Have you ever wondered how modern technology is revolutionizing the metal fabrication industry? In this blog post, we’ll explore the game-changing impact of tube laser cutting machines. Discover how these innovative tools are transforming the way manufacturers cut, shape, and process metal tubes, unlocking new possibilities for design and efficiency. Join us as we delve into the world of advanced laser technology and its far-reaching implications for the future of metal fabrication.

Laser technology possesses three key characteristics that make it exceptionally suitable for material processing: excellent monochromaticity, coherence, and collimation. These properties enable precise and efficient tube cutting operations across various industrial applications.

Traditional tube cutting methods, such as hand sawing, machine sawing, roller extrusion, abrasive wheel cutting, and gas welding, often suffer from low cutting efficiency and high labor intensity. In contrast, laser cutting has gained widespread adoption in industrial settings due to its superior processing speed and exceptional cutting quality.

The tube manufacturing industry has experienced significant growth, with tubular components finding extensive use in sectors including aerospace, engineering machinery, transportation, petrochemical, and agricultural equipment. Tubes offer several advantages in production, including lower costs, excellent formability, lightweight structural properties, and material efficiency. Consequently, tube cutting plays a crucial role in various industrial processes.

The diversity in tube shapes, sizes, and applications, coupled with the need for high-quality processing, necessitates careful selection of machining equipment, processing methods, and technological measures. While traditional cutting methods can sometimes achieve the desired results, they often fall short in terms of processing efficiency and overall effectiveness.

Laser tube cutting technology addresses these challenges by offering:

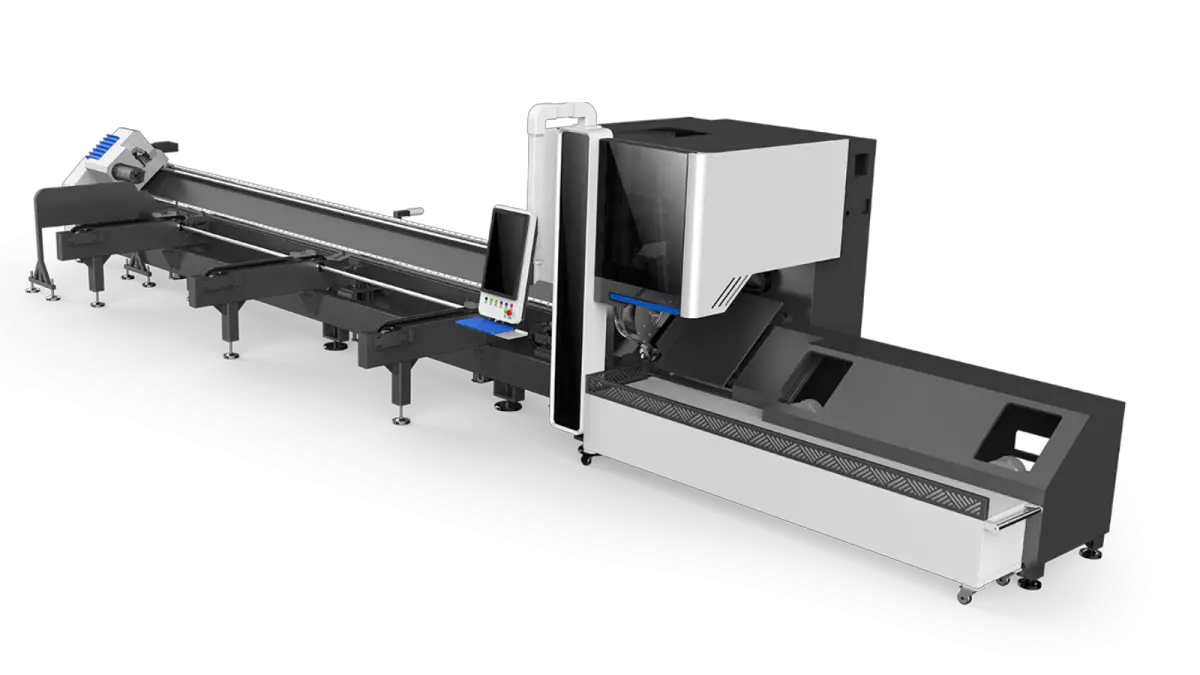

A tube laser cutting machine is a specialized industrial equipment designed primarily for cutting various metal hollow tubular materials, including stainless steel, carbon steel, galvanized steel, and other metallic pipes used in industrial and commercial applications. This advanced cutting technology utilizes a high-powered fiber laser to achieve precise, efficient, and versatile cutting of tubular components.

