Have you ever wondered what keeps hydraulic cylinders functioning smoothly without leaks? The secret lies in the types of seals used within them. This article dives into six essential types of cylinder seals—dust seals, cylinder rod seals, buffer seals, guide support seals, end cover seals, and piston seals. Each type plays a crucial role in maintaining the efficiency and longevity of hydraulic systems. By understanding these seals, you can better appreciate their importance and ensure your machinery runs flawlessly. Read on to discover how each seal type contributes to the overall performance.

Construction machinery relies heavily on hydraulic cylinders, which are integral components in transmitting force and motion. The efficiency and reliability of these cylinders are critically dependent on high-performance seals.

One essential type of seal used in hydraulic cylinders is the sealing ring, also referred to as an oil seal or hydraulic seal. These components play a crucial role in maintaining system integrity by preventing oil leakage, contamination ingress, and pressure loss. Properly selected and installed sealing rings ensure optimal cylinder performance, extended service life, and reduced maintenance costs.

In this comprehensive guide, we have compiled an extensive list of various types and configurations of sealing rings commonly employed in hydraulic cylinders for construction equipment.

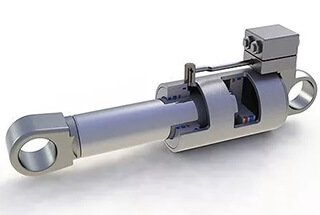

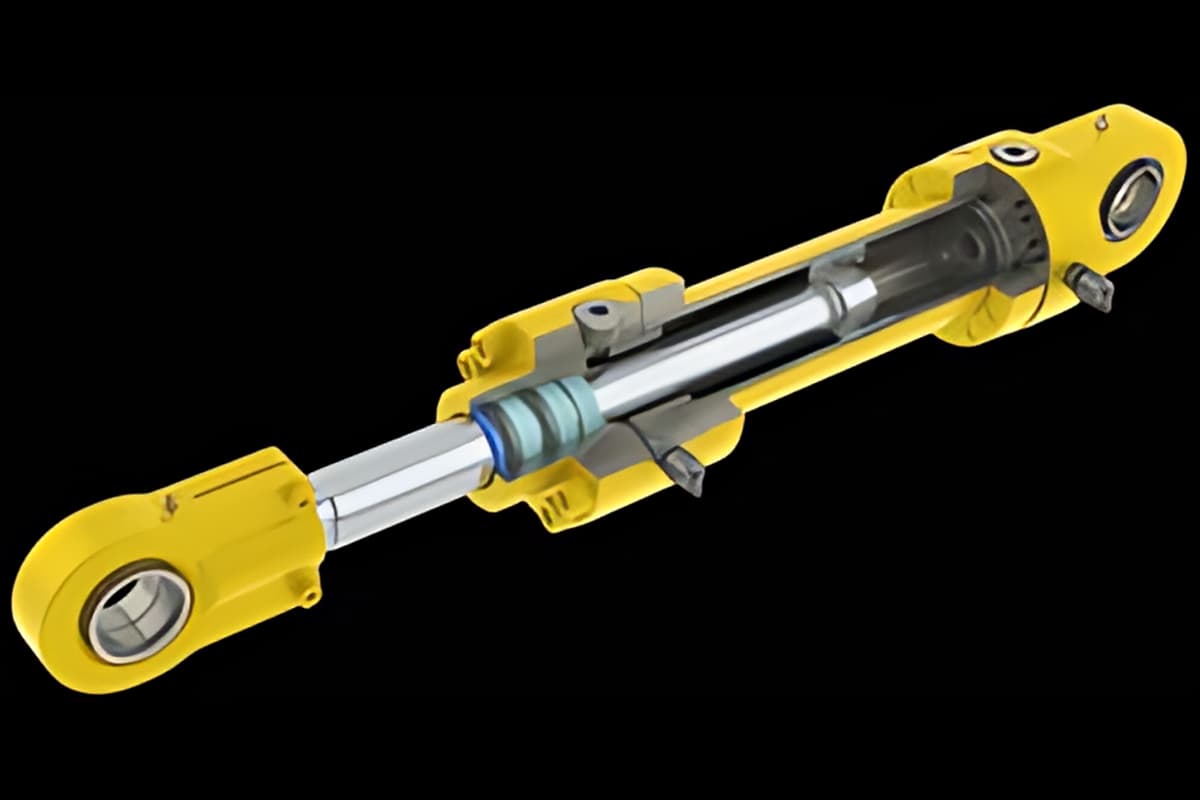

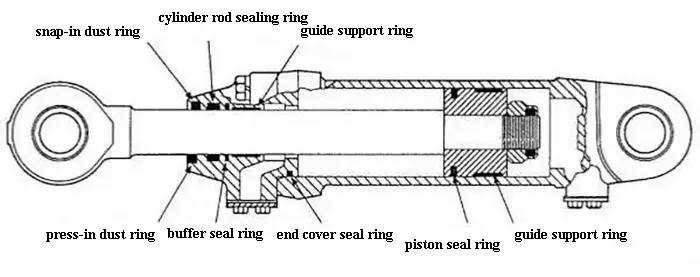

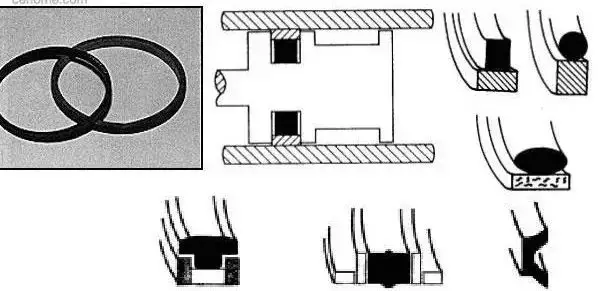

Fig. 1 Sealing rings.

The hydraulic cylinder employs a variety of specialized sealing components to ensure optimal performance and longevity. These essential sealing elements include:

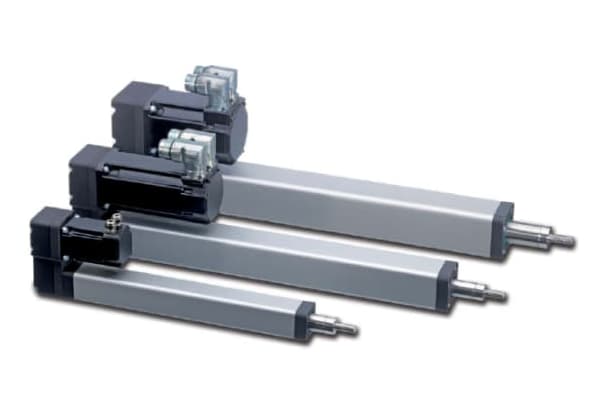

Fig. 2 The position of different seal rings.

