Have you ever wondered how we can precisely cut through tough materials like glass and ceramics? In this article, we explore ultrasonic machining, a fascinating technology that uses high-frequency vibrations to shape hard and brittle materials. Learn about its principles, applications, and the incredible accuracy it offers.

Electrical Discharge Machining (EDM) and Electrochemical Machining (ECM) are specialized processes primarily suited for conductive metal materials, limiting their application to non-conductive or non-metallic substrates.

In contrast, Ultrasonic Machining (USM) offers a versatile solution for processing a wide range of materials, including both conductive and non-conductive substances. This technique excels in machining brittle and hard metal materials such as advanced alloys and hardened steels, while also providing superior capabilities for non-conductive, non-metallic materials like precision glass, advanced ceramics, semiconductor materials, and critical components such as germanium and silicon wafers used in the electronics industry.

The applications of USM extend beyond traditional material removal processes. It has proven effective in precision cleaning operations, particularly for intricate parts with complex geometries. Moreover, USM technology has been adapted for specialized welding applications and non-destructive testing procedures, enhancing its value across various manufacturing sectors.

Ultrasonic welding, a subset of USM technology, utilizes high-frequency mechanical vibrations (typically 20-40 kHz) transmitted to the interface of two components requiring joining. Under controlled pressure, these vibrations induce localized friction and heat generation at the material interface, promoting molecular interdiffusion and creating a solid-state bond without melting the bulk material. This process is particularly advantageous for joining thermoplastics, non-ferrous metals, and dissimilar materials where traditional welding methods may be ineffective or detrimental.

A typical ultrasonic welding system comprises four essential components:

The primary components of an ultrasonic welding system include a trio assembly of an ultrasonic generator, transducer, boosters, welding head, mold, and frame.

Ultrasonic welding involves converting a 50/60 Hz current into 15, 20, 30, or 40 KHz electrical energy via an ultrasonic generator. The converted high-frequency electrical energy is once again transformed into mechanical motion of the same frequency via a transducer.

Subsequently, the mechanical motion is transferred to the welding head through a set of booster devices that can alter the amplitude. The welding head conveys the received vibrational energy to the joint of the workpiece to be welded. In this region, the vibrational energy is converted into thermal energy through friction, melting the areas that need to be welded.

Ultrasonics can not only be used to weld metals and thermosetting plastics but also process fabrics and films.

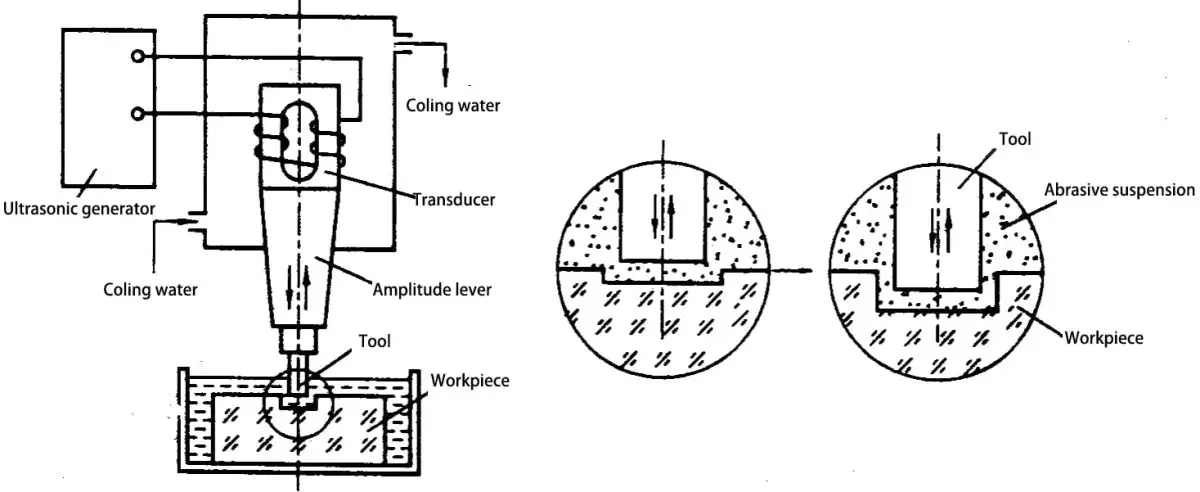

Specifically, ultrasonic machining (USM) is a method of processing hard and brittle materials through the use of ultrasonic vibration at the tool’s end face, combined with the action of abrasive suspension.

