Have you ever thought about how intricate parts are made with precision? This article explores four fascinating methods: Electrical Discharge Machining (EDM), Electrochemical Machining (ECM), Ultrasonic Machining (USM), and Laser Machining. Each technique has unique features, from using electrical pulses to high-frequency vibrations, providing insights into modern engineering marvels. By the end, you’ll understand how these processes shape the advanced components we rely on daily.

This article mainly introduces several mature special processing methods.

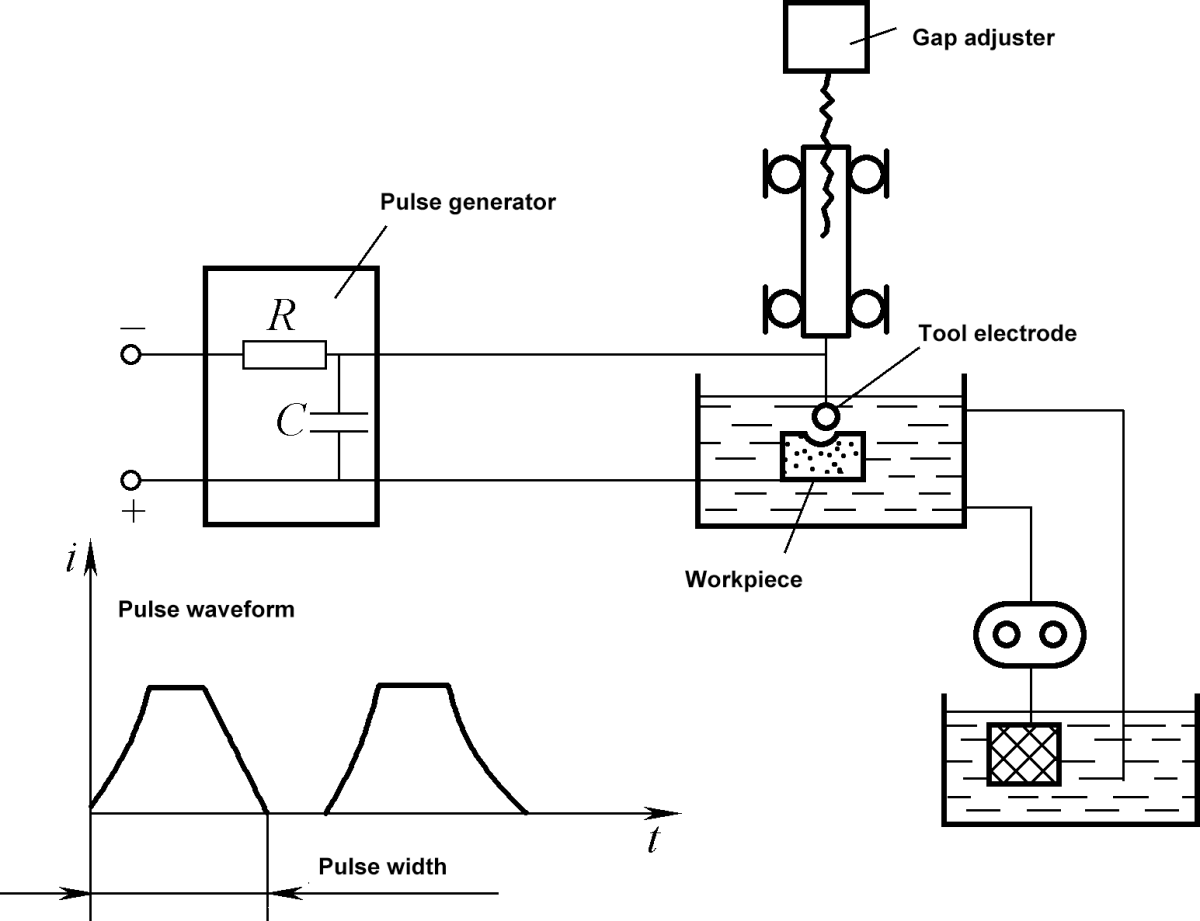

EDM is a method of machining conductive materials by utilizing the phenomenon of electrical corrosion during pulse discharge between positive and negative electrodes in a certain liquid medium. This results in the dimensions, shape, and surface quality of the parts meeting technical requirements. It is also known as discharge machining or electro-erosion machining. The working principle is shown in Figure 8-41.

During EDM, the workpiece and the tool (made of pure copper or graphite), which are charged with pulse voltage, act as positive and negative electrodes respectively. When they are close in the insulating working fluid (kerosene or mineral oil), the inter-electrode voltage will break down at the closest point between the two electrodes, forming a pulse discharge.

