Have you ever wondered what powers the machinery we rely on daily? From steam turbines to electric motors, rotating machinery plays a crucial role in various industries. This blog post explores the different types of rotating machinery, including their components and functions. By the end, you’ll gain a clear understanding of how these machines operate and their significance in our world. Dive in to learn about the fascinating mechanisms that keep our modern world turning!

The majority of machines incorporate rotating components.

Rotating machinery refers to those machines whose primary function is fulfilled through rotational motion, particularly those machines in which the main components rotate at high speeds.

The types of rotating machinery are diverse and include steam turbines, gas turbines, centrifugal compressors, generators, pumps, water turbines, fans, and electric motors.

The principal components of these machines consist of rotors, bearing systems, stators, and unit casings, as well as couplings.

The rotational speed of these machines can range from a few dozen to several hundred thousand revolutions per minute. A few examples of typical rotating machinery are described below.

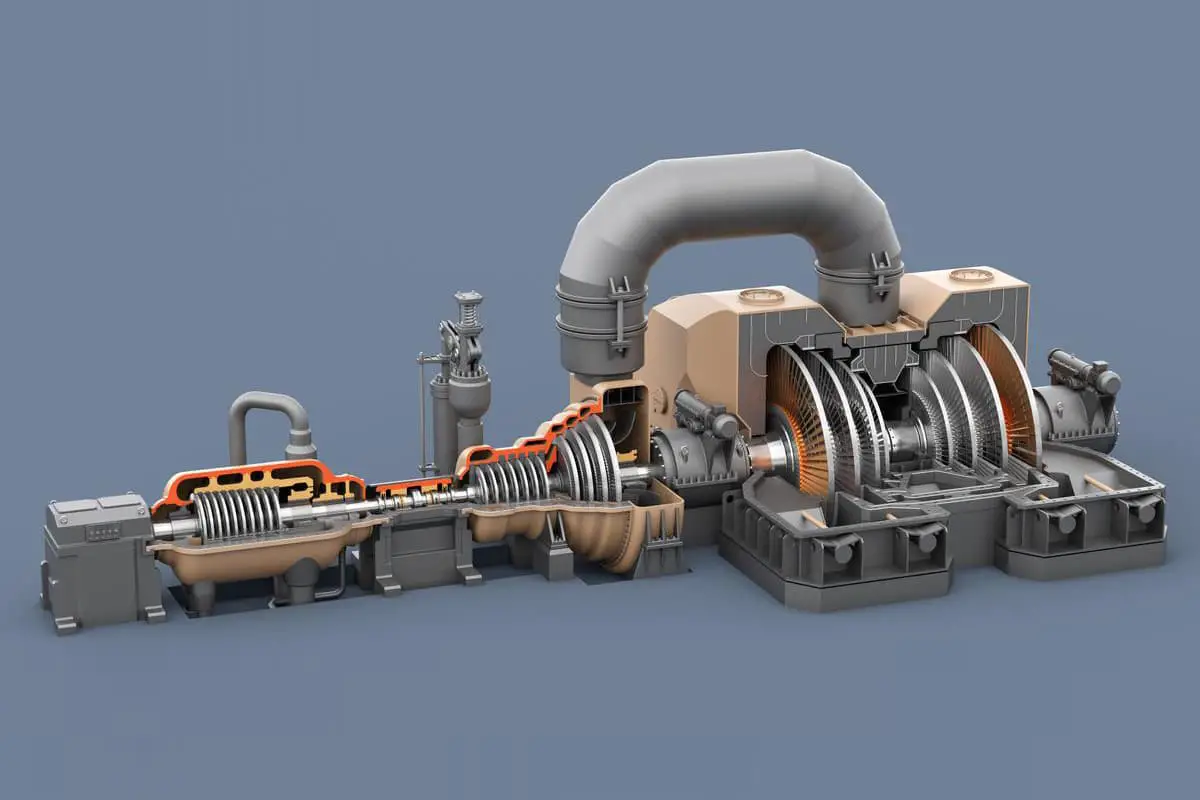

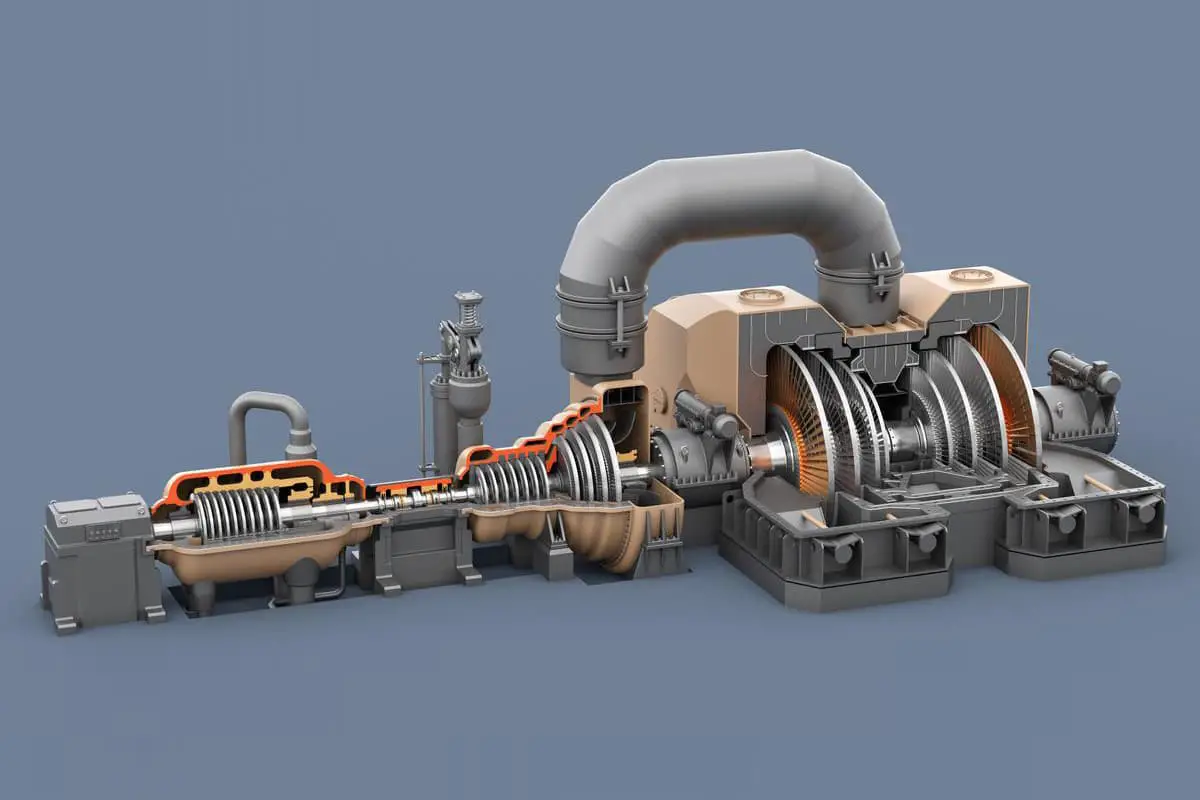

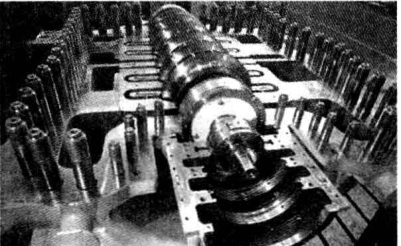

A steam turbine is a rotating power machine that converts the energy of steam into mechanical work, also known as a steam rotor.

