Lasers are a fascinating and diverse tool in modern technology. Did you know there are over ten different types of lasers, each with unique applications? From medical procedures to cutting-edge communication systems, these lasers are classified based on their working mode, wavelength, and doping materials. In this article, we’ll explore the distinctive features and uses of various lasers, providing insights into how each type can benefit different industries. Get ready to uncover how these beams of light are transforming our world!

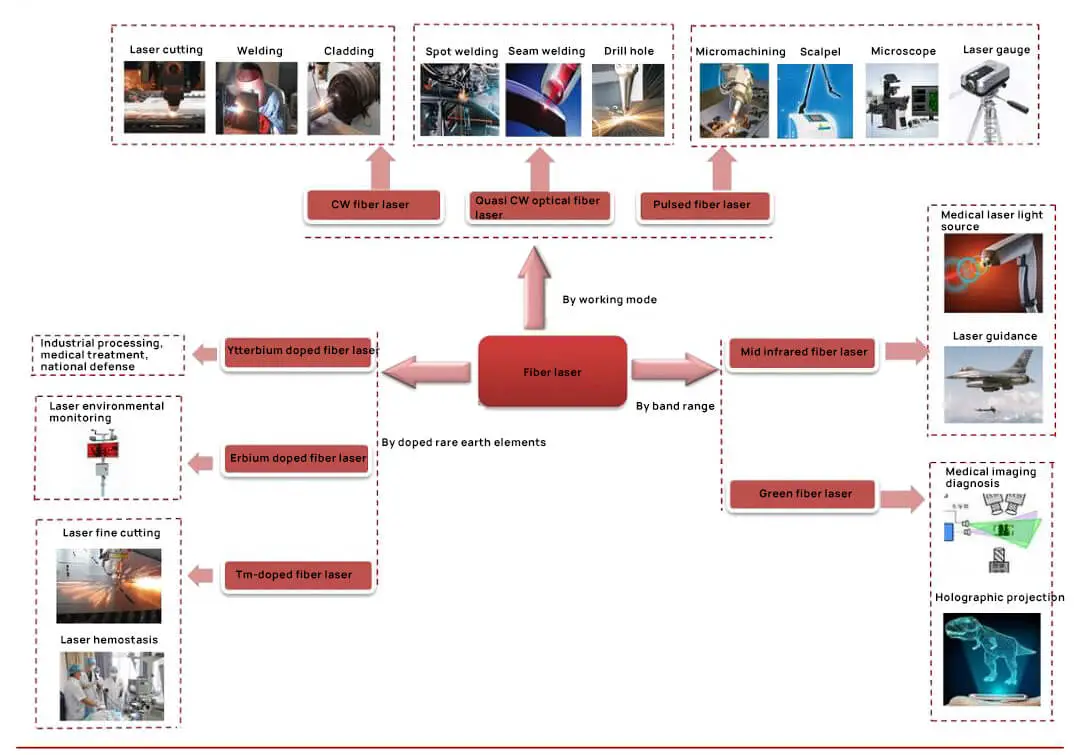

There are many classification methods for fiber lasers, among which the more common ones are classified by working mode, band range and medium doped rare earth elements.

Lasers are usually named according to one or two of these three categories.

For example, the YLM-QCW series of IPG is translated into quasi continuous ytterbium doped fiber lasers.

Fiber lasers have a wide range of applications.

Different subdivided lasers have different characteristics and suitable application fields.

For example, the mid infrared band is safe for human eyes and can be strongly absorbed in water. It is an ideal medical laser source;

Erbium doped fiber can open the window of optical fiber communication because of its suitable wavelength, which is widely used in the field of optical fiber communication;

Because of its visibility, green laser is essential in entertainment and projection.