Hydraulic cylinder seals are critical components in hydraulic systems, playing a vital role in maintaining system integrity and efficiency. Their primary functions include preventing fluid leakage, maintaining pressure, and ensuring smooth operation of moving parts. Understanding the characteristics and applications of different seal types is essential for optimal hydraulic system performance. Seals are broadly categorized into two main types: static seals and dynamic seals, each with distinct properties and applications.

Static Seals

Static seals are employed where there is no relative motion between mating surfaces, such as in flange connections, access covers, or ports. These seals are designed to create a tight barrier against fluid leakage and maintain system pressure. Common types of static seals include:

Dynamic Seals

Dynamic seals are used in applications involving relative motion between mating surfaces, such as in pistons or rods. These seals must withstand constant movement and friction, requiring enhanced durability and wear resistance compared to static seals. Key types of dynamic seals include:

Seal selection and design considerations are critical for optimal hydraulic system performance. Factors influencing seal choice include:

Advancements in seal technology have led to the development of specialized materials and designs, such as PTFE-based seals for high-temperature applications or polyurethane seals for improved wear resistance. Additionally, innovations like energized seals and composite seals offer enhanced performance in challenging operating conditions.

The dust seal is located on the exterior of the hydraulic cylinder’s end cap and serves to prevent external debris from entering the cylinder.

Based on the method of installation, dust seals can be classified into two types: snap-in and press-in.

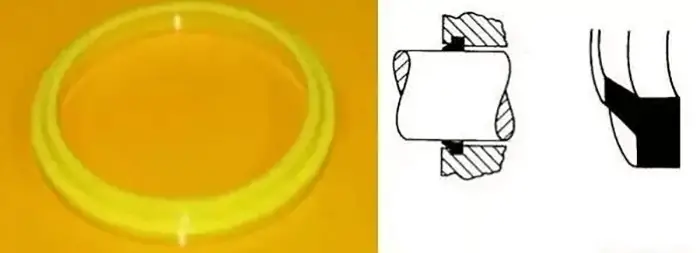

Fig. 3 Basic form of snap-in dust ring.