These machines are extensively employed in diverse sectors such as construction, industrial piping, office furniture manufacturing, sports equipment production, and automotive industries. The ability to process a wide range of tube diameters, wall thicknesses, and profiles makes tube laser cutting machines indispensable for both small-to-medium enterprises and large-scale manufacturing operations.

Key features of tube laser cutting machines include:

The adoption of fiber laser technology in these machines offers several advantages over traditional CO2 lasers, including higher energy efficiency, lower maintenance requirements, and superior beam quality. This has led to the widespread adoption of tube laser cutting machines across various industries.

As laser technology continues to mature and evolve rapidly, its applications have expanded from sheet metal cutting to sophisticated tube and pipe processing. The development and implementation of specialized tube laser cutting machines have revolutionized metal tube fabrication, dramatically improving processing efficiency, quality, and design possibilities in tubular component manufacturing.

A tube laser cutting machine is a sophisticated piece of equipment designed for high-precision processing and cutting of tubular materials. This advanced system typically comprises several key components, each playing a crucial role in the overall performance and efficiency of the machine:

Tube laser cutting machines are advanced metal pipe processing systems that utilize laser technology for high-precision cutting. Here’s an optimized explanation of their working principle:

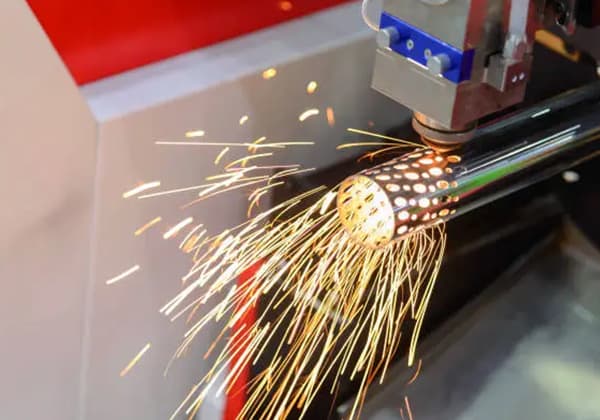

Tube laser cutting machines employ focused laser beams to cut various patterns and shapes on pipes, tubes, and profiles. This non-contact cutting method offers superior precision and versatility compared to traditional mechanical cutting techniques.

These machines integrate cutting-edge numerical control technology, laser cutting systems, and precision mechanical components. Key features include:

The laser cutting process offers remarkable flexibility in terms of:

Modern tube laser cutting machines can process symmetrical metal profiles such as I-beams and angle irons, expanding their application scope.

The laser beam’s controllability is a significant advantage, allowing for:

The high-precision cuts produced by laser technology significantly reduce post-processing requirements, minimizing burrs and improving overall efficiency.