Fig. 1 Application diagram of laser subdivision and classification corresponding to relevant industries

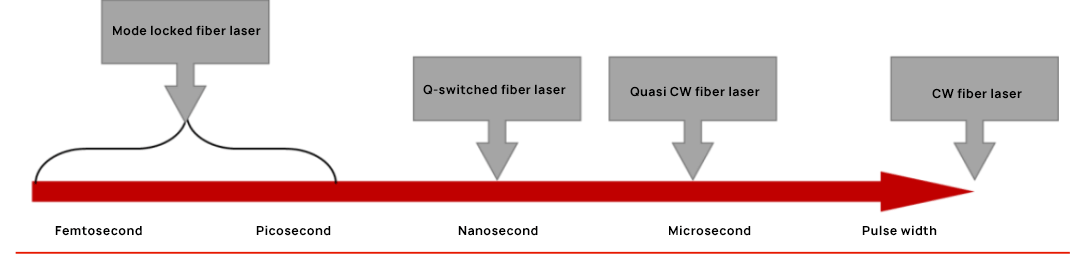

According to the working mode, fiber lasers can be divided into mode-locked fiber lasers, Q-switched fiber lasers, quasi continuous fiber lasers and continuous fiber lasers.

The technical approaches to realize pulsed fiber laser mainly include Q-switching technology, mode locking technology and seed source main oscillation power amplification (MOPA) technology.

Mode locking technology can achieve femtosecond or picosecond pulse output, and the peak power of the pulse is high, generally in the order of megawatts, but the average power of the output pulse is low;

Fig. 2 Working mode and pulse width of fiber laser

The laser output of CW laser is continuous, which is widely used in the fields of laser cutting, welding and cladding.

The laser pump source continuously provides energy and produces laser output for a long time, so as to obtain continuous laser.

The number of particles in each energy level and the radiation field in the cavity have a stable distribution.

Its working characteristic is that the excitation of working material and corresponding laser output can be carried out continuously in a long time range.

The fiber laser excited by continuous light source is a continuous fiber laser.

Compared with other types of lasers, continuous fiber lasers can achieve relatively high power. IPG has produced a single-mode 20000 watt continuous fiber laser, which is often used in the fields of laser cutting, welding and cladding.

Quasi CW laser can work in continuous and high peak power pulse mode at the same time.

According to the official website of IPG, the peak power and average power of traditional CW laser are always the same in CW and CW / modulation mode, while the peak power of quasi CW laser in pulse mode is 10 times higher than the average power.

Therefore, microsecond and millisecond pulses with high energy can be generated at repetition frequencies from tens of hertz to thousands of Hertz, and average power and peak power of several kilowatts can be realized.

Quasi CW fiber laser will provide higher electro-optic conversion efficiency and significantly improve processing speed and production efficiency.

Compared with other laser systems, quasi CW fiber laser can provide ten times of photoelectric conversion efficiency increment, and can achieve more than 30% electro-optic conversion efficiency under passive cooling scheme.

Due to its high average power and pulse repetition rate, its processing speed is 3-4 times that of most lasers.

The significantly reduced power cost, no consumables and spare parts, low maintenance demand and no preheating time requirements will lead to cost optimization.

Pulsed fiber lasers are divided into Q-switched fiber lasers and mode-locked fiber lasers.

Q-switching technology is to compress the laser energy in a short time interval to form a laser output with high peak power and narrow pulse width.

The principle of Q-switching is to add a loss adjustable device into the laser.

In most time areas, the loss of the laser is very large and there is almost no light output.

In a short time, reduce the loss of the device, so as to make the laser output a short pulse with high intensity.

Q-switch is the core device of Q-switched technology, which can realize Q-switched fiber laser in an active or passive way.

Q-switched pulse fiber laser has the characteristics of high peak power, high single pulse energy and optional spot diameter.

It is widely used in the marking, precision processing, graphic marking, deep engraving, sheet precision cutting, drilling and other fields of non-metallic, gold, silver, copper, aluminum and non-high reflection material stainless steel.

In terms of marking application, compared with CO2 laser, the cost is lower and the performance is more stable.

Mode locked pulse fiber laser generates ultrashort pulses by active mode locking or passive mode locking.

Limited by the response time of the modulator, the pulse width generated by active mode locking is wide, generally in the order of picosecond;

Passive mode locking uses passive mode locking devices with short response time and can produce femtosecond pulses.