The most commonly used dust ring is the snap-in type. As the name implies, it snaps into the groove on the inner wall of the end cover and is used in less harsh environmental conditions. The material used for the snap-in dust ring is usually polyurethane and it comes in different structures, such as the double-lip structure type H and K-sections. Despite the variations, their basic design remains the same.

Fig. 4 Some variants of snap-in dust ring.

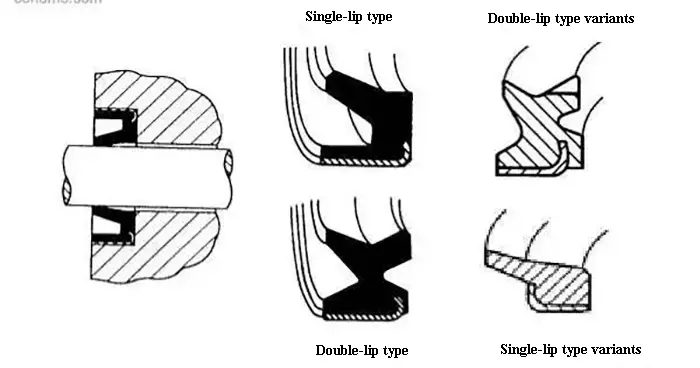

The press-in type dust ring is used in harsh and high-stress environments. Unlike the snap-in type, it is not inserted into the groove but is reinforced with a metal layer to enhance its strength and then inserted into the hydraulic cylinder’s end cover. There are different types of press-in dust rings, such as single-lip and double-lip.

Fig. 5 Press in dust ring and some variants.

