Have you ever wondered about the fascinating world of brass? This versatile alloy, made from copper and zinc, has a rich history and countless applications. In this blog post, we’ll dive into the different types of brass, their unique properties, and how they shape our everyday lives. From musical instruments to industrial components, brass plays a vital role in various fields. Get ready to uncover the secrets behind this remarkable material and expand your knowledge of metallurgy.

Brass is a versatile alloy primarily composed of copper and zinc, with copper typically being the predominant element. The standard formulation, known as ordinary brass, consists of these two metals in varying proportions. When additional elements are incorporated into the alloy, such as lead, tin, aluminum, or nickel, it is classified as special brass, each variant offering unique properties tailored to specific applications.

This copper-zinc alloy is renowned for its exceptional combination of properties, including excellent corrosion resistance, high formability, and notable wear resistance. Brass exhibits a distinctive golden hue, which can range from reddish to silvery depending on its composition. Its low friction characteristics and antimicrobial properties further enhance its utility across various industries.

Brass finds widespread use in numerous applications, particularly in plumbing and HVAC systems. It is the material of choice for manufacturing valves, water pipes, and connecting pipes for air conditioners due to its resistance to corrosion and ability to withstand high pressures. The alloy’s thermal conductivity makes it ideal for radiators and heat exchangers. Additionally, brass is extensively used in musical instruments, decorative hardware, electrical components, and marine applications, owing to its durability, machinability, and aesthetic appeal.

The versatility of brass, combined with its cost-effectiveness compared to pure copper, ensures its continued importance in modern manufacturing and engineering applications.

Lead Brass

Lead is virtually insoluble in brass and exists as discrete particles along grain boundaries. Two types of lead brass are distinguished: α and (α+β). α lead brass is limited to cold-forming or hot-extrusion processes due to its poor impact resistance and low plasticity at elevated temperatures. In contrast, (α+β) lead brass exhibits excellent plasticity at high temperatures, making it suitable for forging operations.

Tin Brass

The addition of tin to brass significantly enhances the alloy’s heat resistance and, notably, its resistance to seawater corrosion. This characteristic has earned tin brass the moniker “naval brass”. Tin dissolves into the copper-based solid solution, improving its strength properties.

However, increasing tin content beyond a certain threshold leads to the formation of the brittle ε phase (Cu3Sn intermetallic compound), which impedes plastic deformation. Consequently, tin content in tin brass is typically restricted to 0.5-1.5% by weight.

Common tin brass alloys include HSn70-1, HSn62-1, and HSn60-1. HSn70-1 is a highly ductile alloy suitable for both cold and hot forming processes. The latter two grades possess an α+(α+β) dual-phase microstructure, often containing small amounts of the ε phase. These alloys exhibit low plasticity at room temperature and are primarily suited for hot working.

Manganese Brass

Manganese demonstrates higher solubility in solid brass compared to other alloying elements. The addition of 1-4% manganese significantly improves the strength and corrosion resistance of brass without compromising its ductility. Manganese brass typically exhibits an (α+β) microstructure. HMn58-2 is a commonly used alloy in this category, offering excellent workability in both cold and hot forming operations.

Iron Brass

In iron-containing brass alloys, iron precipitates as iron-rich particles that serve as nucleation sites for grain refinement. This mechanism inhibits recrystallized grain growth, thereby enhancing the mechanical and technological properties of the alloy. Iron content in these brasses is usually limited to 1.5% or less, resulting in an (α+β) microstructure. These alloys exhibit high strength, toughness, and good plasticity at elevated temperatures, while also allowing for cold working. HFe59-1-1 is a widely used alloy in this category.

Nickel Brass

Nickel forms a continuous solid solution with copper, significantly expanding the α-phase region in brass. The addition of nickel substantially improves the corrosion resistance of brass in both atmospheric and marine environments.

Furthermore, nickel increases the recrystallization temperature of brass and promotes the formation of finer grains. HNi65-5 nickel brass, characterized by a single-phase α structure, demonstrates excellent plasticity at room temperature and can also be hot-worked effectively.

However, it is crucial to strictly control the lead impurity content in nickel brass, as elevated levels can severely compromise the alloy’s hot workability.

Purity Measurement

To determine the purity of brass, the Archimedes principle can be utilized to measure the volume and mass of the sample, after which the proportion of copper in brass can be calculated based on the density of copper and zinc.

