What if the tiny particles in your welds were causing big problems? This article delves into how tungsten inclusions, despite their high melting point, can weaken welding seams and lead to defects. By understanding the causes, such as improper welding techniques and material issues, you can learn to prevent these defects. Expect to uncover practical strategies to enhance the quality and strength of your welds, ensuring more reliable and robust connections in your metalworking projects.

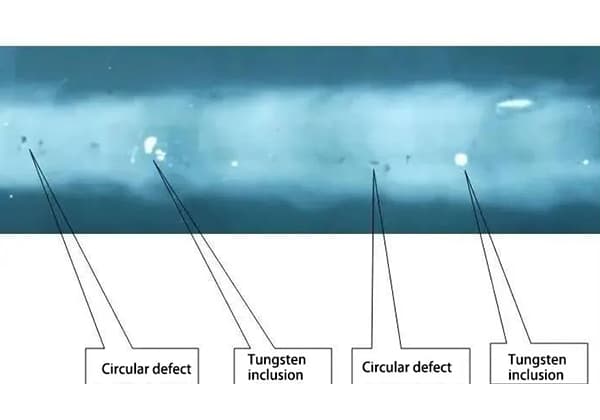

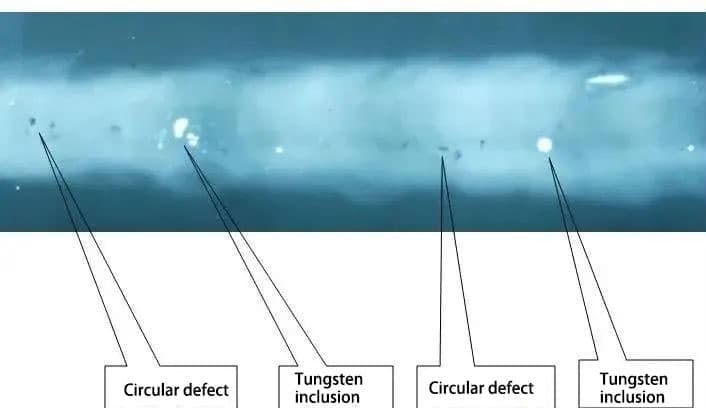

The irregular shape, sharp corners, and edges of tungsten clamps have a cutting effect on the welded joint, causing stress concentration and making it one of the root causes of cracking.

Therefore, tungsten is a relatively serious defect.