USM is a result of the combined effects of mechanical impact and abrasive grinding caused by the vibration of abrasives under ultrasonic waves, with the continuous impact of the abrasives being the main factor.

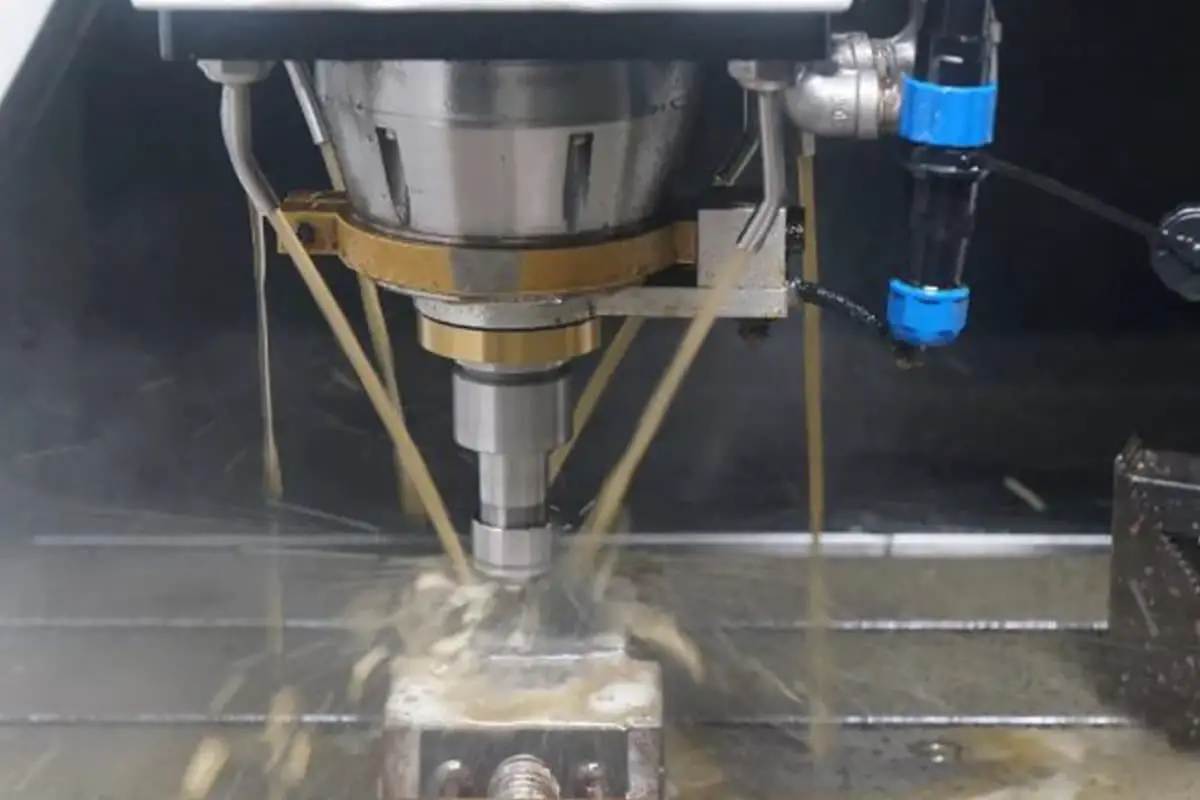

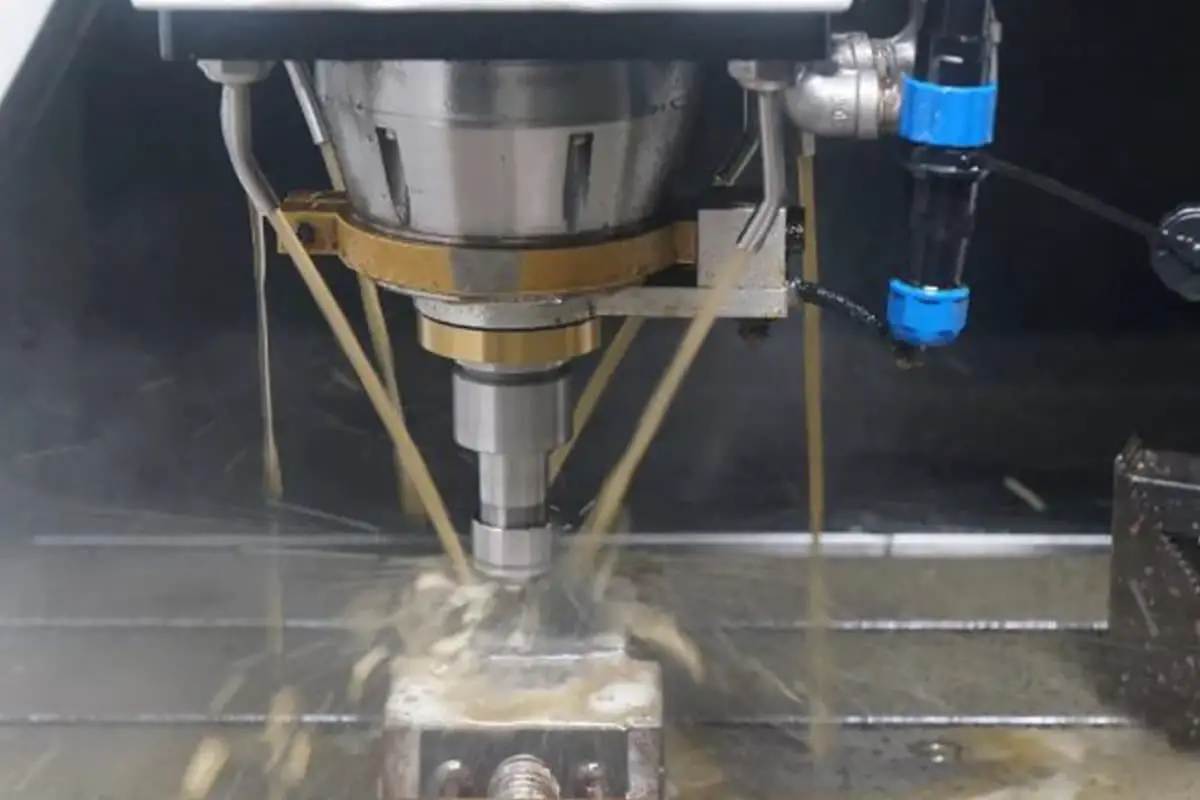

During the ultrasonic machining process, a suspension of liquid and abrasive mixture is introduced between the tool head and the workpiece. A slight pressure is applied in the direction of tool head vibration.

The ultrasonic frequency generated by the ultrasonic generator is transformed into mechanical vibrations by the transducer. The amplitude is amplified to 0.01-0.15mm by the amplitude rod and then transmitted to the tool.

The tool’s end face is driven to vibrate ultrasonically, causing the abrasive particles in the suspension to continuously impact and grind the surface of the workpiece at a high speed. This results in the crushing of material in the machining area into fine particles, which are then removed from the material.

Although each impact removes a small amount of material, the high frequency of over 16,000 impacts per second allows for a certain processing speed.

At the same time, the hydraulic impact and cavitation phenomenon caused by the ultrasonic vibration at the tool end result in the penetration of the liquid into the cracks of the workpiece material, accelerating the destruction process.

The hydraulic impact also forces the suspension working fluid to circulate in the machining gap, ensuring timely renewal of the worn-out abrasive particles.

1. Principle of Ultrasonic Metal Welding

Ultrasonic metal welding is an advanced solid-state joining process that utilizes high-frequency mechanical vibrations (typically exceeding 20 kHz) to create strong metallurgical bonds between similar or dissimilar metals. This innovative technique offers unique advantages over traditional welding methods.

