influence.

Aida serves a broad spectrum of industries, including:

Chin Fong Group was established in Changhua, Taiwan, in 1948 by Mr. Ji Jinbiao. Over the decades, through relentless dedication and innovation, it has grown to become the largest forging machinery manufacturer in Taiwan and the fourth largest globally.

Chin Fong’s products have a significant international presence, being available in numerous countries, including the UK, US, Japan, Australia, South America, and Southeast Asia. Notably, it is one of the few Taiwanese machinery manufacturers with a strong foothold in Japan, supplying major Japanese automobile companies such as Toyota, Mazda, and Isuzu.

The company is renowned for the quality, accuracy, and durability of its products. In recognition of its high standards, Chin Fong received the ISO9001 international quality certification from Yarsley in the UK in 1994.

Chin Fong offers a diverse range of mechanical presses, catering to various industrial needs. Their product line includes:

These machines boast a capacity of up to 2,400 tons, making them suitable for a wide range of forging applications.

Ajax Manufacturing, established in 1875 and headquartered in the United States, has a long-standing history of producing high-quality forging machinery. Over the past 145 years, the company has built a reputation for excellence in the industry.

In 1996, Ajax Manufacturing acquired Chambersburg Engineering Company (CECO), leading to the formation of Ajax CECO (Park Ohio). This acquisition allowed the company to expand its product offerings and capabilities significantly.

In 2018, Erie Press Systems joined Ajax CECO, resulting in the company being renamed Ajax/CECO/Erie Press. This merger further strengthened the company’s position in the market, combining the expertise and technologies of all three entities. The headquarters of Ajax/CECO/Erie Press is located in Erie, Pennsylvania.

Ajax/CECO/Erie Press provides a comprehensive range of industrial machinery and equipment, catering to various sectors within the manufacturing industry. Their product offerings include:

Hwail Press, established in 1961, holds the distinction of being the first stamping machinery manufacturer in Korea. Over the decades, the company has developed a reputation for producing high-quality and reliable machinery, catering to a diverse range of industrial needs.

Hwail Press offers an extensive array of products designed to meet various stamping and pressing requirements. Their portfolio includes:

Jinan No.2 Machine Tool Group Co., Ltd., commonly known as JIER, was established in 1937. Over the decades, it has grown into a prominent state-owned enterprise, covering an expansive area of 1.01 million square meters and employing more than 5,800 individuals.

JIER stands as the largest forging equipment and manufacturing enterprise in China. It boasts the most comprehensive range of product categories and possesses the largest comprehensive manufacturing capability in the country. The company is renowned for its robust strength in producing heavy metal cutting machine tools and is recognized as one of the leading mechanical press manufacturers globally.

In 2000, JIER achieved the ISO9001 quality system certification from Det Norske Veritas (DNV). This certification was updated in 2003 to the 2000 version of the ISO9001 quality system, underscoring the company’s commitment to maintaining high standards in quality management.

JIER’s diverse product portfolio includes:

Koatsu, established in 1994, is a prominent metal forming machinery company. The company specializes in the production of both small and large presses, as well as a variety of sheet metal processing machines. Over the years, Koatsu has built a reputation for delivering high-quality, reliable machinery that meets the diverse needs of the metal forming industry.

Koatsu is committed to innovation and continuous improvement. The company invests heavily in research and development to incorporate the latest technologies into their machinery. This ensures that their products not only meet but exceed industry standards. Quality control is a critical aspect of Koatsu’s manufacturing process, with rigorous testing and inspection procedures in place to ensure every machine delivers optimal performance.

Koatsu places a strong emphasis on customer satisfaction. They offer comprehensive support services, including installation, maintenance, and training, to help clients maximize the efficiency and longevity of their machinery. Their global network of service centers ensures that customers receive timely and effective support, no matter where they are located.

Schuler was established in Germany in 1839 and has since become a pioneer in the field of metal and composite forming equipment. Over the years, Schuler has built a reputation for innovation and excellence, significantly contributing to advancements in metal forming technology.