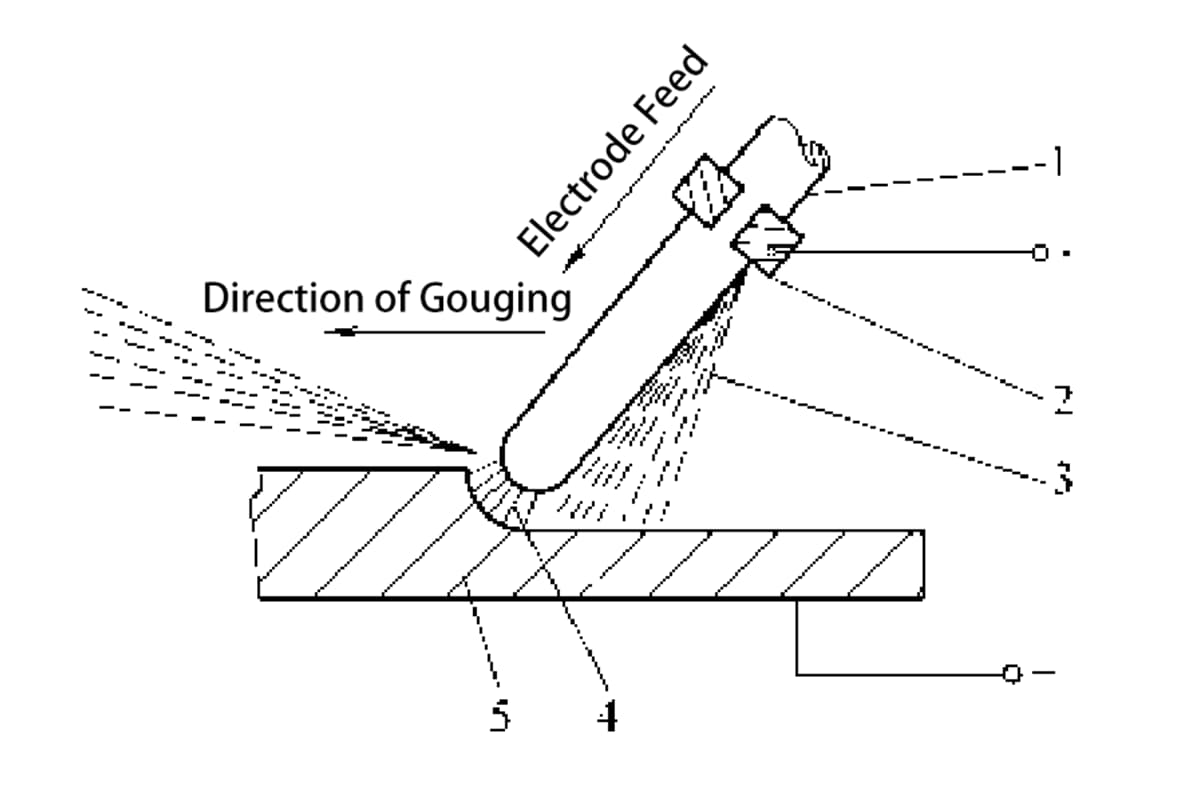

Tungsten clamps in the welded joint are a new defect that emerged with the adoption of tungsten electrode argon arc welding, a new and advanced welding method.

When the welding current is large and the welding time is long, the tungsten electrode melts into the molten pool because tungsten has a much higher melting point than the melting point of the weld metal.

Therefore, tungsten solidifies before the weld metal.

Due to the fact that tungsten solidifies into a spherical or ellipsoidal shape, it not only does not cause stress concentration like pores, but the tungsten clamps in the welded joint can also withstand a small amount of stress.

Therefore, the harm of tungsten clamps is smaller than that of pores and slag inclusions.

However, since tungsten’s solidification point is much higher than that of the weld metal, tungsten solidifies before the weld metal and cannot melt into an organic whole with the weld metal.

As a result, the strength of the welded joint with tungsten clamps is slightly reduced, so tungsten is still regarded as a welding defect.