The process relies on the conversion of ultrasonic energy into localized frictional heat and plastic deformation at the interface of the workpieces. Unlike conventional welding, ultrasonic welding occurs without melting the base materials or using external heat sources. Instead, a combination of controlled pressure and high-frequency oscillations (usually 20-40 kHz) generates the necessary conditions for bonding.

During the welding cycle, the following key mechanisms contribute to joint formation:

Ultrasonic metal welding offers several advantages:

This technique is particularly suited for joining thin sheets, foils, and fine wires of non-ferrous metals such as aluminum, copper, nickel, and precious metals. Common applications include:

2. Principle of Ultrasonic Plastic Welding

When ultrasonic waves act on the contact surface of thermoplastic materials, they generate high-frequency vibrations tens of thousands of times per second. This high-frequency vibration, once it reaches a certain amplitude, is transmitted to the welding area through the weldment, converting ultrasonic energy into heat.

The sound resistance at the junction of the two welds in the welding area is large, thus generating local high temperatures. Due to the poor heat conduction of plastics, the heat cannot be dissipated promptly and accumulates in the welding area, causing the contact surfaces of the two plastics to rapidly melt.

With the application of a certain pressure, the plastics are made to fuse into one. When the ultrasonic waves cease, the pressure is maintained for a few seconds to allow solidification, forming a robust molecular chain to achieve the welding purpose. The welding strength can approach the strength of the original material.

The quality of ultrasonic plastic welding depends on three factors: the amplitude of the transducer welding head, the applied pressure, and the welding time. Both the welding time and the pressure of the welding head can be adjusted, while the amplitude is determined by the transducer and amplitude rod.

These three factors interact and have an optimal value. When the energy exceeds this optimal value, the amount of plastic melted is high, and the welded material is prone to deformation.

If the energy is too low, the resulting weld is not firm, and the applied pressure should not be too high either. The optimal pressure is the product of the edge length of the welding part and the optimal pressure per millimeter of the edge.

a. Excels in machining hard-to-process materials, including both metals and non-metals. Particularly effective for non-conductive materials such as glass, ceramics, quartz, silicon, agate, gemstones, and diamonds. Can also process conductive hard metals like hardened steel and advanced alloys, albeit with reduced efficiency.

b. Ideally suited for challenging geometries: deep holes, thin-walled components, slender rods, low-rigidity parts, and complex shapes with stringent specifications.

c. Optimized for high-precision machining, delivering superior accuracy and low surface roughness for critical components.

The localized, high-frequency impact mechanism results in negligible macroscopic cutting forces. This leads to significantly reduced cutting stresses and heat generation, preserving material integrity and enhancing overall efficiency.

Ultrasonic machining achieves exceptional dimensional accuracy (typically 0.005-0.02mm) and surface finish (Ra values of 0.05-0.2μm). The process leaves no residual stresses or thermal damage on machined surfaces, making it ideal for delicate components, narrow tolerances, and low-rigidity workpieces.

Excels in producing intricate cavities and molded surfaces with high fidelity, outperforming conventional machining methods for complex 3D shapes.

Allows the use of relatively soft tool materials with complex geometries, reducing tooling costs and enabling rapid prototyping of custom shapes.

Ultrasonic machining systems generally feature straightforward designs, facilitating ease of operation, maintenance, and integration into existing manufacturing processes.

Machining speed refers to the amount of material removed per unit time and is expressed in mm3/min or g/min.

The factors influencing machining speed include tool amplitude and frequency, feed pressure, type and particle size of abrasive, workpiece material, and concentration of abrasive suspension.

a. Influence of tool amplitude and frequency:

Excessive amplitude and high frequency can subject the tool and amplitude rod to high internal stress. The amplitude is generally between 0.01-0.1mm, and the frequency is between 16,000-25,000Hz.

In actual machining, it is necessary to adjust to the resonant frequency according to different tools to obtain maximum amplitude and achieve higher machining speed.

b. Influence of feed pressure:

The tool should have an appropriate feed pressure during machining. Too low pressure increases the gap between the tool end face and the workpiece surface, reducing the impact force of the abrasive on the workpiece.