Schuler offers a comprehensive range of solutions tailored to the metal forming industry. These include:

With a workforce of approximately 5,500 employees, Schuler operates production bases and provides technical services in over 40 countries worldwide. This extensive global presence allows Schuler to offer localized support and services, ensuring that customers receive timely and efficient assistance regardless of their location.

As a leader in metal forming technology, Schuler’s line of CNC (Computer Numerical Control) products is particularly well-known in the industry. These CNC products are renowned for their precision, reliability, and advanced features, making them a preferred choice for manufacturers seeking high-performance metal forming solutions.

Established in 1962, Seyi Machinery has grown into a prominent global manufacturer specializing in punch equipment. With a product range spanning from 25 to 4000 tons, Seyi has built a reputation for delivering high-quality and reliable machinery to meet diverse industrial needs.

Seyi’s manufacturing facilities are strategically located in Taiwan and mainland China, enabling efficient production and distribution. The company also boasts an extensive sales and service network, ensuring comprehensive support and accessibility for customers worldwide.

Seyi’s product portfolio is not limited to punch equipment alone. The company also provides a wide array of peripheral equipment designed to enhance production efficiency and effectiveness. These include:

Seyi is dedicated to maximizing customer revenue through innovative production solutions. By offering a comprehensive range of equipment and services, Seyi ensures that customers can achieve optimal performance and productivity in their operations.

Founded in 1871, SMS Group is a renowned multinational corporation specializing in the manufacture of equipment and machines for the processing of steel, non-ferrous metals, and plastics on a global scale. With a rich history spanning over a century, SMS Group has established itself as a leader in the industry, providing innovative solutions and high-quality machinery.

SMS Group offers an extensive array of products designed to meet the diverse needs of its clients. Their product portfolio includes:

SMS Group’s comprehensive services ensure that clients receive end-to-end support for their projects. These services include:

Established in 1949, Stamtec has been a prominent player in the American market for nearly four decades. Renowned for its extensive experience and robust manufacturing capabilities, Stamtec has solidified its position as one of the largest press manufacturers globally.

Stamtec’s expansive manufacturing footprint, spanning 6.5 million square feet, underscores its capacity to produce a significant volume of presses annually. The company’s production of over 3,000 presses each year highlights its efficiency and ability to meet global demand.

With factories strategically located in the United States, Taiwan, China, and Mexico, Stamtec ensures a broad and efficient distribution network. This global presence not only facilitates timely delivery but also supports local economies by providing employment opportunities.

Stamtec’s products have been operational in more than 40 countries for over 70 years, demonstrating the reliability and durability of its machinery. This extensive market presence is a testament to the company’s commitment to quality and customer satisfaction.

Sutherland Presses was established in 1946 and is headquartered in the United States. The company specializes in providing comprehensive solutions for stamping, forging, and metal forming. With over 70 years of experience, Sutherland has established itself as a leader in the mechanical press industry. The company offers a complete range of mechanical presses with capacities of up to 2,500 tons. These presses come in various configurations, including gap frames, straight sides, and single, double, and four-point configurations, to cater to a wide range of industrial applications.

Sutherland’s mechanical presses are designed to meet and exceed the highest industry standards. All of their presses are constructed to surpass JIS First Class standards, which are recognized as the highest standards in the world for industrial machinery. This commitment to quality ensures that Sutherland’s presses deliver exceptional performance, reliability, and longevity.

The versatility of Sutherland’s mechanical presses makes them suitable for a variety of applications, including:

Sutherland Presses continues to innovate and expand its product offerings to meet the evolving needs of the metal forming industry. Their expertise in mechanical press technology, combined with a commitment to quality and customer satisfaction, makes Sutherland a trusted partner for businesses seeking reliable and high-performance metal forming solutions.

