Have you ever wondered how different laser cutting machines meet the diverse needs of industries today? This article breaks down the various types of laser cutting machines, from those designed for intricate PCB work to those capable of slicing through thick metal pipes. By exploring their unique features and applications, you’ll gain a clear understanding of how each type optimizes efficiency and precision in its specific field. Dive in to discover which laser cutting technology best suits your industry’s demands.

Recently, I have received a lot of inquiries from readers about laser cutting. Maybe many people don’t know much about laser cutting machines. For this reason, I have sorted out an article about the types of laser cutting machines here, hoping to help you who are confused.

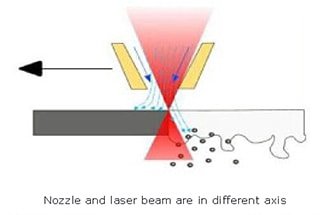

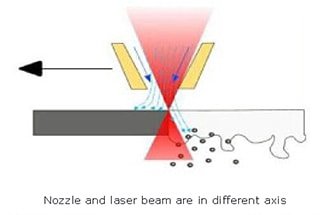

The principle of the laser cutting machine is to focus the laser emitted from the laser into a high power density laser beam.

When the laser beam is irradiated on the surface of the workpiece, the workpiece will reach the melting point or boiling point.

At the same time, the high-pressure gas coaxial with the beam will blow away the molten or vaporized metal.

With the relative position of the beam and the workpiece moving, the material will eventually form a slit, thus achieving the purpose of cutting.

What are the types of laser cutting machines?

Model introduction

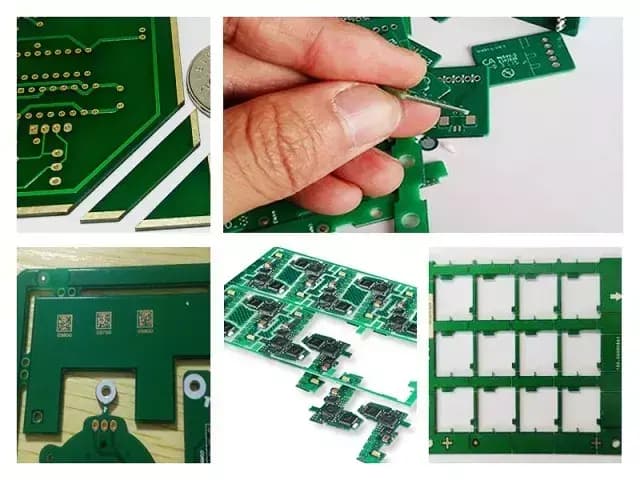

PCB laser cutting machine: adopt high-performance green/purple laser, with good beam quality, small focus spot and uniform power distribution, and can process various high complexity circuit boards, flexible circuit boards and soft and hard combination boards.

By reducing the power by pulse, PCB two-dimensional code printing can be carried out to realize cutting and code printing with one machine for two purposes.

Meet the high yield and efficiency requirements of mass production of cutting and coding processing in the circuit board industry.

Model features

Scope of application

PCB hard board cutting, splitting, soft and hard combination board cutting, SMT industry splitting, two-dimensional code marking process, fingerprint identification chip cutting, camera module laser cutting, circuit board cutting with welded components, PI protective film cutting, glass cutting, hole cutting, ceramic cutting, drilling, scribing, silicon chip cutting, copper foil cutting.