Common Brass

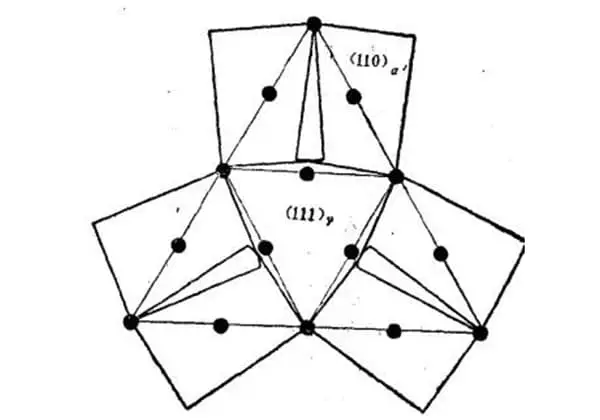

Common brass is an alloy of copper and zinc. When the zinc content is less than 35%, it can dissolve in copper to form a single-phase α structure, which is known as single-phase brass. This structure has good plasticity and is ideal for cold and hot pressing.

When the zinc content ranges from 36% to 46%, there is a single-phase α and a copper-zinc-based β solid solution, which is known as two-phase brass. The β phase reduces the plasticity of brass and increases its tensile strength, making it only suitable for hot pressure processing. If the zinc content continues to increase, the tensile strength will decrease, making it useless.

The code for brass is represented by “H+number,” where “H” stands for brass and the “number” represents the mass fraction of copper. For instance, H68 represents brass with 68% copper and 32% zinc content.

For cast brass, the letter “Z” is added before the code, such as ZH62. For example, ZCuZnZn38 represents a cast brass with a zinc content of 38% and the rest being copper.

H90 and H80 are single-phase brass and have a golden yellow color. H59 is two-phase brass and is widely used in electrical appliance structural parts, such as bolts, nuts, washers, and springs. Typically, single-phase brass is used for cold deformation processing, while two-phase brass is used for hot deformation processing.

Special Brass

An alloy formed by adding other elements to ordinary brass is known as special brass. Commonly added elements include lead, tin, and aluminum, which are referred to as lead brass, tin brass, and aluminum brass, respectively. The purpose of adding these elements is mainly to improve the tensile strength and processability of the brass.

The code for special brass is represented as “H+symbol of main added element (excluding zinc)+mass fraction of copper+mass fraction of main added element+mass fraction of other elements”. For example, HPb59-1 indicates that the mass fraction of copper is 59%, the mass fraction of lead (the main added element) is 1%, and the rest is zinc.

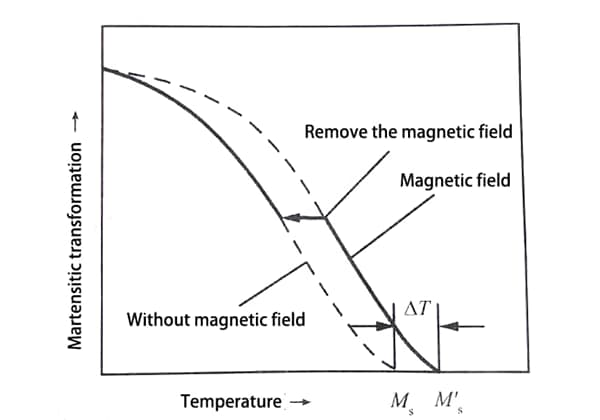

The hot working temperature range for brass is 750 to 830°C (1382 to 1526°F). Annealing is performed between 520 and 650°C (968 to 1202°F), while stress relief annealing occurs at lower temperatures, typically 260 to 270°C (500 to 518°F). These precise temperature ranges are critical for achieving optimal mechanical properties and microstructure.

Environmentally friendly brass C26000 (also known as cartridge brass or C2600) exhibits exceptional characteristics, including excellent formability, high tensile strength, superior machinability, good weldability, and robust corrosion resistance. These properties make it ideal for various applications, including heat exchangers, paper manufacturing equipment, precision machinery components, and intricate electronic parts.

C26000 brass is available in a wide range of dimensions to suit diverse manufacturing needs. Thickness options span from ultra-thin 0.01mm to substantial 2.0mm sheets, while width varieties extend from narrow 2mm strips to broad 600mm plates. The material’s versatility is further enhanced by its range of temper options, including fully annealed (O), quarter-hard (1/2H), three-quarter hard (3/4H), full hard (H), extra hard (EH), and spring hard (SH). These tempers allow for tailored mechanical properties to meet specific application requirements. The brass conforms to multiple international standards, including GB (Chinese), JIS (Japanese), DIN (German), ASTM (American), and EN (European), ensuring global compatibility and quality assurance.

The exceptional machinability of C26000 brass makes it particularly suitable for high-precision machining operations. Its optimal chip formation characteristics and low tool wear properties make it an excellent choice for both high-speed automatic lathes and advanced CNC (Computer Numerical Control) machining centers, enabling the production of complex, tight-tolerance components with superior surface finishes.