Established: 1953

Headquarters: China

Workforce: Over 2,500 employees, including 270 engineering and technical personnel

World specializes in the research, development, and manufacture of metal forming and forging equipment. Their product range includes:

World has established sales outlets and service institutions in major and medium-sized cities across China. Additionally, their products are exported to various international markets, including:

Xuduan was established in 1951 in China and has grown to become a significant player in the mechanical press industry. The company began mass-producing open mechanical presses in 1964, marking a pivotal moment in its history. Over the years, Xuduan has adhered to a strategy of science and technology leadership, which has been instrumental in its sustained growth and innovation.

With nearly 60 years of production experience, Xuduan boasts robust technical equipment and production organizational capacity. The company employs over 280 professional and technical personnel, ensuring a high level of expertise and innovation in its operations. Xuduan’s facilities include 695 sets of various machinery and equipment, among which 86 sets are precision, large, and thin equipment. This extensive array of machinery underscores the company’s capability to handle complex and large-scale production requirements.

Xuduan is particularly noted for having the most comprehensive heat treatment equipment in the Huaihai economic zone. This capability is crucial for ensuring the durability and performance of the mechanical presses and other products manufactured by the company.

Xuduan’s marketing and after-sales service infrastructure is extensive and well-organized. The company operates 21 marketing branches and 40 offices across China. Its marketing and after-sales service team comprises over 100 people, supported by more than 60 specialized vehicles. This robust network ensures that Xuduan can provide timely and efficient service to its customers.

The company has established a broad distribution network by signing special distribution agreements with over 60 dealers nationwide. This network ensures that Xuduan’s products and services are accessible throughout the country, reinforcing its market presence and customer support capabilities.

Yangzhou Forging Machine Tool Co., Ltd. (Yadon) was established in 1958 and has since become a prominent player in the forming equipment industry. As a Chinese subsidiary of Schuler, Germany, Yadon leverages advanced German engineering and technology to enhance its product offerings and maintain a competitive edge in the global market.

Yadon specializes in the research and development, manufacturing, and sales of a wide range of forming equipment. Their product portfolio includes:

Yadon boasts a workforce of over 940 employees, underscoring its capacity for large-scale production and innovation. The company operates more than 80 marketing outlets both domestically and internationally, ensuring a robust presence in key markets.

Yadon prides itself on its comprehensive customer service network, offering integrated pre-sales, in-sales, and after-sales services around the clock. This global marketing and service network ensures that customers receive timely and effective support, enhancing overall satisfaction and loyalty.

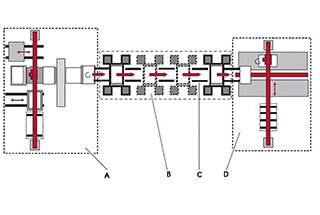

Founded in 1966, Yangli has grown to become one of the largest metal forming equipment manufacturers in China. With a workforce exceeding 5,000 employees, the company is dedicated to the research and development of various metal sheet processing equipment and intelligent production lines. Their product range includes equipment for stamping, sheet metal processing, and forging.

Yangli offers a comprehensive array of products designed to meet the diverse needs of the metal forming industry. Their product lineup includes:

Yangli’s dedication to innovation is evident in their continuous efforts to develop advanced metal sheet processing equipment and intelligent production lines. By integrating cutting-edge technology and focusing on research and development, Yangli ensures that their products meet the highest standards of quality and performance.

As a major player in the metal forming equipment industry, Yangli’s products are widely used across various sectors, including automotive, aerospace, and general manufacturing. Their comprehensive product range and commitment to innovation make them a trusted partner for companies seeking reliable and efficient metal forming solutions.

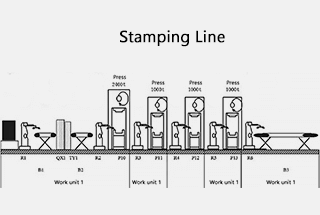

Punch press machines come in various types, each designed to meet specific manufacturing needs. These machines can be categorized based on driving force, slide movement and action, frame structure, and advanced functionalities.

Mechanical punch presses are powered by an electric motor that drives a flywheel. The flywheel, in turn, drives a gear, crankshaft, and connecting rod to convert circular motion into linear motion. These presses are known for their high processing accuracy and ease of operation.