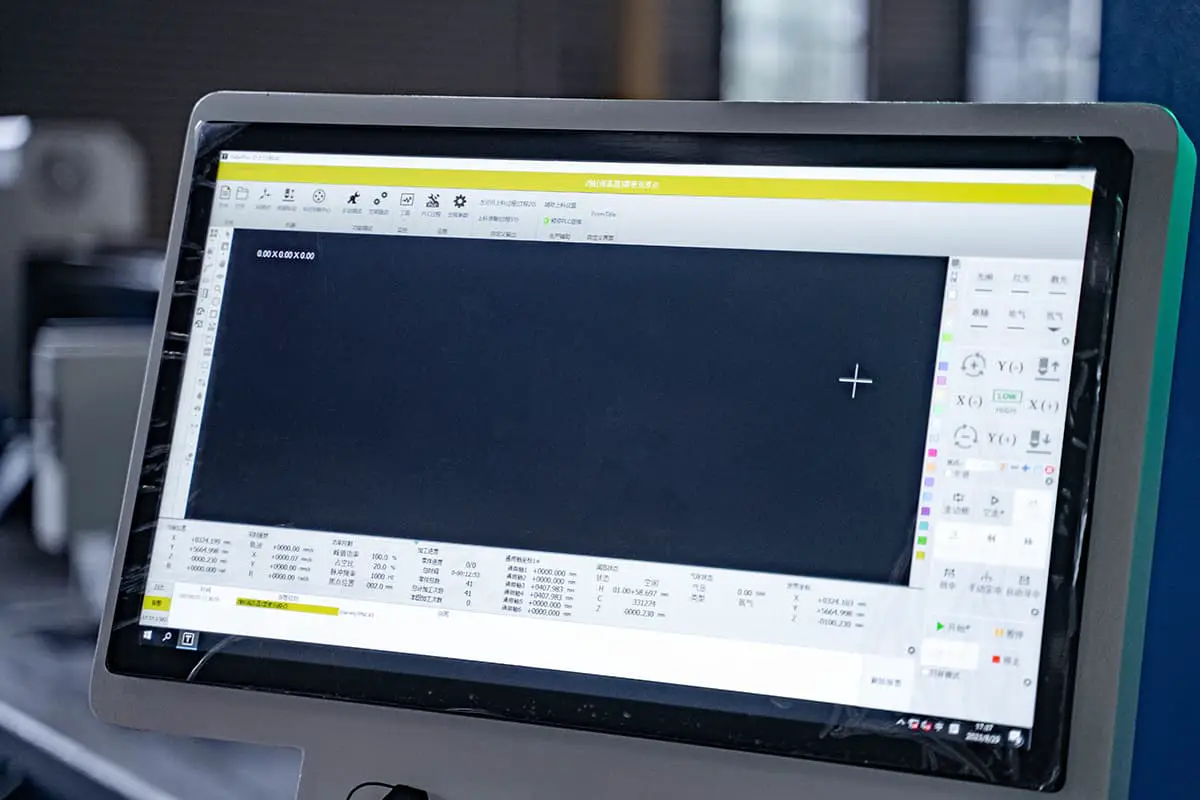

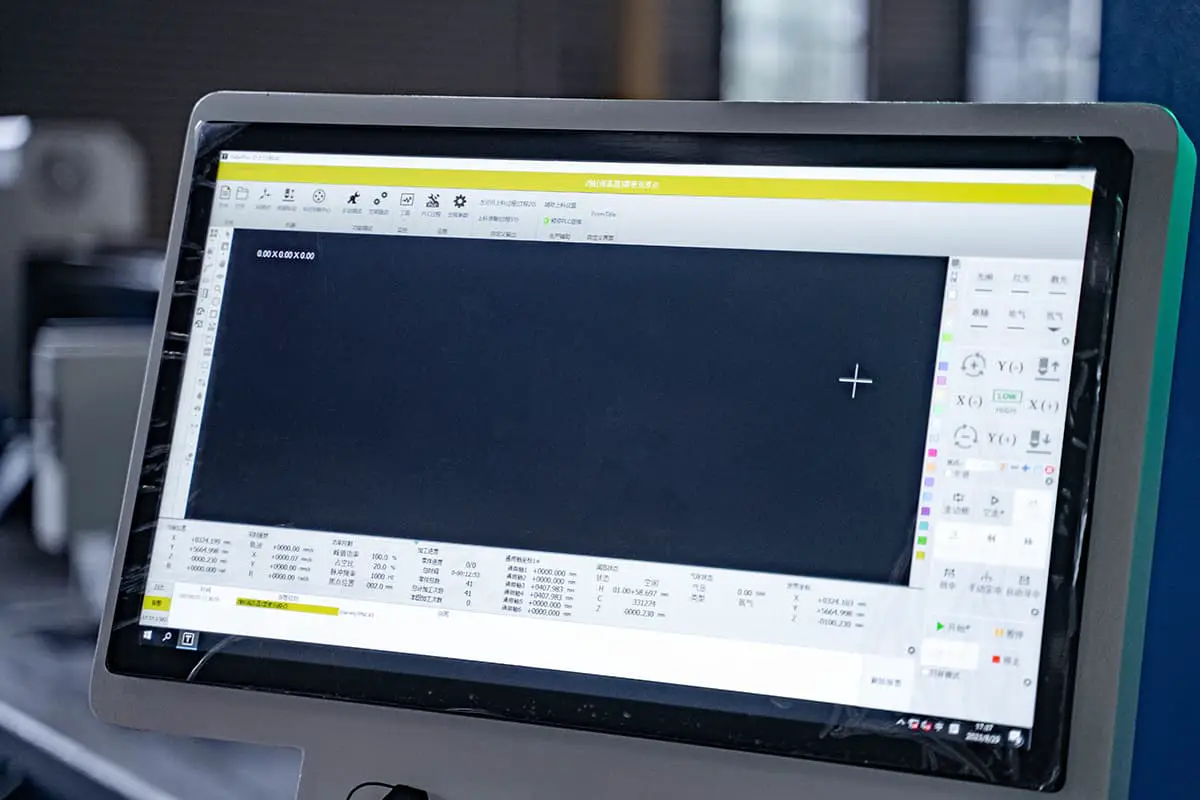

Changing workpiece specifications (e.g., pipe diameter or profile shape) typically only requires software adjustments, eliminating the need for mechanical tooling changes. This flexibility underscores the importance of advanced pipe cutting software development.

