Have you ever wondered how 3D printing has evolved to revolutionize manufacturing? This article dives into the key processes and features of 3D printing, from its origins with powder and binder techniques to its modern applications in creating complex, functional parts. You’ll learn how innovations like binder jetting work and discover the advantages and limitations of this transformative technology. Explore how 3D printing continues to shape industries with its ability to produce detailed, customizable, and cost-effective products.

Utilizing powder materials for 3D printing, the above-mentioned SLS process is relatively costly due to the use of lasers. However, employing a binding agent to adhere the powder particles and build up layers to form shapes is theoretically sound. On April 20, 1993, Professor Emanuel Sachs and his team at MIT were granted a U.S. patent for “Three-Dimensional Printing Techniques,” known as 3DP.

The invention was inspired by the widespread inkjet printers of the time, substituting the ink in the cartridges with a liquid binding agent. By extruding this binder onto a bed of loose powder with the print head, three-dimensional objects could be printed. Similarly, by utilizing primary color binders and precise digital color matching, color printing on powder was achievable, akin to color inkjet printing on paper.

This 3D printing process closely resembles conventional printers, and its patent title, “3D printing,” is straightforward and easy to grasp. Prior to this, 3D printing technology was known as rapid prototyping. Since then, the term “3D printing” has gained popularity, and all rapid prototyping technologies are commonly referred to as 3D printing, with the devices themselves called 3D printers.

In 2012, the American Society for Testing and Materials (ASTM) defined this 3D printing process as “Binder Jetting” in their additive manufacturing terminology standard (ASTM F2792-12a).

In theory, the binder jetting process can be used to 3D print various powder materials such as ceramics, metals, gypsum, plastics, and sand. In 1995, Z Corporation was established with a license from MIT, focusing on the commercialization of binder jetting with gypsum powder.

Since 1997, they have introduced a series of binder jetting printers, including the monochrome entry-level ZPrinter 310 Plus and, in 2005, the world’s first color 3D printer, the Spectrum Z510, as shown in Figure 5-31 with the color printer and its printed models. This marked a significant step in the evolution of 3D printing, making it vibrant and colorful. In 2012, Z Corporation was acquired by 3D Systems, which further developed the Color-Jet series of printers.

The specifications for the Color-Jet series currently sold on the 3D Systems website are shown in Table 5-1.

Table 5-1: 3D Systems’ official specifications for the Color-Jet series printers.

| Model | ProJet260C | ProJet360 | ProJet 460Plus | ProJet660Pro | ProJet860Pro |

| Color | Basic Color (CMY) | Monochrome (White) | Basic Color (CMY) | Full Color (CMYK) | Basic Color (CMY) |

| Layer Thickness/mm | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| Resolution/dpi | 300×450 | 300×450 | 300×450 | 600×540 | 600×540 |

| Print Dimensions/mm | 236×185×127 | 203×254×203 | 203×254×203 | 254×381×203 | 508×381×229 |

| Print Speed/(mm/h) | 20 | 20 | 23 | 28 | 5~15 |

| Number of Print Heads | 2 (HP57+HP11) | 1 (HP11) | 2(HPS7+HP11) | 5(HP11) | 5(HP11) |

| Number of Nozzles | 604 | 304 | 604 | 1520 | 1520 |

In 1996, Extrude Hone Corporation received a license from MIT to research and commercialize metal powder material formed by binder jetting, introducing the world’s first metal powder binder jetting device, ProMetal RTS-300, in 1997.

In 2003, ExOne Company emerged from Extrude Hone, focusing solely on the 3D printing industry, later launching the world’s first sandstone 3D printer, the S15. Since then, ExOne has specialized in binder jetting of metal and sandstone materials, gradually becoming a leader in 3DP technology. Figure 5-32 shows the ExOne Innovent+ printer and some of the metal models printed by the company.

Founded in 1999, the German company Voxeljet also obtained a license from MIT and has been dedicated to developing sand 3D printers for casting molds. The company employs binder jetting technology to print sand molds for use in traditional metal casting processes.

