1. Cold Bending Forming Technology Cold bending forming technology is a continuous localized cold processing method, which involves applying external force to the metal at the bend angle through multiple stages to make it undergo bending deformation, achieving the desired shape. Compared to hot bending, cold bending offers superior production efficiency, energy consumption, and product […]

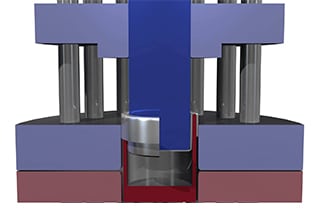

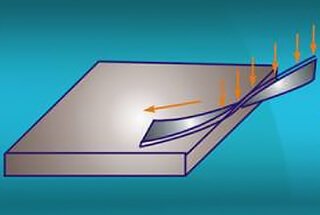

Cold bending forming technology is a continuous localized cold processing method, which involves applying external force to the metal at the bend angle through multiple stages to make it undergo bending deformation, achieving the desired shape.

Compared to hot bending, cold bending offers superior production efficiency, energy consumption, and product quality.

As a cost-effective and efficient forming technique, cold bending forming technology is widely used in the manufacturing of corrugated steel pipes.

By adjusting the parameters of the cold bending forming equipment, one can control the bending radius, angle, and length to obtain various shapes of corrugated steel pipes.

Cold-formed corrugated steel pipes have the same performance characteristics as hot-formed pipes, such as compression resistance, vibration resistance, and malleability, but at a lower cost and with more stable quality, making them highly favored in the corrugated steel pipe industry.

Related reading: Steel Corrugated Pipe: A Guide to Different Types

In sponge city construction:

Compared to cast iron and concrete pipes, cold bending formed corrugated steel pipes boast lower material costs, high strength, lightweight construction, excellent corrosion resistance, easy installation, and a longer service life.

For shorter pipes or scenarios where bending isn’t required, whole corrugated steel pipes are more appropriate due to their higher strength and better sealing capabilities.

However, for pipework systems that require bending, segmental corrugated steel pipes are more practical since they can be combined to form pipes of different lengths and angles, offering greater flexibility.

For particular situations, like on-site pipe fabrication, spiral corrugated steel pipes are the most suitable as they can be manufactured on-site to various lengths and angles, offering the highest adaptability.

In underground utility tunnel projects (Figure 7), cold-formed corrugated steel pipes are used for drainage systems as drainage ditches and pipes.

They also serve as ventilation ducts in ventilation systems, ensuring air circulation and harmful gas expulsion.

These pipes are used in the fire protection systems of underground utility tunnels and are integral to cable protection systems, made into various shapes and sizes as cable protection ducts.

Corrugated steel pipes are generally more suitable for small diameter pipes and short-distance transmission than reinforced concrete main tunnels.

They offer excellent flexibility and sealing, adapting to ground changes and pipeline bends. Furthermore, the manufacturing and installation costs of corrugated steel pipes are relatively lower, reducing project costs.

They are also easy to transport, quick to install, and have high construction precision.

In culvert projects, cold-formed corrugated steel pipes can be utilized for drainage, ventilation, support systems (making various shapes and sizes of arches and sidewall structures), and protective systems (protecting culvert structures from water and sediment erosion, as seen in Figure 8).

Corrugated steel pipes used in culverts have excellent vibration resistance and water-proofing capabilities.

Compared to concrete culverts, corrugated steel pipes have a longer lifespan (over 100 years), shorter construction cycles, are less challenging to build, cost less, have high deformation resistance, and low maintenance costs post-completion.

The presence of axial corrugation helps distribute stress and strain along axial and radial directions, diffusing stress concentrations more effectively.

Especially in cold regions with permafrost, soft soil, expansive soil, and loess, the economic benefits are significant. Corrugated steel culverts prevent displacement of heating pipelines.

Thus, rust removal from these heating pipes ensures the lifespan of the corrugated culverts. Rust removal methods include technical rust removal, mechanical rust removal, and chemical rust removal.

Experience shows that using corrugated steel culverts instead of reinforced concrete for culvert construction has unmatched advantages in terms of construction cycles, cost, environmental protection, and more.

Using metal corrugated culverts significantly improves road comfort and safety, preventing the “jumping car” phenomenon in road culverts and addressing frost damage in cold regions.

Water conservation agriculture is a crucial component of agricultural production involving water resource development, utilization, and management.

Cold-formed corrugated steel pipes have extensive applications in water conservation agricultural construction, including:

1) Irrigation Channels: Corrugated steel pipes act as main components in irrigation channels, diverting water from reservoirs and rivers into farmland to supply crops.

