Imagine cutting through metal as effortlessly as slicing through butter. This is the power of laser perforation. In this article, we’ll explore the two main types: pulse perforation and blasting perforation. By understanding their principles and applications, you can harness these techniques to enhance precision and efficiency in your projects. Ready to discover how these methods can transform your metalworking process? Read on to find out more.

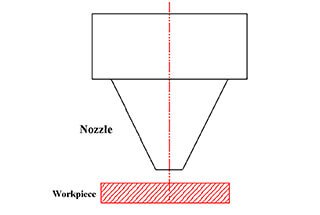

Laser cutting involves the use of a laser beam to heat, melt, and vaporize the material to be cut. The melted material is then blown away with high-pressure gas to create a hole, and the beam continues to move along the material, forming a continuous cutting seam.

For most thermal cutting techniques, with the exception of a few cases that can begin from the edge of the plate, it is necessary to create a small hole on the plate before cutting can commence. The cutting then proceeds from this small hole.

The basic principle of laser perforation is that when a laser beam with a certain amount of energy is directed at the surface of a metal plate, a part of it gets reflected, while the remaining energy is absorbed by the metal. This leads to the melting of the metal and the formation of a molten pool.

The absorption rate of molten metal from the metal surface increases, allowing it to absorb more energy and accelerate the melting process.

Proper control of energy and air pressure can be used to remove the molten metal from the molten pool and continuously deepen it until the metal is penetrated.

In practical applications, perforation is usually divided into two methods: pulse perforation and blasting perforation.

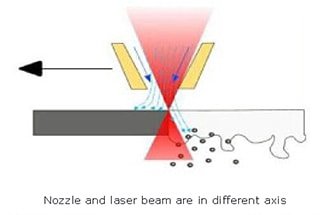

The principle of pulse perforation is to use a pulse laser with high peak power and low duty cycle to irradiate the plate to be cut, melting or vaporizing a small amount of material, which is then discharged from the hole through the joint action of continuous beating and auxiliary gas, penetrating the plate step by step.

The laser irradiation time is intermittent, and the average energy used is relatively low, resulting in less heat absorbed by the processed materials. As a result, there is less residual heat and residue around the perforation, and the through hole is small and regular, with minimal impact on the initial cutting.

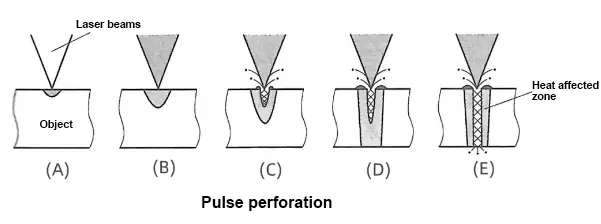

The process is shown in the following figure: after the laser beam irradiates the workpiece, the material surface is first heated (as shown in A). With gradual deepening of heating, perforation occurs (as shown in BCD) until penetration is achieved (as shown in E).

The entire perforation process is accomplished gradually, step by step, until penetration is achieved. Therefore, the perforation time of this method is relatively long. However, the obtained holes are smaller and have less thermal impact on the surrounding areas.

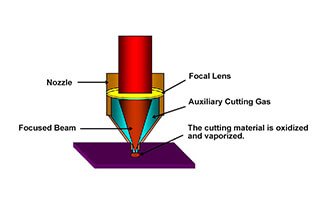

The principle of blasting perforation involves irradiating the target object with a continuous wave laser beam of a certain energy, causing it to absorb a significant amount of energy and melt, thereby forming a pit. Then, with the aid of auxiliary gas, the molten material is removed to create a hole, thus achieving the objective of rapid penetration.

However, due to the continuous laser irradiation, the hole diameter of the blasting perforation is relatively large, and the splash is severe. Thus, it is not well-suited for cutting applications that require high accuracy.

The entire process is shown in the figure above: set the focus higher than the material’s surface and increase the aperture of the perforation for quick heating.

While this method of perforation produces a considerable amount of molten metal that sprays onto the surface of the processed material, it can significantly reduce perforation time.

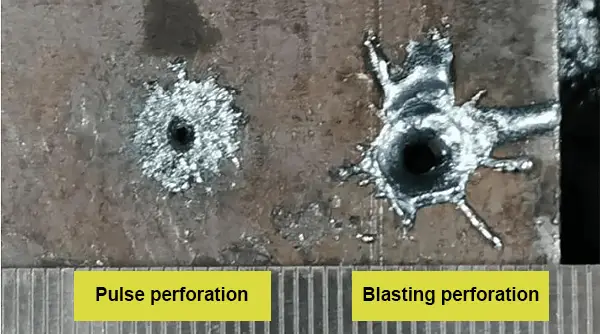

The actual effects of the two perforation methods are displayed in the figure below.

In most instances, the quality of pulse perforation is superior to that of blasting perforation.