When it comes to precise measurements, should you reach for a Vernier caliper or a micrometer? Both tools are essential in various industries, but each has its strengths. This article compares their features, accuracy, and best-use cases, helping you decide which tool suits your needs. Discover how the Vernier caliper measures lengths, diameters, and depths with ease, while the micrometer excels in extreme precision, perfect for minute measurements. Read on to find out which tool will enhance your measurement tasks.

Vernier calipers are indispensable precision measuring instruments widely utilized across various manufacturing and engineering sectors. These versatile tools offer high-accuracy measurements for critical dimensions of workpieces, including length, inner diameter, outer diameter, and depth.

The design of Vernier calipers incorporates a main scale and a sliding Vernier scale, enabling measurements with typical resolutions of 0.02 mm or 0.001 inches. This level of precision is crucial for quality control in metal fabrication, machining operations, and assembly processes where tight tolerances are essential.

Vernier calipers are a widely utilized high-precision measuring instrument in manufacturing and quality control processes. They consist of a main scale and a sliding vernier scale, enabling accurate measurements of linear dimensions. The device’s design allows for both external and internal measurements, as well as depth gauging.

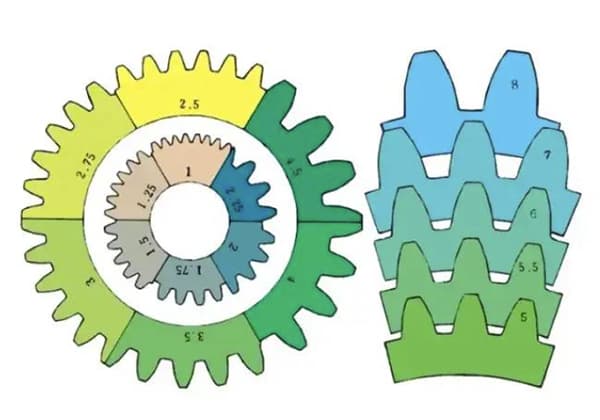

The precision of vernier calipers is determined by the scale value on the vernier, which can be categorized into three common types:

Modern vernier calipers often incorporate digital displays for ease of reading, while maintaining the traditional vernier scale for reliability. The measuring range typically spans from 0 to 150 mm or 0 to 6 inches, with larger sizes available for specialized applications.

Key features of vernier calipers include:

Proper calibration and careful handling are essential to maintain the accuracy of vernier calipers, ensuring reliable measurements in various industrial and scientific applications.

Taking an accurate Vernier caliper with a scale value of 0.02mm as an example, the reading method can be divided into three steps:

1) The whole millimeter value is read based on the closest scale on the main ruler to the left of the zero line of the vernier scale.

2) The decimal value is read by multiplying the number of scales aligned on the main ruler to the right of the zero line on the vernier scale by 0.02.

3) The final measurement is obtained by adding up the integer and decimal parts detailed above.

Method of Reading a 0.02mm Vernier Caliper.

As shown in the figure above, the zero line of the vernier scale corresponds to the 64mm mark on the main scale. The ninth line behind the zero line of the vernier scale aligns with a scale line on the main scale.

The ninth line behind the zero line of the vernier scale represents: 0.02×9= 0.18mm;

Therefore, the dimension of the measured workpiece is: 64+0.18=64.18mm.

Before taking measurements, ensure proper calibration of the Vernier caliper. Fully close the jaws and verify that the Vernier scale’s zero mark aligns precisely with the main scale’s zero mark. If alignment is perfect, proceed with measurements. If misalignment exists, record the zero error for later compensation.

A positive zero error occurs when the Vernier’s zero mark is right of the main scale’s zero, while a negative zero error is when it’s left. This convention mirrors number line principles, where right is positive and left is negative. Always factor this error into your final measurements for accuracy.