The brief principle of mode locking is to take appropriate measures to make the mutually independent longitudinal modes in the resonator have a certain relationship in phase.

Even if the phase difference of adjacent longitudinal modes is a constant, the laser will output pulses with extremely narrow pulse width and high peak power.

Mode locked pulse laser has the advantages of excellent beam quality, ultra short pulse width and high pulse energy.

It is suitable for micromachining of various materials, including metal, glass, ceramics, silicon and plastics.

In the medical field, mode-locked lasers are also used in laser scalpels or ophthalmic surgery.

For example, photochemical effects are also used for some skin care.

Due to the characteristics of short pulse and high peak power, mode-locked lasers are widely used in various methods of imaging, microscopy and spectroscopy.

They are also used in the fields of electro-optic sampling measurement, distance measurement, frequency measurement and timing on integrated electronic circuits.

The laser directly output by fiber laser is mostly near-infrared light with wavelength between 960nm-2.05μm.

According to the order of wavelength from short to long, the laser category covers all kinds of lasers from X-ray to far infrared, with wavelengths ranging from 0.001 nm to 1000 microns.

Among them, the laser directly output by fiber laser is mainly in the near-infrared part.

However, in order to meet the needs of different applications, fiber lasers can output visible light through frequency doubling, and the main application is green light;

Medium infrared light can be output by doping fluoride in the optical fiber.

Fig.3 List of different optical fiber wavelengths

Table 1. Lasers by wavelength

| Name | Wavelength range | Main products |

| Far infrared laser | 30 ~ 1000 microns | Molecular gas laser, free electron laser |

| Mid infrared laser | 3 ~ 30 microns | CO2 molecular gas laser |

| Near infrared laser | 0.76 ~ 3 microns | Fiber laser, CaAs semiconductor diode laser, partial gas laser |

| Visible laserNear infrared laser | 380 nm ~ 780 nm | Ruby laser, He Ne laser, argon ion laser, krypton ion laser |

| Near ultraviolet laser | 200 nm ≈ 400 nm | Nitrogen molecular laser, xenon fluoride excimer laser, krypton fluoride (KrF) excimer laser |

| Vacuum ultraviolet laser | 5 nm ~ 200 nm | Hydrogen (H) excimer laser, Xenon (Xe) excimer laser |

| X-ray laser | 0.001 nm ~ 5 nm |

The wavelength of mid infrared laser is mainly about 23 microns to 3.9 microns, which needs fluoride glass fiber medium doped with rare earth ions to excite.

From the fluorescence spectrum generated by the infrared transition of fiber laser in the figure below, it can be seen that holmium doped ion (Ho3 +) and erbium-doped ion (Er3 +) can be directly generated by being excited under appropriate medium conditions.

Fluoride glass fiber laser has high efficiency and output power in the band of 2.3 ~ 3.5μm, while the wavelength is more than 3.5μm.

There are very few materials that can meet the low phonon energy required for optical fiber transmission and rare earth ion transition radiation.

Single doped Ho3 + fluoride fiber laser produces 3.9μm band laser at low temperature, which is the longest wavelength of direct output at present.

Fig.4 Relationship between maximum output power and emission wavelength of different rare earth ion fiber lasers

Due to its wavelength characteristics, mid infrared laser can open the atmospheric window and is widely used in laser guidance, positioning and measurement.

In military affairs, the application of directional energy of laser and long-distance transmission through atmospheric transmission window requires strong beam energy.

In the infrared missile countermeasure, the mid infrared laser can obtain the atmospheric transmission window of 3 ~ 5μm band.

The medium infrared fiber laser with several kilowatts of single-mode output may be further widely used in national defense war platforms such as anti cruise missile, rocket guidance and UAV airspace reconnaissance.

Mid infrared fiber laser has been widely used in medical field because of its strong directivity and human eye safety.

The band of mid infrared laser is safe for human eyes and can be strongly absorbed in water.

Due to the strong directionality of laser, the depth of tissue penetration can be shallow and the area of physical damage can be very small in laser surgery, so as to achieve high precision.

