How can shielding gas significantly improve your laser welding projects? In laser welding, shielding gas plays a critical role in enhancing weld quality by preventing reactions with air components and managing spatter. This article explores the different types of shielding gases, their specific applications, and the methods of delivery to optimize your welding results. Dive in to learn how the right shielding gas can lead to stronger, cleaner welds and increased efficiency in your projects.

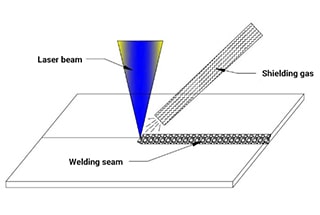

In laser welding, shielding gases play a crucial role in optimizing weld quality and protecting equipment. These gases are classified into three distinct categories: auxiliary gas (MDE gas), shielding gas, and jet gas, each serving specific functions in the welding process.

Auxiliary gas, particularly effective with yttrium aluminum garnet (YAG) lasers, mitigates the absorption of the laser beam by metal vapor plasma. This enhances beam penetration and energy transfer efficiency. Common auxiliary gases include helium or argon-helium mixtures, chosen for their high ionization potentials.

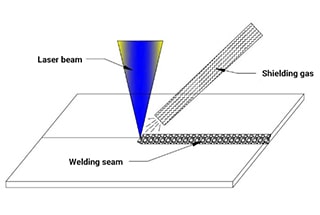

Shielding gas serves to displace atmospheric air from the weld zone, preventing detrimental reactions between the molten metal and atmospheric elements like oxygen and nitrogen. This results in improved weld quality, reduced oxidation, and minimized porosity. Typical shielding gases include argon, helium, or specific mixtures tailored to the base material and welding parameters.

Jet gas, employed in high-energy density welding processes prone to excessive spatter and vapor generation, creates a protective air curtain. This curtain is directed at a 90-degree angle to the machining head through a specialized nozzle. It effectively shields the optics and focusing system from weld spatter and condensation, ensuring consistent performance and extending equipment lifespan. Importantly, the jet gas is designed to operate without interfering with the weld pool dynamics or the primary shielding gas envelope.

The laser produces a beam of energy essential for the welding process. This high-intensity beam is precisely directed to the joint position on the workpiece through a sophisticated optical system comprising steering mirrors, laser optical cables, and focusing devices.

Accurate positioning and fixation of the workpiece are crucial for precise guidance of the focused laser beam. The focusing optical element traverses along the seam position, directing the concentrated laser energy onto the workpiece with micrometer precision.

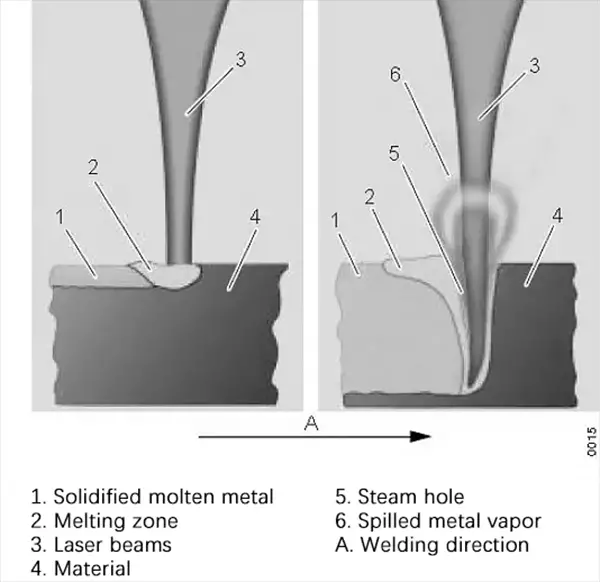

At the focal point, the laser beam’s extreme power density induces rapid melting and partial vaporization of the material. The resultant metal vapor pressure is so intense that it creates a narrow, deep penetration channel known as a “keyhole.” This keyhole typically extends several millimeters into the material, enabling deep, narrow welds characteristic of laser welding.

As the focus lens moves relative to the workpiece, the keyhole follows beneath it. This dynamic process allows the molten metal to flow and coalesce behind the keyhole, solidifying into a narrow, high-quality weld seam.

However, many metals are highly reactive in their molten state, particularly with atmospheric gases like oxygen and nitrogen. These reactions can lead to weld defects such as porosity, oxidation, and embrittlement, significantly compromising weld quality and mechanical properties.

The shielding gas plays a critical role in mitigating these issues. It creates a protective atmosphere around the weld pool, effectively displacing reactive air components. Typically, inert gases like argon or helium, or sometimes active gases like CO2 for specific applications, are used. The shielding gas not only prevents atmospheric contamination but also influences several key welding parameters:

Inert gas is commonly used in metal laser welding due to its properties of not reacting, or rarely reacting, with the matrix material. Some recommended shielding gases include nitrogen (N2), argon (AR), and helium (He).