The high temperature generated in the discharge channel causes the metal to melt and vaporize, and the melted metal is thrown out under the effect of discharge explosion force and carried away by the insulating working fluid.

Due to the polar effect (i.e., the unequal erosion amounts of the two electrodes), the erosion speed of the workpiece electrode is much greater than that of the tool electrode. Thus, during the electro-erosion process, if the tool electrode is continuously fed into the workpiece, the machining of the workpiece can be accurately completed according to the shape of the tool.

1) It can process any hard, brittle, tough, and high melting point conductive materials, such as hard alloys, hardened steel, and stainless steel.

2) There is no significant mechanical force during processing, which is beneficial for machining small holes, thin walls, and parts with various complex cross-sectional shapes and cavities.

3) Pulse parameters can be adjusted, allowing for rough and fine machining on the same machine.

4) The machining size accuracy can reach 0.01mm, and the surface roughness Ra value is 0.8μm. For micro-precision machining, the size accuracy can reach 0.04~0.002mm, and the surface roughness Ra value is 0.1~0.05μm.

5) EDM has a slow processing speed, and the tool electrode suffers from wear, affecting the processing efficiency and forming accuracy.

EDM is used for machining various cross-sectional shapes of shaped holes, small holes; machining various forging molds, extrusion molds, die-casting molds and other shaped cavities, integral impellers, blades and various curved surface parts; surface strengthening and engraving; and for electrical discharge wire cutting processing.

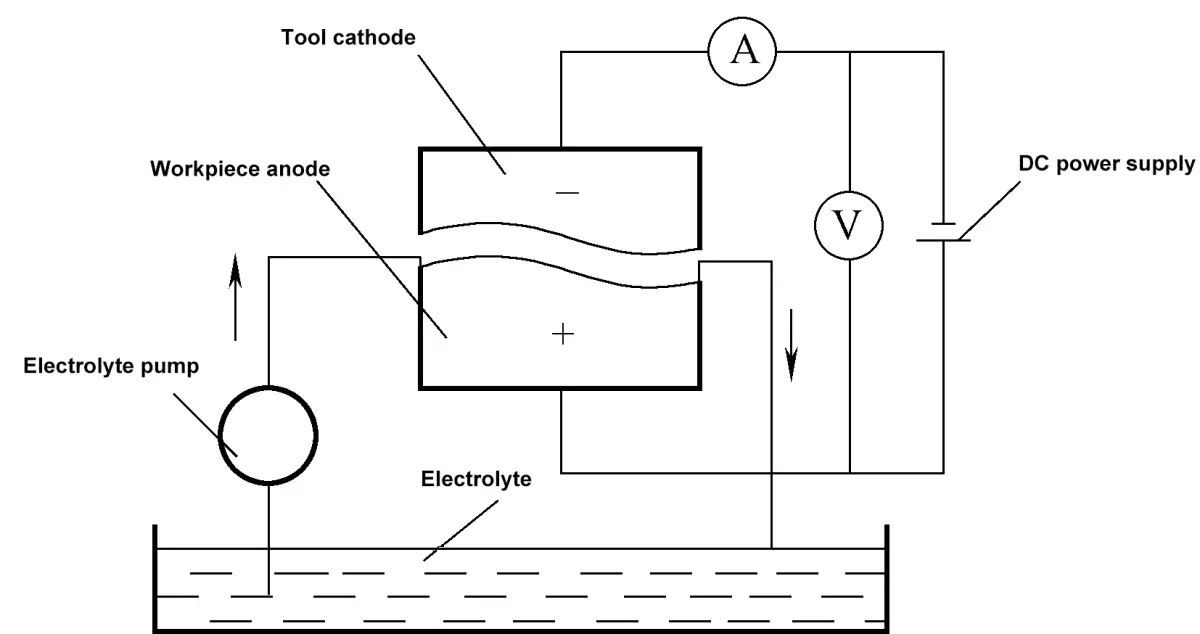

ECM is a method of shaping a workpiece by using the principle of an electrochemical reaction, where the metal dissolves as an anode in the electrolyte. As illustrated in Figure 8-42, during ECM, the workpiece is connected to the positive terminal, and the tool electrode to the negative terminal, with a low voltage, high current passing between them.

A high-speed electrolyte is injected into the narrow gap between the two terminals. As the tool electrode continuously feeds into the workpiece, the material of the workpiece dissolves in the shape of the tool surface due to the anodic dissolution of the metal in the electrolyte. The electrolysis products are then removed by the high-speed electrolyte flow, hence creating a shape on the workpiece that corresponds to the tool surface.

