Have you ever wondered how different lathe cutting tools can transform a simple piece of metal into a precision-crafted component? This article breaks down the ten types of lathe cutting tools, exploring their unique purposes and materials. By reading further, you’ll learn how each tool, from cylindrical turning tools to diamond blades, plays a crucial role in metalworking. Get ready to enhance your machining knowledge and discover which tools are essential for your next project.

Turning tools are essential in machining operations and can be classified based on their purpose and structure. Below is a detailed classification:

Cylindrical turning tools are categorized according to their main deflection angles, each serving specific machining purposes:

Grooving tools are designed for creating grooves and cutting operations:

External thread turning tool

Internal thread turning tool

Thread turning tools are specialized for threading operations and are divided into two main types:

Inner hole turning tools are specifically designed for internal hole processing.

Turning tools can also be classified based on their structural design:

High-speed steel (HSS) tools are made from a type of tool steel that retains its hardness at high temperatures, allowing it to cut faster than high-carbon steel. These tools can be continuously polished, making them suitable for general-purpose rough and semi-finish machining. HSS tools are known for their toughness and resistance to chipping, which makes them ideal for applications where tool breakage is a concern.

Cemented carbide cutting tools are composed of fine particles of carbide cemented into a composite by a binder metal. These tools are highly suitable for cutting a wide range of materials, including:

Additionally, cemented carbide tools can handle more challenging materials such as:

Their high hardness and wear resistance make them ideal for high-speed cutting and heavy-duty machining operations.

Diamond tools have blades embedded with diamond, the hardest known material. They offer several advantages:

These properties make diamond tools suitable for precision processing of brittle and hard non-metallic materials, such as:

Other advanced materials used in cutting tools include cubic boron nitride (CBN) and ceramic cutting tools. These materials are being developed for rough machining and intermittent cutting of high-hardness alloy cast iron. CBN tools are particularly effective for machining hardened steels and superalloys, while ceramic tools are known for their high-temperature stability and wear resistance.

The turning tool tip must be at the same height as the rotation center of the workpiece. Common methods to achieve this include:

The length of the turning tool extending out of the tool holder should be appropriate. Generally, the extension should be 1-1.5 times the thickness of the tool bar. Excessive extension can reduce the rigidity of the tool bar, leading to vibrations during cutting.

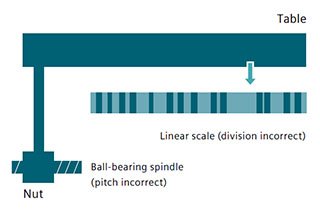

The sizing block of the NC lathe’s turning tool should be flat, with a smaller number indicating better flatness. The sizing block should be aligned with the tool holder to prevent vibration.

The NC lathe’s turning tool should be secured to the tool holder with a minimum of two screws. These screws should be tightened sequentially with appropriate force to ensure stability.

The centerline of the NC lathe’s turning tool bar should be perpendicular to the feed direction. Misalignment can alter the values of the main and auxiliary deflection angles, affecting the machining accuracy. Different NC machine tools may have varying loading and unloading methods, so it is essential to follow the specific guidelines for each machine.

By adhering to these mounting requirements, the performance and accuracy of the turning tools can be optimized, leading to better machining results.