In modern medicine, mid infrared laser in medical application mainly uses photothermal effect to treat or ablate diseased tissues.

It has been widely used in orthopedics, gastroenterology and urology.

It has become an ideal medical laser light source for ablating and cutting urinary tissues, steaming and removing failed organs.

In the process of cutting tissue rich in lipid, bone and protein, the use of mid infrared laser will cause minor damage.

Fiber laser can obtain green light output by frequency doubling.

Although the frequency doubled green fiber laser is not a green fiber laser in the strict sense, because its activation medium does not directly release the 532 nm laser beam, this type of fiber laser provides a narrow range of pulse duration and repetition frequency up to 600kHz.

The laser source with high spectral brightness promotes efficient conversion, realizing 84% conversion efficiency and more than 20% electro-optic conversion efficiency.

It is feasible to upgrade to high power at 355 and 266 nm.

Green laser is widely used in printing, medical treatment, data storage, military, biology and other fields.

For example, IPG’s green fiber laser can be used in particle imaging, velocity measurement / flow visualization, image diagnosis and surgery, optical capture / optical tweezers, solar cell manufacturing, manufacturing inspection & quality control, holography and interferometry, entertainment and projection, etc.

The fiber laser mainly uses the fiber doped with rare earth elements as the gain medium, and different rare earth elements correspond to different working wavelengths.

Doped fiber is to add impurities, such as rare earth ions, into the fiber core, which will lead to fiber modification and show laser effect.

The working principle is that the pump light is first coupled into the gain medium doped with rare earth ions through the coupling system, and then the rare earth ions in the doped core absorb the pump photon energy and produce energy level transition.

For example, rare earth ions such as erbium (Er3 +), praseodymium (Pr3 +), thulium (Tm3 +), neodymium (Nd3 +) and ytterbium (Yb3 +) can be used as dopants to make optical fibers, and then made into doped fiber amplifier (XDFA) and fiber laser (XDFL).

Different rare earth elements work in different wavelength ranges, but they are in the near-infrared range.

Fig. 5 Operating wavelengths of rare earth ions in commonly doped cores.

Ytterbium doped fiber laser has developed rapidly because of its high stability, good beam quality and high slope efficiency.

Ytterbium doped fiber has many advantages.

The fiber laser developed by ytterbium doped fiber has high slope efficiency and optical optical conversion efficiency, and can obtain high-power laser output in 1m band.

Therefore, it has attracted extensive attention and developed rapidly.

It has become the main guiding force in the laser industry and has good application prospects in industrial processing, medical treatment, national defense and other fields.

Most laser products of Ruike laser use ytterbium doped fiber.

Table 2. Comparison of main mirror doped optical fiber products of domestic and foreign companies

| Company | Adopt technology | Product status / price | Core diameter( μ m) | Cladding diameter | Core numerical aperture NA |

| Nufern | Super large mode field mirror doped fiber (three cladding) | SellUSD 1030 / M | 290.0±20.0 | 400±18 | 0.110±0.010 |

| NIight | Double clad ytterbium doped fiber with large mode field | Sell | 20.0±1.5 | 400±10.0 | 0.070±0.005 |

| Changfei optical fiber | Double clad ytterbium fiber with large mode field | Sell | 20.0±2.0 | 400±15.0 | 0.06±0.01 |

| Beacon Technology | Double clad ytterbium doped fiber | Sell | 20.0±2.0 | 400±5.0 | 0.075±0.005 |

| Wuhan Ruixin | Double clad ytterbium doped fiber with large mode field | Sell | 20.0±1.5 | 400.0±10.0 | 0.065±0.005 |

Ytterbium doped fiber lasers are mainly used in continuous lasers and pulse Q-switched lasers.

Due to the simple energy level structure of ytterbium ion and small particle loss, the laser has high conversion efficiency and low thermal effect under high power operation, and the gain bandwidth is large (975nm ~ 1200nm).

At the same time, the upper level life of ytterbium ion is relatively long, usually about 1 millisecond.

These factors are conducive to Q-switching technology.

Therefore, ultrashort pulse output has been realized in pulse laser.

