What if you could strengthen metals by combining heat and pressure in a single, seamless process? Thermomechanical treatment does just that. This technique not only improves the durability and toughness of metals but also optimizes their structural properties. In this article, we’ll uncover the seven essential types of thermomechanical treatments and their applications, providing insights that can enhance your understanding of metalworking innovations. Get ready to explore how this transformative process can elevate your material engineering projects.

Thermomechanical treatment is a metal heat treatment process that combines pressure processing with heat treatment to effectively utilize deformation strengthening and phase transformation strengthening on metal materials.

By combining pressure processing with heat treatment operations, this process unifies the forming process with obtaining final properties.

Now, let’s explore the categories and applications of thermomechanical treatment.

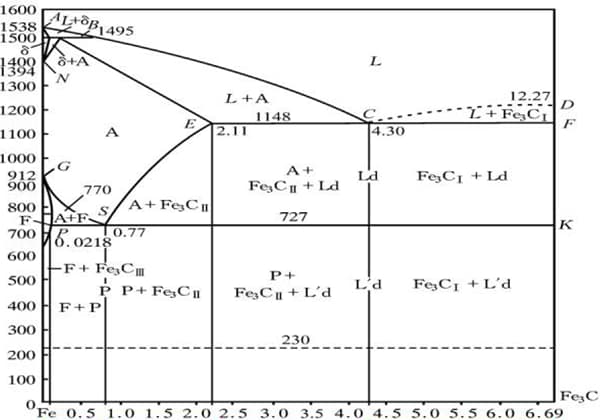

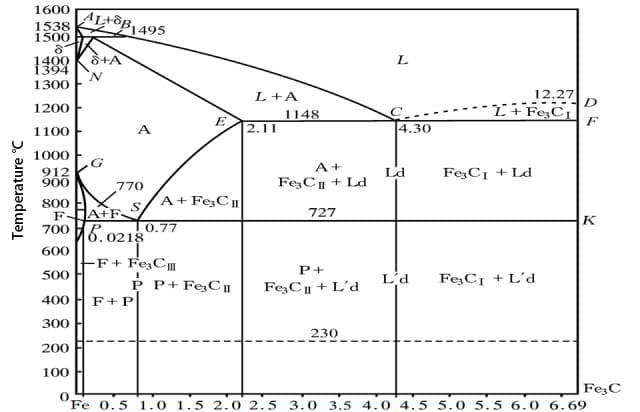

| Symbol | Meaning |

| A1 | Temperature at which austenite, ferrite, cementite or carbide coexist in equilibrium |

| A3 | The highest coexistence temperature of austenite and ferrite in hypoeutectoid steel in equilibrium |

| Ac1 | Temperature at which austenite begins to form when steel is heated |

| Ac3 | The temperature at which all ferrite is transformed into austenite when hypoeutectoid steel is heated. |

| Ar1 | The temperature at which austenite decomposes into ferrite and pearlite during high temperature austenitizing and cooling of steel. |

| Ar3 | The temperature at which the cooling austenite begins to precipitate free ferrite. |

| Acm | The highest temperature at which austenite and cementite or carbide coexist in hypereutectoid steel in equilibrium state is the upper critical point of hypereutectoid steel. |

| Accm | The final temperature at which all secondary cementite dissolves into austenite during heating. |

| Arcm | The temperature at which austenite begins to precipitate secondary cementite during cooling. |

Thermomechanical treatment

This is a comprehensive strengthening process that combines deformation strengthening and phase transformation strengthening. It involves two processes, namely plastic deformation and solid-phase transformation of metal materials, which are integrated to influence the phase transformation process and products. By utilizing the changes in the structure of metal materials during deformation, this process aims to obtain the desired structure and properties.

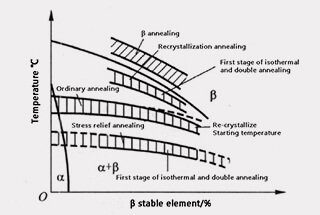

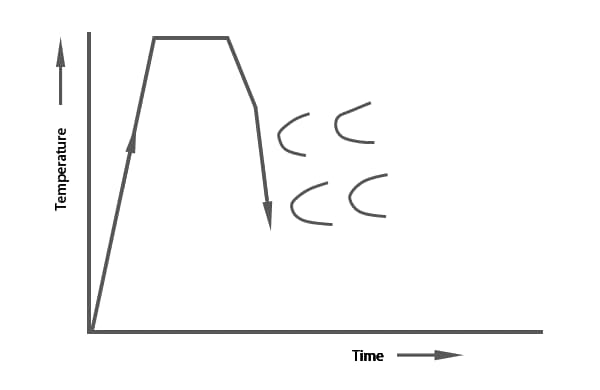

Deformation is performed either above the Ar3 transformation temperature of steel, or between the Ar1 and Ar3 temperature range. Alternatively, it can be carried out above the solution heat treatment temperature of alloys. After deformation, the material is quenched and tempered.

Eliminating the processes of reheating and quenching can enhance the strength of steel by 10-30%, improve its toughness and fatigue resistance, and decrease the risk of temper brittleness. This technique is also effective in improving the strength and plasticity of nonferrous alloys.

The method is commonly employed in the production of plates, strips, pipes, wires, and bars made of carbon steel, low and medium alloy steel, as well as mechanical parts with simple shapes.