Hydraulic punch presses use a hydraulic pump to drive hydraulic oil into the cylinder and piston, converting hydraulic energy into mechanical energy. They offer variable force and speed, precision, and safety features like built-in emergency brakes.

Pneumatic punch presses utilize high-pressure gas generated by a compressor to control the operation and return of the cylinder. They are simple to operate and controlled by an electromagnetic valve.

H-Type presses are characterized by their H-shaped frame, providing better rigidity and stability. They are suitable for medium-scale stamping operations and can be customized with programmable controls, automation systems, and specialized tooling.

This type of press features four columns supporting the frame, offering excellent stability and suitability for large, high-precision stamping operations.

C-Frame presses have a frame shaped like the letter “C” from the side view, with the front completely open. They are suitable for applications needing smaller bed sizes and lower tonnages, such as assembly tasks.

CNC turret punch presses use a turret to hold multiple tools, allowing for quick changes between punches or dies. They are highly versatile, energy-efficient, and precise.

These presses combine the versatility of a turret with the precise control of a servo motor. They are suitable for frequent changes in punches or dies.

CNC punch presses incorporate computer numerical control (CNC) for high precision, repeatability, and automation.

When considering the purchase of a punch press machine, understanding the pricing and order process is crucial for making an informed decision. This chapter provides detailed insights into the different types of punch press machines, their pricing, order process, payment options, delivery, and after-sales support.

The cost of punch press machines varies widely based on their specifications, capacity, and features.

Most manufacturers and suppliers require a minimum order quantity, typically set at 1 piece or 1 set. This makes it accessible for businesses of various sizes to procure the necessary equipment. Many punch press machines can be customized to meet specific customer requirements, such as varying tonnages, features, and automation levels. For example, the AMADA EMK 3610NT can be tailored with additional tool stations and automation options.

Manufacturers generally accept multiple payment methods, including credit cards (American Express, Discover, MasterCard, Visa), wire transfers, company checks, and purchase orders. For larger purchases, manufacturers may offer financing or leasing options. This can be particularly beneficial for businesses looking to spread the cost over time rather than making a single large payment. Leasing options can provide flexibility and allow companies to upgrade their equipment as needed without significant upfront costs.

Manufacturers often provide shipping services and work with various shipping companies to offer competitive rates. Customers can also arrange their own shipping if they prefer. Ensuring timely and economical delivery is a priority for manufacturers. They coordinate with logistics providers to meet delivery deadlines and minimize disruptions to the customer’s operations.

Reliable after-sales service is essential for maintaining the performance and longevity of punch press machines. Manufacturers typically offer prompt technical support, including troubleshooting and repair services. Comprehensive customer assistance, including training and maintenance services, ensures that operators are well-equipped to use the machines efficiently and safely.

By considering these factors, buyers can navigate the pricing and order process effectively, ensuring they select the right punch press machine to meet their specific needs while managing costs and logistical considerations.

Below are answers to some frequently asked questions:

Some of the top punch press machine manufacturers include Amada, Trumpf Inc., Aida, SEYI, LVD, Chin Fong, JIER, TAILIFT, Murata Machinery USA, Inc. (Muratec USA), Macrodyne Technologies, Inc., EAM, Inc., and Stanley Spring and Stamping.

Amada is known for its precision and cutting-edge technology in CNC-controlled punch presses, making them a top choice for sheet metal fabrication. Trumpf Inc., a German company, produces high-performance punch presses with advanced features like self-measuring angle adjustments and energy-efficient systems, serving versatile metalworking needs. Aida offers high-quality and reliable machines suitable for various metalworking applications, including the automotive and aerospace industries. SEYI, with a global presence, provides a wide range of punch presses from 25 to 4000 tons, serving industries such as automotive and aerospace. LVD is recognized for its precision and efficiency in turret punch press and single head punching machines, particularly in the aerospace and industrial sectors.

