Ever wondered what makes the perfect cut in manufacturing? This article explores various cutting tool materials, detailing their unique properties and uses. With insights from seasoned mechanical engineers, you’ll discover how these materials revolutionize efficiency and precision in machining. Prepare to upgrade your knowledge and optimize your tooling choices.

See also:

High-speed steel is a type of tool steel that is known for its high hardness, high wear resistance, and high heat resistance, achieved through the addition of elements such as tungsten, molybdenum, chromium, and vanadium. Also known as high-speed tool steel or hot-work steel, it is commonly referred to as “white steel.”

High-speed steel is primarily used to create complex, lightweight, and impact-resistant metal cutting tools. The manufacturing process of high-speed steel tools is straightforward and allows for easy sharpening, which is why they still make up a significant proportion of metal cutting tools despite the emergence of newer materials.

Cemented Carbide is an alloy made of refractory metals and binder metals, produced through P/M metallurgical techniques. This material has excellent properties such as high hardness, wear resistance, good strength and toughness, heat resistance, and corrosion resistance.

In particular, its high hardness and wear resistance remain constant even at temperatures up to 500°C, and it still has a high hardness at 1000°C. Thus, cemented carbide has a higher cutting performance compared to high-speed steel and can improve the durability of the tool several to dozens of times.

With the same durability, cemented carbide allows for cutting speeds to increase by 4-10 times. As a result, it is widely used as a tool material, capable of cutting difficult-to-machine materials such as heat-resistant steel, stainless steel, high manganese steel, and tool steel.

Diamond is considered to be the hardest substance with exceptional thermal conductivity among known mineral materials. Its friction wear with various metal and non-metal materials is only 1/50-1/800 of cemented carbide, making it the ideal material for cutting tools.

Mostly, the cutting tools are made of artificial single crystal diamonds. The cutting edge of diamond tools is incredibly sharp, which is important for cutting chips with small sections. Its cutting edge has a low roughness and low friction coefficient, making it unlikely to produce chipping during cutting, thus resulting in high-quality machined surfaces.

There are three types of diamond cutting tools: natural single crystal diamond tools, solid synthetic single crystal diamond tools, and diamond compound tools. However, natural diamond tools are rarely used in actual production due to their high cost.

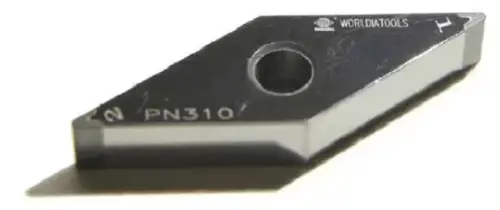

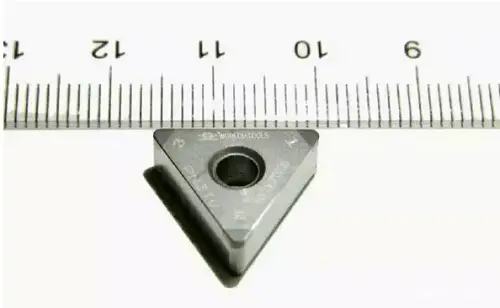

It is a newly developed artificially synthesized material, sintered from CBN (Cubic Boron Nitride) powder and a small amount of binder (such as Co-Ni, TiC, TiN, or Al2O3) under high temperature and pressure and with the help of a catalyst. It boasts high hardness, good abrasion resistance, exceptional chemical stability, and higher thermal stability compared to diamond tools.

It can maintain its properties even when used at temperatures between 1200-1300°C and does not react with metals in the iron group, making it ideal for processing steel. Hence, CBN cutting tools are primarily used for efficient machining of difficult-to-machine materials and have a broad range of applications in the machining industry.

The main advantages of ceramic tool materials are their high hardness and resistance to abrasion, as well as minimal reduction in bending strength and resistance to bending at high temperatures.

They have high chemical stability, low affinity with metals, and good resistance to oxidation at high temperatures. They do not react with steel even at melting temperatures, resulting in less adhesion, diffusion, and oxidative wear, and a lower coefficient of friction. Chips are also less likely to stick to the cutting tools and it is less likely to produce chipping.

However, the disadvantages of ceramic tools include high brittleness, low strength and toughness, and weaker bending strength compared to cemented carbide.

When choosing cutting tool materials, it’s crucial to consider various factors to ensure optimal performance, longevity, and cost-effectiveness. This section outlines the key considerations for selecting cutting tool materials: Strength and Hardness, Toughness, Wear Resistance, Thermal Stability, and Economic Viability.

Strength and Hardness

Strength and hardness are fundamental properties that determine a material’s ability to withstand cutting forces and maintain dimensional stability during machining operations. Key considerations include:

Toughness

Toughness is a critical factor that measures a material’s ability to absorb energy and resist fracture or chipping. When evaluating toughness, consider:

Wear Resistance

Wear resistance is paramount in prolonging tool life and maintaining machining accuracy. Key aspects include:

Thermal Stability

High temperatures generated during machining necessitate excellent thermal stability in cutting tool materials:

Economic Viability

The economic aspect of cutting tool material selection is crucial for optimizing overall machining costs:

By carefully evaluating these criteria, engineers can select the most appropriate cutting tool material for specific machining applications, balancing performance requirements with economic considerations. This approach ensures optimal tool life, machining quality, and overall process efficiency.