1) It can machine high-hardness, high-strength, and high-toughness metals like hardened steel, hard alloy, and stainless steel, with high production rates.

2) There are no cutting forces or cutting heat, making it suitable for machining easily deformable parts (like thin-walled parts).

3) The average machining accuracy can reach 0.03~0.05mm, and the surface roughness Ra value can reach 1.6~0.2μm, with no residual stress.

4) In theory, the tool cathode does not wear out during the process, allowing for long-term use.

5) The electrolyte corrodes the machine tool, and the electrolysis products are difficult to treat and recycle.

ECM is widely used for deep hole drilling, hole enlargement, spline hole drilling, small-sized and intricately shaped hole drilling, low-precision cavity mold processing, irregular part blanking, deburring, and electrochemical chamfering.

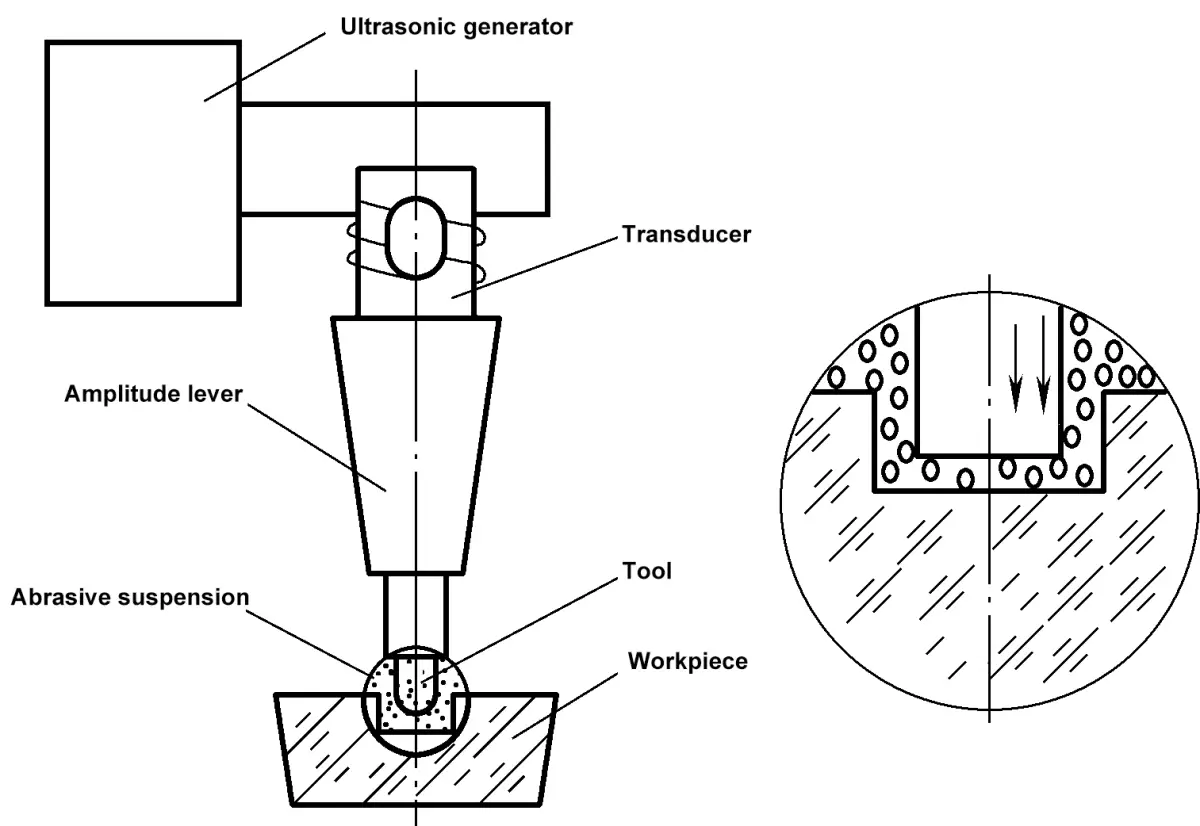

USM is a method of machining a workpiece using high-frequency vibrations on the tool face and abrasive slurry. As shown in Figure 8-43, the ultrasonic generator creates high-frequency electrical oscillations that are transformed into small amplitude ultrasonic mechanical vibrations by the transducer. The amplitude is then amplified to 0.01~0.15mm by the amplitude rod and transferred to the tool to cause it to vibrate.

Meanwhile, the abrasive slurry is continuously injected between the workpiece and the tool. The ultrasonically vibrating tool face continuously hammers the abrasive on the workpiece surface, pulverizing the material in the machining area into fine particles that are removed by the circulating abrasive slurry. The tool gradually enters the workpiece, replicating its shape on the workpiece.