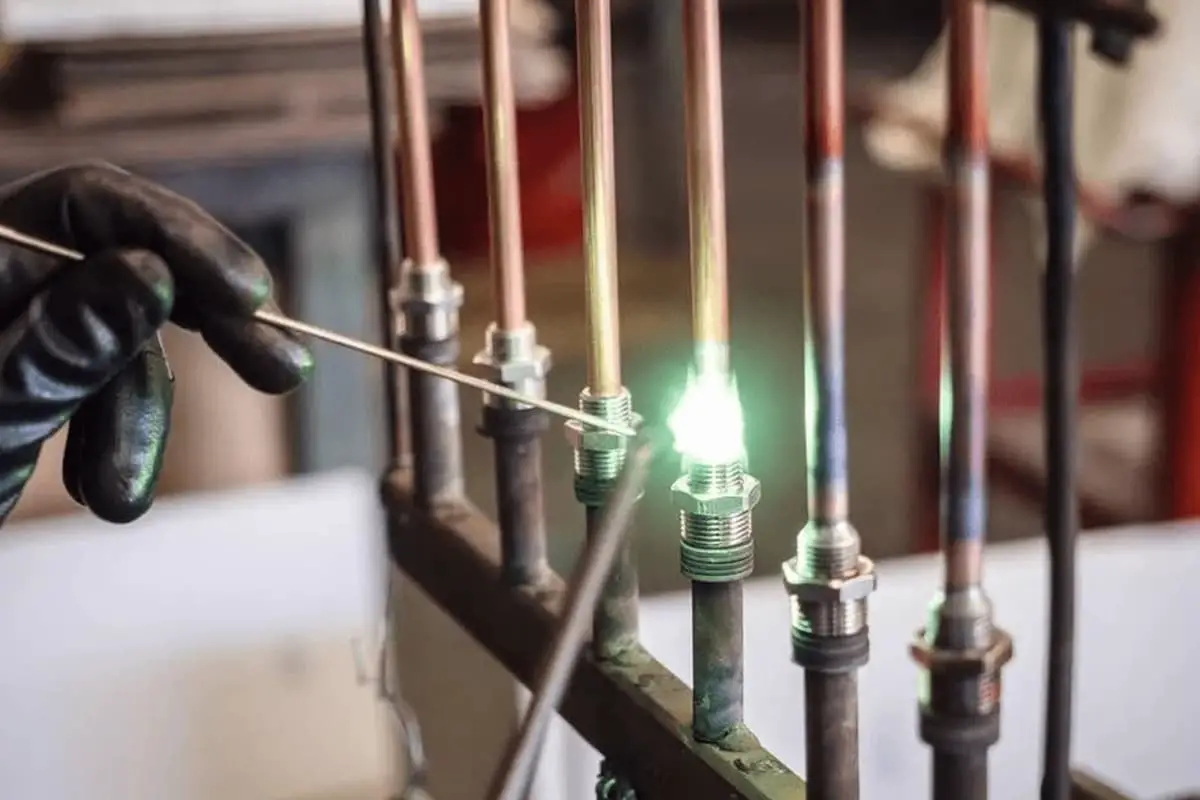

Poor proficiency of the welder and unskilled techniques can cause the tungsten electrode to frequently touch the workpiece or filler wire.

When the position of the weld seam is affected by the spatial position or the welding gun is obstructed, the difficulty of the operation will be increased, which will increase the probability of the tungsten electrode touching the molten pool or filler wire.

Under the circumstances of fixed tungsten electrode type and diameter, the tungsten electrode has a certain limit to its current carrying capacity. Excessive welding current will cause tungsten electrode burnout and ultimately lead to tungsten clamps defect.

During the shielded inert gas welding process, the impurity of the gas or the selection of active mixed gas as the protective gas will reduce the protective effect, resulting in a lack of protection for the tungsten electrode and eventually oxidation.

When welding with direct current polarity or TIG welding in the negative half-cycle of alternating current, the temperature of the tungsten electrode will increase, burnout will become severe, and tungsten particles will enter the molten pool.

Thoriated tungsten electrode: a traditional electrode with superior welding performance. It does not break the arc, is not scattered, does not float, does not splash, has a stable arc and high-temperature resistance. The tungsten electrode head is not easily rounded, and its service life is long.

Zirconiated tungsten electrode: exhibits excellent welding performance under AC conditions, especially under high load current, which cannot be replaced by other electrodes.

Yttrium tungsten electrode: has a slender arc, high compression, and the maximum melting depth in medium and large currents. It is mainly used in military and aerospace industries.

Ceriated tungsten electrode: has excellent arc-starting performance under low current conditions, and has relatively fewer maintenance currents.

Lanthanum tungsten electrode: can be used under both AC and DC conditions, has high tolerance currents, and the lowest burnout rate.

Pure tungsten electrode: does not add any rare earth oxides, has the minimum electron emission capability, and is only suitable for welding under high AC loads.

Due to the alternating cold and hot temperature during welding, the tungsten electrode end angle is small, making it prone to stress concentration and tungsten electrode tip stress fracture, resulting in tungsten clamps in the molten pool.

If the tungsten electrode surface is rough during welding, the oxide generated at high temperature can accumulate locally during movement towards the tip, leading to the accumulation of local oxides and the possibility of cracking, resulting in tungsten clamps.

(1) Strictly select the welding current based on the type and diameter of the tungsten electrode used.

(2)Strictly control the purity of the inert shielding gas (≥99.9%). Ar+O2 or Ar+CO2 gas cannot be used in TIG welding.

(3)Use short arc welding as much as possible during welding to enhance the protective effect.

(4)Strengthen the basic skills of the welder, and strictly control the distance between the tungsten electrode and the workpiece to avoid tungsten clamps caused by contact with the workpiece during welding.

(5)Use direct current positive polarity for DC TIG welding.

(6)Choose a reasonable gas flow rate value, and use a windbreak board in outdoor places with strong winds during welding.

(7)Control the extension length of the tungsten electrode during welding. For butt welds, the extension length of the tungsten electrode is generally kept at 5-6 mm, and for fillet welds, the extension length of the tungsten electrode is best at 7-8 mm.

(8)Use dedicated grinding equipment to grind the tungsten electrode. For small current welding, grind a small clamping angle and sharp angle on the tungsten electrode, while for large current welding, grind an appropriate clamping angle, and grind the end into a large angle and round corner.