By combining laser cutting systems with computer numerical control (CNC) technology, these machines offer:

The fundamental cutting principles of tube laser cutting machines closely align with those of planar laser cutting systems, with specialized adaptations for tubular geometries.

Tube laser cutting machines are engineered specifically for processing standard metal tubes (including round, rectangular, and oval profiles), structural sections (such as channel and angle steel), and various custom-shaped tubular components.

The advantages of tube laser cutting over traditional processing techniques are significant:

The rapid expansion of metal tube production and consumption has led to widespread adoption of laser tube cutting machines in manufacturing industries. These advanced systems offer precision, efficiency, and versatility in processing tubular components.

Laser tube cutting machines available in the market can be broadly categorized into two main types based on the axial feeding method of the tube:

This kind of laser tube cutting machine only processes fixed length tube, which is mostly used for processing the contour of the tube surface with constant axis and changing cross-section, the two ends of the tube can not be processed.

Although the cut-to-length laser tube cutter has great limitations and low productivity, it occupies a large market share because of its special features.

Figure 1 shows the decorative pattern on the surface of a lamp stem and lampshade processed by a fixed material cutting laser tube cutter.

Fig.1 Lamp shank and lamp shade processed by a fixed material cutting laser tube cutter.

Working Principle

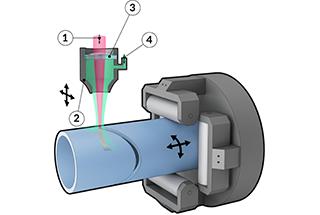

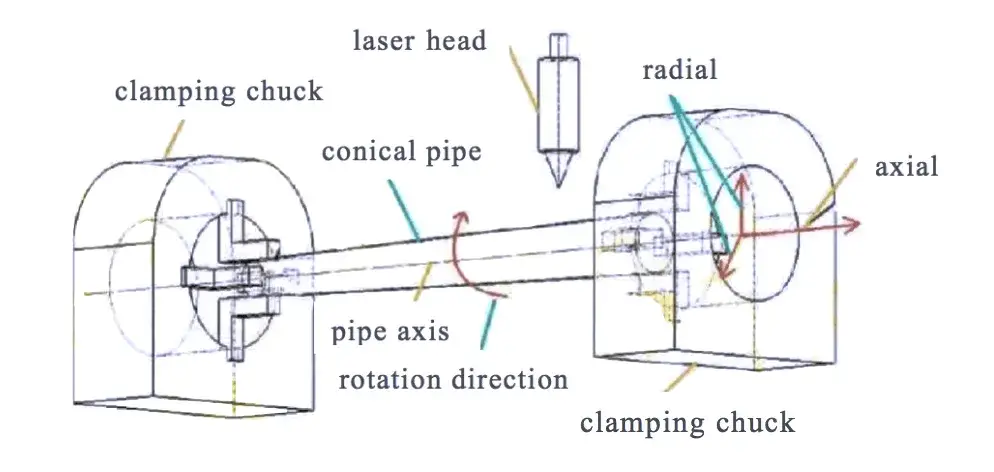

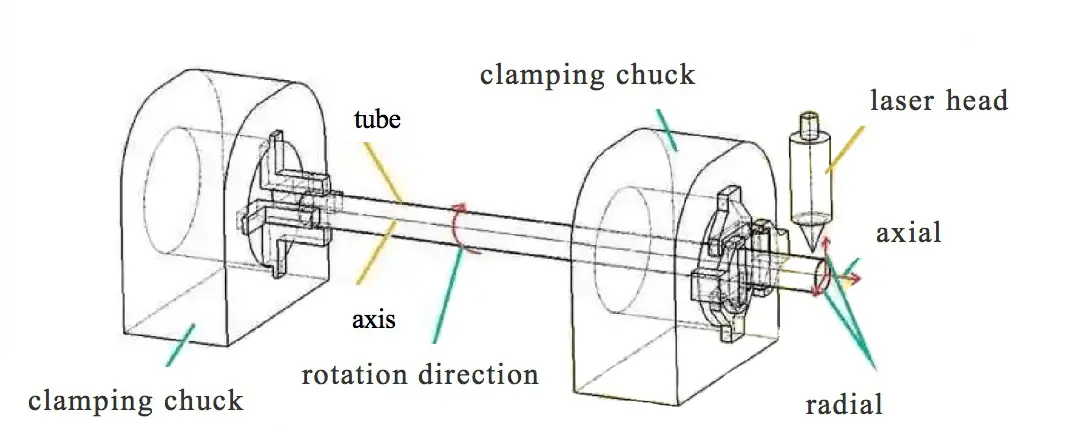

As shown in Fig. 2, the fixed material cutting laser tube cutter consists of two clamping chucks that hold the tube in place, the chuck makes a synchronized rotational motion around the tube axis and the laser head makes axial and radial feeds of the tube for cutting.