In recent years, binder jetting technology has garnered increasing attention within China, with companies such as Wuhan Yizhi Technology Co., Ltd., Aisikai Technology Co., Ltd., Guangdong Fenghua Zhuoli Technology Co., Ltd., and Ningxia Sharing Group taking the lead.

Additionally, a team from Huazhong University of Science and Technology has been researching binder jetting technology since 2012, initially focusing on printing with gypsum, polymers, and casting sand, and currently concentrating on metal binder jetting technology. In 2017, in collaboration with Wuhan Yizhi Technology Co., Ltd., they introduced a metal binder jetting printer capable of printing with materials such as 316L stainless steel, 420 stainless steel, copper, and titanium alloys.

Below is a comparative table of the technical details of some domestic and international companies developing metal binder jetting technology.

Table 5-2: Comparative Chart of Technical Details for Metal Adhesive Spray Forming Technologies from Select Domestic and International R&D Companies

| Company | Printing Speed (cm3/h) | Build Volume | Materials Available | Density /% | Resolution /dpi | Layer Thickness /μm |

| Digital Metal | 100 | 203mm×180mm×69mm | SS:316L,17-4 | 96 | — | 30~200 |

| Exone | Up to 10,000 | 800mm×500mm×400mm | SS:316L,304 | 96~99 | 600~1200 | 30~200 |

| Desktop Metal | 12000 | 750mm×330mm×250mm | — | 一 | 一 | 50 |

| HP | – | 430mm×320mm×200mm | SS:316L | >93 | 1200 | 50~100 |

| GE | – | – | SS:316L | – | 一 | – |

| 3DEO | – | – | SS: 17-4 | 99 | — | – |

| Wuhan Yizhi | – | 500mm×450mm×400mm | SS:316,420 | 95~99 | 600 | 50~200 |

Reviewing the abstract schematic of Professor Emanuel Sachs’ 3DP patent, as shown in Figure 5-33, key information is presented: “…produce a layer of bonded powder material…” indicates the creation of a layer of bonded powder material through a layer-by-layer accumulation process using powder material.

The question arises of how the powder is shaped: “…depositing a binder material…” suggests that instead of using a laser, a binder material is distributed in selected areas of each layer, bonding the powder into shape. The abstract also notes that the material can be “…further processed as, for example, by heating…” to enhance strength.