It is primarily used as a prime mover for power generation, but can also directly drive various pumps, fans, compressors, and ship propellers.

Additionally, the exhaust or intermediate extraction of a steam turbine can be utilized to meet heating needs in both manufacturing and domestic settings.

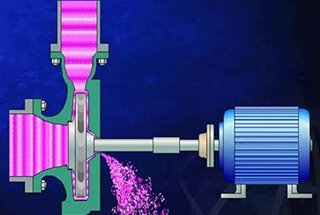

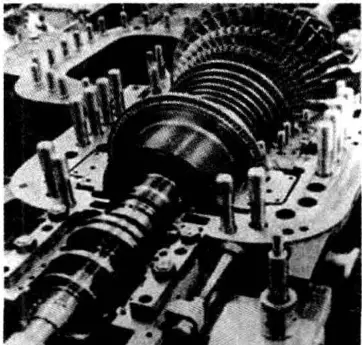

A centrifugal compressor works by transferring energy to a gas through a rotor, thus boosting its pressure.

It can consist of a single or multiple stages. This type of compressor falls under the category of rotary blade compressors, also known as turbo compressors.

Within the centrifugal compressor, the high-speed rotation of the rotor exerts a centrifugal force on the gas, and the expansion in the diffuser channel further increases the gas pressure.

An electric generator is a mechanical device that converts various forms of energy into electrical energy.

Originating during the Second Industrial Revolution, it was first developed by German engineer Siemens in 1866.

Powered by water turbines, steam turbines, diesel engines, or other mechanical devices, generators transform energy generated from water flow, air flow, fuel combustion, or nuclear fission into mechanical energy.

This mechanical energy is then converted into electrical energy by the generator. Generators have a wide range of applications in industrial and agricultural production, defense, technology, and everyday life.