This type of laser tube cutting machine is mainly used for the processing of coaxial tube of the same cross-section, which not only can process various contour shapes on the surface of the tube, but also can cut according to the designed length of the tube part within the designed stroke of the machine.

Compared to the fixed material cutting laser tube cutter, it is more flexible, scalable and higher cutting efficiency, which currently occupies the majority market share of the professional laser tube cutter.

As shown in Figure 3, the feed cutting laser tube cutter can be used to batch process various profiles of standard metal tubes such as square and round tubes, and cut off.

Fig.3 Square and round tubes processed by a feed cutting laser tube cutter.

Working Principle

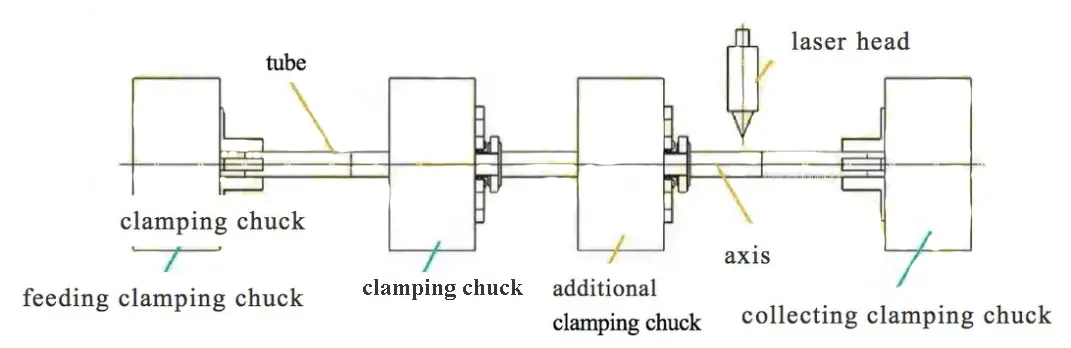

As shown in Figure 4, the tube is held by a clamping chuck, the support chuck holds the tube radially.

All the chucks around the tube axis synchronous rotary movement, clamping chuck fixed tube to do axial feed, the laser head to do the tube radial feed and cutting.

Currently, the feed cutting laser tube cutter is mainly based on two chucks on the market, which is cost-effective, but its shortcomings are also obvious.

Fig.4 Working principle diagram

1) Poor stability of cutting accuracy

For the tube with too long parts or poor rigidity, with gravity deformation plus the action of centrifugal force of chuck rotation, even if the increase of servo roller or profiling wheel support, it is difficult to ensure the stability of cutting accuracy.

2) Tail material, even if the laser head can cross the support chuck cutting, but the chuck clamping end is still unable to cut, resulting in tube waste.

To address these shortcomings, some equipment manufacturers use two chuck feed cutting laser tube cutting machines as the basis, expand the design of multi-chuck laser tube cutting machine, as shown in Figure 5.

Among them,

1) It increases a set of support chuck and can ensure that a certain length of tube almost free from gravity deformation and chuck rotation centrifugal force, which can effectively ensure the stability of cutting accuracy and the parts cutting length is not limited in the machine stroke range.

2) It increases a set of clamping chucks for catching material, when the feeding chuck is in the limit position, the tube is clamped by the catching chuck to do axial feeding movement, which can ensure most of the tube zero-tail material cutting.

3) Although the above design can completely solve the shortcomings of the two chuck feed cutting type laser tube cutter, the increased cost of chucks, the number of servo axes and CNC system.

It also explains why the current multi-chuck feeding and cutting type laser tube cutter has not become a mainstream trend.

The operation of a tube laser cutting machine involves several critical steps to ensure precise and efficient cutting:

The auxiliary gas is one of the important components of the laser pipe cutting machine.

The main function is to blow away the iron scraps generated by cutting the pipe through the high-pressure auxiliary gas ejected by the laser head when the laser head of the laser pipe cutting machine is cutting the pipe, so as to achieve the ideal cutting effect.