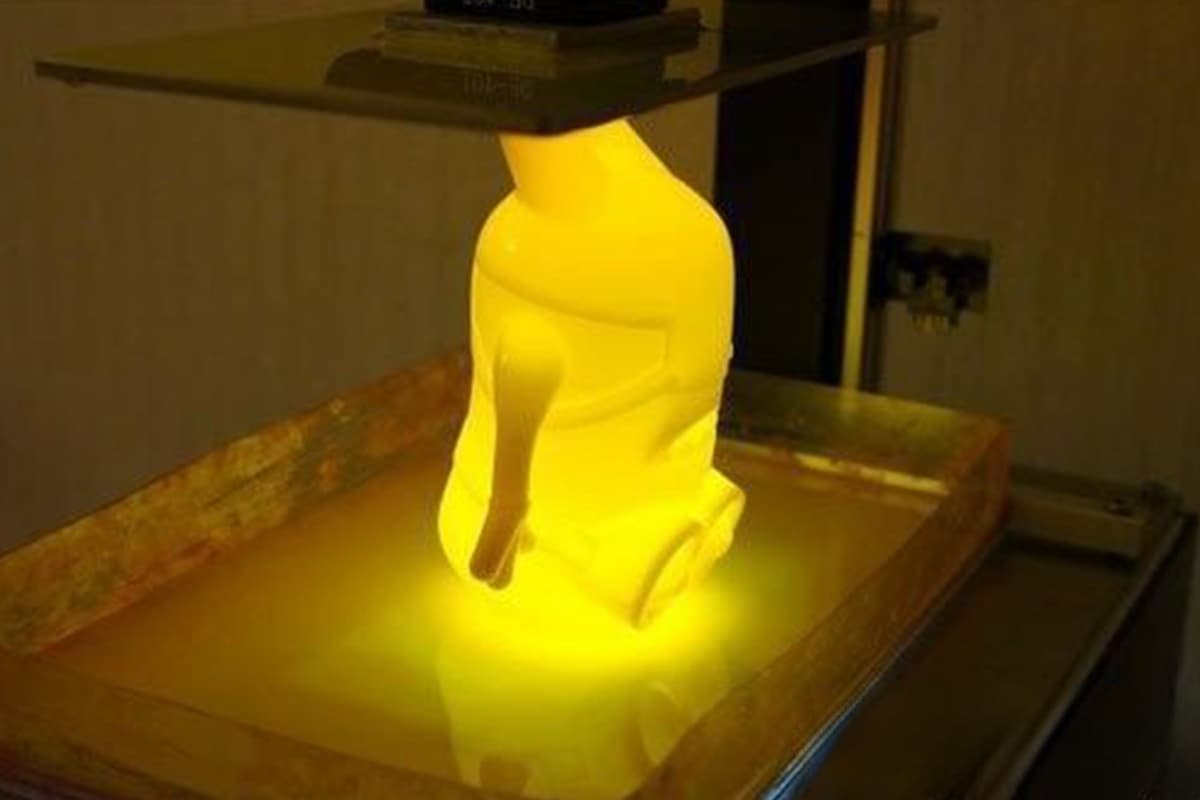

Figure 5-34 illustrates the 3DP process, detailed as follows:

① Data preparation. Obtain a three-dimensional model of the part and process it into two-dimensional slices.

② Powder laying. The powder is stored either in a hopper or a feed cylinder, with two methods of application: the hopper releases a certain amount of powder onto the powder bed from above, known as the feeding method, while the feed cylinder dispenses a preset amount of powder by raising the feed piston to a certain height, known as the powder laying method, as shown in Figure 5-34(a) and (b).

A roller then spreads and compacts the powder across the forming area of the powder bed.