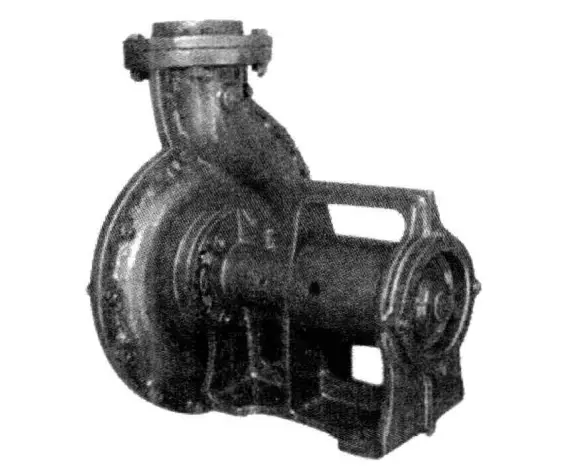

A water pump is a mechanical device designed to transport or pressurize liquids.

It transfers the mechanical energy of the prime mover or other external energy sources to the liquid, enhancing its energy.

It is primarily used for conveying various liquids, including water, oil, acid-base solutions, emulsions, suspensions, and liquid metals.

The pump can also handle mixtures of liquids and gases, as well as liquids containing suspended solids.

A fan is a mechanical device that relies on the input of mechanical energy to increase gas pressure and expel gas.

It is a type of driven fluid machinery, with an exhaust pressure less than 1.5×105Pa. Fans are widely used for ventilation, dust extraction, and cooling in factories, mines, tunnels, cooling towers, vehicles, ships, and buildings.

They are also used for ventilation and air drafting in boilers and industrial furnaces, for cooling and ventilation in air conditioning devices and household appliances, for grain drying and selection, as well as for wind tunnel airflow and the inflation and propulsion of hovercrafts.

The electric motor is a device that converts electrical energy into mechanical energy. It is designed based on the phenomenon of an electrified coil rotating under the force within a magnetic field.

Depending on the power source used, motors are categorized into direct current motors and alternating current motors.

Most motors in power systems are alternating current motors, which can either be synchronous or asynchronous. The electric motor primarily consists of a stator and a rotor.

The direction of the force exerted on the electrified wire in the magnetic field is related to the direction of the current and the magnetic field lines.

The operating principle of an electric motor is the force exerted by the magnetic field on the current, causing the motor to rotate.

The primary function of rotational machinery is executed by its rotating components, with the rotor being the most critical element.

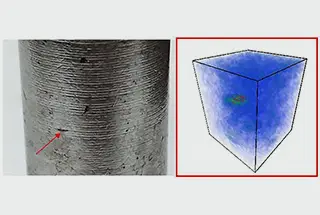

Abnormal vibration and noise are the principal indicators of malfunction in rotational machinery. Vibration signals, manifested in amplitude, frequency, and time domains, reveal crucial fault information about the machine.

Therefore, a comprehensive understanding of vibration mechanisms in rotational machinery under various fault conditions is essential for effective operational monitoring and enhancing the accuracy of fault diagnosis.

Based on the nature of mechanical vibration, rotational machinery vibrations can be classified into three distinct categories:

Forced vibration, also termed synchronous vibration, results from continuous, periodic external excitation forces.

This type of vibration continuously draws energy from the external environment to offset energy losses due to damping, thereby maintaining a consistent vibration amplitude within the system.

Notably, the vibration itself does not influence the disturbing force. Common causes of forced vibration include rotor mass imbalance, misaligned couplings, static friction in the rotor, loose mechanical components, and damage to rotor elements or bearings.

The characteristic frequency of forced vibration invariably equals the frequency of the disturbing force. For example, forced vibration induced by rotor mass imbalance exhibits a vibration frequency that consistently matches the rotational speed frequency.

Self-excited vibration arises from alternating forces generated by the machine’s internal movement during operation. These alternating forces naturally cease when the vibration stops.

The frequency of self-excited vibration corresponds to the machine’s natural (or critical) frequency, independent of any external excitation frequency.

Common manifestations of self-excited vibration in rotating machinery include oil whirl and oil film oscillation, primarily caused by rotor internal resistance and friction between static and dynamic components.

Compared to forced vibration, self-excited vibration occurs more abruptly and with higher vibration intensities, potentially causing severe machine damage within a short timeframe.

Non-steady forced vibration is a variant of forced vibration triggered by external disturbances.

It shares the frequency of the disturbance, but uniquely, the vibration itself reciprocally influences the magnitude and phase of the disturbance. Consequently, both the amplitude and phase of the vibration fluctuate.

For instance, localized uneven thermal deformation in the rotor shaft effectively adds an unbalanced mass to the rotor, causing variations in vibration amplitude and phase.

These changes in amplitude and phase, in turn, affect the magnitude and location of the uneven thermal deformation, resulting in continual variations in the forced vibration.

Understanding these vibration types is crucial for implementing effective condition monitoring strategies and developing advanced fault diagnosis algorithms for rotational machinery.