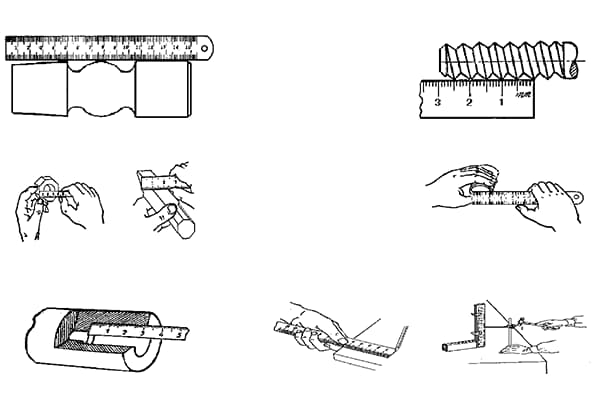

To measure, grip the caliper’s main body firmly in your dominant hand, typically the right. Use your thumb to smoothly slide the Vernier scale. This technique ensures stability and precise control during measurement.

For external measurements, hold the object in your non-dominant hand (usually left) and gently position it between the main jaws. Adjust the jaws until they make firm, even contact with the object’s surface without applying excessive pressure, which could distort readings. For internal measurements, use the smaller protrusions on the upper part of the jaws.

Once the object is securely positioned, refer to the scales for your reading:

The figure below illustrates this reading process:

Remember to account for any zero error in your final calculation. Regular practice will improve your speed and accuracy in using this precision instrument.

Vernier calipers, as a versatile and precise measuring instrument, find extensive applications in various industrial and engineering fields. Their ability to provide accurate measurements makes them indispensable in quality control, manufacturing, and research. The following four key applications demonstrate the versatility of vernier calipers:

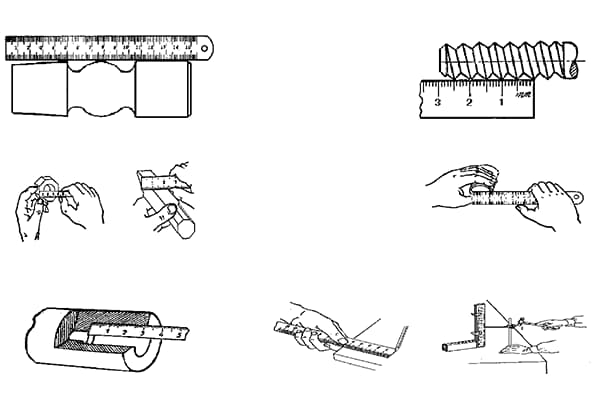

Please refer to the figure below for specific measurement techniques for these four applications:

Usage Precautions

The Vernier caliper is a highly precise measuring instrument. Certain care should be taken during its use:

1. Before using, clean both jaws’ measuring surfaces. Close the jaws and check if the zero line on the vernier scale aligns with the main scale’s zero line. If misaligned, adjust the measurement reading according to the original error.

2. When measuring a workpiece, the jaws’ measuring surfaces must be parallel or perpendicular to the surface of the workpiece. Avoid tilting and excessive force to prevent the jaws from deforming or wearing, which could affect measurement accuracy.

3. When reading the calibration, your line of sight should be perpendicular to the scale surface. Otherwise, the measurement value may be inaccurate.

4. When measuring the inner diameter, gently swing the caliper to find the maximum value.

5. After using the Vernier caliper, clean it thoroughly, apply protective oil, and store it flat inside a case to prevent rusting or bending.

The micrometer, also known as a screw gauge, is another precise measuring instrument. The following will explain the principles, structure, and usage methods of the micrometer.

A micrometer, also known as a micrometer screw gauge, is a precision measuring instrument designed for highly accurate dimensional measurements. It offers superior precision compared to tools like vernier calipers, typically allowing measurements down to 0.001 inches (0.025 mm) or even 0.0001 inches (0.001 mm) in some specialized models.

The device consists of a C-shaped frame with a spindle that moves through a sleeve. The spindle is connected to a thimble, which is marked with graduations. As the thimble is rotated, it advances or retracts the spindle, allowing for precise measurements of the object placed between the spindle face and the anvil.

Most standard micrometers have a measurement range of 1 inch (25.4 mm), though models with larger ranges are available for specific applications. The accuracy and reliability of micrometers make them indispensable in machining, metalworking, and quality control processes where tight tolerances are critical.

