Imagine your factory’s production line suddenly grinds to a halt due to a leak in a crucial pipeline. How do you fix it without risking further damage or downtime? This article delves into six essential welding techniques for stopping leaks, highlighting practical methods and safety measures. From hammering to riveting, you’ll learn strategies to manage leaks efficiently and ensure safety in high-pressure, hazardous environments. Prepare to equip yourself with the knowledge to tackle leaks effectively and keep your production running smoothly.

In industrial production, continuous operation of equipment can lead to various leaks in pipes, valves, and containers. These leaks significantly impact production stability, product quality, and can result in environmental pollution and resource waste. Moreover, leaks of hazardous media such as toxic gases and flammable substances pose severe threats to production safety and the surrounding ecosystem.

Historical incidents like the Qingdao Huangdao oil pipeline explosion (November 22, 2013) and the Tianjin Binhai New Area dangerous goods warehouse explosion (August 2, 2015) underscore the catastrophic consequences of media leaks, resulting in substantial loss of life and property.

Addressing industrial leaks promptly is crucial, yet repairing leaks in equipment containing pressurized flammable, explosive, or toxic substances presents significant technical challenges. Such repairs require specialized welding techniques under hazardous conditions, diverging from standard welding procedures and demanding stringent safety protocols.

Prior to welding, comprehensive safety measures must be implemented to mitigate risks and safeguard the workplace, welders, and auxiliary personnel. Only highly skilled and experienced welders should undertake these tasks, guided by welding engineers with extensive technical expertise to ensure safe operations.

For example, when repairing an oil tank, it’s imperative to know the tank’s capacity, the oil’s flash point, internal pressure, and other relevant parameters. The welding process must be meticulously planned to prevent personal injury or escalation into larger safety incidents.

To ensure safety before and during welding operations, the following critical steps must be adhered to:

Several specialized welding techniques for leak repair are commonly employed in engineering practice. These methods, which are continually evolving, merit in-depth study and further refinement to enhance their effectiveness and safety in industrial applications.

This specialized repair technique is particularly effective for addressing cracks, sand holes, and blowholes in low-pressure vessels and pipes, especially in materials prone to hot cracking or porosity.

For optimal results, utilize small-diameter electrodes (typically 2.5-3.2 mm) during the welding process. Adhering strictly to the specified welding current is crucial to minimize heat input and control the weld pool size. For most low-pressure applications, maintain a current range of 70-110 A, depending on material thickness and electrode size.

Employ a rapid welding technique to maximize efficiency and minimize heat-affected zone (HAZ) expansion. The arc heat should be strategically utilized to preheat the area immediately surrounding the leak, improving weld penetration and reducing the risk of cold lap defects.

Immediately upon extinguishing the arc, apply rapid localized pressure to the still-molten weld pool using a properly sized hammer or a pointed shovel tool. This action, known as “peening,” helps to:

Continue intermittent welding and peening cycles, allowing for brief cooling periods between passes to prevent excessive heat buildup. This technique is particularly effective for materials with higher carbon equivalents or those susceptible to hardening in the HAZ.

It’s important to note that while this method can be highly effective for temporary repairs or in certain low-stress applications, it may not be suitable for all pressure vessel or piping systems. Always consult relevant codes and standards (e.g., ASME BPVC, API 510) and conduct appropriate non-destructive testing (NDT) to ensure the integrity of the repair.

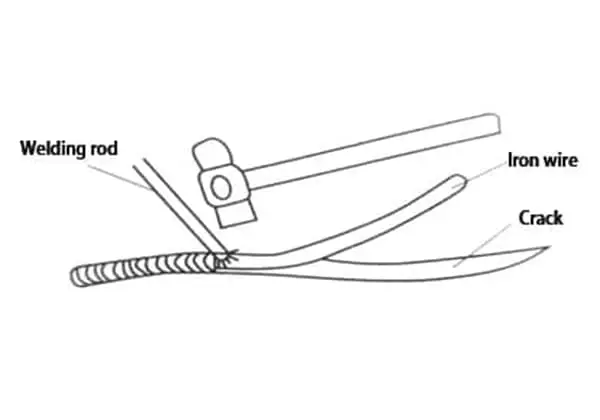

For wide cracks or large-diameter sand and gas porosity, conventional repair techniques such as peening, twisting, and pressing often prove inadequate. In these scenarios, a specialized rivet welding method offers a more effective solution.

This technique involves strategically plugging the defects with compatible filler materials, typically iron wires or welding electrodes of appropriate composition and diameter. This initial plugging serves to reduce the pressure and flow rate of potential leaks, creating more favorable conditions for subsequent welding.

The critical aspect of this method lies in its sequential approach:

This step-by-step procedure ensures better control over the repair process and minimizes the risk of introducing additional stresses or defects.

Key considerations for successful implementation include:

Figure 1 provides a visual representation of this rivet welding method, illustrating the sequential plugging and welding process.

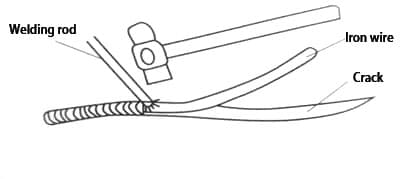

Leaks caused by corrosion, wear, and material thinning require a specialized approach to repair. Direct welding on the leak site is inadvisable, as it can exacerbate the problem and potentially lead to more significant breaches.