1) It is suitable for machining various non-conductive hard, brittle materials, such as glass, ceramics, gemstones, and diamond.

2) It is easy to machine various complex shapes of holes, cavities, and forming surfaces, and with a hollow-shaped tool, various shapes of blanking can also be achieved.

3) The cutting force and thermal effect are small, making it suitable for machining thin-walled, narrow gap, and other low-rigidity workpieces.

4) Ordinary USM equipment is simple.

5) The accuracy can reach 0.05~0.01mm, and the surface roughness Ra value can reach 0.8~0.1μm, but the production rate is relatively low.

USM is suitable for machining thin-walled, narrow gap, thin sheet parts; it is widely used for hole drilling, blanking, cutting, and engraving of hard, brittle materials, and machining of diamond wire drawing dies; in combination with other machining methods, it can also perform composite machining.

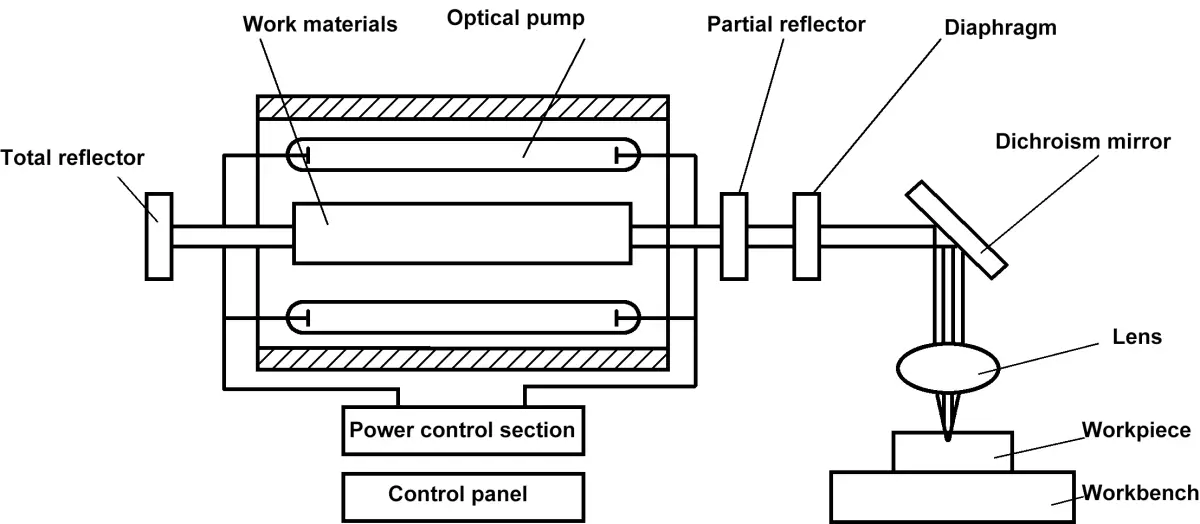

Laser machining is a method of machining where a laser, a coherent light with good monochromaticity, strong directionality, and excellent focusing performance, is used. After focusing, the power density reaches 108~1012W/cm2, and the temperature reaches over 10,000℃.

The laser irradiates the material being machined, causing it to instantaneously melt and even vaporize, and strong shock waves are generated, explosively removing the material. The working principle of laser machining is shown in Figure 8-44.

1) Laser machining has a short action time, small heat-affected zone, is not affected by electromagnetic interference, and can almost process all metal and non-metal materials.

2) The machining speed is extremely high, easy to realize automated production and assembly line operations, and thermal deformation is also very small.

3) The process does not require the use of tools and is a non-contact machining method, with no mechanical processing deformation.

4) It can process through air, inert gases, or optically transparent media.

5) The machining accuracy can reach 0.01mm, and the surface roughness Ra value can reach 0.1μm.

1) Laser machining is mostly used for small hole machining in materials such as diamond wire drawing dies, clock and jewelry bearings, ceramics, glass, hard alloys, and stainless steel. The hole diameter is generally 0.01~1mm, and the smallest hole diameter can reach 0.001mm; the depth-to-diameter ratio of the hole can reach 50~100.

2) Laser machining is used for cutting, and the material thickness can reach several tens of millimeters. It can also cut the filament inside a vacuum tube through glass. It can weld through glass, which is difficult to accomplish with any other mechanical machining. By scanning the surface of the workpiece material with a laser, surface heat treatment of the material can be carried out, such as laser hardening of the surface of low carbon steel.