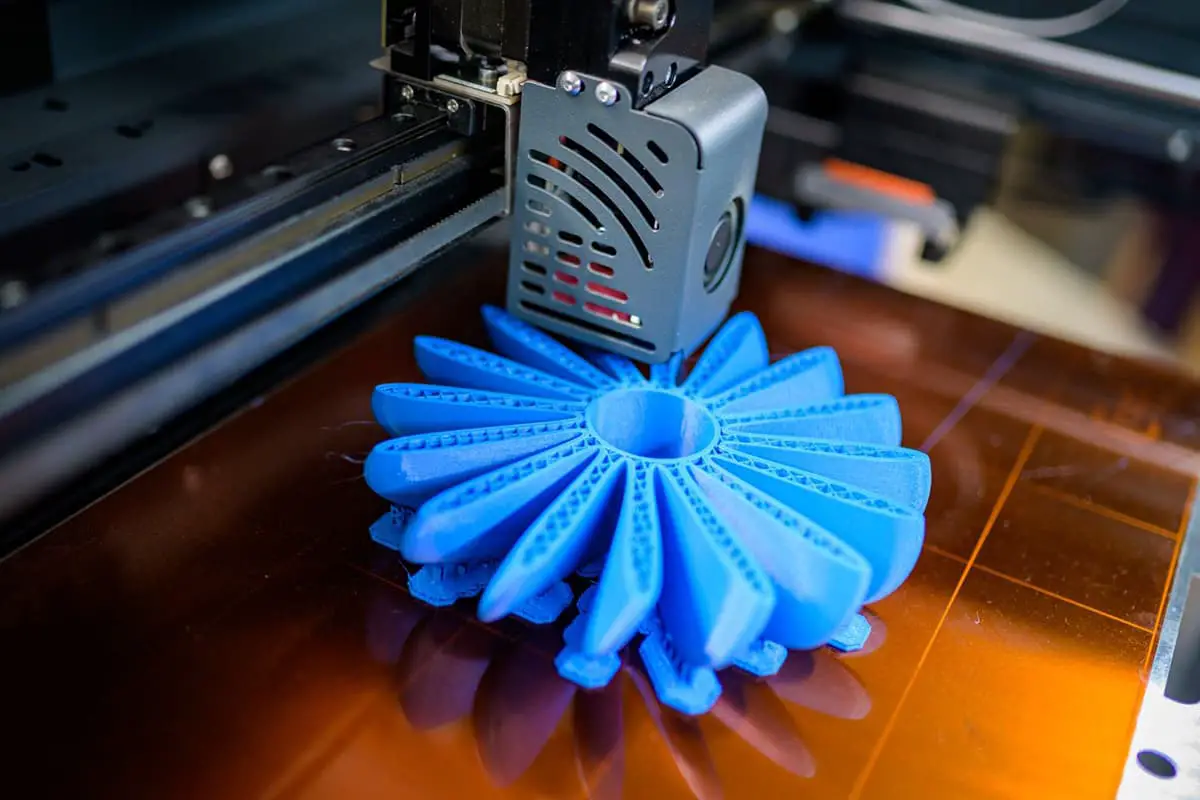

③ Two-dimensional movement. The print head, loaded with binder, is controlled by the command file to move in the X and Y directions, spraying binder to bond the powder into shape. The areas not sprayed remain loose and provide support for subsequent layers (for printing colored models, three primary color binders are used).

④ Z-direction movement. The powder bed descends one layer in the Z direction, the forming area is replenished with a new layer of powder, and the powder layer is kept level.

⑤ Interlayer bonding. The print head moves under new X and Y commands, spraying binder to bond the current layer of powder into shape while also adhering it to the layer above, achieving interlayer bonding.

⑥ Repeat the above process until the final three-dimensional part is obtained.

The unused powder material from 3DP printing, which is not preheated or exposed to laser irradiation, can be completely recycled for reuse, theoretically achieving a 100% material utilization rate. After 3D printing, parts require further post-processing, typically involving three steps:

Since the parts are entirely buried in powder, it is necessary to remove the residual powder on the part’s surface within a glove box using brushes, air guns, etc., for recycling and reuse in subsequent printing.