Machining Operations

Cutting tool materials play a pivotal role in various machining operations, significantly impacting productivity, cost-effectiveness, and product quality. Key machining operations include:

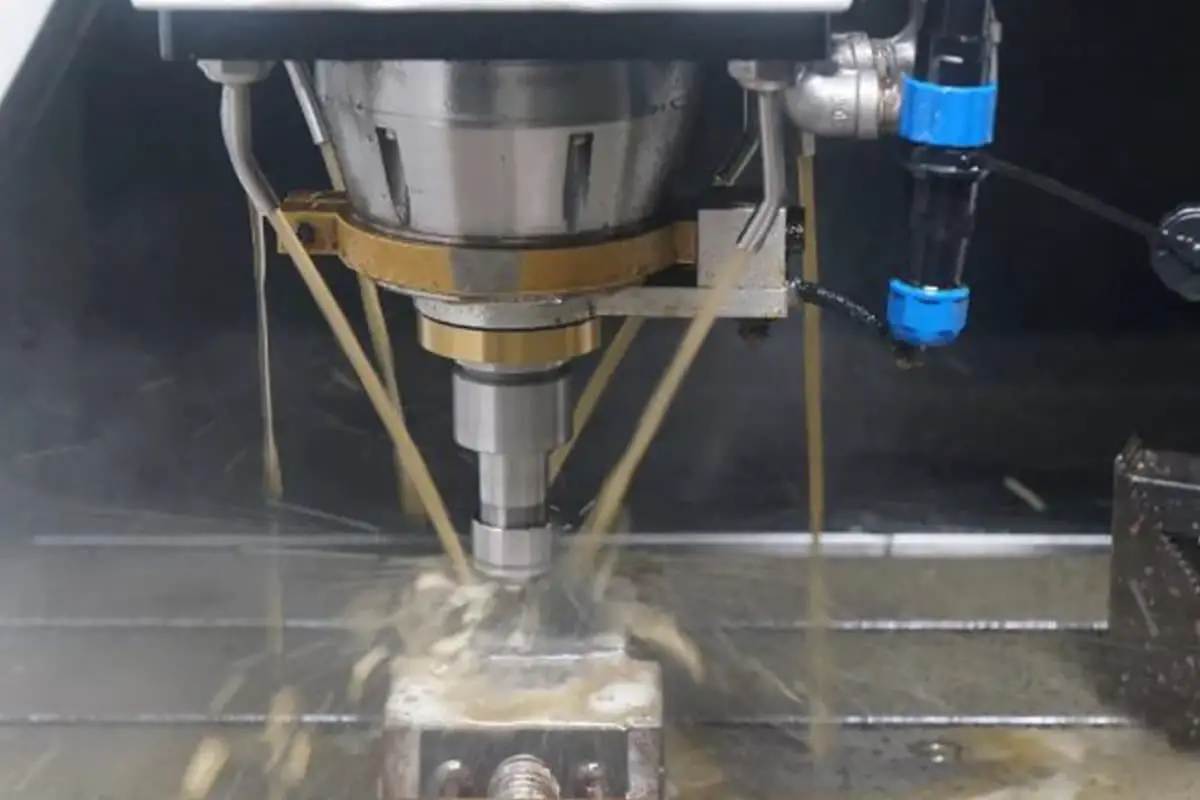

Milling: This versatile process utilizes rotary cutters to remove material from the workpiece. High-speed steel (HSS) and carbide tools remain industry standards, but advanced ceramic-metal composites (cermet) and cubic boron nitride (CBN) inserts are gaining traction for high-speed machining of hardened steels and superalloys.

Turning: In this operation, single-point cutting tools remove material as the workpiece rotates. While ceramics, polycrystalline diamond (PCD), and carbide are common, cryogenically treated tools and nano-structured multilayer coatings are emerging as game-changers for enhanced tool life and surface finish quality.

Drilling: Multi-point or single-point cutting tools create cylindrical holes in the workpiece. Beyond HSS and carbide, modern drilling operations benefit from through-coolant drills and indexable insert drills, offering improved chip evacuation and heat dissipation in deep-hole applications.

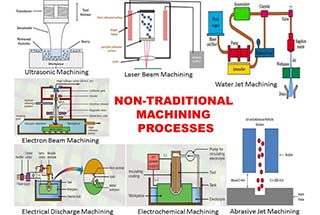

Emerging Technologies

Several cutting-edge technologies are reshaping the cutting tool landscape:

Additive Manufacturing (AM): Beyond producing tools with complex geometries, AM enables the creation of hybrid cutting tools with optimized internal cooling channels and customized substrate compositions, enhancing performance in challenging machining scenarios.

Coating Technologies: Advanced physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques now allow for precisely engineered multi-layer coatings. These include temperature-resistant AlTiN coatings for dry machining and self-lubricating MoS2 coatings for improved chip flow in difficult-to-machine materials.

Smart Tools: The integration of micro-sensors and IoT connectivity in cutting tools facilitates real-time monitoring of cutting forces, temperatures, and tool wear. This data, when coupled with machine learning algorithms, enables predictive maintenance, adaptive machining strategies, and overall equipment effectiveness (OEE) optimization.

Cryogenic Machining: Liquid nitrogen cooling systems are being integrated into cutting tools, allowing for sustainable, high-performance machining of heat-resistant superalloys and composites used in aerospace applications.

By staying abreast of these technological advancements, manufacturing professionals can make informed decisions to optimize their machining processes, reduce cycle times, and improve overall product quality in an increasingly competitive global market.