A standard micrometer typically consists of the following main parts:

These components work together to allow precise measurements of small distances or thicknesses, typically in the range of 0-25mm or 0-1 inch, with accuracy often to 0.01mm or 0.001 inch.

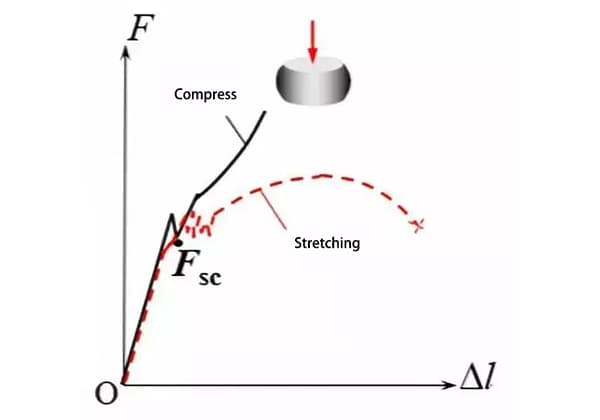

The micrometer screw gauge operates on the principle of helical amplification, a fundamental concept in precision metrology. This principle leverages the relationship between rotational and linear motion in a screw mechanism. When the screw completes one full revolution within its mating nut, it advances or retracts axially by a distance equal to its pitch.

This mechanical advantage allows for the conversion of a small linear displacement into a larger, more easily measurable rotational movement. Consequently, minute axial displacements can be accurately quantified by observing angular positions on the circumference of the thimble.

In a typical precision micrometer, the screw thread is engineered with a pitch of 0.5 mm. The thimble, which serves as the movable scale, is precisely divided into 50 equal increments. A complete revolution of the thimble corresponds to a 0.5 mm linear movement of the spindle.

This configuration results in each increment on the thimble representing a linear displacement of 0.01 mm (0.5 mm / 50 divisions). This relationship forms the basis of the micrometer’s measurement resolution. The fixed sleeve scale, typically graduated in 0.5 mm increments, works in conjunction with the thimble to enable readings down to 0.01 mm.

Advanced micrometers incorporate a vernier scale on the sleeve, allowing for interpolation between thimble divisions. This enhancement enables measurements to a resolution of 0.001 mm (1 μm), earning the device its colloquial name “thousandths ruler” in some regions.

The precision and reliability of micrometer measurements depend on factors such as the accuracy of the screw thread, the quality of the measuring faces, and proper calibration and use techniques. Regular calibration against certified gauge blocks is essential to maintain measurement accuracy and traceability to international standards.

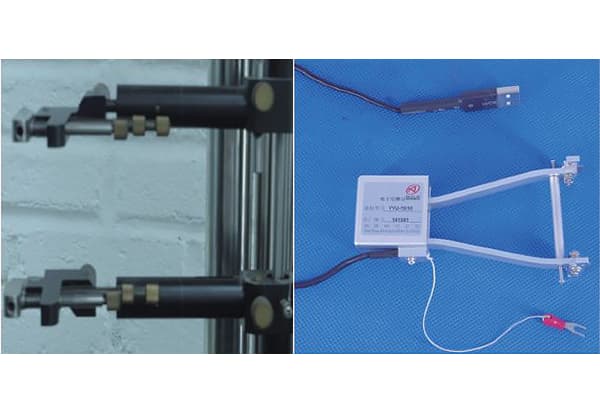

When we often help customers connect our data acquisition device with the screw micrometer for high-efficiency measurements, we typically instruct them to adhere to the following points:

1. Prior to use, check the zero point: Slowly rotate the fine-tuning knob D′ to make the measuring rod (F) and the measuring anvil (A) contact until a click sound can be heard. At this point, the zero marking on the movable sleeve should align with the baseline (long horizontal line) on the fixed sleeve, otherwise, a zero error exists.