It’s important to note that industrial gases often contain small amounts of impurities. The purity of the gas is indicated using a digital system, where the first number represents the number of nines in the percentage value and the second number represents the last digit of the percentage value. For example, He 4.6 indicates a helium purity of 99.996% (by volume).

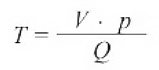

The service life of a gas cylinder can be easily calculated. Welding gas is stored in gas cylinders, with a typical gas storage cylinder containing 50 liters of gas at a pressure of 200 bar.

Example:

V = 50l,p = 200bar,Q =40l/h → T = 50l • 200bar/40l/h = 250 h

Nitrogen is a colorless and odorless inert gas that is suitable for welding chromium-nickel steel. However, it is not recommended for use with zirconium alloys and titanium materials, as although it is inactive, it can form compounds with these materials.

It is important to note that when welding steel with nitrogen, the presence of nitrogen can slightly reduce rust resistance by dissolving chromium and nickel from the steel.

The following table gives an overview of the recommended shielding gases.

| Ar | He | N2 | Note | |

| Aluminum & Aluminum alloy | – | + | – | Smooth and glossy welds can be formed with hydrogen or hydrogen mixture.

The use of hydrogen will cause pores in the material Hydrogen-containing gas will cause pores in the material Very high quality welds can be formed when welding with carbon dioxide (CO2) or hydrogen/carbon dioxide mixture. However, the smoothness and gloss of these welds are slightly poor. |

| Chromium nickel steel | + | – | + | It is recommended to use argon on devices that are prone to overflow gas because it is heavier than nitrogen.If corrosion is to be avoided, argon must be used because nitrogen reacts with chromium and nickel in the material. |

| Titanium and titanium alloys | + | – | + | Titanium reacts strongly with components in the air. As long as the weld temperature after cooling is still 200 ℃, it is necessary to completely cover the solution pool with argon (for example, a glove box can be used) |

| Chromium alloy | + | – | – | – |

| Copper | – | – | – | It is generally not necessary to use shielding gas when welding copper. |

Suggestions for protective gas of raw materials: “+” = yes, “-” = no

Note: When welding on narrow devices, self-protection occurs as the metal vapor pushes out the oxygen in the surrounding environment. In this case, the use of a shielding gas is not required.

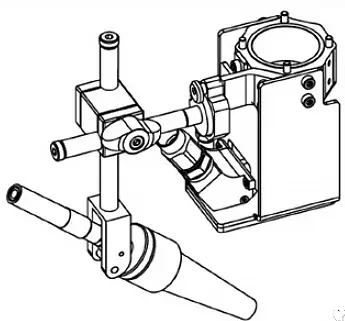

The ways to input shielding gas into the processing position are:

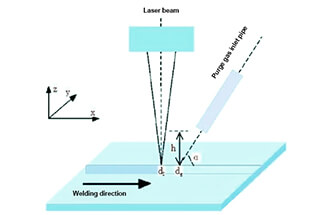

The following parameters must be optimally set for use:

The amount of shielding gas input must be adjusted based on the type of laser (continuous or pulsed), the welding speed, and the weld. TRUMPF provides some standard nozzles, which will be further described in subsequent information.

The linear nozzle is an advanced version of the compound pipe, where each pipe is assembled individually.

The linear nozzle has the following advantages:

prerequisite:

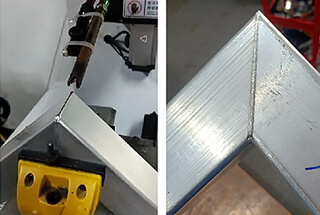

Welding application:

The linear nozzle is suitable for linear weld welding:

Using this nozzle, the shielding gas can be directed in a straight line, and the influence of metal vapor can be reduced through the use of a lateral MDE nozzle.

prerequisite:

Welding application:

Linear nozzle is suitable for linear weld welding:

The conical nozzle features a ray regulator, which ensures a laminar flow and a uniform distribution of the shielding gas.

Bubbling nozzles may be used when the following preconditions are met:

Welding application:

The bubbling nozzle can provide a large-area laminar gas supply when the beam power and welding speed are low. On the other hand, conical nozzles offer a uniform distribution of shielding gas, especially in hard-to-reach areas.

It is recommended to maintain a distance of 8 – 12 mm and an angle of 30° – 50° from the workpiece, depending on the application.

Other methods

In situations where it is necessary to ensure complete and even coverage of the material with shielding gas, the use of glove boxes is recommended. The glove box completely encloses the working area and prevents the overflow of the protective gas.

As the glove box is entirely filled with the shielding gas, there is no need for a separate shielding gas nozzle.

There are two different welding processes for laser welding:

In thermal conductivity welding, only the surface of the material melts, resulting in a weld that is only a few tenths of a millimeter deep. This welding process is primarily used with pulsed Nd:YAG lasers.

In contrast, deep penetration welding creates deep and narrow welds. This process is performed using an Nd:YAG laser in continuous wave operation mode.