Instead, a strategic spot welding technique should be employed. Begin by selecting sound, leak-free areas adjacent to or slightly below the compromised section. These locations will serve as anchor points for the repair process.

Initiate the repair by establishing a stable molten pool in the chosen area. Gradually progress towards the leak, depositing weld metal in a series of overlapping spots. This technique, reminiscent of a swallow’s nest construction, creates a reinforced structure that effectively contains the leak.

To complete the repair, seal the leak using a precision welding approach. Utilize a low amperage welding current and a small diameter electrode to ensure minimal heat input and maximum control. This final step, depicted in Figure 2, allows for a controlled closure of the leak without compromising the integrity of the surrounding material.

This method not only repairs the immediate leak but also reinforces the weakened area, potentially preventing future failures in the vicinity. It’s crucial to note that post-weld inspection and testing should be conducted to verify the efficacy of the repair and ensure no new weak points have been inadvertently created.

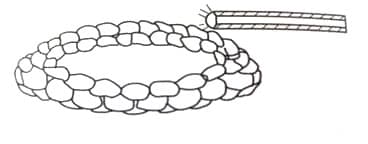

This advanced welding technique is specifically designed for addressing leaks characterized by large surface areas, high flow rates, or elevated pressures, as illustrated in Figure 3.

To effectively mitigate the leak, a custom-engineered complementary plate incorporating a precision closure mechanism must be fabricated to match the leak’s unique geometry and flow characteristics.

For substantial leaks, employ an interceptor system consisting of a strategically designed diversion pipe section equipped with an integrated high-pressure valve. This setup allows for controlled flow management during the repair process.

When dealing with smaller leaks, enhance repair efficiency by pre-welding a reinforced nut onto the repair plate, facilitating easier attachment and pressure adjustment.

The dimensions of the patching plate should exceed the leak area by a minimum of 25% to ensure adequate coverage and structural integrity. Position the closure device on the patching plate in precise alignment with the leak center for optimal sealing.

Apply a continuous bead of industrial-grade, pressure-resistant sealant along the perimeter of the patching plate’s contact surface. This critical step creates a robust seal, channeling the leaking medium through a designated guide pipe while minimizing peripheral leakage around the patch.

Once the repair plate is securely welded in place using appropriate filler materials and techniques, engage the closure mechanism by either closing the valve or tightening the bolts to the specified torque. Conduct a post-repair pressure test to verify the integrity of the seal.

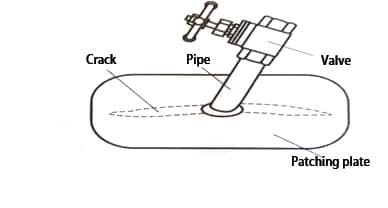

When a pipeline exhibits extensive leakage due to corrosion or wear, a sleeve tube repair method can be employed. This technique utilizes a sleeve with a diameter matching or slightly larger than the compromised pipeline. The length of the sleeve tube is determined by the extent of the damaged area, ensuring complete coverage of the leak.

The repair process involves the following steps:

1. Sleeve Preparation:

2. Welding Sequence:

3. Quality Control:

Figure 4 illustrates the sleeve tube welding method, highlighting the welding sequence and critical areas of focus during the repair process.

This repair technique offers a robust solution for extensive pipeline damage, providing structural reinforcement and leak prevention without the need for complete pipeline replacement. It is particularly effective for in-situ repairs in challenging environments where pipeline replacement may be impractical or cost-prohibitive.

Continuous welding should be avoided in oil leakage container repair due to the risk of excessive heat input. The weld temperature must be carefully controlled to prevent further damage or potential safety hazards.

Spot welding with simultaneous cooling is the preferred method. This technique involves:

In some cases, a combination of welding techniques may be necessary for effective leak stoppage. The success of welding leak repairs often depends on the welder’s versatility and ability to adapt to specific situations.

It’s crucial to note that not all metals are suitable for welding leak stoppage:

Important safety precautions:

It’s essential to understand that these welding methods are temporary solutions and do not provide the same mechanical properties as properly executed, full-penetration welds. The repaired area may have reduced strength and corrosion resistance compared to the original material.

When the equipment is depressurized and free of medium, the temporary leak-blocking weld should be completely removed. The equipment should then be properly rewelded or repaired using alternative methods that meet product specifications and industry standards.

In all cases, proper risk assessment, adherence to safety protocols, and consideration of material properties are crucial for successful and safe leak repairs in oil containment systems.

With the advancement of modern industrial processes, welding leak stoppage technology has emerged as a critical emergency technique in continuous production environments. This innovative approach allows for rapid intervention without halting operations, minimizing downtime and production losses.

Addressing a leak demands a strategic balance between immediate action and long-term solutions. While temporary leak stoppage measures can be implemented swiftly, it’s imperative to schedule a comprehensive repair or replacement during planned maintenance to ensure long-term integrity and safety.

The application of leak stoppage technology must be highly adaptable, considering factors such as the nature of the leak, operating conditions, and material properties. This flexibility enables technicians to select the most effective method for each unique situation.

Multiple sophisticated techniques can be employed to address leaks, including composite wraps, clamps, and injectable sealants. The primary objective is not only to stop the immediate leak but also to prevent future occurrences through the application of advanced welding and sealing technologies. This proactive approach enhances overall system reliability and operational efficiency.