Increasing the pressure reduces the gap, but when the gap decreases to a certain extent, it will reduce the circulation and renewal speed of the abrasive and working fluid, thus lowering productivity.

c. Influence of abrasive type and particle size:

Different abrasives can be selected for materials with varying strength during machining. Higher abrasive strength results in faster machining speed, but cost must also be considered. For processing materials like gemstones or diamonds, diamond abrasives must be used.

Boron carbide is suitable for machining hardened steel and hard alloys, while aluminum oxide abrasives are used for processing materials such as glass, quartz, silicon, and germanium.

d. Influence of workpiece material:

Hard and brittle materials are easier to remove during machining, while materials with good toughness are more difficult to process.

e. Influence of abrasive suspension concentration:

Lower concentration of abrasive suspension means fewer abrasive particles in the machining gap, which can lead to a significant decrease in machining speed, especially for large surface areas and deep depths.

Increasing the concentration of abrasives improves machining speed, but excessively high concentration can affect the circulation and impact of abrasive particles in the machining area, leading to a decrease in machining speed.

The accuracy of ultrasonic machining is influenced by machine tool and fixture precision, as well as abrasive particle size, tool precision and wear, lateral vibration magnitude, machining depth, and properties of the workpiece material.

Ultrasonic machining provides excellent surface quality, without generating surface layers or burn marks. Surface roughness mainly depends on abrasive particle size, ultrasonic amplitude, and workpiece material hardness.

Smaller abrasive particle size, smaller ultrasonic amplitude, and harder workpiece material lead to improved surface roughness, as the roughness value is mainly determined by the size and depth of the grooves left by each abrasive particle impact on the workpiece material.

Although the productivity of ultrasonic machining is lower compared to electrical discharge machining and electrochemical machining, its machining accuracy and surface quality are superior.

Importantly, it can process semiconductor and non-metallic hard and brittle materials, such as glass, ceramics, quartz, silicon, agate, gemstones, and diamonds, which are difficult to machine using other methods.

Additionally, it is often employed in the final finishing stages of hardened steel, hard alloy molds, wire drawing dies, and plastic molds processed by electrical discharge machining, to further reduce surface roughness.

Ultrasonic machining is primarily used for processing circular holes, shaped holes, cavities, nesting, and micro-holes in brittle and hard materials.

Ultrasonic machining is suitable for cutting brittle and hard materials such as ceramics, quartz, silicon, and gemstones, which are difficult to cut using conventional methods. It offers advantages such as thin slices, narrow cuts, high precision, high productivity, and cost-effectiveness.

This method is based on the cavitation effect produced by the cleaning solution under the action of ultrasonic waves. The strong impact generated by cavitation directly acts on the surface being cleaned, causing the debris to disintegrate and detach from the surface.

This method is mainly used for precision cleaning of small and medium-sized precision parts with complex geometries, where other cleaning methods are less effective, especially for deep holes, micro-holes, curved holes, blind holes, grooves, narrow gaps, etc. It provides high productivity and purification rates.

Currently, it is applied in the cleaning of semiconductor and integrated circuit components, instrument parts, electronic vacuum devices, optical components, and medical instruments.

Ultrasonic welding utilizes ultrasonic vibration to remove the oxide film from the surface of workpieces, exposing the base material surface. The high-speed vibrating impact between the two welded workpiece surfaces causes frictional heating and bonding.

It can be used to weld nylon, plastics, and aluminum products prone to oxide film formation. It can also be used to apply tin or silver on the surfaces of ceramics and other non-metallic materials, improving their weldability.

To increase machining speed and reduce tool wear when machining hard metal materials such as hard alloys and heat-resistant alloys, ultrasonic-assisted combined machining with electrochemical or electrical discharge machining is employed.

This is often used for machining holes or narrow slots in components such as fuel injectors and wire drawing plates, resulting in significantly improved productivity and quality.

Ultrasonic vibration cutting (e.g., turning, drilling, thread cutting) has also been developed over several decades as a new technology for precision machining and difficult-to-cut materials, reducing cutting forces, surface roughness, tool wear, and increasing productivity.

Some commonly used applications include ultrasonic vibration turning, ultrasonic vibration grinding, ultrasonic machining of deep holes, small holes, and thread tapping, among others.