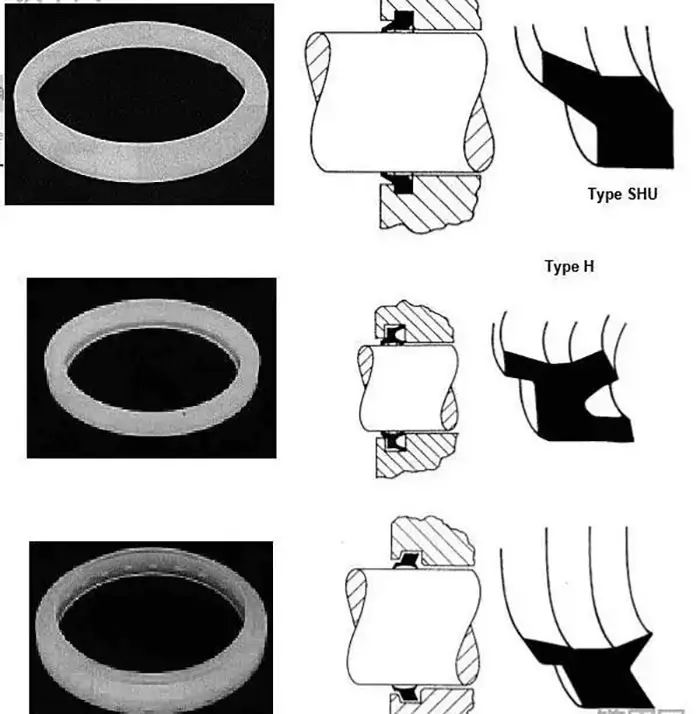

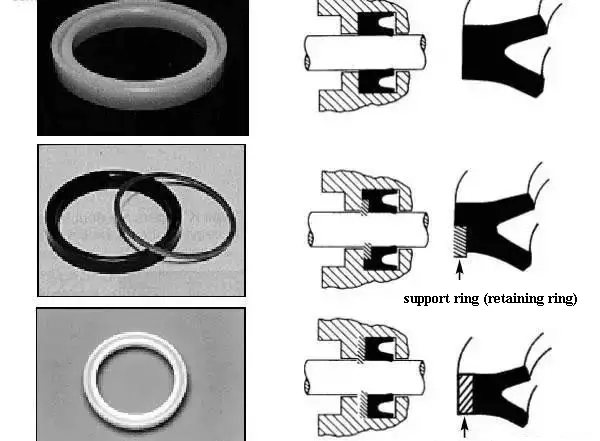

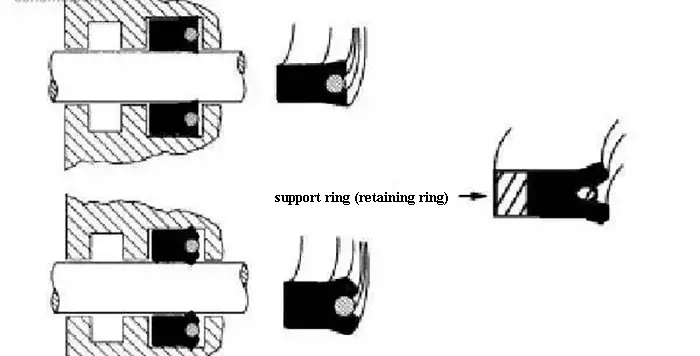

The cylinder rod sealing ring, commonly referred to as a U-cup, serves as the primary sealing element for the piston rod. It is strategically installed within the end cover of the hydraulic cylinder to effectively prevent hydraulic oil leakage. These sealing rings are predominantly manufactured from high-performance materials such as polyurethane or nitrile rubber, chosen for their excellent wear resistance, low friction properties, and compatibility with hydraulic fluids.

In high-pressure applications or when dealing with larger cylinder bores, the sealing ring is often used in conjunction with a support ring (also known as a back-up ring or anti-extrusion ring). This additional component prevents the sealing ring from undergoing extrusion deformation under intense pressure, thereby extending the seal’s lifespan and maintaining its integrity. The support ring is typically made of harder materials like PTFE or high-density polyethylene.

The design of cylinder rod sealing rings has evolved to address various operational requirements and environmental conditions. Manufacturers offer a wide range of variations, including:

Selecting the appropriate cylinder rod sealing ring involves considering factors such as operating pressure, temperature range, fluid compatibility, surface finish of the rod, and reciprocating speed to ensure optimal performance and longevity of the hydraulic system.

Fig. 6 Common types of cylinder rod seal ring.

Fig. 7 Some variants of cylinder rod sealing rings.

The buffer seal ring, a critical auxiliary component in piston rod sealing systems, plays a vital role in safeguarding the piston rod against sudden pressure spikes and fluctuations. This dynamic seal not only protects the primary sealing elements but also contributes to the overall system longevity and reliability. There are three primary configurations of buffer seals, each designed to meet specific operational requirements:

Type A: A single-piece, monolithic seal fabricated from high-performance polyurethane. This design offers excellent wear resistance, good elasticity, and moderate pressure capabilities. It’s particularly suitable for applications with moderate pressure fluctuations and where simplicity of installation is desired.

Type B and Type C: These are advanced two-piece seal assemblies engineered to prevent extrusion and withstand significantly higher pressure differentials. The two-piece construction typically consists of a resilient sealing element paired with an anti-extrusion ring:

Both Type B and Type C configurations provide enhanced pressure resistance, improved stability under dynamic conditions, and better protection against seal failure in high-pressure environments. The choice between these types depends on factors such as maximum system pressure, temperature range, fluid compatibility, and cycle frequency.

Fig. 8 Common types of the buffer seal ring.

The guide support ring, a critical component in hydraulic cylinders, is strategically positioned on both the end cover and piston. This multifunctional element plays a pivotal role in ensuring the cylinder’s optimal performance and longevity. Its primary functions include:

Guide support rings are typically manufactured from high-performance materials carefully selected for their specific properties. Common materials include:

The choice of material depends on factors like operating pressure, temperature, fluid compatibility, and expected service life. Advanced manufacturing techniques, such as precision CNC machining or injection molding, ensure tight tolerances and superior surface finish, critical for the ring’s performance.

Fig. 9 Guide support ring used on the end cover of the hydraulic cylinder and the piston.