Model introduction

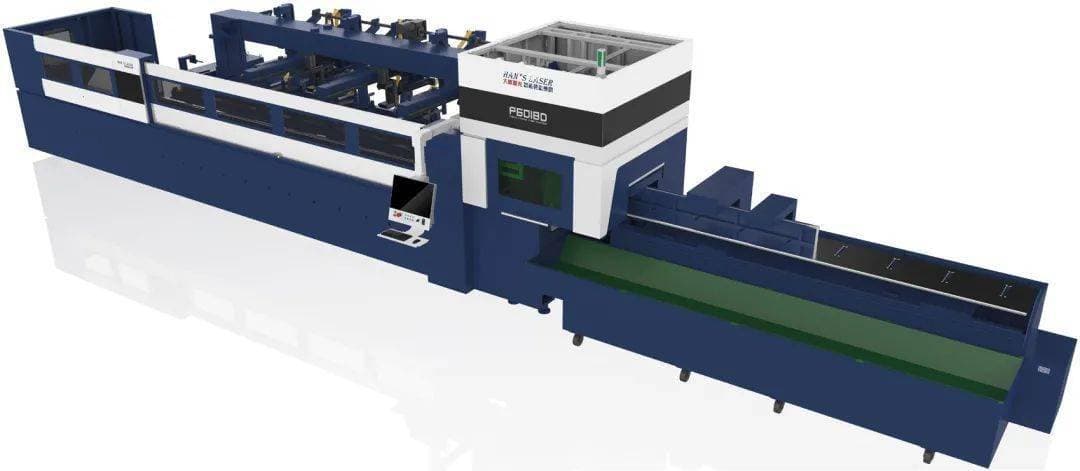

Laser metal pipe cutting machine: applicable to the one-time cutting and forming of round tubes, square tubes and special-shaped tubes.

It adopts a reciprocating feeding system, which is not limited to the length of the tubes, and has a high degree of automation.

It directly imports three-dimensional graphics, automatically identifies the cutting path, and carries out precision high-speed processing.

The machine is equipped with a fully automatic loading system, which can be selected according to customer requirements.

The parts formed by laser processing have no burr and black hole, and the same product size has high consistency.

Model features

Scope of application

Suitable for stainless steel, carbon steel, alloy steel, aluminum, copper, titanium and other metal pipes.

It is applied to sports fitness equipment, clothing and props display rack, medical equipment, steel furniture, doors and windows, kitchen and bathroom, steel furniture industry, etc.

Model introduction

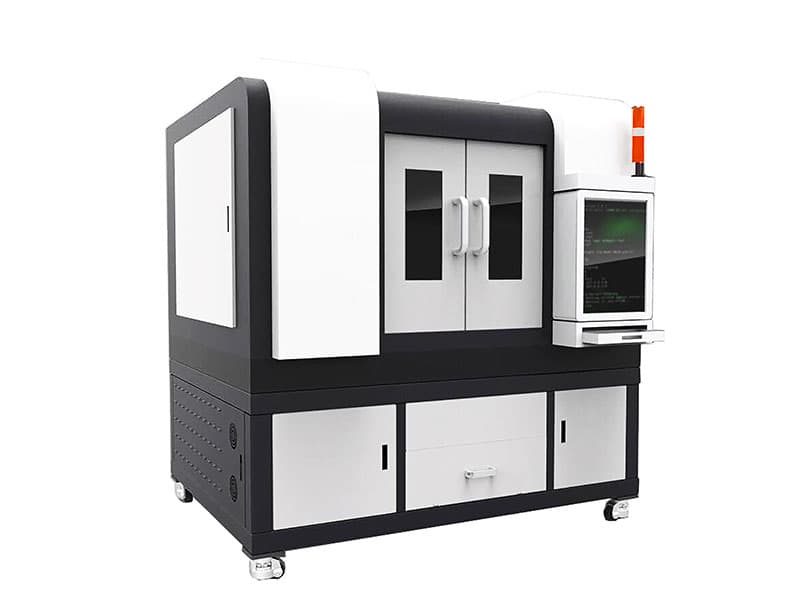

Laser cutting machine is to use the focused high-energy pulse laser with auxiliary blowing to partially melt and vaporize metal workpiece, so as to achieve the purpose of accurate cutting.