2) Drainage Systems: These pipes serve as primary conduits in farmland drainage systems (Figure 9), discharging excess water into rivers and reservoirs, preventing waterlogging in farmlands.

3) Reservoirs & Storage Ponds: Corrugated steel pipes are used in constructing reservoirs and storage ponds, ensuring a consistent water supply (Figure 10). Their high strength and lightweight nature give them extended durability and low maintenance costs.

4) Water-saving Irrigation: Corrugated steel pipes are used in drip and sprinkler irrigation, increasing water utilization and conserving resources.

5) Soil and Water Conservation Projects: These pipes play a role in projects like anti-slide dams, embankments, preventing soil erosion, and safeguarding the agricultural environment.

6) Aquaculture: Corrugated steel pipes can be employed in aquaculture constructions, such as fish ponds and shrimp ponds, providing a consistent water supply and enhancing the breeding environment.

7) Maintenance of Agricultural Water Facilities: These pipes are essential for maintaining agricultural water facilities, like dredging rivers and silt clearing channels, ensuring the normal operation of agricultural water facilities.

8) Water Resource Monitoring & Management: Corrugated steel pipes can be used in constructing water resource monitoring and management systems, such as water level observation stations and water quality monitoring stations, offering accurate water resource data to guide policy-making in water conservation agriculture.

In water and agricultural applications, the type of cold-formed steel corrugated pipe to select depends primarily on the following factors:

In the realm of coal mine tunnels, the advantages of steel corrugated pipes lie in their strength, flexibility, and corrosion resistance. The environment in coal mine tunnels is harsh and space-restricted, demanding high-quality pipeline materials.

Cold-formed steel corrugated pipes meet these demands perfectly. Their strength can be 3-5 times greater than that of regular steel pipes, enabling them to handle high pressures and heavy loads commonly encountered in coal mine tunnels.

Moreover, cold-formed steel corrugated pipes possess excellent vibration resistance and anti-corrosion properties, making them suitable for areas with complex geological conditions and frequent natural disasters, ensuring the safe operation of coal mine tunnels.

Additionally, the installation and maintenance costs for these pipes are lower, effectively reducing operational costs for coal mine tunnels.

Therefore, cold-formed steel corrugated pipes hold vast market potential in coal mine tunnel applications.

For their application in coal mine tunnels, the selection of steel corrugated pipes depends on the following factors:

The media typically transported within coal mine tunnels are compressed air and water, with few solid suspended particles present. Also, coal mine tunnel spaces are narrow with many pipeline bends.

Thus, segmented steel corrugated pipes, due to their smaller size and better maneuverability, are more suitable for installation in tight spaces with many bends.

Full-length steel corrugated pipes and spiral steel corrugated pipes are less appropriate in these situations.

In conclusion, for coal mine tunnel applications, segmented steel corrugated pipes are the preferred choice.

In bridge and tunnel projects, cold-formed steel corrugated pipes exhibit high strength and durability.

In bridge projects, cold-formed steel corrugated pipes are commonly used for load-bearing structures of bridge piers and abutments, as shown in Figures 11 and 12.

Given the vast span and heavy loads of highway bridges, there’s a high demand for structural piping material strength. The strength of cold-formed steel corrugated pipes can be 3-5 times that of ordinary steel pipes, fully meeting the requirements of bridge structures.

Additionally, steel corrugated pipes have inherent ductility, allowing them to absorb dynamic load impacts, thus enhancing structural safety.

In tunnel projects, cold-formed steel corrugated pipes are frequently used in support structures, like arch constructions and anchor bolts. Tunnel environments are harsh, demanding high strength and durability from the materials used.

Cold-formed steel corrugated pipes not only possess high strength but, through surface treatments, offer excellent corrosion resistance, ensuring long-term structural safety.

Moreover, due to their lightweight nature, they’re easy to transport and install, especially in confined spaces like tunnels.

Currently, with accelerated highway construction worldwide, tens of thousands of kilometers of highways demand vast amounts of structurally safe materials. This demand has paved the way for the application of cold-formed steel corrugated pipes.

The selection of cold-formed steel corrugated pipes in highway applications is mainly based on the following considerations:

In summary, the selection of steel corrugated pipes for highway applications requires comprehensive judgment based on the specifics of the project.

Generally speaking, for smaller diameters and lesser load-bearing requirements, segmented steel corrugated pipes are ideal. For larger diameters or higher load-bearing demands, full-length or spiral steel corrugated pipes are more suitable.

While cold-forming technology is widely used in the steel corrugated pipe industry, it still faces certain challenges and difficulties.