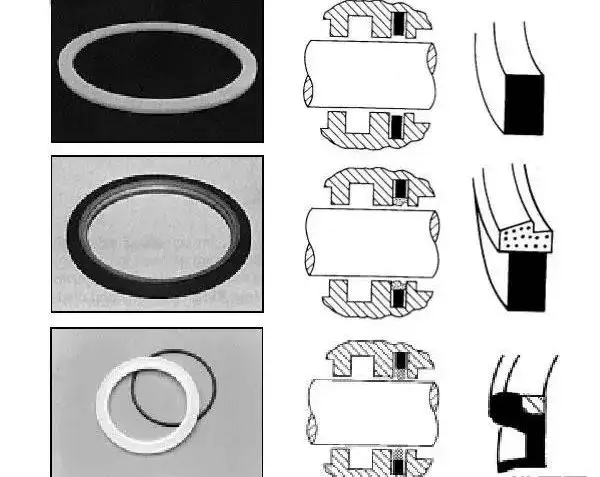

The end cover seal ring is a critical component engineered to provide a hermetic seal at the interface between the cylinder end cover and the cylinder wall. Functioning as a static seal, it plays a crucial role in maintaining system integrity by preventing hydraulic fluid leakage from the juncture of these two primary components.

Typically, the end cover seal ring assembly comprises two key elements: a resilient NBR (Nitrile Butadiene Rubber) O-ring and a rigid support ring, often referred to as a backup ring or anti-extrusion ring. This dual-component design offers several advantages:

The precise material selection and dimensional specifications for both components are critical and depend on factors such as operating pressure, temperature range, fluid compatibility, and expected service life of the hydraulic system. Proper installation and periodic inspection of the end cover seal ring assembly are essential for optimal hydraulic cylinder performance and reliability.

Fig. 10 End cover sealing ring.

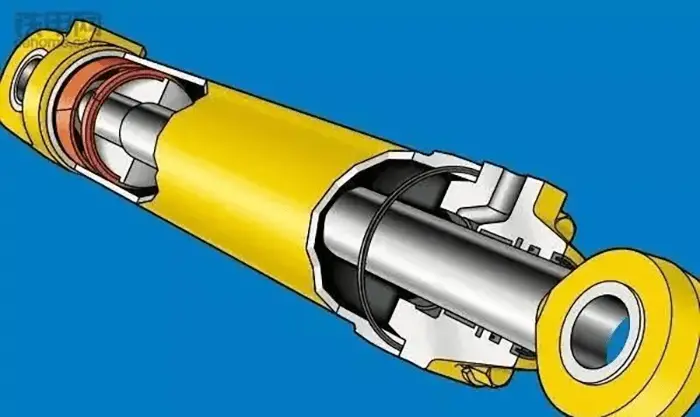

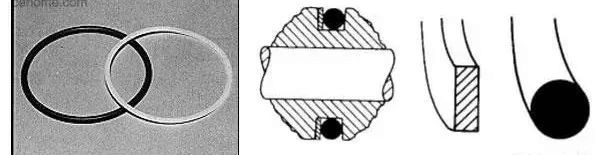

The piston seal ring is a critical component in hydraulic cylinders, serving as the primary sealing element that effectively separates the two pressure chambers within the cylinder. This separation is crucial for maintaining optimal hydraulic performance and efficiency.

Typically, the piston seal ring utilizes a two-piece design, consisting of an outer ring and an inner ring. The outer ring is commonly manufactured from high-performance polymers such as polytetrafluoroethylene (PTFE) or nylon, chosen for their low friction properties and excellent wear resistance. The inner ring, often referred to as the energizer, is usually made of nitrile butadiene rubber (NBR), which provides the necessary elasticity to maintain constant pressure against the cylinder wall.

Several variations of the piston seal ring exist to suit different applications and operating conditions. One notable variant incorporates a bronze-filled PTFE compound, which combines the low friction characteristics of PTFE with the improved thermal conductivity and wear resistance of bronze. This design is particularly effective in high-pressure and high-temperature applications.

In single-acting hydraulic cylinders, where pressure is applied in only one direction, a polyurethane U-cup seal may be employed as an alternative piston seal ring. Polyurethane U-cups offer excellent abrasion resistance, good elasticity, and effective sealing properties, making them suitable for moderate pressure applications where cost-effectiveness is a consideration.

The selection of the appropriate piston seal ring design and material depends on factors such as operating pressure, temperature, fluid compatibility, cylinder speed, and expected service life. Proper selection and installation of the piston seal ring are essential for ensuring optimal cylinder performance, minimizing leakage, and maximizing the overall efficiency of the hydraulic system.

Fig. 11 Common types of the piston seal ring.