In the aspect of CW laser, the output power of ytterbium doped fiber laser has reached the order of 10000 watts.

Erbium doped fiber laser has the characteristics of safe wavelength and ultra-high pulse energy. Erbium doped fiber laser can realize single-mode operation, with extremely narrow linewidth, good monochromaticity and stability.

Erbium ion has a wide gain bandwidth, which can aggravate the multimode oscillation in the laser cavity, so as to realize ultrashort pulse laser.

Because of its unique characteristics for human eye safety (“human eye safety” refers to that the laser with the wavelength of 1.5 μm is significantly lower than the threshold of human eye damage), it has a wide range of practical applications in the fields of free space optical communication, lidar, environmental detection, workpiece calibration and industrial processing.

Erbium doped fiber has been widely used in the field of optical fiber communication because of its suitable wavelength.

Because erbium-doped fiber has high gain at 1550nm wavelength, its gain spectral profile of about 40nm corresponds to the best window of low loss in optical fiber communication, which has potential application value.

Thulium doped fiber laser has the characteristics of low threshold, high efficiency and good beam quality.

Thulium doped fiber laser is the research hotspot of fiber laser in the field of safe wavelength for human eyes, and thulium doped fiber laser can work in S-band (150 – 75mm).

It plays a very important role in developing the frequency space of potential communication resources and improving the capacity of optical fiber communication system.

Q-switched and continuous thulium doped fiber lasers have developed to higher average power in the past few years.

Now a certain number of suppliers can provide commercial pulse lasers with average power of 10W.

Thulium doped fiber laser is widely used in laser medical treatment, lidar, space light remote sensing and other fields.

The output wavelength of thulium doped fiber laser is about 2μm.

The strong absorption band of liquid water is about 1950 nm, which is close to the wavelength of standard Thulium fiber laser, so the absorption characteristics are significantly improved.

Water generally exists in many organic and inorganic compounds, which means that a large number of materials improve the absorption characteristics in the 2μm spectral range.

Therefore, thulium doped fiber laser is considered as an ideal light source for medicine, eye safety, ultrafast optics, short-range remote sensing and biology, and has a good development prospect.

At the same time, in the field of medicine, thulium doped fiber laser also has many applications, including accelerated vaporization, ultra-fine cutting technology, and coagulation hemostasis in medicine.

High power thulium doped fiber laser can not only be used for the safe wavelength of human eyes and lidar light source, but also be used as the pump source of solid-state crystal laser to further realize the output of infrared laser with longer wavelength.

Fig. 6 Absorption characteristics of liquid water at different wavelengths

Fiber laser has outstanding performance advantages and obvious substitution effect.

Carbon dioxide laser is a kind of molecular laser.

It is one of the common high-power CW lasers.

The main material is carbon dioxide molecule.

The main structure of CO2 laser includes laser tube, optical resonator, power supply and pump.

The main feature is that the output power is large and continuous work can be realized, but the structure is complex, the volume is large and the maintenance is difficult.

Fig. 7 Carbon dioxide laser structure

Particle number inversion is the key to the luminescence of carbon dioxide laser.

The working substances in the carbon dioxide laser include carbon dioxide, nitrogen and helium. After the DC power supply is input, the nitrogen molecules in the mixed gas will be excited by electron impact.

When the excited nitrogen molecules collide with carbon dioxide molecules, they will transfer energy to carbon dioxide molecules, so that the carbon dioxide molecules transition from low-energy level to high-energy level to form particle number inversion and emit laser.

Fig.8 Schematic diagram of emission process of carbon dioxide laser

Optical fiber and carbon dioxide laser have their own advantages, so different tools should be selected according to different needs.

From the cutting technology which is widely used at present, fiber laser and CO2 laser have their own advantages and disadvantages in the face of specific application requirements.

They can not completely replace each other, but need to complement and coexist.