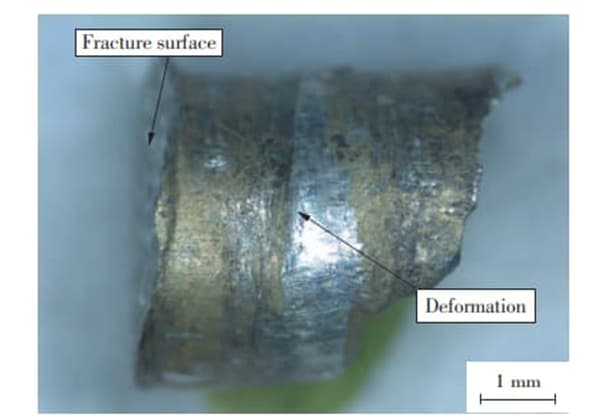

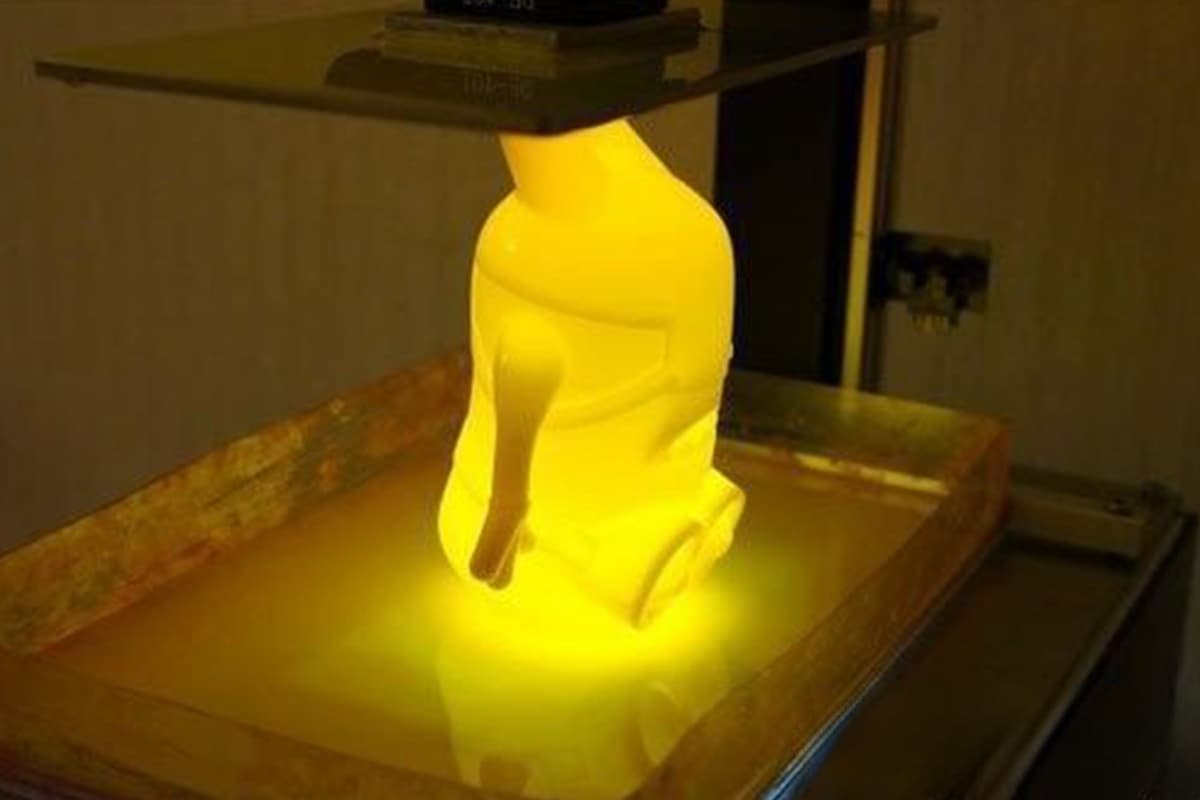

3DP printed parts often contain numerous pores and are comparatively weak, necessitating post-processing for reinforcement. For parts printed with inorganic powder materials like gypsum, different instant-curing infiltrants are selected based on the intended use to penetrate the parts.

For example, infiltrants suitable for color models can improve strength, color, and color stability; binary infiltrants for functional models can significantly enhance model strength; and environmentally friendly infiltrants can be used for impregnation or spraying to enhance surface hardness and modulus.

Metal powder printed parts generally require additional post-processing steps such as degreasing, high-temperature sintering, hot isostatic pressing, infiltration, or copper impregnation to increase part strength and density.

Typically, a combination of sandblasting, polishing, painting, and machining is used to further improve the quality and accuracy of the part’s surface, as well as its smoothness and color.

The 3DP process has five notable advantages:

3DP can realize full-color printing, perfectly expressing product design creativity in color, and is widely used in cultural creativity, film, animation, and other fields.

The 3DP process can print with almost any powder material, including metal powders, thereby significantly expanding its functional applications.

Unbound powder serves as natural support, eliminating the need for additional auxiliary supports, which means high printing efficiency and low material costs during the printing process.