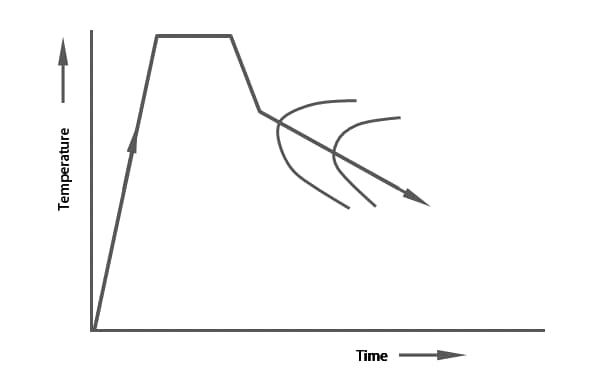

The steel is deformed either above Ar3 or between Ar1 and Ar3. It is then cooled with either air or water until it reaches above 550 ℃, and subsequently air-cooled to obtain either ferrite-pearlite or bainite structure.

By increasing the yield strength, it is possible to obtain excellent low-temperature toughness, making it suitable for producing a range of products including low carbon steel, weldable steel plate, strip, wire rod, and other items containing Nb, V, and Ti. These products are not quenched or tempered.

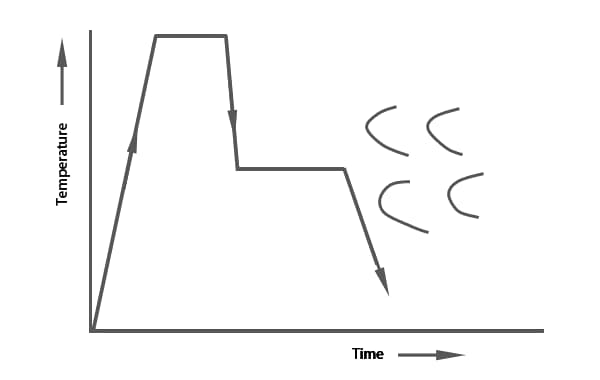

The steel is deformed in the stable zone of undercooled austenite (500~600 ℃), and then quenched and tempered.

Under the condition of ensuring the plasticity of steel, its strength can be significantly enhanced. This is applicable to components made of medium alloy high-strength steel that require high strength, small section high-strength steel wires, as well as high-alloy steel molds, high-speed steel tools, and so on.

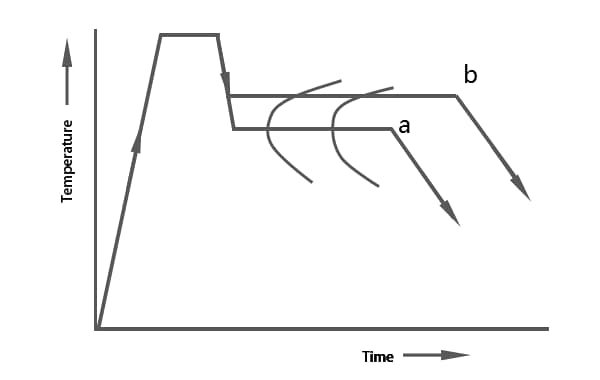

(a) Deformation occurs both before and during the pearlite transformation temperature range of steel.

(b) Deformation can also occur after the pearlite transformation.

(a) Fine ferrite subgrains and spherical carbides can improve the impact toughness of steel several times and are suitable for producing small parts of alloy structural steel.

(b) This process can significantly shorten the spheroidizing time, lower the spheroidizing temperature, and improve the spheroidizing structure. It is commonly used in tool steel and bearing steel manufacturing.

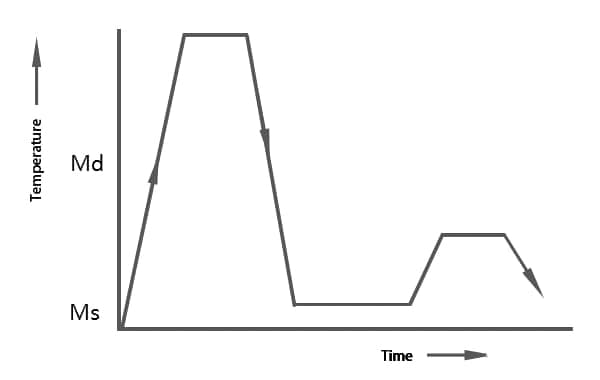

Deformation is carried out in the temperature range Ms ~ Md of steel.

Improve the strength under the condition of ensuring plasticity.

It is applicable to austenitic stainless steel and transformation induced plasticity steel (TRIP steel).

After solution treatment, the steel or alloy shall be cold worked or warm worked before aging.

The strength is significantly improved, and the necessary plasticity can still be ensured.

Used for steel grades or alloys requiring strengthening, such as austenitic steel, maraging steel, nickel base superalloy, aluminum alloy, copper alloy, etc.

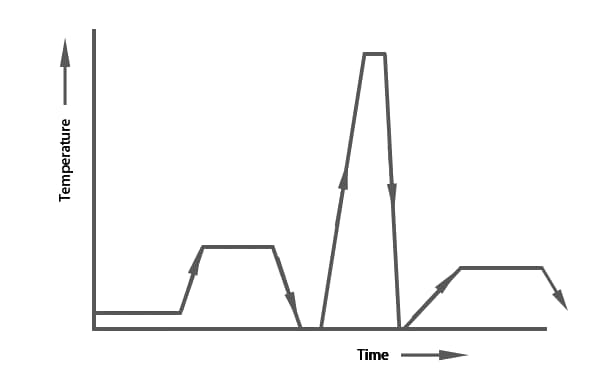

The process begins with cold deformation at room temperature, followed by intermediate tempering. After that, secondary rapid heating and quenching are performed, followed by final tempering.

It can still retain the strengthening effect from deformation, making it suitable for producing cold-rolled steel tubes, cold-drawn high-strength steel wires, or small parts with simple shapes that can be cold-formed.