The product has high cutting accuracy and is suitable for cutting precision workpiece;

The cutting speed is 60 times faster than that of wire cutting;

The heat-affected zone is small, the workpiece to be processed is not easy to deform, and the cutting seam is smooth and smooth, without subsequent treatment;

It can process multiple beams and multiple stations simultaneously (optional function).

Model features

Scope of application

Suitable for precision instruments, hardware, sheet metal processing, etc.

It is especially suitable for stainless steel, iron plate, aluminum plate, copper plate, diamond saw blade and other materials, and has excellent processing effect for various high hardness and brittle alloys.

Model introduction

Precise cutting machine of precious metal adopts the original double-layer precious metal recovery system.

Imported fiber laser, high configuration cutting head, high precision rotary servo motor, professional laser cutting control software, and automatic following focusing system, which can automatically follow the bending fluctuation of the workpiece to adjust the focus position during cutting to ensure the quality of precision cutting.

Automatic feeding and cutting system and bracelet and ring rotary cutting system are optional.

Model features

Scope of application

18K/24K gold, 925 silver, jewelry metal, precision accessories

Model introduction

The machine adopts high-precision linear motor working platform, with high precision and fast speed;

Select high-precision CCD automatic positioning and automatic correction.

The whole processing process is automatically controlled by computer software, the software interface is real-time feedback, and the processing status is timely understood.

The non-contact processing scheme has no mechanical stress deformation, simple operation, and high cutting accuracy.

Model features

Scope of application

It is suitable for various kinds of laser processing such as metal sheet cutting and punching, such as cutting of hardware, consumer electronic components, various instruments, sheet metal processing industry, etc;

Precise cutting and drilling of various metal materials.

Model introduction

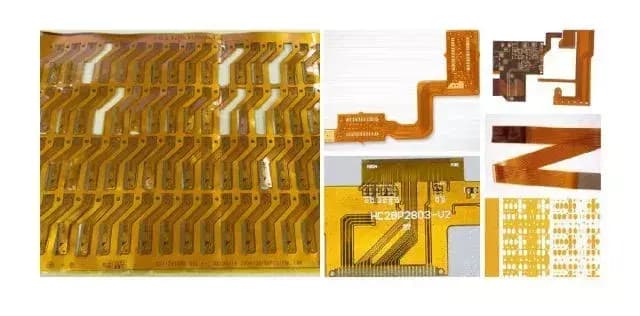

Flexible circuit board laser cutting machine: combines laser technology, visual positioning technology and electronic technology, and adopts high-performance ultraviolet laser.

It has the characteristics of advanced automatic manufacturing such as high beam quality, high peak power, high accuracy, high stability, high efficiency and high flexibility.

It can cut and process all kinds of flexible circuit boards with high precision and high complexity, and can be applied to the processing of auxiliary materials of flexible circuit boards.

Model features

Scope of application

It is applicable to FPC flexible circuit board, flexible circuit board sub-processing, including contour cutting, slotting, opening, FR4, cell membrane window, etc.

It is widely used in circuit board factories, electrical appliances and electricians, electronic manufacturing, printing and other industries.

Model introduction

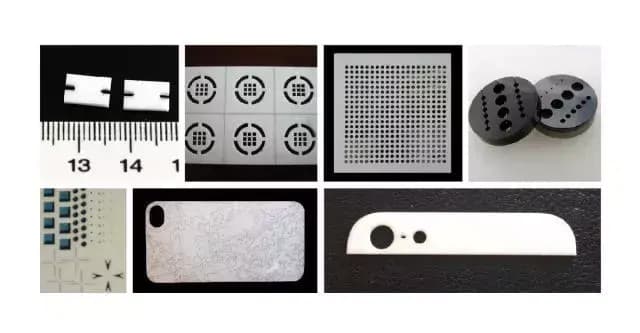

Laser cutting of ceramic substrate and laser drilling are focused by the laser beam emitted by the laser through the lens, and converge into a tiny spot at the focal point.

The workpiece at the focal point is irradiated by a high power density laser spot, which will produce a local high temperature of more than 10000 ° C.