Secondly, it can protect the lens and prevent the iron scraps during cutting from bouncing on the lens to affect the output of the laser beam and the effect during cutting.

At present, there are three commonly used auxiliary gases for laser:

① air ② oxygen ③ nitrogen;

How can we choose auxiliary gas to achieve better cutting effect in daily life?

Air is the lowest cost auxiliary gas among the three common auxiliary gases.

Of course, it can not be used for laser cutting simply by breathing air.

The air used by the laser cutting machine can only be used after the water, oil, dust and other impurities in the air are filtered through the filter and the filtered air is compressed to about 20kg by the air compressor.

It is suitable for aluminum, aluminum alloy, galvanized steel and other thin pipes, as well as in the case where the cutting requirements are not too high.

The oxygen here refers to the gas with a purity of 99.5%.

The laser pipe cutter cuts the metal at the cutting place by melting and evaporating the high temperature generated by the laser focus to perform laser cutting.

While oxygen contributes to the aerobic reaction of laser metal and improves the cutting efficiency.

At the same time, the oxide film of oxygen on the surface of the pipe contributes to the absorption of the light beam by the reflective material.

However, the surface after cutting will be black or dark yellow, which is suitable for cutting thick carbon steel pipes.

Nitrogen is the most expensive auxiliary gas among the three auxiliary gases.

Since nitrogen is an inert gas, the oxygen reaction on the cutting surface of the pipe is suppressed when cutting with the laser pipe cutter, contrary to the oxygen cutting.

Therefore, the surface of the pipe cut with nitrogen will be bright and white.

However, due to the cost, it is recommended to use nitrogen as the auxiliary gas when the surface of the pipe is relatively strict.

The above three different auxiliary gases have their own advantages.

Therefore, when selecting other auxiliary gases, it is necessary to cut them according to the actual situation.

For those who do not know the technology well, do not arbitrarily set and modify the auxiliary gas cutting, which will easily generate burrs and lead to poor stability of the laser tube machine.

In a laser cutting device, the function of the light guiding system is to direct the beam output from the laser generator to the cutting head of the focusing light path.

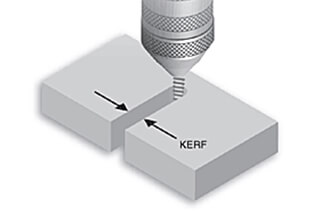

For tube laser cutting, if want to get high-quality cutting slit, the small diameter and high power of focus spot of focus beam are necessary.

This allows the laser generator to perform the low-order mode output.

In the laser cutting of the tube, in order to obtain a relatively small beam focusing diameter, the laser must have a small transverse mode order time, preferably a fundamental mode.

The cutting head of the laser cutting device is equipped with a focusing lens. After the laser beam is focused by the lens, a small focused spot can be obtained, so that high-quality tube cutting can be performed.

In tube cutting, the tube to be processed belongs to a space curved surface, and the shape of the tube is relatively complicated.

If it is programmed and machining by conventional methods, there will be certain difficulties.

This requires the operator to select the correct machining path and the appropriate reference point according to the machining process requirements, and use the numerical control system to record the feed condition of each axis and the coordinate of the reference point, and then record the coordinates of the machining process and generate a machining program through the linear and circular interpolation functions of the laser cutting system.

Therefore, studying the automatic vertical function of the laser beam and cutting tube is also one of the important technical contents of tube laser cutting.

In order to ensure the cutting quality of the laser-cut tube, keep the focus on the vertical direction of the workpiece surface by means of automatic measuring and control devices is the key to tube laser cutting.

