Have you ever wondered which manufacturers dominate the turret punch press industry? This article introduces the top five global manufacturers of turret punch presses, detailing their histories, innovations, and standout products. By the end, you’ll understand the key players in this field and what sets each apart, helping you make informed decisions for your machinery needs.

The following 5 leading turret punch press manufacturers offer a comprehensive range of high-performance solutions, serving as an excellent reference for selecting the optimal machine supplier to meet your specific sheet metal fabrication needs:

Amada, founded in Japan in 1946, has grown into a global leader in sheet metal processing machinery with a workforce of 5,899 employees worldwide. The company’s extensive global presence is evident through its 83 branches across all continents, with its products distributed in over 100 countries and regions.

In the 1990s, Amada revolutionized the sheet metal industry by developing and manufacturing an intelligent automatic sheet metal processing center. This innovation set a new standard for intelligent processing in the global sheet metal sector, earning Amada Japan’s highest technological invention award. The company’s product portfolio encompasses a wide range of sheet metal processing machinery, including CNC punch presses, press brakes, shearing machines, and laser cutting systems.

Amada’s turret punch presses are renowned for their meticulous attention to detail and user-centric design. The company’s proprietary control systems offer intuitive operation and seamless integration with other Amada machines. These punch presses excel in high-precision applications, maintaining consistent pressure accuracy even in small-batch production scenarios. This makes them particularly suitable for industries requiring tight tolerances, such as aerospace and medical device manufacturing. However, the advanced features and precision come at a premium price point. Additionally, Amada’s punch presses utilize proprietary tooling systems, which, while ensuring optimal performance, may limit flexibility in tooling options.

Ermaksan, established in 1965 and now employing over 700 professionals, has emerged as a preeminent manufacturer, exporter, and supplier of Turkish CNC machine tools. The company has garnered a stellar reputation in the global market for its high-precision hydraulic press brakes, CNC punching machines, and other advanced metalworking equipment. Leveraging decades of industry experience and strong brand recognition, Ermaksan has solidified its position as an industry leader, particularly in its innovative punch press series.

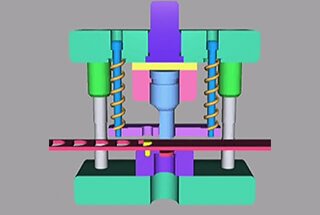

The ETP-s CNC servo turret punch press exemplifies Ermaksan’s commitment to cutting-edge technology and manufacturing excellence. This machine stands out for its unique design, which eliminates the need for a hydraulic servo driver system, traditionally used in many punching machines. Instead, it incorporates a fully electric servo-driven mechanism, offering superior energy efficiency, reduced maintenance requirements, and enhanced precision. The ETP-s integrates globally sourced, top-tier electronic components and robust mechanical systems, resulting in a harmonized, high-performance punching solution. This integration of world-class components ensures optimal reliability, accuracy, and productivity in sheet metal fabrication processes.

Muratec, established in 1935, stands as a leading machinery manufacturer in Japan, with a diverse product portfolio spanning six distinct business divisions. These divisions encompass:

Muratec has established a robust presence in North America, with an extensive distribution network covering the United States, Canada, and Mexico. The company offers a comprehensive range of automated material handling equipment, including:

This strategic expansion enables Muratec to deliver cutting-edge manufacturing and logistics solutions to a broad spectrum of industries across the North American market, reinforcing its position as a global leader in industrial automation and machinery.

Prima Power, established in Italy in 1977, has emerged as a global leader in sheet metal processing machinery and systems. The company’s integrated facilities encompass production workshops, offices, and exhibition halls, focusing primarily on the manufacture, distribution, and servicing of advanced sheet metal processing equipment. Their comprehensive product portfolio includes state-of-the-art two-dimensional laser cutting machines, high-precision punching systems, and versatile bending machines.

Prima Power’s extensive product line spans the entire spectrum of sheet metal fabrication, offering:

This comprehensive range enables Prima Power to address all stages of sheet metal processing, from raw material to finished product, catering to diverse industry needs.

The company’s global manufacturing footprint includes strategically located production facilities in Italy, Finland, the United States, and China. This international presence allows Prima Power to leverage regional expertise, optimize supply chains, and provide responsive support to customers worldwide. Equipment and systems are shipped globally from these manufacturing hubs, ensuring efficient distribution and timely delivery to meet the demands of the international sheet metal fabrication market.

Prima Power’s commitment to innovation, quality, and customer satisfaction has solidified its position as a trusted partner in the sheet metal processing industry, serving a wide range of sectors including automotive, aerospace, HVAC, and general fabrication.

Tailift Group, established in 1973, is headquartered in Taiwan with a workforce of approximately 200 employees. The company’s manufacturing facilities are strategically located in Taiwan and Qingdao, China, leveraging the strengths of both regions in precision engineering and advanced manufacturing.

Tailift’s diverse product portfolio showcases its expertise in metal fabrication and CNC technologies. Their offerings include:

Tailift’s commitment to innovation and quality has enabled them to establish a global presence, with their products being exported to over 50 countries worldwide. This international reach underscores the company’s ability to meet diverse manufacturing needs across various industries and markets.

When selecting a turret punch press manufacturer, several critical factors should be considered to ensure you invest in a machine that meets your production needs and offers long-term value. Here are the key aspects to evaluate:

By carefully evaluating these factors, you can select a turret punch press manufacturer that not only meets your current production requirements but also provides a solid foundation for future growth and technological advancements in your sheet metal fabrication processes.