Thus, the material in the vertical direction of the gathering part will vaporize instantaneously, and then the vaporized material will be blown away with auxiliary gas, so that the workpiece will be cut into a very small hole.

With the movement of the CNC machine tool, countless small holes will be connected to form the shape to be cut.

Model features

Good cutting quality: good cutting quality can be obtained due to small laser spot, high energy density and fast cutting speed.

① Narrow slit: the slit of laser cutting is generally 0.10~0.20MM, saving material.

② The perpendicularity of the cutting edge is good, the cutting surface is smooth and free of burrs, and the surface roughness is generally controlled above RA: 12.5.

③ Small heat affected zone: the laser cutting of laser processing is thin, fast and concentrated, so the heat transferred to the cut material is small, and the deformation of the material is also very small.

In some cases, the width of the heat-affected zone is less than 0.05MM.

It can cut a variety of materials, both metal materials and non-metallic materials.

There is no contact between the cutting torch and the workpiece during cutting, and there is no tool wear problem.

Good cutting environment: there is no strong radiation, noise and environmental pollution during cutting, which creates a good working environment for the operator’s health.

Scope of application

Ceramic substrates, ceramic capacitors, ceramic materials for sensitive ceramics, ceramic optical fiber connectors and other functional ceramic products;

Ceramic cutters, ceramic bearings, ceramic sealing rings and ceramic spark plugs required by the machinery industry;

Ceramic roller bar of roller kiln required by building materials industry;

Structural ceramic products such as wear-resistant and corrosion-resistant ceramic parts such as ball valves and cylinder liners required by the petrochemical industry;

Special ceramic materials required by the national defense industry;

Ecological ceramic materials and biomedical ceramic materials needed for environmental protection.

Model introduction

Sapphire is the most basic material besides diamond. Sapphire is fragile and easy to collapse. This material is difficult to be processed in fine processing.

The sub-nanosecond long pulse sapphire ultra-fast precision laser cutting equipment has the advantages of fast cutting speed, high dimensional accuracy, no need to replace consumables, complete functions, simple operation, and stable and reliable performance indicators under continuous working conditions;

Model features

Scope of application

It is mainly used in the precision cutting and drilling of sapphire windows and various brittle and hard materials in the electronic industry;

It can also be used for thin-walled high-reflective metal cutting and marking and etching of non-metallic materials, such as hardware, ceramics, electronic devices, various instruments, plastics, etc.

Model introduction

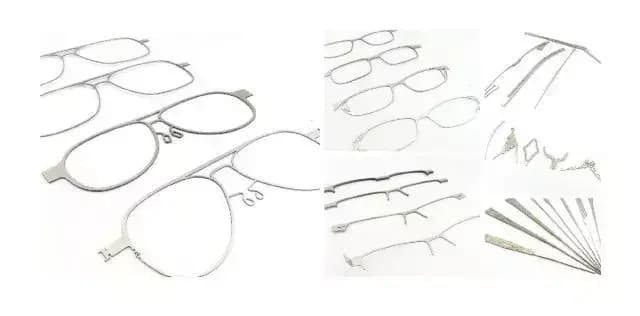

The special laser cutting machine for glasses can cut arbitrary design patterns on the plate, with high speed, high precision, one-time molding, no need for subsequent processing, more than ten times faster than wire cutting, greatly improving the processing efficiency;

Visible layout, close fitting and material saving. It can not only meet the cutting requirements of customers for flat plates, with 3D software, but also meet the cutting requirements of pipe circles and special-shaped materials (square steel, flat iron, channel steel, square tube).

Model features

Scope of application

It is widely used in sheet metal processing, advertising sign word production, mechanical parts, kitchen utensils, metal handicrafts, saw blades, glasses industry, spring blades, hardware and other industries.

It can also be used for cutting carbon steel, stainless steel, aluminum alloy, copper, silver, gold, titanium and other metals.