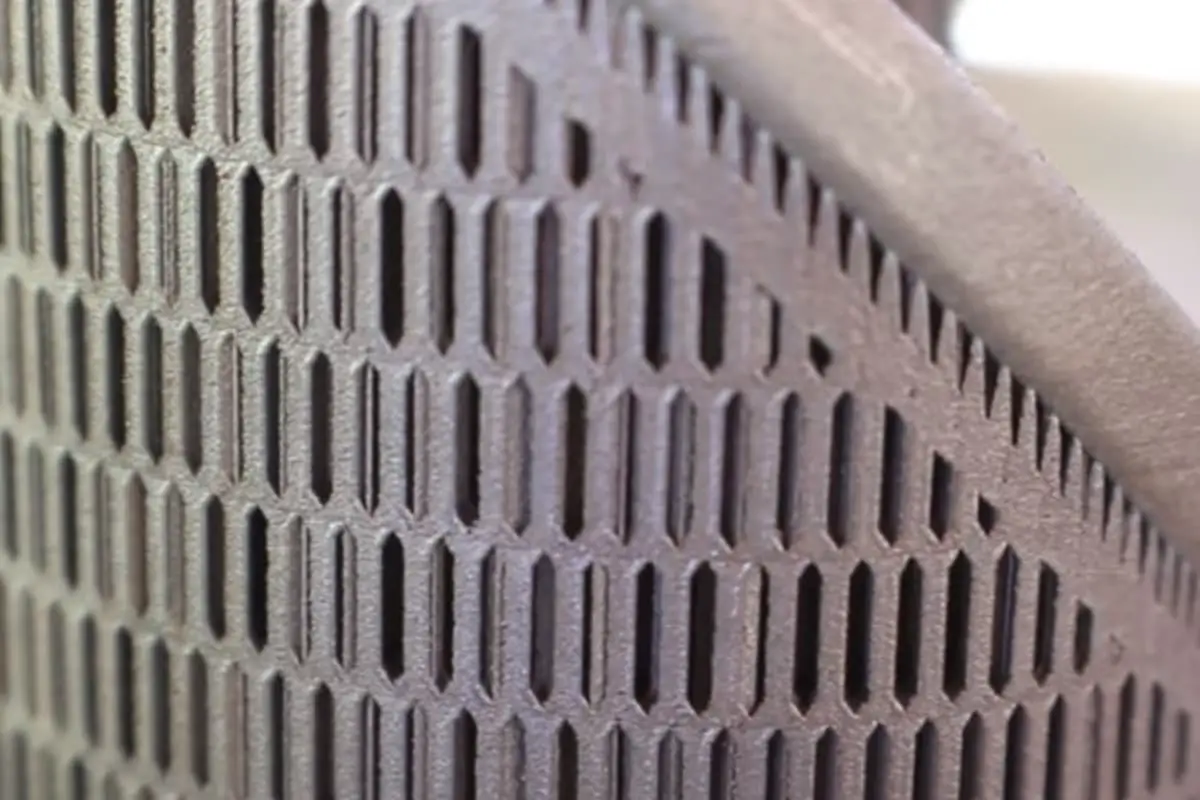

The 3DP process imposes virtually no restrictions on the complexity of parts, allowing for the production of various complex shapes such as porous parts, hollowed-out parts, and nested parts. It is suitable for new product development or for producing individual and small-batch parts.

On one hand, the 3DP process does not use lasers, which reduces equipment operation and maintenance costs; on the other hand, its binder jetting heads can perform array scanning rather than laser point scanning, resulting in high printing efficiency and low cost.

However, the 3DP process also has certain limitations and drawbacks, as follows:

The strength and toughness are relatively low, usually only suitable for sample displays or casting molds (such as sand molds). Functional testing is not viable, and metal printed parts require further sintering and copper infiltration in a sintering furnace to achieve final strength and density.

Since the parts are formed by powder binding, the surface has a certain grainy texture, which makes it difficult to achieve the smoothness of parts printed with photopolymerization techniques.

As powder bed storage is used and considering the surface activity of the powder materials, bulk material storage is large and challenging. The hopper feeding mechanism, although somewhat overcoming storage issues, does not change the fundamental principle of powder bed storage.