Chin Fong, based in Taiwan, is one of the largest forging machinery manufacturers globally, known for their quality and precision in punch press machines. JIER, China’s premier forging equipment manufacturer, offers a comprehensive range of products adhering to ISO9001 standards. TAILIFT, from Taiwan, is notable for its CNC turret punch presses used in the aerospace industry. Murata Machinery USA, Inc. specializes in precision turret punch press machinery, serving industries such as consumer goods, job shops, and healthcare. Macrodyne Technologies designs and installs metal forming presses for punching applications with advanced features. EAM, Inc. provides a range of punching presses for various industries, including aerospace and automotive. Stanley Spring and Stamping offers state-of-the-art punch press and stamping services, suitable for cutting accurate holes in various materials.

These manufacturers are recognized for their advanced technology, precision, and reliability, catering to a wide range of metalworking applications and industries.

Punch press machines are available in several types, distinguished by their driving forces, slide movements, specific functionalities, and frame designs.

Based on driving forces, there are mechanical punch presses, which use an electric motor and flywheel for consistent force and durability; hydraulic punch presses, which offer variable force and precision through hydraulic power; and pneumatic punch presses, which operate using high-pressure gas for simple and convenient control.

Regarding slide movement, single-action punch presses apply a single force to shape the material, double-action punch presses use two distinct actions for larger workpieces, and triple-action punch presses provide even more complex shaping with three actions.

Specific types of punch presses include flywheel drive punch presses, which are cost-effective and easy to maintain; CNC punch presses, which use computer numerical control for high precision and automation; servo drive turret punch presses, known for high accuracy and energy efficiency; and turret punch presses, which utilize a turret for quick and economical creation of various holes in sheet metal.

Frame types include C-frame (gap-frame) presses, which offer easy access to the work area and are suitable for smaller operations; H-type presses, providing better rigidity for medium-scale operations; and four-column presses, which offer stability for large, high-precision stamping tasks.

Each type of punch press machine caters to different manufacturing needs and applications, making them versatile tools in various industrial contexts.

Punch press machines are utilized across a wide range of industries due to their precision, efficiency, and versatility. Some of the key industries that rely heavily on these machines include:

The automotive industry, where punch press machines are essential for producing car parts such as brackets, panels, and other structural components. The high precision and consistency provided by these machines are crucial for meeting the exact specifications required in vehicle manufacturing.

In the construction industry, punch press machines are used to produce vital structural components, tools, and metals, aiding in the fabrication of parts essential for building and infrastructure projects.

The aerospace industry benefits from the precision and versatility of punch press machines, particularly in producing lightweight yet durable components for aircraft. These machines can handle complex designs and materials, adhering to stringent safety and quality standards.

In the electronics industry, punch press machines are used to craft intricate casings, panels, and other components for electronic devices, ensuring the parts are both aesthetically pleasing and functionally sound.

Home appliance production also relies on punch press machines to create metal parts for household appliances such as washing machines, refrigerators, and stoves, ensuring their efficiency and longevity.

The packaging industry uses punching machines to create precise holes and shapes in materials like cardboard, essential for producing functional and attractive packaging for various products.

In the realm of HVAC and other metal fabrication, punch press machines are indispensable for producing intricate components, handling various sheet metal thicknesses and efficiently processing different materials.

Additionally, punch press machines have historical significance in currency and coin production, allowing for high-volume stamping with precise designs.

Finally, furniture manufacturing and other sectors that require precision metal components also benefit from the capabilities of punch press machines, which can handle diverse materials and create complex shapes.

Manufacturers like AjaxCECO Erie Press, STAMTEC, SUTHERLAND PRESSES, TAILIFT, TRUMPF, PRIMA POWER, and Tommy Industrial provide these machines to various industries, each offering unique features and capabilities tailored to specific industrial needs.

To ensure reliability, a punch press machine manufacturer should have several key certifications. ISO 9001 certification is essential, indicating a robust quality management system and a commitment to continuous improvement. Compliance with industry-specific standards such as ANSI, ASME, ASTM, and AWS is crucial for meeting safety and performance criteria. For manufacturers serving the defense industry, adherence to Mil-Spec standards is necessary.