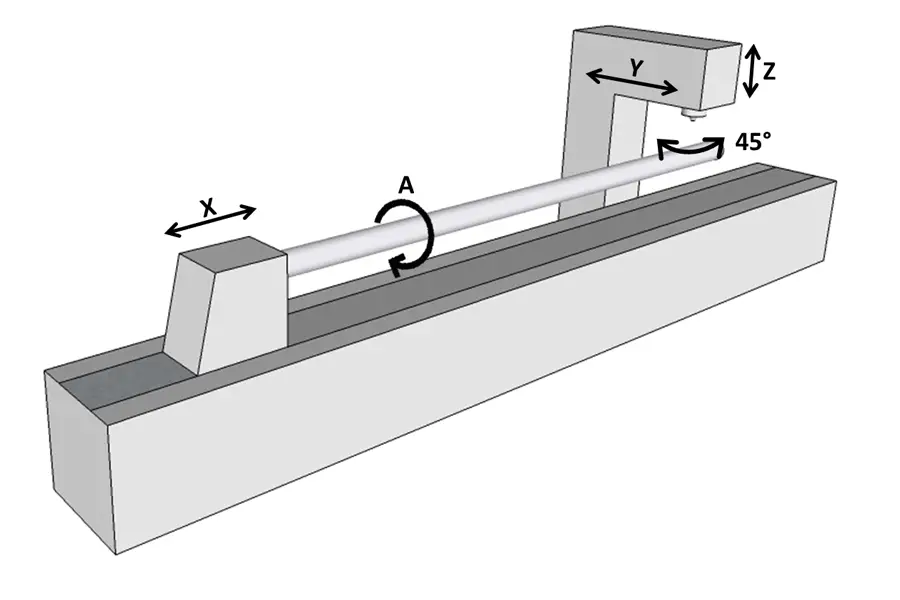

At present, we integrate the laser focus position with the direct axis(X-Y-Z) of the laser processing system, which makes the movement of the laser cutting head more light and flexible, and the position of the focus can be well understood, so as to avoid the collision of the cutting head with cutting pipe or other objects during the processing.

Tube laser cutting is becoming more and more widely used in today’s industrial society, and the tube to be cut are more and more diversified.

Besides, the tube parts themselves have their own complexity.

Therefore, according to the material, shape and processing requirements of cutting pipe, choosing appropriate laser cutting process parameters to obtain the best cutting efficiency and cutting quality has become the most concerned issue for all users of laser cutting system.

For a continuous wave output laser generator, laser power has an important effect on laser cutting.

In theory, the greater the laser power, the faster the cutting speed.

But considering the features of the pipe itself, the maximum cutting power is not the best choice.

When the cutting power is increased, the mode of the laser itself changes, which affects the focus of the laser beam.

In practical processing, we often choose to get the highest power density in the case of less than the maximum power, so as to guarantee the efficiency and cutting quality of the whole laser cutting.

When cutting the tube by laser, it is must be ensured that the cutting

speed is within a certain range in order to obtain better cutting quality.

If the cutting speed is slow, excessive heat will accumulate on the surface of the tube, and the heat-affected zone will become larger, and then the slit will become wider. Besides, The surface of the incision is cauterized by the discharged hot melt material, which makes the surface of the cut rough.

When the cutting speed is increased, the average circumferential slit width of the tube becomes smaller. The smaller the diameter of the pipe, the more obvious the effect.

With the acceleration of cutting speed, the time of laser action is shortened, the total energy absorbed by the pipe becomes less, the temperature at the front end of the pipe decreases, and the width of the slit turns smaller.

If the cutting speed is too fast, the pipe will not be cut through or cut off, which will affect the whole cutting quality.

When cutting the tube by laser, the characteristics of the tube itself can have a great influence on the processing.

For example, the size of the tube diameter has a significant impact on processing quality.

Through the research on laser-cut thin wall seamless steel pipe, it is found that the tube diameter and the slit width will continue to increase while the various process parameters remain unchanged.

When cutting nonmetal and part of metal tubes, compressed air or the inert gas such as nitrogen can be used as an auxiliary gas.

However, for most metal tubes, the active gas such as oxygen can be used.

After determining the type of auxiliary gas, it is also important to determine the pressure of the auxiliary gas.

When cutting a tube with a small wall thickness at a relatively high speed, the pressure of the auxiliary gas should be increased to prevent the adhering slag from being caught in the slit; When the thickness of the cutting pipe wall is large or the cutting speed is slow, the pressure of the auxiliary gas should be appropriately reduced to prevent the tube from being not cut through or not cut off.

The position of the beam focus is also vital for tube laser cutting. During cutting, the focus position is generally at the surface position of cutting pipe fitting. When the focus is in a good position, the slit is the smallest, the cutting efficiency is the highest, and the cutting effect is also the best.

In most cases, the focus of the beam is adjusted below the nozzle and the distance between the nozzle and the surface of the tube is approximately 1.5 mm.

At the same time, factors such as laser pulse-shape and light output mode also have a certain influence on the cutting effect.

The future demand for tubes is growing, processing requirements will be higher and higher, and improving processing accuracy and production efficiency is a necessary factor in the rapid development of professional laser tube cutting machine.

User requirements change over time, and the modular design allows the addition or replacement of functional components to meet user requirements and maximize the benefits for both parties.

There are already many users equipped with automatic loading and unloading unit, the development of automation can effectively liberate the labor force, alleviating the problem of labor shortage in enterprises.

With the popularization of the concept of “Industry 4.0” and the maturity of the development of 5G technology, the future of the laser tube cutting machine will certainly achieve complete automation.