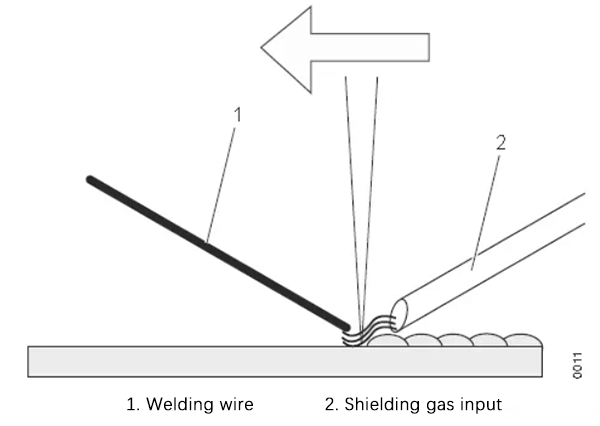

To achieve the best results when welding with a pulsed laser, the welding wire (if used) is typically inserted slowly. The direction of the shielding gas input can be chosen freely.

To achieve optimal results when welding with a continuous wave laser, it is necessary to input the shielding gas forward and slow down the insertion of the welding wire (if used).

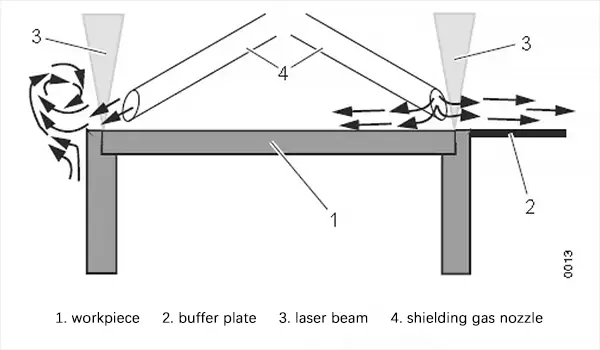

The shielding gas input nozzle should be arranged to produce a smooth and uniform flow of air. When welding along the edge, a vortex can be created, bringing in oxygen from the surrounding environment to the welding area.

If the oxygen content exceeds 0.5%, the material may react with the oxygen. To prevent the airflow vortex along the edges during welding, buffer plates can be installed.

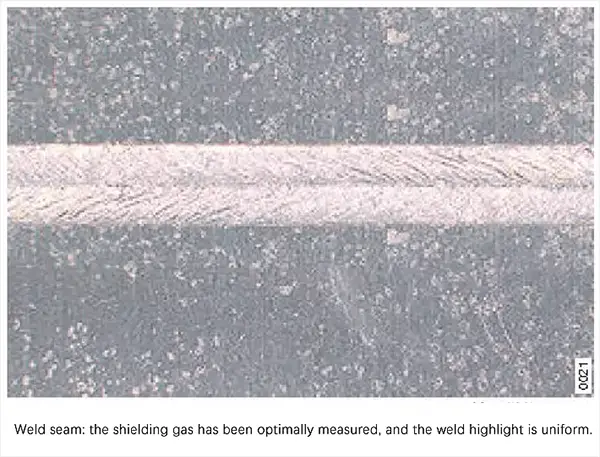

Accurately measuring the shielding gas is crucial to achieve optimal welding results. Ideally, a smooth and uniform laminar airflow should be present above the processing point.

If the amount of shielding gas input is too low, it may not provide adequate protection, allowing moisture in the gas or air to enter the weld. On the other hand, if too much shielding gas is used, it can create vortices that bring in air to the welding area.

The color of the weld can provide insight into the amount of shielding gas used during welding. If the weld appears gray, it suggests that no shielding gas was used. If the weld appears yellow, the measurement of the shielding gas needs to be optimized.

If the shielding gas measurement is optimized, a high-gloss weld will be produced.

A shielding gas nozzle with a ray regulator can ensure an even flow of shielding gas. The same result can be achieved by using steel wool in the nozzle.

Transverse air curtain:

Wind curtains are useful in welding applications that generate a significant amount of spatter and steam. The air curtain must be adjusted so that the flow of the air curtain does not interfere with the shielding gas.

Suggestion:

A simple test can determine if the jet gas has been set optimally. Place a piece of paper above the workpiece and adjust the air pressure of the jet so that the paper is not pushed down or drawn in by the jet.

Different shielding gases can produce different results, affecting the shape of the weld and creating a smoother and more polished weld surface. The choice of shielding gas can also impact the formation of pores in the weld and spatter, and hinder the coupling of the laser beam.

| Ar | He | N2 | No protection gas | |

| Welding shape

b = width T = depth |  |  |  |  |

| Weld surface | ++ | + | + | – |

| Spatter | + | + | 0 | – |

| Stoma | ++ | + | + | – |

| Laser beam coupling | – | – | – | + |

| Cost | – | – | 0 | Less |

To optimize the effect of the shielding gas, it is necessary to briefly open the shielding gas before and after welding. After opening the shielding gas, there is a time lag before the gas reaches the workpiece. The still-cooling melt after welding also requires brief coverage with shielding gas.