CE certification is important for manufacturers exporting to the European Union, ensuring compliance with EU health, safety, and environmental regulations. FDA approval is required for manufacturers supplying the medical or food production sectors, ensuring strict hygiene and safety standards. RoHS compliance is vital for environmental safety, ensuring the restriction of hazardous substances in products.

Additional certifications, like HubZone certification, can indicate operational advantages in specific business zones. Adherence to JIS First Class standards ensures high-quality mechanical presses, and compliance with other custom and specific certifications may be necessary depending on the industry and application. These certifications collectively demonstrate a manufacturer’s dedication to quality, safety, and customer satisfaction.

Choosing the right punch press machine for your needs involves evaluating several key factors to ensure it aligns with your production requirements. First, consider the material size and thickness you will be working with, as this will dictate the type of machine suitable for your operations. For instance, hydraulic punch presses are better for thicker materials and complex forming, while mechanical presses are often sufficient for thinner materials.

Next, determine the required tonnage and power, ensuring the machine can provide the necessary force for your specific operations, such as bending or drawing. The type of punch press is also crucial; mechanical presses are typically used for smaller parts, hydraulic presses for precise control over heavier materials, and CNC punching machines for high-volume, automated production.

The table size and production method are important considerations, especially if you process flat sheet metal parts. Additionally, assess the complexity of the parts you produce to determine the tool capacity and turret stations required. Speed and efficiency are also key factors; evaluate the machine’s strokes per minute (SPM) to ensure it meets your production demands.

Precision and control are vital for achieving consistent results, so look for machines with advanced digital controls. Maintenance and reliability should not be overlooked; choose a machine that is easy to maintain and reliable over time.

Your budget will play a significant role in the decision-making process. Compare prices and consider whether the additional features of more expensive models are necessary for your operations. Finally, innovative tooling and additional features, such as autoindex stations and quick-change die bases, can enhance productivity and reduce setup times.

By carefully evaluating these factors, you can select a punch press machine that optimizes your operations, reduces costs, and enhances productivity.

Punch press machine manufacturers offer a variety of additional services to support their clients beyond the basic punching operations. These services include:

Custom Design and Fabrication: Manufacturers provide custom design, fabrication, and installation of punch presses tailored to specific industry needs, catering to applications ranging from large body panels to small individual parts in industries like automotive, aerospace, and consumer products.

Maintenance, Repair, and Upgrade Services: They offer comprehensive maintenance, repair, rebuild, and upgrade services for punch presses. This includes field service, in-house repair, press controls, and the addition of components such as squaring arms and support tables for dies.

Training and Installation: Manufacturers provide installation, training, and decommissioning services to ensure clients can effectively use and manage their punch press machines. Some even offer 24-hour emergency services to address immediate issues.

Custom Tooling and Accessories: Companies create customized dies and tooling to meet specific project requirements, which can include auto-index stations, air-blow holders, and specialized dies for punching, tapping, and forming operations.

Material Handling and Automation: Automated material handling solutions, such as sheet loaders/unloaders and manipulators for unmanned loading and unloading operations, are available to enhance efficiency and reduce labor costs.

Quality Assurance and Certifications: Emphasis on quality assurance with certifications like ISO 9001:2015, AS9100D, and compliance with industry standards such as Mil-Spec, ANSI, ASME, ASTM, and AWS ensures that manufactured parts meet or exceed required quality standards.

Additional Fabrication Services: Some manufacturers offer a broader range of fabrication services, including fourslide stamping, precision wire forming, spring fabrication, laser cutting, and other metal processing services, enabling them to handle complex projects requiring multiple fabrication techniques.

Technical Support and Customer Service: Comprehensive technical support and customer service are provided, with some manufacturers emphasizing personalized service to ensure projects are managed with attention to detail and delivered on time.

These additional services enhance the overall value proposition of punch press machine manufacturers, making them comprehensive solution providers for metal fabrication needs.