That is, it integrates information collection, order placing, feeding, loading, tube identification, length measurement, automatic call program cutting, unloading, palletizing and shipping, which finally realizes intelligence.

There are many advantages of tube cutting by lasers such as narrow incision width, small heat-affected zone, fast cutting speed, good flexibility, smooth cut and no tool wear.

With the emergence and development of CNC (Computerized Numerical Control) laser cutting machines, the development of various machining techniques of space free-form surfaces and curves can show their unique side.

In laser cutting, not only the laser spot is required to move in 3d space relative to the workpiece according to a certain trajectory, but also the laser axis is required to be perpendicular to the machining surface of the pipe to be cut throughout the machining process.

For CNC fiber laser cutting heads that can autofocus, the nozzles automatically track the surface of the workpiece through an automated measurement and control system.

The production practice indicates that the key to tube cutting is to eliminate the defects of cutting quality to the greatest extent, so as to meet the processing requirements of the tube.

For complex tube processing such as perforation, slotting, trimming or undercutting, laser cutting is not only faster than traditional machining methods but also ensures great processing quality.

During the processing, the cutting of pipe parts should be ensured first to obtain the blank of the required length of pipe.

The traditional tube cutting method is difficult to meet the needs of mass production, and the tube parts processed by these traditional processing methods have generally poor quality of the cut surface, and some even have processing defects such as deformation and collapse.

In addition to the need to cut the tube, some other forms of processing are required, such as pattern cutting for decoration and lamps, spiral, sine, cosine linear cutting, and marking, etc.

If these forms of tube machining use traditional methods, not only the processing efficiency is low, but also it is difficult to achieve the ideal processing requirements, and some even can not be processed.

The notch width is generally 0.1-0.3mm for tube cutting by laser (include straight-cut, beveling, and form cutting).

The cutting position and temperature can be precisely controlled, which are more conducive to automation and intelligent production.

What’s more, compared with the traditional processing method, the cutting efficiency can be increased by 8 to 20 times, the processing cost can be reduced by 70% to 90%, and the material loss can be saved by 15% to 30%.

Besides, the noise of laser cutting is low, and the impact on the environment is also slight.

Conventional machining methods that require multiple sequential processes to complete the machining can be achieved by laser cutting on the same equipment.

With the continuous improvement of equipment performance and processing technology, high-quality cutting of tubes can be achieved by laser.

Laser cutting adopts non-contact processing method, which does not exert any pressure on the tube wall during the whole process, so it will not cause deformation or collapse of the outer surface of the pipe.

At the same time, when cutting the tube by laser, the slotting thermal field is complicated, the cooling is difficult, and the cutting slag is easy to block, which increases the cutting difficulty.

Therefore, it is necessary to strengthen the in-depth study of these aspects.

Laser cutting has a great deal of freedom in the requirements of the material, shape, size and processing environment of the tube. Its spatial control (beam direction change, rotation, scanning, etc.) and time control (on, off, pulse interval) are excellent and easy to control.

Moreover, the higher precision and fewer burrs of laser cutting greatly reduce the follow-up time spent in processing.

When changing the diameter or shape of the tube, it is only necessary to modify the program, so the development of the tube cutting software is of great research value.

The combination of laser cutting system and computer numerical control technology can form efficient automation equipment and open up a new path for high quality, high efficiency and low-cost processing.

In order to improve the efficiency of tube cutting, the use of laser cutting automatic production line is the most effective production method.

How to use the tube cutting automatic production line?

First of all, the laser beam after focusing must be guaranteed to run synchronously with the tube which is for cutting by the automatic production line.

Secondly, it is required that the laser spot after focusing can be rotated one circle relative to the tube to be cut, and the laser beam axis is always perpendicular to the pipe axis. During the cutting process, the laser beam of the pipe cutting production line moves together with the pipe being cut.

During the cutting process, the laser beam of the tube cutting production line follows the tube to be cut. These synchronous movements must be controlled by a specialized control system, so the research on the automatic production line of tube laser cutting is also very significant.

Tube laser cutting is inseparable from the hardware – laser cutting system (including laser generators) and software – laser cutting technology.

From the hardware point of view, the future laser cutting machine will develop in the direction of high speed, high precision, high automation, flexibility and diversification; from the software point of view, the future laser cutting will be combined with CNC technology to develop new software.

Therefore, the collection and finishing of laser cutting process data, the establishment and improvement of expert systems, are of great significance and research value for the development of the entire laser cutting industry.