In terms of processing material types, due to the absorption effect, fiber lasers are not suitable for cutting non-metallic materials, while conventional CO2 lasers are not suitable for cutting high reflectivity materials such as copper and aluminum;

In terms of cutting speed, CO2 has advantages in the sheet with thickness > 6mm, while the fiber laser cuts the sheet faster;

The workpiece needs to be penetrated before laser cutting, and the perforation speed of CO2 is significantly faster than that of fiber laser;

In terms of cutting section quality, CO2 laser is better than fiber laser as a whole.

Table 3. Comparison between fiber laser and carbon dioxide laser

| Fiber laser | Carbon dioxide laser | |

| Cutting material | Non metallic materials cannot be cut | High reflective materials have poor adaptability |

| Cutting speed | Obvious advantages below 3mm | Carbon dioxide has an advantage when it is greater than 6mm. |

| Penetration efficiency | The speed is relatively slow | The greater the thickness, the more obvious the advantage |

| Section quality | Slightly worse | Better roughness and verticality |

Fiber laser has higher light conversion efficiency and lower cost.

According to the calculation, the use cost of fiber laser is 23.4 yuan / hour, the use cost of carbon dioxide laser is 39.1 yuan / hour, among which the power cost of fiber laser is 7 yuan / hour, the water cooling cost is 8.4 yuan / hour, and other costs are 8 yuan / hour;

The power cost of carbon dioxide laser is 21 yuan / hour, the water cooling cost is 12.6 yuan / hour, and other costs are 5.5 yuan / hour.

Table 4. Cost comparison between fiber laser and carbon dioxide laser

| Fiber laser | Carbon dioxide laser | |

| Power (kw) | 3 | 3 |

| Light conversion efficiency | 30% | 10% |

| Power consumption (kw) | 10 | 30 |

| Electricity price (yuan / kWh) | 1 | 1 |

| Load duration | 70% | 70% |

| Power cost (yuan / hour) | 7 | 21 |

| Water cooling equipment power (kw) | 12 | 18 |

| Electricity price (yuan / kWh) | 1 | 1 |

| Load duration | 70% | 70% |

| Water cooling cost (yuan / hour) | 8.4 | 12.6 |

| Consumables cost (yuan / hour) | 3 | 2.5 |

| Module consumption cost (yuan / hour) | 5 | |

| Media cost (yuan / hour) | 1 | |

| Conventional point solution (yuan / hour) | 2 | |

| Other costs (yuan / hour) | 8 | 5.5 |

| Use cost (yuan / hour) | 23.4 | 39.1 |

YAG laser generally refers to Nd. YAG laser (rubidium doped yttrium aluminum garnet crystal) belongs to solid-state laser.

The content of rubidium atoms in the crystal is 0.6 ~ 1.1%, which can produce pulsed laser or continuous laser, and the emitted light is infrared with a wavelength of 1.064μm.

Nd. YAG laser often uses krypton or xenon lamp as pump lamp, because only a few specific wavelength pump light will be absorbed by Nd ions, and most of the energy will be converted into heat energy.

Generally, the energy conversion efficiency of YAG laser is low.

Fig. 9 Simple structure of Nd: YAG laser

With the development of fiber laser, YAG laser may be replaced gradually.

YAG laser is mainly used in cutting and welding process in industry, but with the development of fiber laser, YAG laser may be gradually replaced by fiber laser.

In the cutting field, YAG laser has low purchase cost and can cut high reflective materials, but it has low processing power, high energy consumption ratio and slow cutting speed, while fiber laser has high power efficiency, no adjustment and maintenance;

In the field of welding, after the emergence of quasi continuous fiber laser, it began to quickly replace pulsed Nd: YAG laser.

Compared with YAG laser, quasi CW fiber laser can provide pulse energy from several joules to tens of joules under the pulse width of microsecond to millisecond.

Its high average power and pulse repetition frequency significantly improve the processing speed and production efficiency.

It is equivalent to having the advantages of drilling and welding of YAG laser and the cutting ability of CO2 laser at the same time.

It has a wider range of applications.