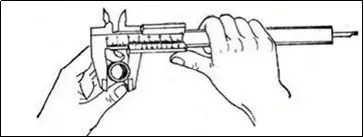

2. Hold the caliper (C) in your left hand, and with your right hand, turn the coarse adjustment knob (D) so that the gap between the measuring rod (F) and the anvil (A) is slightly larger than the object to be measured. Insert the object, then turn the lock knob (D’) until the object is secured and the ratchet emits a sound. Once the measuring rod is fixed by manipulating the lock knob (G), take the reading.

For example, if the fixed scale shows 5mm, the half-scale is visible (0.5mm), and the thimble scale reads 28 (28 × 0.01 = 0.28mm), the total reading would be 5.78mm.

Micrometer screw gauges are capable of measurements to the nearest 0.01mm (10 micrometers) or even 0.001mm (1 micrometer) in high-precision models. This exceptional accuracy in measuring small dimensions is why the instrument is often simply called a “micrometer” in engineering and manufacturing contexts.

To ensure accurate readings, it’s crucial to maintain proper calibration, use consistent measuring pressure (often achieved through a ratchet mechanism), and regularly check for zero error. Additionally, understanding the vernier scale on some models can further enhance measurement precision.

When measuring, approach the object carefully using the thimble until the spindle is close to the workpiece. Then, switch to the ratchet stop or friction thimble for the final adjustment. This controlled approach prevents excessive pressure, ensures accurate measurements, and protects both the micrometer and the object being measured from damage.

Observe the fixed sleeve scale carefully. Pay attention to whether the half-millimeter line is visible between two whole millimeter graduations. This intermediate line is crucial for precise readings to 0.5 mm resolution.

Always include the thousandths digit in your reading, even when the zero mark on the thimble aligns perfectly with the datum line on the sleeve. In such cases, record the thousandths place as “0”. This practice maintains consistency and prevents rounding errors in subsequent calculations.

Before each use, check for zero error by fully closing the micrometer. If the zero on the thimble doesn’t align with the datum line on the sleeve, note this discrepancy as the zero error. For positive errors, subtract this value from your final reading; for negative errors, add it. Alternatively, adjust the thimble position using the provided wrench to eliminate the zero error mechanically.

Maintain proper care of the micrometer by regularly cleaning the measuring faces, lubricating the spindle thread, and storing it in a protective case to prevent corrosion and physical damage.

For optimal accuracy, use the micrometer at a consistent temperature, ideally 20°C (68°F), which is the standard reference temperature for most precision measurements. Significant temperature variations can affect both the micrometer and the workpiece due to thermal expansion.

Post-use care: After each use, carefully clean the micrometer with a soft cloth. Apply a thin film of appropriate protective oil to prevent corrosion. Store the instrument in its designated case, preferably in a temperature-controlled, low-humidity environment to maintain long-term accuracy and prevent damage.

Verify the zero setting accuracy: Before each use, close the spindle against the anvil and ensure the zero marks on the sleeve and thimble align perfectly. If misaligned, adjust using the provided wrench or consult the manufacturer’s calibration procedure.

Prepare the workpiece: Thoroughly clean the surface to be measured, removing any debris, burrs, or contaminants that could affect accuracy. For temperature-sensitive measurements, allow the workpiece to reach ambient temperature.

Position larger workpieces: For components exceeding the micrometer’s frame capacity, utilize a precision V-block or surface plate to ensure stable and perpendicular alignment during measurement.

Clean measuring surfaces: Gently wipe the spindle tip and anvil face with a lint-free cloth to remove any particles or oil residue that could compromise measurement accuracy.

Apply consistent measuring force: Always use the ratchet stop or friction thimble when adjusting the spindle. This ensures a uniform contact pressure, typically around 5-10 N, preventing over-tightening and potential damage to both the micrometer and workpiece.

Preserve calibration integrity: Never disassemble the micrometer or loosen the back cover, as this can alter the critical zero setting and overall accuracy of the instrument.

Avoid contamination: Do not introduce standard machine oils between the fixed sleeve and movable thimble. If lubrication is necessary, use only specialized instrument oils recommended by the manufacturer.