Table 5. YAG laser vs. fiber laser

| Laser | YAG laser | Fiber laser |

| Main composition | Pump lamp, Nd: YAG, resonant system | Semiconductor pump, optical fiber resonance system, transmission system |

| wall-plug efficiency | 4%~5% | About 30% |

| Machining angle | Low purchase cost, capable of cutting highly reflective materials | The cutting power is high, the efficiency is fast, and the high power can be realized in a small package |

| Cost perspective | Mature technology is relatively cheap | With the gradual development of technology, the power consumption is small |

| Maintenance angle | No optical lens, adjustment and maintenance free |

Semiconductor lasers, also known as laser diodes, use semiconductor materials as working materials.

Common working materials include gallium arsenide and cadmium sulfide.

There are three excitation modes: electric injection, electron beam excitation and optical pumping.

The main advantages of semiconductor lasers are small volume, low efficiency and high energy consumption.

They are widely used in laser communication, laser therapy and other fields.

In addition, semiconductor lasers are usually used as the pump source of fiber lasers.

Taking the electric injection semiconductor laser as an example, GaAS (gallium arsenide), InAS (indium arsenide), Insb (indium antimonide) and other materials are usually added to the semiconductor material to make a semiconductor surface junction diode.

When a large enough current is injected into the diode, the electrons (negatively charged) and holes (positively charged) in the middle active region will spontaneously compound and release the excess energy in the form of photons.

Then, the laser is formed after screening and amplification of the resonator.

Fig. 10 Schematic diagram of simple structure of semiconductor laser

Direct semiconductor laser has obvious characteristics and a wide range of downstream applications.

Direct semiconductor laser has compact structure, low maintenance cost and electro-optic conversion efficiency of up to 47%. It is mainly used in industry for welding and cladding.

Low power semiconductor lasers are mainly used in plastic welding and tin welding.

Through optical fiber output welding, non-contact remote operation is realized, which is convenient for integration with automatic production line;

Kilowatt class direct semiconductor can be used for cladding and hardware welding.

It has the characteristics of large light spot and high electro-optic conversion rate.

In the field outside industry, semiconductor lasers are also widely used in military, information, medical and life sciences.

Table 6. Direct semiconductor laser applications

| Field | Subdivision application | Application scenario |

| Industry | Welding | Plastic processing, hardware welding |

| Cladding | Steel, aerospace | |

| Military | Radar | Lidar system, automatic identification and correction system |

| Guidance and Fuze | Laser beam guidance, laser aiming and warning aiming | |

| Information | Signal communication | Optical fiber communication light source |

| Information research | Spectral analysis, optical computing and optical neural network | |

| Medical care | Clinical operation | Soft tissue resection and tissue Union |

| Life science research | Optical tweezers |

Semiconductor lasers have potential for processing applications, but they are limited by technical defects.

The research shows that direct semiconductor laser has strong material processing application potential, and has better cutting speed and cutting quality than fiber laser and carbon dioxide laser.

However, the biggest disadvantage of semiconductor lasers is their low beam quality at high laser power.

At present, industrial semiconductor lasers are limited to a few processing, such as electroplating, brazing and more and more high-power welding.

Therefore, semiconductor lasers are unlikely to revolutionize the whole field of material processing or replace other light sources in the next few years.

Table 7. Comparison of cutting processes of direct semiconductor laser, fiber laser and carbon dioxide laser

| Direct semiconductor laser | Fiber laser | Carbon dioxide laser | |

| Common band( μ m) | 0.97 | 1.07 | 10.6 |

| Electro optic conversion rate | 47% | 30% | 10% |

| Metal absorptivity | 0.97 | 1.07 | 10.6 |

| Sheet cutting speed | 47% | 30% | 10% |

| Maximum cutting thickness (mm) | 15 | 12 | 25 |

| Cutting quality (above 4mm) | higher | higher | Lower |

| Output beam quality | Fastest | Faster | Slowest |

According to the above analysis, we believe that compared with CO2 laser and YAG laser, fiber laser has obvious cost and application advantages, or will be gradually replaced.

At the same time, semiconductor lasers are still limited by the technical bottleneck.

At present, they have limitations and are unlikely to replace other light sources in the next few years.

Therefore, there is a wide space for fiber laser permeability improvement.